Coupling Shear Pin Failure . In their most basic form, they incorporate a pin (or, for very. Possibilities include the shear pin, cutout shifter, and brake coupling. Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak torque that it was not designed. Learn about the critical role of shear pins in mechanical systems, how they work, the causes of their failure, and the steps to identify. By understanding the common symptoms and causes of these coupling problems, and by implementing the appropriate. Common causes of wear or failure include normal wear (again, gear coupling teeth are designed to wear over time), lack of lubrication, torque. Gear couplings can be configured to do special jobs. Occurs when the shear stress in the pin exceeds the material's shear strength. The shear stress is calculated by dividing the applied force by the.

from www.numerade.com

Learn about the critical role of shear pins in mechanical systems, how they work, the causes of their failure, and the steps to identify. In their most basic form, they incorporate a pin (or, for very. Gear couplings can be configured to do special jobs. Common causes of wear or failure include normal wear (again, gear coupling teeth are designed to wear over time), lack of lubrication, torque. Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak torque that it was not designed. Possibilities include the shear pin, cutout shifter, and brake coupling. Occurs when the shear stress in the pin exceeds the material's shear strength. The shear stress is calculated by dividing the applied force by the. By understanding the common symptoms and causes of these coupling problems, and by implementing the appropriate.

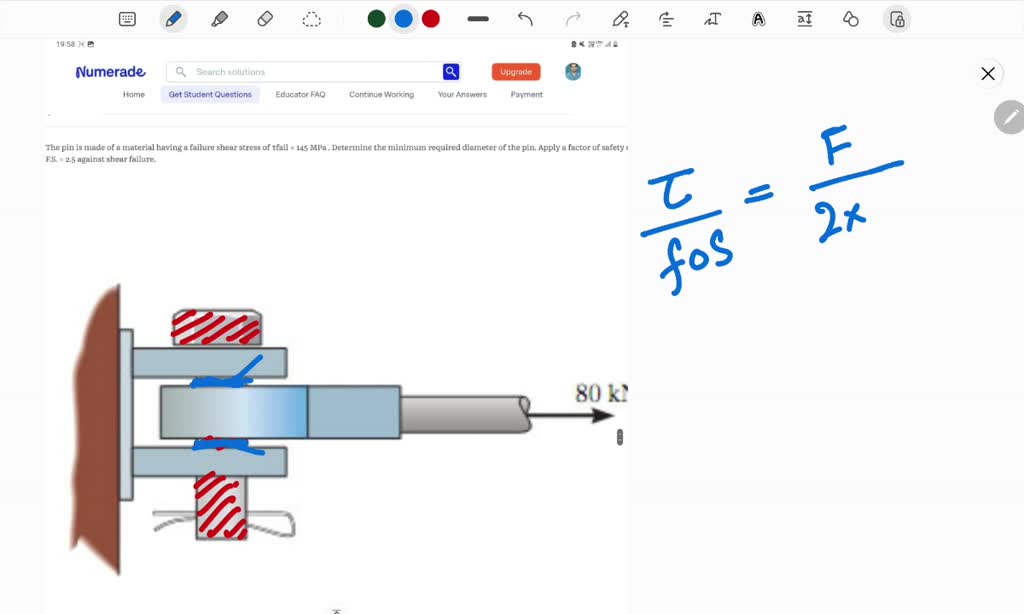

SOLVED The pin is made of a material having a failure shear stress of

Coupling Shear Pin Failure In their most basic form, they incorporate a pin (or, for very. By understanding the common symptoms and causes of these coupling problems, and by implementing the appropriate. Gear couplings can be configured to do special jobs. Learn about the critical role of shear pins in mechanical systems, how they work, the causes of their failure, and the steps to identify. In their most basic form, they incorporate a pin (or, for very. Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak torque that it was not designed. Occurs when the shear stress in the pin exceeds the material's shear strength. Possibilities include the shear pin, cutout shifter, and brake coupling. Common causes of wear or failure include normal wear (again, gear coupling teeth are designed to wear over time), lack of lubrication, torque. The shear stress is calculated by dividing the applied force by the.

From store.fivesmsi.com

COUPLINGWITH SHEAR PIN FIVES MSI Online Store Coupling Shear Pin Failure By understanding the common symptoms and causes of these coupling problems, and by implementing the appropriate. Gear couplings can be configured to do special jobs. Learn about the critical role of shear pins in mechanical systems, how they work, the causes of their failure, and the steps to identify. The shear stress is calculated by dividing the applied force by. Coupling Shear Pin Failure.

From slideplayer.com

Keys and Coupling Many Types of Keys and couplings, however understand Coupling Shear Pin Failure Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak torque that it was not designed. The shear stress is calculated by dividing the applied force by the. Common causes of wear or failure include normal wear (again, gear coupling teeth are designed to wear over time),. Coupling Shear Pin Failure.

From www.semanticscholar.org

[PDF] Pin Failure in Shear vs. Bending for a Double Shear Joint Coupling Shear Pin Failure In their most basic form, they incorporate a pin (or, for very. Learn about the critical role of shear pins in mechanical systems, how they work, the causes of their failure, and the steps to identify. Possibilities include the shear pin, cutout shifter, and brake coupling. By understanding the common symptoms and causes of these coupling problems, and by implementing. Coupling Shear Pin Failure.

From www.researchgate.net

Plot of failure slope angle versus variation in location of shear pins Coupling Shear Pin Failure Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak torque that it was not designed. Common causes of wear or failure include normal wear (again, gear coupling teeth are designed to wear over time), lack of lubrication, torque. Occurs when the shear stress in the pin. Coupling Shear Pin Failure.

From mooneyspace.com

SBY ALT shear coupling failure and replacement Acclaim Owners Coupling Shear Pin Failure Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak torque that it was not designed. The shear stress is calculated by dividing the applied force by the. Common causes of wear or failure include normal wear (again, gear coupling teeth are designed to wear over time),. Coupling Shear Pin Failure.

From www.researchgate.net

Shear Pin Failure History of Shiroro HydroElectric Power Station Coupling Shear Pin Failure Occurs when the shear stress in the pin exceeds the material's shear strength. Possibilities include the shear pin, cutout shifter, and brake coupling. Gear couplings can be configured to do special jobs. Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak torque that it was not. Coupling Shear Pin Failure.

From www.semanticscholar.org

Figure 9 from Pin Failure in Shear vs. Bending for a Double Shear Joint Coupling Shear Pin Failure By understanding the common symptoms and causes of these coupling problems, and by implementing the appropriate. Common causes of wear or failure include normal wear (again, gear coupling teeth are designed to wear over time), lack of lubrication, torque. Gear couplings can be configured to do special jobs. The shear stress is calculated by dividing the applied force by the.. Coupling Shear Pin Failure.

From www.im-tek.com

Desch GCT with shear pins Gear Couplings IMTEK Coupling Shear Pin Failure By understanding the common symptoms and causes of these coupling problems, and by implementing the appropriate. Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak torque that it was not designed. In their most basic form, they incorporate a pin (or, for very. Occurs when the. Coupling Shear Pin Failure.

From www.youtube.com

Types of failures in bolted Connections Block shear failure Prying Coupling Shear Pin Failure Gear couplings can be configured to do special jobs. By understanding the common symptoms and causes of these coupling problems, and by implementing the appropriate. Common causes of wear or failure include normal wear (again, gear coupling teeth are designed to wear over time), lack of lubrication, torque. Possibilities include the shear pin, cutout shifter, and brake coupling. The shear. Coupling Shear Pin Failure.

From store.fivesmsi.com

COUPLINGWITH SHEAR PIN FIVES MSI Online Store Coupling Shear Pin Failure By understanding the common symptoms and causes of these coupling problems, and by implementing the appropriate. The shear stress is calculated by dividing the applied force by the. Learn about the critical role of shear pins in mechanical systems, how they work, the causes of their failure, and the steps to identify. In their most basic form, they incorporate a. Coupling Shear Pin Failure.

From www.sleipnergroup.com

Flexible coupling w/shear pin SE20/SE25/SE30/SE40 Coupling Shear Pin Failure Possibilities include the shear pin, cutout shifter, and brake coupling. The shear stress is calculated by dividing the applied force by the. Occurs when the shear stress in the pin exceeds the material's shear strength. By understanding the common symptoms and causes of these coupling problems, and by implementing the appropriate. Gear couplings can be configured to do special jobs.. Coupling Shear Pin Failure.

From www.mudgefasteners.com

Fastener Failures and How to Prevent Them Coupling Shear Pin Failure Common causes of wear or failure include normal wear (again, gear coupling teeth are designed to wear over time), lack of lubrication, torque. Possibilities include the shear pin, cutout shifter, and brake coupling. Occurs when the shear stress in the pin exceeds the material's shear strength. Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure. Coupling Shear Pin Failure.

From engineeringdiscoveries.com

What Is Punching Shear Failure And How To Prevent Engineering Discoveries Coupling Shear Pin Failure Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak torque that it was not designed. By understanding the common symptoms and causes of these coupling problems, and by implementing the appropriate. In their most basic form, they incorporate a pin (or, for very. Learn about the. Coupling Shear Pin Failure.

From www.researchgate.net

Modes of bolted joint failures (a) net tension failure, (b) shearout Coupling Shear Pin Failure Possibilities include the shear pin, cutout shifter, and brake coupling. Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak torque that it was not designed. Learn about the critical role of shear pins in mechanical systems, how they work, the causes of their failure, and the. Coupling Shear Pin Failure.

From www.researchgate.net

(PDF) An Experimental Investigation on the ShearSeepage Coupling Coupling Shear Pin Failure Common causes of wear or failure include normal wear (again, gear coupling teeth are designed to wear over time), lack of lubrication, torque. Occurs when the shear stress in the pin exceeds the material's shear strength. Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak torque. Coupling Shear Pin Failure.

From www.chegg.com

Solved The pin is made of a material having a failure shear Coupling Shear Pin Failure Learn about the critical role of shear pins in mechanical systems, how they work, the causes of their failure, and the steps to identify. By understanding the common symptoms and causes of these coupling problems, and by implementing the appropriate. The shear stress is calculated by dividing the applied force by the. Gear couplings can be configured to do special. Coupling Shear Pin Failure.

From www.powertech-group.fi

Couplings Power Tech Group Coupling Shear Pin Failure Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak torque that it was not designed. In their most basic form, they incorporate a pin (or, for very. Learn about the critical role of shear pins in mechanical systems, how they work, the causes of their failure,. Coupling Shear Pin Failure.

From www.slideserve.com

PPT The Art of Coupling PowerPoint Presentation, free download ID Coupling Shear Pin Failure Learn about the critical role of shear pins in mechanical systems, how they work, the causes of their failure, and the steps to identify. By understanding the common symptoms and causes of these coupling problems, and by implementing the appropriate. The shear stress is calculated by dividing the applied force by the. In their most basic form, they incorporate a. Coupling Shear Pin Failure.

From dhevilsmechanic.blogspot.com

Perbaikan Shear Pin Coupling Turbine Generator Coupling Shear Pin Failure Possibilities include the shear pin, cutout shifter, and brake coupling. The shear stress is calculated by dividing the applied force by the. Common causes of wear or failure include normal wear (again, gear coupling teeth are designed to wear over time), lack of lubrication, torque. Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode. Coupling Shear Pin Failure.

From store.fivesmsi.com

COUPLINGWITH SHEAR PIN FIVES MSI Online Store Coupling Shear Pin Failure Possibilities include the shear pin, cutout shifter, and brake coupling. Occurs when the shear stress in the pin exceeds the material's shear strength. Common causes of wear or failure include normal wear (again, gear coupling teeth are designed to wear over time), lack of lubrication, torque. In their most basic form, they incorporate a pin (or, for very. Learn about. Coupling Shear Pin Failure.

From www.semanticscholar.org

Figure 4 from Pin Failure in Shear vs. Bending for a Double Shear Joint Coupling Shear Pin Failure Occurs when the shear stress in the pin exceeds the material's shear strength. Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak torque that it was not designed. Common causes of wear or failure include normal wear (again, gear coupling teeth are designed to wear over. Coupling Shear Pin Failure.

From shear-pin-coupling.com

Home manufacturer, suppliers, factory, exporters Coupling Shear Pin Failure Learn about the critical role of shear pins in mechanical systems, how they work, the causes of their failure, and the steps to identify. Occurs when the shear stress in the pin exceeds the material's shear strength. Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak. Coupling Shear Pin Failure.

From www.numerade.com

SOLVED The pin is made of a material having a failure shear stress of Coupling Shear Pin Failure Learn about the critical role of shear pins in mechanical systems, how they work, the causes of their failure, and the steps to identify. In their most basic form, they incorporate a pin (or, for very. Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak torque. Coupling Shear Pin Failure.

From catalog.daltongear.com

Dalton Roller Chain Shear Pin Coupling "RCSPC" On Dalton Gear Co. Coupling Shear Pin Failure Gear couplings can be configured to do special jobs. Possibilities include the shear pin, cutout shifter, and brake coupling. Occurs when the shear stress in the pin exceeds the material's shear strength. Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak torque that it was not. Coupling Shear Pin Failure.

From www.researchgate.net

Punching shear failures of slabcolumn joints with drop panels Coupling Shear Pin Failure Gear couplings can be configured to do special jobs. Possibilities include the shear pin, cutout shifter, and brake coupling. Learn about the critical role of shear pins in mechanical systems, how they work, the causes of their failure, and the steps to identify. In their most basic form, they incorporate a pin (or, for very. The shear stress is calculated. Coupling Shear Pin Failure.

From www.couplingtips.com

Reaction forces from couplings How to prevent or mitigate? Coupling Shear Pin Failure Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak torque that it was not designed. In their most basic form, they incorporate a pin (or, for very. Gear couplings can be configured to do special jobs. Common causes of wear or failure include normal wear (again,. Coupling Shear Pin Failure.

From www.researchgate.net

Summary of different failure modes observed during static lap shear Coupling Shear Pin Failure In their most basic form, they incorporate a pin (or, for very. By understanding the common symptoms and causes of these coupling problems, and by implementing the appropriate. Possibilities include the shear pin, cutout shifter, and brake coupling. Learn about the critical role of shear pins in mechanical systems, how they work, the causes of their failure, and the steps. Coupling Shear Pin Failure.

From www.couplinganswers.com

Coupling Failure Analysis Jaw Couplings (includes hub & spider photos Coupling Shear Pin Failure The shear stress is calculated by dividing the applied force by the. Learn about the critical role of shear pins in mechanical systems, how they work, the causes of their failure, and the steps to identify. Gear couplings can be configured to do special jobs. Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode. Coupling Shear Pin Failure.

From www.researchgate.net

Typical failure mechanisms of RC walls (a) shear sliding failure, (b Coupling Shear Pin Failure Learn about the critical role of shear pins in mechanical systems, how they work, the causes of their failure, and the steps to identify. In their most basic form, they incorporate a pin (or, for very. Occurs when the shear stress in the pin exceeds the material's shear strength. Coupling hubs failing, cracking, or bursting over the keyway corners is. Coupling Shear Pin Failure.

From engineerexcel.com

Double Shear Loading Strength Analysis for Engineers EngineerExcel Coupling Shear Pin Failure Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak torque that it was not designed. Possibilities include the shear pin, cutout shifter, and brake coupling. By understanding the common symptoms and causes of these coupling problems, and by implementing the appropriate. Learn about the critical role. Coupling Shear Pin Failure.

From www.eigenplus.com

Blockshearfailurestaggeredbolting eigenplus Coupling Shear Pin Failure Common causes of wear or failure include normal wear (again, gear coupling teeth are designed to wear over time), lack of lubrication, torque. Possibilities include the shear pin, cutout shifter, and brake coupling. The shear stress is calculated by dividing the applied force by the. In their most basic form, they incorporate a pin (or, for very. Coupling hubs failing,. Coupling Shear Pin Failure.

From www.slideserve.com

PPT The Art of Coupling PowerPoint Presentation, free download ID Coupling Shear Pin Failure In their most basic form, they incorporate a pin (or, for very. Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak torque that it was not designed. By understanding the common symptoms and causes of these coupling problems, and by implementing the appropriate. Common causes of. Coupling Shear Pin Failure.

From www.semanticscholar.org

[PDF] Pin Failure in Shear vs. Bending for a Double Shear Joint Coupling Shear Pin Failure Gear couplings can be configured to do special jobs. Common causes of wear or failure include normal wear (again, gear coupling teeth are designed to wear over time), lack of lubrication, torque. In their most basic form, they incorporate a pin (or, for very. Possibilities include the shear pin, cutout shifter, and brake coupling. By understanding the common symptoms and. Coupling Shear Pin Failure.

From mooneyspace.com

Shear Coupling Failure Ovation 2 Standby Alternator Modern Mooney Coupling Shear Pin Failure Common causes of wear or failure include normal wear (again, gear coupling teeth are designed to wear over time), lack of lubrication, torque. In their most basic form, they incorporate a pin (or, for very. Coupling hubs failing, cracking, or bursting over the keyway corners is a common failure mode that clearly indicates the coupling hit a peak torque that. Coupling Shear Pin Failure.

From www.chegg.com

Solved The pin is made of a material having a failure shear Coupling Shear Pin Failure Gear couplings can be configured to do special jobs. Learn about the critical role of shear pins in mechanical systems, how they work, the causes of their failure, and the steps to identify. The shear stress is calculated by dividing the applied force by the. Common causes of wear or failure include normal wear (again, gear coupling teeth are designed. Coupling Shear Pin Failure.