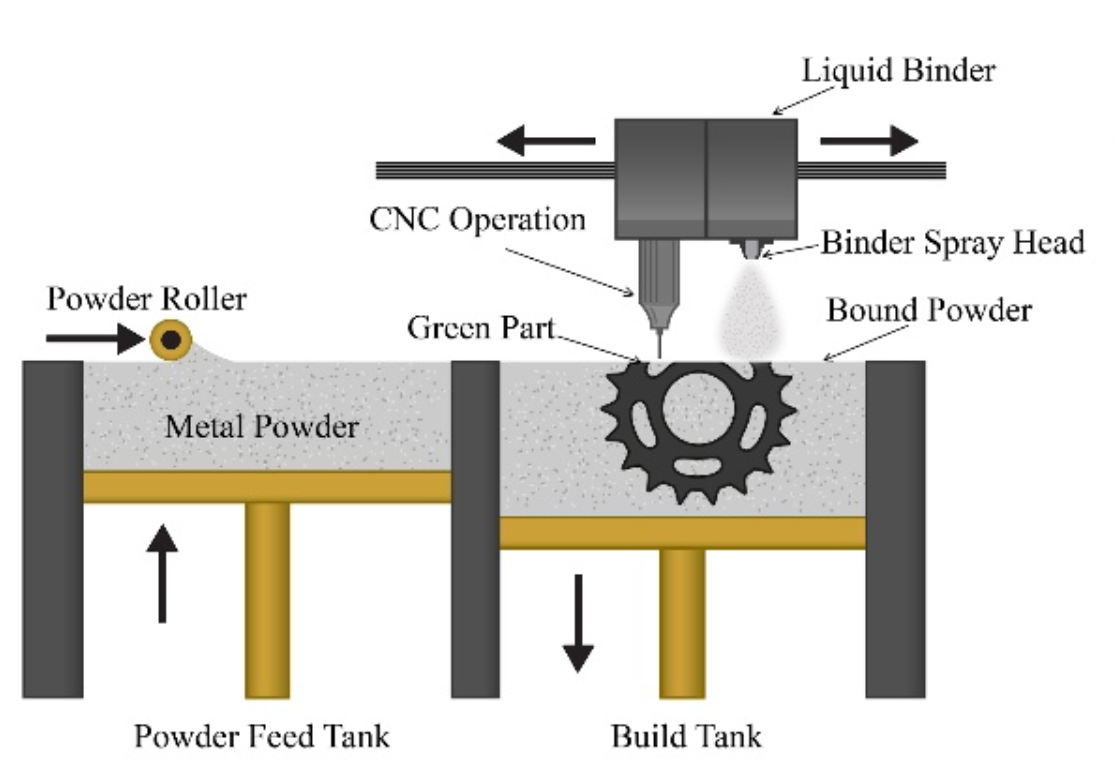

Binder Jetting Components . In metal binder jetting, a liquid binder is selectively applied to join powder particles, layer by layer. A powder layer is applied (1), into which an. The process begins by spreading a. Binder jetting is a 3d printing process that uses a liquid binding agent deposited onto powdered material to create a part’s geometry. Binder jetting is an additive manufacturing process that deposits a liquid binding agent over powder particles. The technique involves laying down layers of material, creating a solid object one layer at a time. A key benefit of using binder jetting is the full color 3d printer advantage, a rarity in 3d printing. Fast and flexible production of complex metal components. Binder jetting can be used to print with a. The binder jetting 3d printing technique consists of the deposition of an adhesive binding agent onto thin layers of powdered material.

from facfox.com

A key benefit of using binder jetting is the full color 3d printer advantage, a rarity in 3d printing. A powder layer is applied (1), into which an. Binder jetting can be used to print with a. Binder jetting is an additive manufacturing process that deposits a liquid binding agent over powder particles. The binder jetting 3d printing technique consists of the deposition of an adhesive binding agent onto thin layers of powdered material. The technique involves laying down layers of material, creating a solid object one layer at a time. In metal binder jetting, a liquid binder is selectively applied to join powder particles, layer by layer. Binder jetting is a 3d printing process that uses a liquid binding agent deposited onto powdered material to create a part’s geometry. The process begins by spreading a. Fast and flexible production of complex metal components.

All You Need to Know About Metal Binder Jetting FacFox Docs

Binder Jetting Components A key benefit of using binder jetting is the full color 3d printer advantage, a rarity in 3d printing. Fast and flexible production of complex metal components. Binder jetting can be used to print with a. The binder jetting 3d printing technique consists of the deposition of an adhesive binding agent onto thin layers of powdered material. Binder jetting is a 3d printing process that uses a liquid binding agent deposited onto powdered material to create a part’s geometry. In metal binder jetting, a liquid binder is selectively applied to join powder particles, layer by layer. The process begins by spreading a. A powder layer is applied (1), into which an. The technique involves laying down layers of material, creating a solid object one layer at a time. A key benefit of using binder jetting is the full color 3d printer advantage, a rarity in 3d printing. Binder jetting is an additive manufacturing process that deposits a liquid binding agent over powder particles.

From acam.rwth-campus.com

Binder Jetting ACAM Aachen Navigating AM Complexity Binder Jetting Components The process begins by spreading a. In metal binder jetting, a liquid binder is selectively applied to join powder particles, layer by layer. A key benefit of using binder jetting is the full color 3d printer advantage, a rarity in 3d printing. Binder jetting can be used to print with a. A powder layer is applied (1), into which an.. Binder Jetting Components.

From www.metal-am.com

Binder Jetting and FDM vs Powder Bed Fusion and Injection Moulding Binder Jetting Components The technique involves laying down layers of material, creating a solid object one layer at a time. The binder jetting 3d printing technique consists of the deposition of an adhesive binding agent onto thin layers of powdered material. Fast and flexible production of complex metal components. Binder jetting is an additive manufacturing process that deposits a liquid binding agent over. Binder Jetting Components.

From www.metal-am.com

Binder Jet Additive Manufacturing in series production Binder Jetting Components Binder jetting is an additive manufacturing process that deposits a liquid binding agent over powder particles. The technique involves laying down layers of material, creating a solid object one layer at a time. A powder layer is applied (1), into which an. Fast and flexible production of complex metal components. The process begins by spreading a. Binder jetting can be. Binder Jetting Components.

From best3dprintingresources.blogspot.com

BINDER JETTING Binder Jetting Components In metal binder jetting, a liquid binder is selectively applied to join powder particles, layer by layer. Binder jetting is a 3d printing process that uses a liquid binding agent deposited onto powdered material to create a part’s geometry. A key benefit of using binder jetting is the full color 3d printer advantage, a rarity in 3d printing. The technique. Binder Jetting Components.

From amfg.ai

All You Need to Know About Metal Binder Jetting AMFG Binder Jetting Components A key benefit of using binder jetting is the full color 3d printer advantage, a rarity in 3d printing. Fast and flexible production of complex metal components. Binder jetting can be used to print with a. The binder jetting 3d printing technique consists of the deposition of an adhesive binding agent onto thin layers of powdered material. In metal binder. Binder Jetting Components.

From www.researchgate.net

Binder jetting testbed a CAD model showcasing major components with Binder Jetting Components Binder jetting can be used to print with a. Binder jetting is a 3d printing process that uses a liquid binding agent deposited onto powdered material to create a part’s geometry. The process begins by spreading a. A powder layer is applied (1), into which an. A key benefit of using binder jetting is the full color 3d printer advantage,. Binder Jetting Components.

From ampower.eu

AMPOWER metal Binder Jetting training handson with Fraunhofer IAPT Binder Jetting Components Binder jetting is an additive manufacturing process that deposits a liquid binding agent over powder particles. Fast and flexible production of complex metal components. In metal binder jetting, a liquid binder is selectively applied to join powder particles, layer by layer. The technique involves laying down layers of material, creating a solid object one layer at a time. The process. Binder Jetting Components.

From www.mkstechgroup.com

Binder Jetting Process MKS Technologies Pvt Ltd. Binder Jetting Components Binder jetting can be used to print with a. Fast and flexible production of complex metal components. A powder layer is applied (1), into which an. Binder jetting is an additive manufacturing process that deposits a liquid binding agent over powder particles. Binder jetting is a 3d printing process that uses a liquid binding agent deposited onto powdered material to. Binder Jetting Components.

From www.hubs.com

How to design parts for binder jetting 3D printing Hubs Binder Jetting Components Binder jetting is a 3d printing process that uses a liquid binding agent deposited onto powdered material to create a part’s geometry. The process begins by spreading a. The binder jetting 3d printing technique consists of the deposition of an adhesive binding agent onto thin layers of powdered material. Binder jetting can be used to print with a. Fast and. Binder Jetting Components.

From www.metal-am.com

Effective metal powder specifications for Binder Jet Additive Manufacturing Binder Jetting Components A key benefit of using binder jetting is the full color 3d printer advantage, a rarity in 3d printing. A powder layer is applied (1), into which an. Binder jetting is a 3d printing process that uses a liquid binding agent deposited onto powdered material to create a part’s geometry. The process begins by spreading a. Binder jetting can be. Binder Jetting Components.

From www.mdpi.com

JMMP Free FullText A Review on Binder Jet Additive Manufacturing Binder Jetting Components Binder jetting is an additive manufacturing process that deposits a liquid binding agent over powder particles. Binder jetting is a 3d printing process that uses a liquid binding agent deposited onto powdered material to create a part’s geometry. Binder jetting can be used to print with a. The binder jetting 3d printing technique consists of the deposition of an adhesive. Binder Jetting Components.

From www.ifam.fraunhofer.de

Metal Binder Jetting From Prototype to Series Production Binder Jetting Components The binder jetting 3d printing technique consists of the deposition of an adhesive binding agent onto thin layers of powdered material. Binder jetting is an additive manufacturing process that deposits a liquid binding agent over powder particles. The process begins by spreading a. Binder jetting is a 3d printing process that uses a liquid binding agent deposited onto powdered material. Binder Jetting Components.

From tritechtitanium.com

Titanium 3D Printing Binder Jet Printing TriTech Titanium Parts Binder Jetting Components The binder jetting 3d printing technique consists of the deposition of an adhesive binding agent onto thin layers of powdered material. The technique involves laying down layers of material, creating a solid object one layer at a time. Binder jetting is a 3d printing process that uses a liquid binding agent deposited onto powdered material to create a part’s geometry.. Binder Jetting Components.

From amfg.ai

All You Need to Know About Metal Binder Jetting AMFG Binder Jetting Components In metal binder jetting, a liquid binder is selectively applied to join powder particles, layer by layer. The binder jetting 3d printing technique consists of the deposition of an adhesive binding agent onto thin layers of powdered material. The technique involves laying down layers of material, creating a solid object one layer at a time. A powder layer is applied. Binder Jetting Components.

From ampower.eu

AMPOWER metal Binder Jetting training handson with Fraunhofer IAPT Binder Jetting Components A powder layer is applied (1), into which an. The technique involves laying down layers of material, creating a solid object one layer at a time. The process begins by spreading a. The binder jetting 3d printing technique consists of the deposition of an adhesive binding agent onto thin layers of powdered material. Binder jetting can be used to print. Binder Jetting Components.

From www.beamler.com

Binder Jetting Beamler Binder Jetting Components Binder jetting is a 3d printing process that uses a liquid binding agent deposited onto powdered material to create a part’s geometry. The binder jetting 3d printing technique consists of the deposition of an adhesive binding agent onto thin layers of powdered material. A key benefit of using binder jetting is the full color 3d printer advantage, a rarity in. Binder Jetting Components.

From www.fastradius.com

An Overview of Binder Jetting Fast Radius Binder Jetting Components Binder jetting is a 3d printing process that uses a liquid binding agent deposited onto powdered material to create a part’s geometry. In metal binder jetting, a liquid binder is selectively applied to join powder particles, layer by layer. The process begins by spreading a. Binder jetting can be used to print with a. The binder jetting 3d printing technique. Binder Jetting Components.

From www.researchgate.net

Electronic connection diagram for binder jetting testbed, including Binder Jetting Components In metal binder jetting, a liquid binder is selectively applied to join powder particles, layer by layer. The binder jetting 3d printing technique consists of the deposition of an adhesive binding agent onto thin layers of powdered material. The technique involves laying down layers of material, creating a solid object one layer at a time. Binder jetting is an additive. Binder Jetting Components.

From pick3dprinter.com

Metal Binder Jetting (MBJ) 3D Printing Simply Explained Pick 3D Printer Binder Jetting Components The binder jetting 3d printing technique consists of the deposition of an adhesive binding agent onto thin layers of powdered material. A powder layer is applied (1), into which an. Binder jetting can be used to print with a. The technique involves laying down layers of material, creating a solid object one layer at a time. A key benefit of. Binder Jetting Components.

From engineeringproductdesign.com

What is Binder Jetting and how does binder jetting work Binder Jetting Components The technique involves laying down layers of material, creating a solid object one layer at a time. Fast and flexible production of complex metal components. A key benefit of using binder jetting is the full color 3d printer advantage, a rarity in 3d printing. Binder jetting can be used to print with a. Binder jetting is a 3d printing process. Binder Jetting Components.

From www.researchgate.net

Schematic representation of (A) binder jetting printing process, (B Binder Jetting Components The binder jetting 3d printing technique consists of the deposition of an adhesive binding agent onto thin layers of powdered material. Binder jetting can be used to print with a. A powder layer is applied (1), into which an. Fast and flexible production of complex metal components. Binder jetting is a 3d printing process that uses a liquid binding agent. Binder Jetting Components.

From sohaibwrites.com

What is binder jetting? (step by step, materials, advantages and Binder Jetting Components The process begins by spreading a. The binder jetting 3d printing technique consists of the deposition of an adhesive binding agent onto thin layers of powdered material. A key benefit of using binder jetting is the full color 3d printer advantage, a rarity in 3d printing. Fast and flexible production of complex metal components. Binder jetting can be used to. Binder Jetting Components.

From www.researchgate.net

Scheme of principle of Binder jetting process Download Scientific Diagram Binder Jetting Components Fast and flexible production of complex metal components. In metal binder jetting, a liquid binder is selectively applied to join powder particles, layer by layer. A key benefit of using binder jetting is the full color 3d printer advantage, a rarity in 3d printing. The process begins by spreading a. Binder jetting is an additive manufacturing process that deposits a. Binder Jetting Components.

From facfox.com

Introduction to binder jetting 3D printing FacFox Docs Binder Jetting Components Fast and flexible production of complex metal components. Binder jetting can be used to print with a. In metal binder jetting, a liquid binder is selectively applied to join powder particles, layer by layer. The binder jetting 3d printing technique consists of the deposition of an adhesive binding agent onto thin layers of powdered material. The technique involves laying down. Binder Jetting Components.

From www.3dhubs.com

Introduction to Binder Jetting 3D printing 3D Hubs Binder Jetting Components The technique involves laying down layers of material, creating a solid object one layer at a time. A powder layer is applied (1), into which an. Binder jetting is an additive manufacturing process that deposits a liquid binding agent over powder particles. Binder jetting can be used to print with a. A key benefit of using binder jetting is the. Binder Jetting Components.

From www.researchgate.net

Schematic of the Binder Jet Process (Courtesy The ExOne Company Binder Jetting Components The binder jetting 3d printing technique consists of the deposition of an adhesive binding agent onto thin layers of powdered material. Fast and flexible production of complex metal components. Binder jetting is an additive manufacturing process that deposits a liquid binding agent over powder particles. Binder jetting is a 3d printing process that uses a liquid binding agent deposited onto. Binder Jetting Components.

From www.htl.fraunhofer.de

Binder Jetting Process Binder Jetting Components The technique involves laying down layers of material, creating a solid object one layer at a time. A key benefit of using binder jetting is the full color 3d printer advantage, a rarity in 3d printing. Binder jetting is a 3d printing process that uses a liquid binding agent deposited onto powdered material to create a part’s geometry. The process. Binder Jetting Components.

From www.ikts.fraunhofer.de

Additive Manufacturing of ceramics and hardmetal via Binder Jetting Binder Jetting Components The binder jetting 3d printing technique consists of the deposition of an adhesive binding agent onto thin layers of powdered material. Binder jetting can be used to print with a. The technique involves laying down layers of material, creating a solid object one layer at a time. Binder jetting is a 3d printing process that uses a liquid binding agent. Binder Jetting Components.

From ampower.eu

AMPOWER metal Binder Jetting training handson with Fraunhofer IAPT Binder Jetting Components Binder jetting can be used to print with a. A key benefit of using binder jetting is the full color 3d printer advantage, a rarity in 3d printing. Fast and flexible production of complex metal components. A powder layer is applied (1), into which an. The technique involves laying down layers of material, creating a solid object one layer at. Binder Jetting Components.

From www.researchgate.net

Schematic of the Binder Jetting (BJ) process.... Download Scientific Binder Jetting Components Binder jetting is a 3d printing process that uses a liquid binding agent deposited onto powdered material to create a part’s geometry. Fast and flexible production of complex metal components. A key benefit of using binder jetting is the full color 3d printer advantage, a rarity in 3d printing. A powder layer is applied (1), into which an. In metal. Binder Jetting Components.

From www.3dprintedparts.com

Binder Jetting The Future of Production Metal Printing 3D Printed Parts Binder Jetting Components The process begins by spreading a. Binder jetting is an additive manufacturing process that deposits a liquid binding agent over powder particles. The technique involves laying down layers of material, creating a solid object one layer at a time. A powder layer is applied (1), into which an. The binder jetting 3d printing technique consists of the deposition of an. Binder Jetting Components.

From facfox.com

All You Need to Know About Metal Binder Jetting FacFox Docs Binder Jetting Components Binder jetting is a 3d printing process that uses a liquid binding agent deposited onto powdered material to create a part’s geometry. The technique involves laying down layers of material, creating a solid object one layer at a time. A key benefit of using binder jetting is the full color 3d printer advantage, a rarity in 3d printing. In metal. Binder Jetting Components.

From www.researchgate.net

Steps of binder jetting process [63] Download Scientific Diagram Binder Jetting Components Binder jetting is a 3d printing process that uses a liquid binding agent deposited onto powdered material to create a part’s geometry. Binder jetting is an additive manufacturing process that deposits a liquid binding agent over powder particles. In metal binder jetting, a liquid binder is selectively applied to join powder particles, layer by layer. Binder jetting can be used. Binder Jetting Components.

From www.researchgate.net

Steps of binder jetting process [63] Download Scientific Diagram Binder Jetting Components A key benefit of using binder jetting is the full color 3d printer advantage, a rarity in 3d printing. A powder layer is applied (1), into which an. Fast and flexible production of complex metal components. Binder jetting can be used to print with a. The technique involves laying down layers of material, creating a solid object one layer at. Binder Jetting Components.

From ampower.eu

AMPOWER metal Binder Jetting training handson with Fraunhofer IAPT Binder Jetting Components A powder layer is applied (1), into which an. A key benefit of using binder jetting is the full color 3d printer advantage, a rarity in 3d printing. Fast and flexible production of complex metal components. Binder jetting can be used to print with a. The technique involves laying down layers of material, creating a solid object one layer at. Binder Jetting Components.