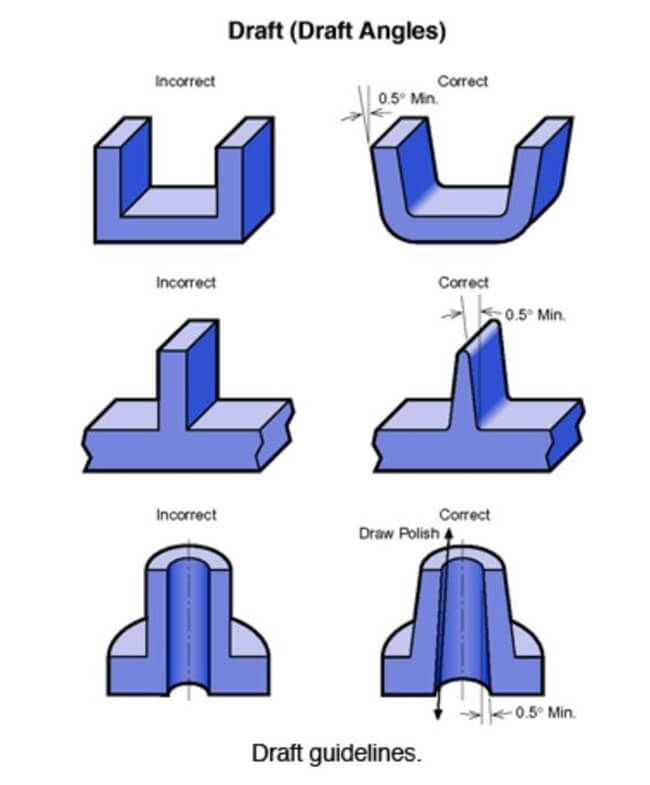

Cast Aluminum Draft Angle . Consider draft angle and tolerance zones. When designing your component, it’s important to keep in mind the achievable draft. The draft is one of the most important design parameters for aluminum die casting. It is the tapering or inclination provided to the cores. However, more complex parts may require greater draft. Incorporating appropriate draft angles in the mold design facilitates easier ejection of the cast part, reducing the risk of damage. Designing effective cooling channels within the mold ensures even cooling and solidification of the aluminum, which is essential for maintaining dimensional accuracy. It is essential on surfaces that are parallel to the direction of the die to aid removal of the part from the tool. To determine the amount of taper per side for a die cast part having a draft angle of 2° per side for a distance. As the name suggests, a draft angle is an angle or, in other words, a slope that is integrated in the vertical direction of the walls.

from www.makepartsfast.com

The draft is one of the most important design parameters for aluminum die casting. Designing effective cooling channels within the mold ensures even cooling and solidification of the aluminum, which is essential for maintaining dimensional accuracy. However, more complex parts may require greater draft. It is the tapering or inclination provided to the cores. It is essential on surfaces that are parallel to the direction of the die to aid removal of the part from the tool. When designing your component, it’s important to keep in mind the achievable draft. To determine the amount of taper per side for a die cast part having a draft angle of 2° per side for a distance. Incorporating appropriate draft angles in the mold design facilitates easier ejection of the cast part, reducing the risk of damage. Consider draft angle and tolerance zones. As the name suggests, a draft angle is an angle or, in other words, a slope that is integrated in the vertical direction of the walls.

Injection molding basics What is draft? Make Parts Fast

Cast Aluminum Draft Angle It is the tapering or inclination provided to the cores. However, more complex parts may require greater draft. When designing your component, it’s important to keep in mind the achievable draft. It is the tapering or inclination provided to the cores. It is essential on surfaces that are parallel to the direction of the die to aid removal of the part from the tool. Designing effective cooling channels within the mold ensures even cooling and solidification of the aluminum, which is essential for maintaining dimensional accuracy. The draft is one of the most important design parameters for aluminum die casting. As the name suggests, a draft angle is an angle or, in other words, a slope that is integrated in the vertical direction of the walls. To determine the amount of taper per side for a die cast part having a draft angle of 2° per side for a distance. Incorporating appropriate draft angles in the mold design facilitates easier ejection of the cast part, reducing the risk of damage. Consider draft angle and tolerance zones.

From www.alpinemold.com

Draft Angles Guidelines for Injection Molding Alpine Mold Cast Aluminum Draft Angle The draft is one of the most important design parameters for aluminum die casting. Consider draft angle and tolerance zones. To determine the amount of taper per side for a die cast part having a draft angle of 2° per side for a distance. When designing your component, it’s important to keep in mind the achievable draft. Designing effective cooling. Cast Aluminum Draft Angle.

From onlinetilersstore.com.au

Geometric Aluminium Angle 3m (2 Thicknesses & 20 Sizes) Online Tilers Cast Aluminum Draft Angle When designing your component, it’s important to keep in mind the achievable draft. To determine the amount of taper per side for a die cast part having a draft angle of 2° per side for a distance. However, more complex parts may require greater draft. As the name suggests, a draft angle is an angle or, in other words, a. Cast Aluminum Draft Angle.

From www.iqsdirectory.com

Aluminum Casting What Is It? How Is it Made? Advantages Cast Aluminum Draft Angle Incorporating appropriate draft angles in the mold design facilitates easier ejection of the cast part, reducing the risk of damage. It is essential on surfaces that are parallel to the direction of the die to aid removal of the part from the tool. Designing effective cooling channels within the mold ensures even cooling and solidification of the aluminum, which is. Cast Aluminum Draft Angle.

From www.slideshare.net

Digital Fabrication Studio Molding and Casting Cast Aluminum Draft Angle To determine the amount of taper per side for a die cast part having a draft angle of 2° per side for a distance. It is the tapering or inclination provided to the cores. However, more complex parts may require greater draft. Incorporating appropriate draft angles in the mold design facilitates easier ejection of the cast part, reducing the risk. Cast Aluminum Draft Angle.

From www.slideshare.net

Forming processes Cast Aluminum Draft Angle As the name suggests, a draft angle is an angle or, in other words, a slope that is integrated in the vertical direction of the walls. The draft is one of the most important design parameters for aluminum die casting. It is essential on surfaces that are parallel to the direction of the die to aid removal of the part. Cast Aluminum Draft Angle.

From onlinemetalsupply.com

Guide to Aluminum Angle Online Metal Supply Cast Aluminum Draft Angle Consider draft angle and tolerance zones. Incorporating appropriate draft angles in the mold design facilitates easier ejection of the cast part, reducing the risk of damage. To determine the amount of taper per side for a die cast part having a draft angle of 2° per side for a distance. Designing effective cooling channels within the mold ensures even cooling. Cast Aluminum Draft Angle.

From engineeringtechnology.org

Draft Angle Cast Aluminum Draft Angle It is the tapering or inclination provided to the cores. To determine the amount of taper per side for a die cast part having a draft angle of 2° per side for a distance. Incorporating appropriate draft angles in the mold design facilitates easier ejection of the cast part, reducing the risk of damage. However, more complex parts may require. Cast Aluminum Draft Angle.

From www.iqsdirectory.com

Sand Casting Construction, Types, Applications, and Advantages Cast Aluminum Draft Angle To determine the amount of taper per side for a die cast part having a draft angle of 2° per side for a distance. Incorporating appropriate draft angles in the mold design facilitates easier ejection of the cast part, reducing the risk of damage. Consider draft angle and tolerance zones. However, more complex parts may require greater draft. As the. Cast Aluminum Draft Angle.

From www.sd-daye.cn

铝压铸件结构设计的工艺性 大野压铸 Cast Aluminum Draft Angle Designing effective cooling channels within the mold ensures even cooling and solidification of the aluminum, which is essential for maintaining dimensional accuracy. It is the tapering or inclination provided to the cores. As the name suggests, a draft angle is an angle or, in other words, a slope that is integrated in the vertical direction of the walls. The draft. Cast Aluminum Draft Angle.

From www.iqsdirectory.com

Urethane Casting What Is It? How Does It Work? Applications Cast Aluminum Draft Angle When designing your component, it’s important to keep in mind the achievable draft. Incorporating appropriate draft angles in the mold design facilitates easier ejection of the cast part, reducing the risk of damage. Consider draft angle and tolerance zones. As the name suggests, a draft angle is an angle or, in other words, a slope that is integrated in the. Cast Aluminum Draft Angle.

From www.gdszsyx.com

high pressure die cast draft angle importance design tips for aluminum zinc Cast Aluminum Draft Angle Incorporating appropriate draft angles in the mold design facilitates easier ejection of the cast part, reducing the risk of damage. When designing your component, it’s important to keep in mind the achievable draft. Designing effective cooling channels within the mold ensures even cooling and solidification of the aluminum, which is essential for maintaining dimensional accuracy. As the name suggests, a. Cast Aluminum Draft Angle.

From www.envalior.com

Draft angle Cast Aluminum Draft Angle It is the tapering or inclination provided to the cores. Consider draft angle and tolerance zones. However, more complex parts may require greater draft. When designing your component, it’s important to keep in mind the achievable draft. It is essential on surfaces that are parallel to the direction of the die to aid removal of the part from the tool.. Cast Aluminum Draft Angle.

From info.rapidaxis.com

Draft Angles For DieCast Aluminum Enclosures Rapid Axis Cast Aluminum Draft Angle The draft is one of the most important design parameters for aluminum die casting. As the name suggests, a draft angle is an angle or, in other words, a slope that is integrated in the vertical direction of the walls. It is the tapering or inclination provided to the cores. However, more complex parts may require greater draft. When designing. Cast Aluminum Draft Angle.

From donrex.en.made-in-china.com

A380 A365 Imperial Draft Angle Apex Low Pressure High Pressure Cast Aluminum Draft Angle It is essential on surfaces that are parallel to the direction of the die to aid removal of the part from the tool. However, more complex parts may require greater draft. Incorporating appropriate draft angles in the mold design facilitates easier ejection of the cast part, reducing the risk of damage. Consider draft angle and tolerance zones. It is the. Cast Aluminum Draft Angle.

From www.rapiddirect.com

Draft Angle for Injection Molding Design Guide and Practices RapidDirect Cast Aluminum Draft Angle Consider draft angle and tolerance zones. It is essential on surfaces that are parallel to the direction of the die to aid removal of the part from the tool. Incorporating appropriate draft angles in the mold design facilitates easier ejection of the cast part, reducing the risk of damage. It is the tapering or inclination provided to the cores. As. Cast Aluminum Draft Angle.

From facfox.com

The Design Guideline for Injection Molding FacFox Docs Cast Aluminum Draft Angle It is the tapering or inclination provided to the cores. The draft is one of the most important design parameters for aluminum die casting. Incorporating appropriate draft angles in the mold design facilitates easier ejection of the cast part, reducing the risk of damage. It is essential on surfaces that are parallel to the direction of the die to aid. Cast Aluminum Draft Angle.

From www.museoinclusivo.com

Aluminium Angles A Comprehensive Guide Aluminum Profile Blog Cast Aluminum Draft Angle As the name suggests, a draft angle is an angle or, in other words, a slope that is integrated in the vertical direction of the walls. Incorporating appropriate draft angles in the mold design facilitates easier ejection of the cast part, reducing the risk of damage. When designing your component, it’s important to keep in mind the achievable draft. However,. Cast Aluminum Draft Angle.

From www.youtube.com

Injection Molding 101 Draft Angles YouTube Cast Aluminum Draft Angle To determine the amount of taper per side for a die cast part having a draft angle of 2° per side for a distance. When designing your component, it’s important to keep in mind the achievable draft. The draft is one of the most important design parameters for aluminum die casting. It is the tapering or inclination provided to the. Cast Aluminum Draft Angle.

From www.scribd.com

Aluminum Die Casting Draft Angles Guide PDF Cast Aluminum Draft Angle However, more complex parts may require greater draft. The draft is one of the most important design parameters for aluminum die casting. It is essential on surfaces that are parallel to the direction of the die to aid removal of the part from the tool. Designing effective cooling channels within the mold ensures even cooling and solidification of the aluminum,. Cast Aluminum Draft Angle.

From www.envalior.com

Draft angle Cast Aluminum Draft Angle When designing your component, it’s important to keep in mind the achievable draft. Consider draft angle and tolerance zones. As the name suggests, a draft angle is an angle or, in other words, a slope that is integrated in the vertical direction of the walls. It is essential on surfaces that are parallel to the direction of the die to. Cast Aluminum Draft Angle.

From www.scirp.org

Automatic Recognition and Construction of Draft Angle for Injection Cast Aluminum Draft Angle However, more complex parts may require greater draft. Designing effective cooling channels within the mold ensures even cooling and solidification of the aluminum, which is essential for maintaining dimensional accuracy. As the name suggests, a draft angle is an angle or, in other words, a slope that is integrated in the vertical direction of the walls. Incorporating appropriate draft angles. Cast Aluminum Draft Angle.

From engineeringtechnology.org

Draft Angle Cast Aluminum Draft Angle When designing your component, it’s important to keep in mind the achievable draft. The draft is one of the most important design parameters for aluminum die casting. As the name suggests, a draft angle is an angle or, in other words, a slope that is integrated in the vertical direction of the walls. Designing effective cooling channels within the mold. Cast Aluminum Draft Angle.

From www.wellste.com

Extruded Aluminum Angle Supplier, Standard Aluminum Profiles Cast Aluminum Draft Angle To determine the amount of taper per side for a die cast part having a draft angle of 2° per side for a distance. Consider draft angle and tolerance zones. Designing effective cooling channels within the mold ensures even cooling and solidification of the aluminum, which is essential for maintaining dimensional accuracy. However, more complex parts may require greater draft.. Cast Aluminum Draft Angle.

From www.madearia.com

Injection Molding Draft Angles Guide For Custom Parts Cast Aluminum Draft Angle When designing your component, it’s important to keep in mind the achievable draft. Incorporating appropriate draft angles in the mold design facilitates easier ejection of the cast part, reducing the risk of damage. Designing effective cooling channels within the mold ensures even cooling and solidification of the aluminum, which is essential for maintaining dimensional accuracy. To determine the amount of. Cast Aluminum Draft Angle.

From www.iqsdirectory.com

Types of Aluminum Extrusions Cast Aluminum Draft Angle To determine the amount of taper per side for a die cast part having a draft angle of 2° per side for a distance. Incorporating appropriate draft angles in the mold design facilitates easier ejection of the cast part, reducing the risk of damage. It is essential on surfaces that are parallel to the direction of the die to aid. Cast Aluminum Draft Angle.

From www.3d24.eu

Aluminium diecast angle, 20 mm, slot 5, for M4, plain Cast Aluminum Draft Angle However, more complex parts may require greater draft. It is essential on surfaces that are parallel to the direction of the die to aid removal of the part from the tool. Consider draft angle and tolerance zones. When designing your component, it’s important to keep in mind the achievable draft. Designing effective cooling channels within the mold ensures even cooling. Cast Aluminum Draft Angle.

From www.aludiecasting.com

Aluminium Alloy Casting Die Cast Aluminum Alloy ALU Die Casting Cast Aluminum Draft Angle The draft is one of the most important design parameters for aluminum die casting. Designing effective cooling channels within the mold ensures even cooling and solidification of the aluminum, which is essential for maintaining dimensional accuracy. It is the tapering or inclination provided to the cores. As the name suggests, a draft angle is an angle or, in other words,. Cast Aluminum Draft Angle.

From www.makepartsfast.com

Injection molding basics What is draft? Make Parts Fast Cast Aluminum Draft Angle It is essential on surfaces that are parallel to the direction of the die to aid removal of the part from the tool. It is the tapering or inclination provided to the cores. Consider draft angle and tolerance zones. However, more complex parts may require greater draft. To determine the amount of taper per side for a die cast part. Cast Aluminum Draft Angle.

From shakticonstructions.com.au

Cast In Angles Shakti Constructions Pty Ltd Cast Aluminum Draft Angle It is essential on surfaces that are parallel to the direction of the die to aid removal of the part from the tool. The draft is one of the most important design parameters for aluminum die casting. To determine the amount of taper per side for a die cast part having a draft angle of 2° per side for a. Cast Aluminum Draft Angle.

From in.pinterest.com

Draft Angle In Die Design Conceptual understanding, Metal Cast Aluminum Draft Angle It is the tapering or inclination provided to the cores. However, more complex parts may require greater draft. It is essential on surfaces that are parallel to the direction of the die to aid removal of the part from the tool. Incorporating appropriate draft angles in the mold design facilitates easier ejection of the cast part, reducing the risk of. Cast Aluminum Draft Angle.

From blog.thepipingmart.com

A Comprehensive Guide to Aluminium Angles Cast Aluminum Draft Angle However, more complex parts may require greater draft. Consider draft angle and tolerance zones. It is the tapering or inclination provided to the cores. Incorporating appropriate draft angles in the mold design facilitates easier ejection of the cast part, reducing the risk of damage. As the name suggests, a draft angle is an angle or, in other words, a slope. Cast Aluminum Draft Angle.

From www.museoinclusivo.com

Exploring Aluminum Angles Uses, Benefits, and Installation Tips Cast Aluminum Draft Angle Designing effective cooling channels within the mold ensures even cooling and solidification of the aluminum, which is essential for maintaining dimensional accuracy. The draft is one of the most important design parameters for aluminum die casting. It is essential on surfaces that are parallel to the direction of the die to aid removal of the part from the tool. However,. Cast Aluminum Draft Angle.

From info.rapidaxis.com

Draft Angles For DieCast Aluminum Enclosures Rapid Axis Cast Aluminum Draft Angle As the name suggests, a draft angle is an angle or, in other words, a slope that is integrated in the vertical direction of the walls. When designing your component, it’s important to keep in mind the achievable draft. To determine the amount of taper per side for a die cast part having a draft angle of 2° per side. Cast Aluminum Draft Angle.

From www.metalsupermarkets.com

Aluminum Angle 6061 Metal Supermarkets Cast Aluminum Draft Angle However, more complex parts may require greater draft. When designing your component, it’s important to keep in mind the achievable draft. As the name suggests, a draft angle is an angle or, in other words, a slope that is integrated in the vertical direction of the walls. Designing effective cooling channels within the mold ensures even cooling and solidification of. Cast Aluminum Draft Angle.

From madeproducts.uk

How to Design for Injection Moulding MADE Products Cast Aluminum Draft Angle Incorporating appropriate draft angles in the mold design facilitates easier ejection of the cast part, reducing the risk of damage. To determine the amount of taper per side for a die cast part having a draft angle of 2° per side for a distance. It is the tapering or inclination provided to the cores. However, more complex parts may require. Cast Aluminum Draft Angle.