Loss Coefficient K For Pipe Fittings Pdf . (1994) demonstrated that 80 % to 90 % of the pressure loss for a tee occurs within 3 to 4 pipe diameters downstream the junction, while. The flow in a piping system may be required to pass through a variety of fittings and bends. Substantial compared to those for flow through short straight pipe segments. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). The local head loss produced by a device obstructing the pipe flow is characterized by the local loss coefficient, k, usually expressed as. In this application, the study of loss calculation for fittings is shown. Losses are commonly reported in velocity heads. Regarding loss coeffcients definition, there are several approaches. These losses are considered minor losses. Assume a 6 angle valve for.

from www.scribd.com

In this application, the study of loss calculation for fittings is shown. These losses are considered minor losses. Assume a 6 angle valve for. The local head loss produced by a device obstructing the pipe flow is characterized by the local loss coefficient, k, usually expressed as. Regarding loss coeffcients definition, there are several approaches. Substantial compared to those for flow through short straight pipe segments. Losses are commonly reported in velocity heads. The flow in a piping system may be required to pass through a variety of fittings and bends. (1994) demonstrated that 80 % to 90 % of the pressure loss for a tee occurs within 3 to 4 pipe diameters downstream the junction, while. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe).

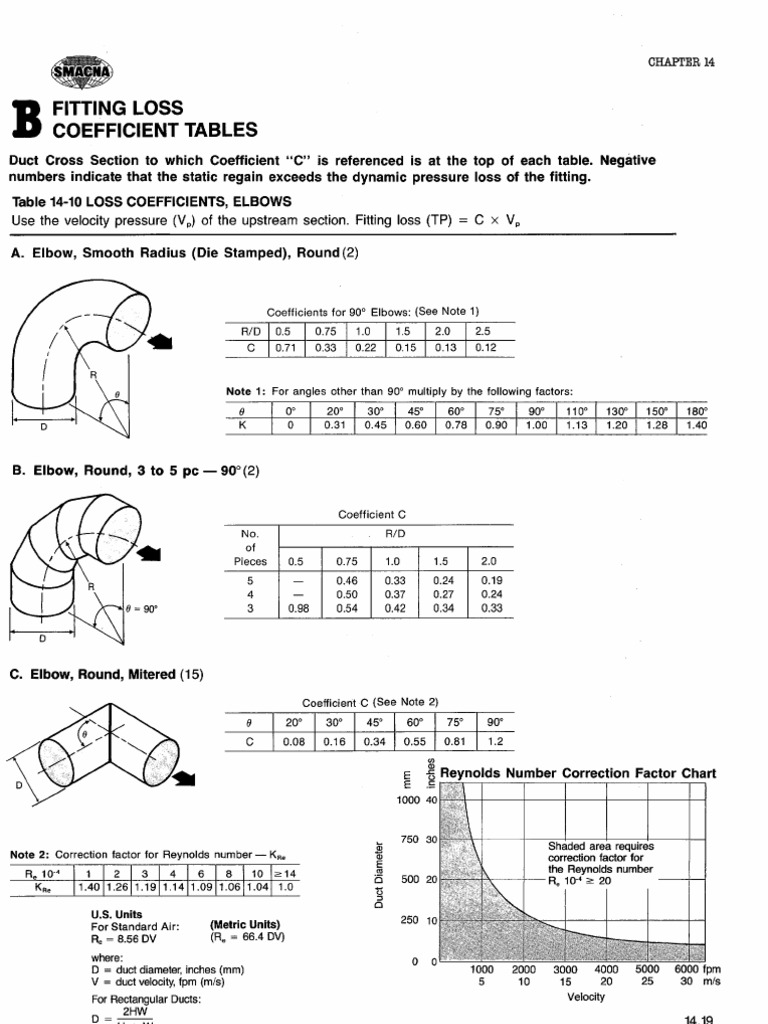

Appendix 6 Fitting Loss Coefficient Tables

Loss Coefficient K For Pipe Fittings Pdf The local head loss produced by a device obstructing the pipe flow is characterized by the local loss coefficient, k, usually expressed as. Regarding loss coeffcients definition, there are several approaches. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). These losses are considered minor losses. Substantial compared to those for flow through short straight pipe segments. (1994) demonstrated that 80 % to 90 % of the pressure loss for a tee occurs within 3 to 4 pipe diameters downstream the junction, while. In this application, the study of loss calculation for fittings is shown. The flow in a piping system may be required to pass through a variety of fittings and bends. Assume a 6 angle valve for. The local head loss produced by a device obstructing the pipe flow is characterized by the local loss coefficient, k, usually expressed as. Losses are commonly reported in velocity heads.

From engineerexcel.com

Loss Coefficients for Pipe Fittings Mastering Fluid Dynamics Loss Coefficient K For Pipe Fittings Pdf Assume a 6 angle valve for. In this application, the study of loss calculation for fittings is shown. Substantial compared to those for flow through short straight pipe segments. (1994) demonstrated that 80 % to 90 % of the pressure loss for a tee occurs within 3 to 4 pipe diameters downstream the junction, while. Regarding loss coeffcients definition, there. Loss Coefficient K For Pipe Fittings Pdf.

From www.chegg.com

Table 4.3.1 Minor Loss Coefficients for Pipe Flow K Loss Coefficient K For Pipe Fittings Pdf In this application, the study of loss calculation for fittings is shown. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). The flow in a piping system may be required to pass through a variety of fittings and bends. Assume a 6 angle valve for. These losses are considered minor losses. Losses. Loss Coefficient K For Pipe Fittings Pdf.

From www.scribd.com

PVC Equivalent Length Friction Loss in Fittings PDF Pipe (Fluid Loss Coefficient K For Pipe Fittings Pdf In this application, the study of loss calculation for fittings is shown. Regarding loss coeffcients definition, there are several approaches. The flow in a piping system may be required to pass through a variety of fittings and bends. The local head loss produced by a device obstructing the pipe flow is characterized by the local loss coefficient, k, usually expressed. Loss Coefficient K For Pipe Fittings Pdf.

From www.corzan.com

How Fittings, Valves and Strainers Affect Pressure Drop and Head Loss Loss Coefficient K For Pipe Fittings Pdf The local head loss produced by a device obstructing the pipe flow is characterized by the local loss coefficient, k, usually expressed as. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). These losses are considered minor losses. Losses are commonly reported in velocity heads. The flow in a piping system may. Loss Coefficient K For Pipe Fittings Pdf.

From exovodadv.blob.core.windows.net

Pipe Fitting K Values at Bryan Tingley blog Loss Coefficient K For Pipe Fittings Pdf The flow in a piping system may be required to pass through a variety of fittings and bends. These losses are considered minor losses. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). The local head loss produced by a device obstructing the pipe flow is characterized by the local loss coefficient,. Loss Coefficient K For Pipe Fittings Pdf.

From www.scribd.com

Experiment No. 13 Loss Coefficient, K, For Pipe Bends and Elbows PDF Loss Coefficient K For Pipe Fittings Pdf The local head loss produced by a device obstructing the pipe flow is characterized by the local loss coefficient, k, usually expressed as. (1994) demonstrated that 80 % to 90 % of the pressure loss for a tee occurs within 3 to 4 pipe diameters downstream the junction, while. The flow in a piping system may be required to pass. Loss Coefficient K For Pipe Fittings Pdf.

From engineerexcel.com

Pipe Flow Rate vs Pressure A Comprehensive Guide EngineerExcel Loss Coefficient K For Pipe Fittings Pdf In this application, the study of loss calculation for fittings is shown. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). Losses are commonly reported in velocity heads. These losses are considered minor losses. The local head loss produced by a device obstructing the pipe flow is characterized by the local loss. Loss Coefficient K For Pipe Fittings Pdf.

From www.scribd.com

friction loss fittings.pdf Pipe (Fluid Conveyance) Valve Loss Coefficient K For Pipe Fittings Pdf Regarding loss coeffcients definition, there are several approaches. (1994) demonstrated that 80 % to 90 % of the pressure loss for a tee occurs within 3 to 4 pipe diameters downstream the junction, while. The flow in a piping system may be required to pass through a variety of fittings and bends. These losses are considered minor losses. Substantial compared. Loss Coefficient K For Pipe Fittings Pdf.

From www.researchgate.net

15 Loss coefficient and equivalent lengths for several fittings [17, 18 Loss Coefficient K For Pipe Fittings Pdf Assume a 6 angle valve for. Losses are commonly reported in velocity heads. The local head loss produced by a device obstructing the pipe flow is characterized by the local loss coefficient, k, usually expressed as. In this application, the study of loss calculation for fittings is shown. These losses are considered minor losses. Regarding loss coeffcients definition, there are. Loss Coefficient K For Pipe Fittings Pdf.

From www.pipeflowcalculations.com

Resistance coefficient K for fittings Loss Coefficient K For Pipe Fittings Pdf These losses are considered minor losses. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). (1994) demonstrated that 80 % to 90 % of the pressure loss for a tee occurs within 3 to 4 pipe diameters downstream the junction, while. The local head loss produced by a device obstructing the pipe. Loss Coefficient K For Pipe Fittings Pdf.

From engineeringness.com

Pressure Drop In Pipe Lines And Fittings Part 2 Engineeringness Loss Coefficient K For Pipe Fittings Pdf Assume a 6 angle valve for. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). The flow in a piping system may be required to pass through a variety of fittings and bends. Losses are commonly reported in velocity heads. The local head loss produced by a device obstructing the pipe flow. Loss Coefficient K For Pipe Fittings Pdf.

From pdfslide.net

Appendix 6 Fitting Loss Coefficient Tables Loss Coefficient K For Pipe Fittings Pdf Assume a 6 angle valve for. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). Substantial compared to those for flow through short straight pipe segments. In this application, the study of loss calculation for fittings is shown. The flow in a piping system may be required to pass through a variety. Loss Coefficient K For Pipe Fittings Pdf.

From katmarsoftware.com

Resistance coefficients (K values) for pipe fittings like bends, tees Loss Coefficient K For Pipe Fittings Pdf In this application, the study of loss calculation for fittings is shown. Substantial compared to those for flow through short straight pipe segments. These losses are considered minor losses. Assume a 6 angle valve for. The flow in a piping system may be required to pass through a variety of fittings and bends. The local head loss produced by a. Loss Coefficient K For Pipe Fittings Pdf.

From exovodadv.blob.core.windows.net

Pipe Fitting K Values at Bryan Tingley blog Loss Coefficient K For Pipe Fittings Pdf Losses are commonly reported in velocity heads. The flow in a piping system may be required to pass through a variety of fittings and bends. Regarding loss coeffcients definition, there are several approaches. These losses are considered minor losses. In this application, the study of loss calculation for fittings is shown. (1994) demonstrated that 80 % to 90 % of. Loss Coefficient K For Pipe Fittings Pdf.

From fitnessretro.blogspot.com

Head Loss Coefficient For Pipe Fittings FitnessRetro Loss Coefficient K For Pipe Fittings Pdf In this application, the study of loss calculation for fittings is shown. Substantial compared to those for flow through short straight pipe segments. Assume a 6 angle valve for. Regarding loss coeffcients definition, there are several approaches. (1994) demonstrated that 80 % to 90 % of the pressure loss for a tee occurs within 3 to 4 pipe diameters downstream. Loss Coefficient K For Pipe Fittings Pdf.

From www.academia.edu

(PDF) Pipe Friction Loss Charts Pipe and Equivalent Length of Pipe Type Loss Coefficient K For Pipe Fittings Pdf The local head loss produced by a device obstructing the pipe flow is characterized by the local loss coefficient, k, usually expressed as. The flow in a piping system may be required to pass through a variety of fittings and bends. Substantial compared to those for flow through short straight pipe segments. In this application, the study of loss calculation. Loss Coefficient K For Pipe Fittings Pdf.

From engineeringness.com

Pressure Drop In Pipe Lines And Fittings Part 2 Engineeringness Loss Coefficient K For Pipe Fittings Pdf (1994) demonstrated that 80 % to 90 % of the pressure loss for a tee occurs within 3 to 4 pipe diameters downstream the junction, while. Losses are commonly reported in velocity heads. The local head loss produced by a device obstructing the pipe flow is characterized by the local loss coefficient, k, usually expressed as. Substantial compared to those. Loss Coefficient K For Pipe Fittings Pdf.

From pump-zone.com

Understand How Valves & Fittings Affect Head Loss Loss Coefficient K For Pipe Fittings Pdf Substantial compared to those for flow through short straight pipe segments. Regarding loss coeffcients definition, there are several approaches. (1994) demonstrated that 80 % to 90 % of the pressure loss for a tee occurs within 3 to 4 pipe diameters downstream the junction, while. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of. Loss Coefficient K For Pipe Fittings Pdf.

From energy-models.com

Pipe Sizing Charts Tables Loss Coefficient K For Pipe Fittings Pdf In this application, the study of loss calculation for fittings is shown. Substantial compared to those for flow through short straight pipe segments. (1994) demonstrated that 80 % to 90 % of the pressure loss for a tee occurs within 3 to 4 pipe diameters downstream the junction, while. These losses are considered minor losses. The flow in a piping. Loss Coefficient K For Pipe Fittings Pdf.

From www.nuclear-power.com

Resistance Coefficient Method K Method Loss Coefficient K For Pipe Fittings Pdf (1994) demonstrated that 80 % to 90 % of the pressure loss for a tee occurs within 3 to 4 pipe diameters downstream the junction, while. The flow in a piping system may be required to pass through a variety of fittings and bends. Regarding loss coeffcients definition, there are several approaches. These losses are considered minor losses. Determine l. Loss Coefficient K For Pipe Fittings Pdf.

From exyjeuopr.blob.core.windows.net

K Values For Ductile Iron Pipe Fittings at Luis Woodruff blog Loss Coefficient K For Pipe Fittings Pdf Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). (1994) demonstrated that 80 % to 90 % of the pressure loss for a tee occurs within 3 to 4 pipe diameters downstream the junction, while. These losses are considered minor losses. In this application, the study of loss calculation for fittings is. Loss Coefficient K For Pipe Fittings Pdf.

From engineerexcel.com

Loss Coefficients A Practical Guide for Engineers EngineerExcel Loss Coefficient K For Pipe Fittings Pdf Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). The flow in a piping system may be required to pass through a variety of fittings and bends. Regarding loss coeffcients definition, there are several approaches. Substantial compared to those for flow through short straight pipe segments. In this application, the study of. Loss Coefficient K For Pipe Fittings Pdf.

From www.academia.edu

(PDF) B FITTING LOSS COEFFICIENT TABLES Usman Qayyum Academia.edu Loss Coefficient K For Pipe Fittings Pdf The flow in a piping system may be required to pass through a variety of fittings and bends. The local head loss produced by a device obstructing the pipe flow is characterized by the local loss coefficient, k, usually expressed as. Losses are commonly reported in velocity heads. These losses are considered minor losses. (1994) demonstrated that 80 % to. Loss Coefficient K For Pipe Fittings Pdf.

From www.semanticscholar.org

Figure 2 from A procedure for predicting pressure loss coefficients of Loss Coefficient K For Pipe Fittings Pdf The flow in a piping system may be required to pass through a variety of fittings and bends. Assume a 6 angle valve for. The local head loss produced by a device obstructing the pipe flow is characterized by the local loss coefficient, k, usually expressed as. These losses are considered minor losses. Losses are commonly reported in velocity heads.. Loss Coefficient K For Pipe Fittings Pdf.

From es.scribd.com

Table 3 Friction Losses Through Pipe Fittings in Terms of Equivalent Loss Coefficient K For Pipe Fittings Pdf The flow in a piping system may be required to pass through a variety of fittings and bends. (1994) demonstrated that 80 % to 90 % of the pressure loss for a tee occurs within 3 to 4 pipe diameters downstream the junction, while. In this application, the study of loss calculation for fittings is shown. Regarding loss coeffcients definition,. Loss Coefficient K For Pipe Fittings Pdf.

From www.academia.edu

(PDF) Friction Losses in Pipe Fittings Resistance Coefficient K (use in Loss Coefficient K For Pipe Fittings Pdf The flow in a piping system may be required to pass through a variety of fittings and bends. The local head loss produced by a device obstructing the pipe flow is characterized by the local loss coefficient, k, usually expressed as. Regarding loss coeffcients definition, there are several approaches. In this application, the study of loss calculation for fittings is. Loss Coefficient K For Pipe Fittings Pdf.

From www.scribd.com

Appendix 6 Fitting Loss Coefficient Tables Loss Coefficient K For Pipe Fittings Pdf Losses are commonly reported in velocity heads. Assume a 6 angle valve for. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). These losses are considered minor losses. The local head loss produced by a device obstructing the pipe flow is characterized by the local loss coefficient, k, usually expressed as. Substantial. Loss Coefficient K For Pipe Fittings Pdf.

From ppr.almatherm.de

Standards & Specifications Loss Coefficient K For Pipe Fittings Pdf Regarding loss coeffcients definition, there are several approaches. The local head loss produced by a device obstructing the pipe flow is characterized by the local loss coefficient, k, usually expressed as. Assume a 6 angle valve for. Losses are commonly reported in velocity heads. In this application, the study of loss calculation for fittings is shown. (1994) demonstrated that 80. Loss Coefficient K For Pipe Fittings Pdf.

From www.scribd.com

Hydraulic Characteristics of Pipe Fittings A Comprehensive Guide to Loss Coefficient K For Pipe Fittings Pdf Substantial compared to those for flow through short straight pipe segments. Assume a 6 angle valve for. Losses are commonly reported in velocity heads. The flow in a piping system may be required to pass through a variety of fittings and bends. (1994) demonstrated that 80 % to 90 % of the pressure loss for a tee occurs within 3. Loss Coefficient K For Pipe Fittings Pdf.

From engineerexcel.com

Pipe Flow Rate vs Pressure A Comprehensive Guide EngineerExcel Loss Coefficient K For Pipe Fittings Pdf Assume a 6 angle valve for. Regarding loss coeffcients definition, there are several approaches. Losses are commonly reported in velocity heads. These losses are considered minor losses. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). The local head loss produced by a device obstructing the pipe flow is characterized by the. Loss Coefficient K For Pipe Fittings Pdf.

From www.pinterest.com

k Value of Fittings Pipe (Fluid Conveyance) Valve Valve, Civic eg Loss Coefficient K For Pipe Fittings Pdf Assume a 6 angle valve for. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). These losses are considered minor losses. Substantial compared to those for flow through short straight pipe segments. The local head loss produced by a device obstructing the pipe flow is characterized by the local loss coefficient, k,. Loss Coefficient K For Pipe Fittings Pdf.

From elchoroukhost.net

Friction Loss Tables Pvc Pipe Elcho Table Loss Coefficient K For Pipe Fittings Pdf Regarding loss coeffcients definition, there are several approaches. Losses are commonly reported in velocity heads. (1994) demonstrated that 80 % to 90 % of the pressure loss for a tee occurs within 3 to 4 pipe diameters downstream the junction, while. In this application, the study of loss calculation for fittings is shown. Substantial compared to those for flow through. Loss Coefficient K For Pipe Fittings Pdf.

From www.chegg.com

We assumed that the gate valve was fully open and Loss Coefficient K For Pipe Fittings Pdf In this application, the study of loss calculation for fittings is shown. These losses are considered minor losses. Determine l (friction loss in pipe fittings in terms of equivalent length in feet of straight pipe). Losses are commonly reported in velocity heads. Regarding loss coeffcients definition, there are several approaches. The flow in a piping system may be required to. Loss Coefficient K For Pipe Fittings Pdf.

From www.scribd.com

Friction Losses in Pipe Fittings Resistance Coefficient K (Use in Loss Coefficient K For Pipe Fittings Pdf These losses are considered minor losses. Regarding loss coeffcients definition, there are several approaches. Substantial compared to those for flow through short straight pipe segments. Assume a 6 angle valve for. (1994) demonstrated that 80 % to 90 % of the pressure loss for a tee occurs within 3 to 4 pipe diameters downstream the junction, while. The flow in. Loss Coefficient K For Pipe Fittings Pdf.

From www.researchgate.net

Typical local loss coefficient k. Download Scientific Diagram Loss Coefficient K For Pipe Fittings Pdf The flow in a piping system may be required to pass through a variety of fittings and bends. Regarding loss coeffcients definition, there are several approaches. Substantial compared to those for flow through short straight pipe segments. In this application, the study of loss calculation for fittings is shown. (1994) demonstrated that 80 % to 90 % of the pressure. Loss Coefficient K For Pipe Fittings Pdf.