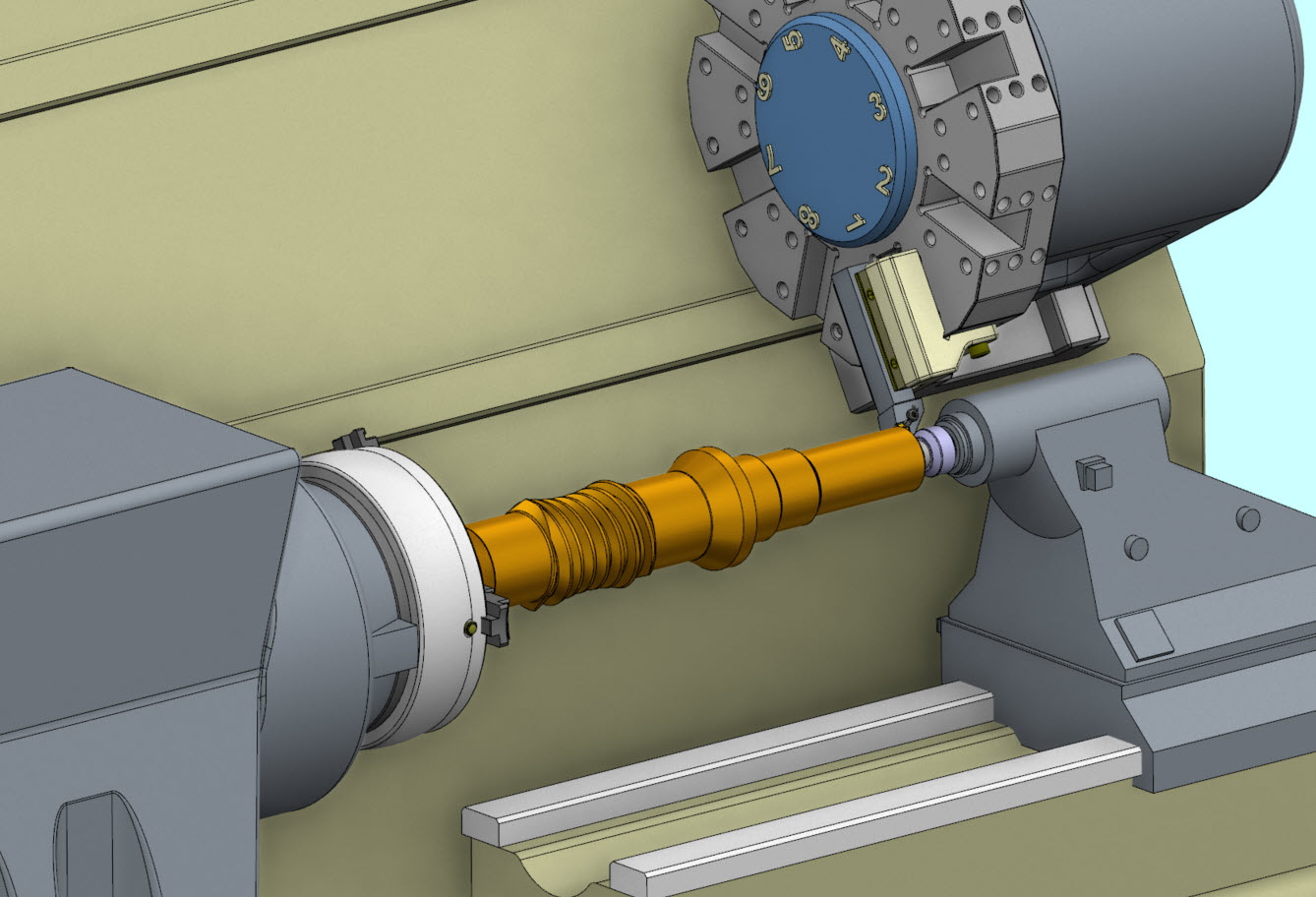

Turning Vs Milling . It uses primarily round bar stock for machining components. In turning, the workpiece rotates while a stationary cutting tool removes material to create cylindrical or conical shapes. Turning involves rotating the workpiece against a stationary cutting tool, while milling involves the rotation of the cutting tool against a stationary workpiece. Both processes utilize cnc technology and cad software to minimize human error and can be used for metals and thermoplastics. Learn the distinct features and applications of turning and milling, two subtractive manufacturing processes that use cnc technology. Compare the advantages and disadvantages of each cnc machining technique and find your fit with mastercam solutions. Turning and milling are two distinct machining processes that differ primarily in how the workpiece and cutting tool move relative to each other. Turning rotates the workpiece against a cutting tool. In this article, we will compare and contrast milling and turning, exploring their mechanics, tooling, material suitability, surface finish, precision, cost analysis,. Compare the tool movement, workpiece orientation, shapes produced, materials, and similarities of these methods. Cnc turning is typically used to create cylindrical parts, while cnc milling can be used to make parts of diverse shapes and. The short answer is that.

from www.mastercam.com

The short answer is that. Turning involves rotating the workpiece against a stationary cutting tool, while milling involves the rotation of the cutting tool against a stationary workpiece. Cnc turning is typically used to create cylindrical parts, while cnc milling can be used to make parts of diverse shapes and. Compare the tool movement, workpiece orientation, shapes produced, materials, and similarities of these methods. In this article, we will compare and contrast milling and turning, exploring their mechanics, tooling, material suitability, surface finish, precision, cost analysis,. It uses primarily round bar stock for machining components. Turning rotates the workpiece against a cutting tool. Turning and milling are two distinct machining processes that differ primarily in how the workpiece and cutting tool move relative to each other. Compare the advantages and disadvantages of each cnc machining technique and find your fit with mastercam solutions. Both processes utilize cnc technology and cad software to minimize human error and can be used for metals and thermoplastics.

Milling, Turning, and MillTurn What are the Differences?

Turning Vs Milling Turning involves rotating the workpiece against a stationary cutting tool, while milling involves the rotation of the cutting tool against a stationary workpiece. Turning involves rotating the workpiece against a stationary cutting tool, while milling involves the rotation of the cutting tool against a stationary workpiece. It uses primarily round bar stock for machining components. In this article, we will compare and contrast milling and turning, exploring their mechanics, tooling, material suitability, surface finish, precision, cost analysis,. Both processes utilize cnc technology and cad software to minimize human error and can be used for metals and thermoplastics. The short answer is that. Turning and milling are two distinct machining processes that differ primarily in how the workpiece and cutting tool move relative to each other. Compare the advantages and disadvantages of each cnc machining technique and find your fit with mastercam solutions. In turning, the workpiece rotates while a stationary cutting tool removes material to create cylindrical or conical shapes. Compare the tool movement, workpiece orientation, shapes produced, materials, and similarities of these methods. Cnc turning is typically used to create cylindrical parts, while cnc milling can be used to make parts of diverse shapes and. Learn the distinct features and applications of turning and milling, two subtractive manufacturing processes that use cnc technology. Turning rotates the workpiece against a cutting tool.

From www.integratedsolutionsco.com

CNC Turning and Milling vs. Manual Turning and Milling ISI Integrated Turning Vs Milling The short answer is that. Turning rotates the workpiece against a cutting tool. It uses primarily round bar stock for machining components. Turning and milling are two distinct machining processes that differ primarily in how the workpiece and cutting tool move relative to each other. Cnc turning is typically used to create cylindrical parts, while cnc milling can be used. Turning Vs Milling.

From thmachining.com

The Difference Between Milling and Turning Custom Metal Parts Turning Vs Milling Both processes utilize cnc technology and cad software to minimize human error and can be used for metals and thermoplastics. In turning, the workpiece rotates while a stationary cutting tool removes material to create cylindrical or conical shapes. Learn the distinct features and applications of turning and milling, two subtractive manufacturing processes that use cnc technology. In this article, we. Turning Vs Milling.

From www.technoxmachine.com

What Are the Basics of CNC Milling and Turning? [Infographic] Technox Turning Vs Milling Cnc turning is typically used to create cylindrical parts, while cnc milling can be used to make parts of diverse shapes and. Both processes utilize cnc technology and cad software to minimize human error and can be used for metals and thermoplastics. It uses primarily round bar stock for machining components. Turning and milling are two distinct machining processes that. Turning Vs Milling.

From okdor.com

Milling vs. Turning An InDepth Look at CNC Machining Processes Turning Vs Milling Turning rotates the workpiece against a cutting tool. In turning, the workpiece rotates while a stationary cutting tool removes material to create cylindrical or conical shapes. Turning and milling are two distinct machining processes that differ primarily in how the workpiece and cutting tool move relative to each other. The short answer is that. It uses primarily round bar stock. Turning Vs Milling.

From pepmfg.us

What is the Difference Between CNC Milling and Turning? PEP Mfg., Inc. Turning Vs Milling The short answer is that. In turning, the workpiece rotates while a stationary cutting tool removes material to create cylindrical or conical shapes. Cnc turning is typically used to create cylindrical parts, while cnc milling can be used to make parts of diverse shapes and. Turning and milling are two distinct machining processes that differ primarily in how the workpiece. Turning Vs Milling.

From wiki.unionfab.cn

CNC Milling vs. Turning Processes, Applications, and Pros/Cons Turning Vs Milling Learn the distinct features and applications of turning and milling, two subtractive manufacturing processes that use cnc technology. Compare the advantages and disadvantages of each cnc machining technique and find your fit with mastercam solutions. Both processes utilize cnc technology and cad software to minimize human error and can be used for metals and thermoplastics. In this article, we will. Turning Vs Milling.

From www.autodesk.com

CNC Turning vs. CNC Milling Fusion Blog Turning Vs Milling Compare the tool movement, workpiece orientation, shapes produced, materials, and similarities of these methods. Both processes utilize cnc technology and cad software to minimize human error and can be used for metals and thermoplastics. The short answer is that. Compare the advantages and disadvantages of each cnc machining technique and find your fit with mastercam solutions. It uses primarily round. Turning Vs Milling.

From www.smartlathe.com

Turning vs Milling What’s the Difference? Turning Vs Milling Compare the tool movement, workpiece orientation, shapes produced, materials, and similarities of these methods. The short answer is that. Both processes utilize cnc technology and cad software to minimize human error and can be used for metals and thermoplastics. Cnc turning is typically used to create cylindrical parts, while cnc milling can be used to make parts of diverse shapes. Turning Vs Milling.

From cncmass.com

Turning Vs. Milling What’s the Difference for Precision Machining Turning Vs Milling The short answer is that. In this article, we will compare and contrast milling and turning, exploring their mechanics, tooling, material suitability, surface finish, precision, cost analysis,. It uses primarily round bar stock for machining components. Both processes utilize cnc technology and cad software to minimize human error and can be used for metals and thermoplastics. Compare the advantages and. Turning Vs Milling.

From knowcnc.com

Turning vs Milling Key Differences Explained Turning Vs Milling Turning involves rotating the workpiece against a stationary cutting tool, while milling involves the rotation of the cutting tool against a stationary workpiece. The short answer is that. Cnc turning is typically used to create cylindrical parts, while cnc milling can be used to make parts of diverse shapes and. Learn the distinct features and applications of turning and milling,. Turning Vs Milling.

From jwmachinecorp.com

Milling Turning What is the difference? Orlando, FL Turning Vs Milling In this article, we will compare and contrast milling and turning, exploring their mechanics, tooling, material suitability, surface finish, precision, cost analysis,. In turning, the workpiece rotates while a stationary cutting tool removes material to create cylindrical or conical shapes. It uses primarily round bar stock for machining components. Compare the advantages and disadvantages of each cnc machining technique and. Turning Vs Milling.

From swmachinetech.com

Turning Vs. Milling What's the Difference for Precision Machining Turning Vs Milling Turning involves rotating the workpiece against a stationary cutting tool, while milling involves the rotation of the cutting tool against a stationary workpiece. The short answer is that. Turning rotates the workpiece against a cutting tool. Turning and milling are two distinct machining processes that differ primarily in how the workpiece and cutting tool move relative to each other. Learn. Turning Vs Milling.

From www.smartlathe.com

Turning vs Milling What’s the Difference? Turning Vs Milling Compare the advantages and disadvantages of each cnc machining technique and find your fit with mastercam solutions. Cnc turning is typically used to create cylindrical parts, while cnc milling can be used to make parts of diverse shapes and. Learn the distinct features and applications of turning and milling, two subtractive manufacturing processes that use cnc technology. Turning involves rotating. Turning Vs Milling.

From www.sundicuttingtools.com

CNC Turning vs Milling Differences and Applications I Sundi Turning Vs Milling Learn the distinct features and applications of turning and milling, two subtractive manufacturing processes that use cnc technology. Compare the advantages and disadvantages of each cnc machining technique and find your fit with mastercam solutions. In turning, the workpiece rotates while a stationary cutting tool removes material to create cylindrical or conical shapes. Compare the tool movement, workpiece orientation, shapes. Turning Vs Milling.

From pepmfg.us

What is the Difference Between CNC Milling and Turning? PEP Mfg., Inc. Turning Vs Milling Compare the tool movement, workpiece orientation, shapes produced, materials, and similarities of these methods. Turning involves rotating the workpiece against a stationary cutting tool, while milling involves the rotation of the cutting tool against a stationary workpiece. In turning, the workpiece rotates while a stationary cutting tool removes material to create cylindrical or conical shapes. Learn the distinct features and. Turning Vs Milling.

From www.redline-cnc.co.uk

Turning Vs. Milling Difference For Precision CNC Machining? Turning Vs Milling Both processes utilize cnc technology and cad software to minimize human error and can be used for metals and thermoplastics. Turning rotates the workpiece against a cutting tool. Turning and milling are two distinct machining processes that differ primarily in how the workpiece and cutting tool move relative to each other. The short answer is that. Turning involves rotating the. Turning Vs Milling.

From pioneerserviceinc.com

Turning vs Milling Pioneer Service Inc Turning Vs Milling Both processes utilize cnc technology and cad software to minimize human error and can be used for metals and thermoplastics. Learn the distinct features and applications of turning and milling, two subtractive manufacturing processes that use cnc technology. In this article, we will compare and contrast milling and turning, exploring their mechanics, tooling, material suitability, surface finish, precision, cost analysis,.. Turning Vs Milling.

From www.pcbway.com

Turning vs Milling What’s the Difference? CNC Machining PCBway Turning Vs Milling Turning rotates the workpiece against a cutting tool. Turning involves rotating the workpiece against a stationary cutting tool, while milling involves the rotation of the cutting tool against a stationary workpiece. It uses primarily round bar stock for machining components. Cnc turning is typically used to create cylindrical parts, while cnc milling can be used to make parts of diverse. Turning Vs Milling.

From www.youtube.com

All Lathe Machine Operations Turning, Facing, Taper Turning, Boring Turning Vs Milling Learn the distinct features and applications of turning and milling, two subtractive manufacturing processes that use cnc technology. Both processes utilize cnc technology and cad software to minimize human error and can be used for metals and thermoplastics. Turning and milling are two distinct machining processes that differ primarily in how the workpiece and cutting tool move relative to each. Turning Vs Milling.

From www.iqsdirectory.com

CNC Machining What Is It? How Does It Work? Types, Codes Turning Vs Milling Turning involves rotating the workpiece against a stationary cutting tool, while milling involves the rotation of the cutting tool against a stationary workpiece. Compare the tool movement, workpiece orientation, shapes produced, materials, and similarities of these methods. Turning rotates the workpiece against a cutting tool. Both processes utilize cnc technology and cad software to minimize human error and can be. Turning Vs Milling.

From pioneerserviceinc.com

Turning Vs. Milling What’s the Difference for Machining? Pioneer Turning Vs Milling Cnc turning is typically used to create cylindrical parts, while cnc milling can be used to make parts of diverse shapes and. Compare the advantages and disadvantages of each cnc machining technique and find your fit with mastercam solutions. Turning involves rotating the workpiece against a stationary cutting tool, while milling involves the rotation of the cutting tool against a. Turning Vs Milling.

From ourelabs.blogspot.com

FACING, PLAIN TURNING AND STEP TURNING Ourengineeringlabs Turning Vs Milling Compare the tool movement, workpiece orientation, shapes produced, materials, and similarities of these methods. The short answer is that. In turning, the workpiece rotates while a stationary cutting tool removes material to create cylindrical or conical shapes. Turning involves rotating the workpiece against a stationary cutting tool, while milling involves the rotation of the cutting tool against a stationary workpiece.. Turning Vs Milling.

From www.difference.minaprem.com

Difference Between Turning and Milling Turning Vs Milling Cnc turning is typically used to create cylindrical parts, while cnc milling can be used to make parts of diverse shapes and. It uses primarily round bar stock for machining components. Turning rotates the workpiece against a cutting tool. Compare the advantages and disadvantages of each cnc machining technique and find your fit with mastercam solutions. In this article, we. Turning Vs Milling.

From www.china-machining.com

CNC Turning and Milling Do You Understand the Difference? Turning Vs Milling In this article, we will compare and contrast milling and turning, exploring their mechanics, tooling, material suitability, surface finish, precision, cost analysis,. Learn the distinct features and applications of turning and milling, two subtractive manufacturing processes that use cnc technology. The short answer is that. Cnc turning is typically used to create cylindrical parts, while cnc milling can be used. Turning Vs Milling.

From www.autodesk.com

CNC Turning vs. CNC Milling Fusion Blog Turning Vs Milling Cnc turning is typically used to create cylindrical parts, while cnc milling can be used to make parts of diverse shapes and. Learn the distinct features and applications of turning and milling, two subtractive manufacturing processes that use cnc technology. It uses primarily round bar stock for machining components. In this article, we will compare and contrast milling and turning,. Turning Vs Milling.

From yijinsolution.com

What is CNC milling A Complete Guide (2024) Turning Vs Milling Turning rotates the workpiece against a cutting tool. The short answer is that. Compare the advantages and disadvantages of each cnc machining technique and find your fit with mastercam solutions. Both processes utilize cnc technology and cad software to minimize human error and can be used for metals and thermoplastics. Turning involves rotating the workpiece against a stationary cutting tool,. Turning Vs Milling.

From www.fictiv.com

CNC Turning Basics Introduction to CNC Turning Turning Vs Milling Turning rotates the workpiece against a cutting tool. Compare the tool movement, workpiece orientation, shapes produced, materials, and similarities of these methods. It uses primarily round bar stock for machining components. In turning, the workpiece rotates while a stationary cutting tool removes material to create cylindrical or conical shapes. Learn the distinct features and applications of turning and milling, two. Turning Vs Milling.

From www.basilius.com

Turning and Milling Stock The Complete Guide Basilius Inc. Turning Vs Milling In this article, we will compare and contrast milling and turning, exploring their mechanics, tooling, material suitability, surface finish, precision, cost analysis,. Turning rotates the workpiece against a cutting tool. Turning and milling are two distinct machining processes that differ primarily in how the workpiece and cutting tool move relative to each other. Cnc turning is typically used to create. Turning Vs Milling.

From www.entrepreneurshipsecret.com

CNC Milling vs. Turning What You Can Use For Creating Your Product? Turning Vs Milling It uses primarily round bar stock for machining components. In turning, the workpiece rotates while a stationary cutting tool removes material to create cylindrical or conical shapes. Compare the advantages and disadvantages of each cnc machining technique and find your fit with mastercam solutions. Turning involves rotating the workpiece against a stationary cutting tool, while milling involves the rotation of. Turning Vs Milling.

From www.youtube.com

Differences between Turning and Milling. YouTube Turning Vs Milling Both processes utilize cnc technology and cad software to minimize human error and can be used for metals and thermoplastics. Turning involves rotating the workpiece against a stationary cutting tool, while milling involves the rotation of the cutting tool against a stationary workpiece. Turning rotates the workpiece against a cutting tool. It uses primarily round bar stock for machining components.. Turning Vs Milling.

From mdaltd.ca

CNC Milling vs CNC Turning Which is the Best Option? Turning Vs Milling It uses primarily round bar stock for machining components. Compare the tool movement, workpiece orientation, shapes produced, materials, and similarities of these methods. Both processes utilize cnc technology and cad software to minimize human error and can be used for metals and thermoplastics. The short answer is that. In this article, we will compare and contrast milling and turning, exploring. Turning Vs Milling.

From fractory.com

What Is the Difference Between CNC Milling & Turning? Turning Vs Milling Compare the tool movement, workpiece orientation, shapes produced, materials, and similarities of these methods. Turning and milling are two distinct machining processes that differ primarily in how the workpiece and cutting tool move relative to each other. Both processes utilize cnc technology and cad software to minimize human error and can be used for metals and thermoplastics. Learn the distinct. Turning Vs Milling.

From www.chap2.com

CNC Turning vs. CNC Milling Chapter 2 Incorporated Turning Vs Milling Compare the tool movement, workpiece orientation, shapes produced, materials, and similarities of these methods. Compare the advantages and disadvantages of each cnc machining technique and find your fit with mastercam solutions. Both processes utilize cnc technology and cad software to minimize human error and can be used for metals and thermoplastics. In this article, we will compare and contrast milling. Turning Vs Milling.

From www.fastradius.com

When to Use CNC Turning over CNC Milling Fast Radius Turning Vs Milling Learn the distinct features and applications of turning and milling, two subtractive manufacturing processes that use cnc technology. Turning and milling are two distinct machining processes that differ primarily in how the workpiece and cutting tool move relative to each other. In this article, we will compare and contrast milling and turning, exploring their mechanics, tooling, material suitability, surface finish,. Turning Vs Milling.

From www.mastercam.com

Milling, Turning, and MillTurn What are the Differences? Turning Vs Milling Turning rotates the workpiece against a cutting tool. Learn the distinct features and applications of turning and milling, two subtractive manufacturing processes that use cnc technology. Turning involves rotating the workpiece against a stationary cutting tool, while milling involves the rotation of the cutting tool against a stationary workpiece. Turning and milling are two distinct machining processes that differ primarily. Turning Vs Milling.