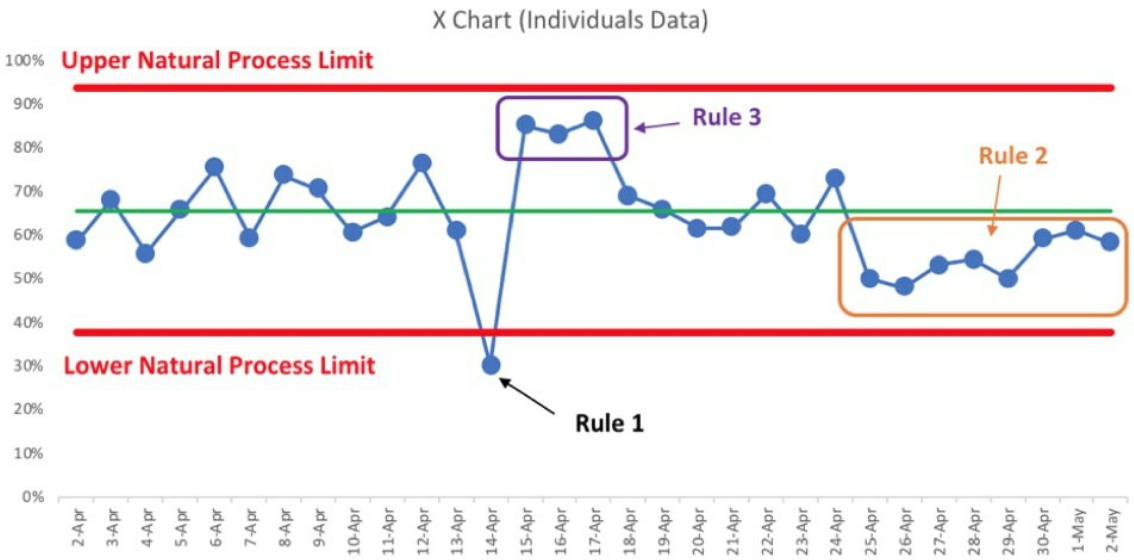

Process Control Limits . A process is in control when you can predict how the process will vary (within limits) in the future. They help in distinguishing between normal process variation (within limits) and variations that require attention (outside They act as sentinels, alerting us to deviations that may indicate the presence of assignable causes or special cause variations, which could compromise the. The choice of three standard deviations is statistically significant as it covers about 99.73% These limits define the boundary of expected process variation and are set at ±3 standard deviations from the center line. Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. The main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to. Control charts use upper and lower control limits, which are statistically derived boundaries. At any rate, control charts are simple, robust tools for understanding process variability. Control limits, also known as natural process limits, are predefined boundaries that encapsulate the expected variation within a process under normal operating conditions. Control limits are the horizontal lines above and below the center line that are used to judge whether a process is out of control.

from digestibledeming.substack.com

The choice of three standard deviations is statistically significant as it covers about 99.73% At any rate, control charts are simple, robust tools for understanding process variability. They act as sentinels, alerting us to deviations that may indicate the presence of assignable causes or special cause variations, which could compromise the. They help in distinguishing between normal process variation (within limits) and variations that require attention (outside A process is in control when you can predict how the process will vary (within limits) in the future. These limits define the boundary of expected process variation and are set at ±3 standard deviations from the center line. Control limits are the horizontal lines above and below the center line that are used to judge whether a process is out of control. The main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to. Control charts use upper and lower control limits, which are statistically derived boundaries. Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process.

Control Charts by Christopher R Chapman

Process Control Limits Control limits, also known as natural process limits, are predefined boundaries that encapsulate the expected variation within a process under normal operating conditions. Control limits, also known as natural process limits, are predefined boundaries that encapsulate the expected variation within a process under normal operating conditions. Control charts use upper and lower control limits, which are statistically derived boundaries. These limits define the boundary of expected process variation and are set at ±3 standard deviations from the center line. Control limits are the horizontal lines above and below the center line that are used to judge whether a process is out of control. The choice of three standard deviations is statistically significant as it covers about 99.73% The main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to. Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. A process is in control when you can predict how the process will vary (within limits) in the future. They help in distinguishing between normal process variation (within limits) and variations that require attention (outside They act as sentinels, alerting us to deviations that may indicate the presence of assignable causes or special cause variations, which could compromise the. At any rate, control charts are simple, robust tools for understanding process variability.

From www.chegg.com

Solved Refer to Table S6.1 Factors for Computing Control Process Control Limits They act as sentinels, alerting us to deviations that may indicate the presence of assignable causes or special cause variations, which could compromise the. Control limits, also known as natural process limits, are predefined boundaries that encapsulate the expected variation within a process under normal operating conditions. A process is in control when you can predict how the process will. Process Control Limits.

From www.chegg.com

Solved At Quickie Car Wash, the wash process is advertised Process Control Limits These limits define the boundary of expected process variation and are set at ±3 standard deviations from the center line. Control limits, also known as natural process limits, are predefined boundaries that encapsulate the expected variation within a process under normal operating conditions. Control charts use upper and lower control limits, which are statistically derived boundaries. Control limits, also known. Process Control Limits.

From www.chegg.com

Solved a) Calculate the 3‐sigma control limits for this Process Control Limits The choice of three standard deviations is statistically significant as it covers about 99.73% These limits define the boundary of expected process variation and are set at ±3 standard deviations from the center line. Control limits are the horizontal lines above and below the center line that are used to judge whether a process is out of control. The main. Process Control Limits.

From www.chegg.com

Solved The Levis' Jeans Company produces denim jeans. The Process Control Limits These limits define the boundary of expected process variation and are set at ±3 standard deviations from the center line. They act as sentinels, alerting us to deviations that may indicate the presence of assignable causes or special cause variations, which could compromise the. A process is in control when you can predict how the process will vary (within limits). Process Control Limits.

From www.slideserve.com

PPT Statistical Process Control PowerPoint Presentation, free Process Control Limits The main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to. Control limits, also known as natural process limits, are predefined boundaries that encapsulate the expected variation within a process under normal operating conditions. They help in distinguishing between normal process variation (within limits) and variations that require attention. Process Control Limits.

From www.aiophotoz.com

What Are Control Limits On A Chart Best Picture Of Chart Process Control Limits Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. They act as sentinels, alerting us to deviations that may indicate the presence of assignable causes or special cause variations, which could compromise the. The main features of a control chart include the data points, a. Process Control Limits.

From www.slideserve.com

PPT Statistical Process Control (SPC) PowerPoint Presentation, free Process Control Limits A process is in control when you can predict how the process will vary (within limits) in the future. Control charts use upper and lower control limits, which are statistically derived boundaries. They act as sentinels, alerting us to deviations that may indicate the presence of assignable causes or special cause variations, which could compromise the. Control limits, also known. Process Control Limits.

From www.sixsigmadaily.com

Control Chart Construction Formulas for Control Limits Process Control Limits They help in distinguishing between normal process variation (within limits) and variations that require attention (outside Control limits are the horizontal lines above and below the center line that are used to judge whether a process is out of control. They act as sentinels, alerting us to deviations that may indicate the presence of assignable causes or special cause variations,. Process Control Limits.

From www.chegg.com

HCH Inc. has decided to use a pChart with 2sigma Process Control Limits The choice of three standard deviations is statistically significant as it covers about 99.73% A process is in control when you can predict how the process will vary (within limits) in the future. These limits define the boundary of expected process variation and are set at ±3 standard deviations from the center line. The main features of a control chart. Process Control Limits.

From christiangould.ca

Statistical Process Control (SPC) Christian Gould Process Control Limits They act as sentinels, alerting us to deviations that may indicate the presence of assignable causes or special cause variations, which could compromise the. Control limits, also known as natural process limits, are predefined boundaries that encapsulate the expected variation within a process under normal operating conditions. Control limits, also known as process control limits or specification limits, are statistical. Process Control Limits.

From www.benchmarksixsigma.com

Control Limits vs Specification Limits We ask and you answer! The Process Control Limits At any rate, control charts are simple, robust tools for understanding process variability. Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. They act as sentinels, alerting us to deviations that may indicate the presence of assignable causes or special cause variations, which could compromise. Process Control Limits.

From spencer-r-hall.medium.com

Multivariate Statistic Process Control method comparison Part 2 Process Control Limits Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. The choice of three standard deviations is statistically significant as it covers about 99.73% Control limits, also known as natural process limits, are predefined boundaries that encapsulate the expected variation within a process under normal operating. Process Control Limits.

From www.chegg.com

Solved Refer to Table 56.1 Factors for Computing Control Process Control Limits The choice of three standard deviations is statistically significant as it covers about 99.73% Control charts use upper and lower control limits, which are statistically derived boundaries. Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. The main features of a control chart include the. Process Control Limits.

From www.slideserve.com

PPT CHAPTER 5 VARIABLE CONTROL CHARTS PowerPoint Presentation, free Process Control Limits These limits define the boundary of expected process variation and are set at ±3 standard deviations from the center line. The main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to. The choice of three standard deviations is statistically significant as it covers about 99.73% Control limits, also known. Process Control Limits.

From www.chegg.com

Solved 70. A control chart is to be established on a process Process Control Limits The choice of three standard deviations is statistically significant as it covers about 99.73% They help in distinguishing between normal process variation (within limits) and variations that require attention (outside At any rate, control charts are simple, robust tools for understanding process variability. These limits define the boundary of expected process variation and are set at ±3 standard deviations from. Process Control Limits.

From www.bartleby.com

Control Limits bartleby Process Control Limits Control limits, also known as natural process limits, are predefined boundaries that encapsulate the expected variation within a process under normal operating conditions. These limits define the boundary of expected process variation and are set at ±3 standard deviations from the center line. The choice of three standard deviations is statistically significant as it covers about 99.73% A process is. Process Control Limits.

From www.chegg.com

Assume that a fraction nonconforming control chart Process Control Limits Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. They act as sentinels, alerting us to deviations that may indicate the presence of assignable causes or special cause variations, which could compromise the. These limits define the boundary of expected process variation and are set. Process Control Limits.

From www.presentationeze.com

C chart control limits PresentationEZE Process Control Limits Control limits, also known as natural process limits, are predefined boundaries that encapsulate the expected variation within a process under normal operating conditions. A process is in control when you can predict how the process will vary (within limits) in the future. At any rate, control charts are simple, robust tools for understanding process variability. Control limits, also known as. Process Control Limits.

From www.chegg.com

Solved S6.2 The overall average on a process you are Process Control Limits The main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to. Control charts use upper and lower control limits, which are statistically derived boundaries. A process is in control when you can predict how the process will vary (within limits) in the future. Control limits, also known as natural. Process Control Limits.

From blog.simplyfeye.com

Simplyfeye Official Blog Statistical Process Control (SPC) and Process Control Limits Control limits are the horizontal lines above and below the center line that are used to judge whether a process is out of control. Control charts use upper and lower control limits, which are statistically derived boundaries. The choice of three standard deviations is statistically significant as it covers about 99.73% At any rate, control charts are simple, robust tools. Process Control Limits.

From www.chegg.com

Solved To determine if their 2.33 centimeter castings are Process Control Limits Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. They help in distinguishing between normal process variation (within limits) and variations that require attention (outside The choice of three standard deviations is statistically significant as it covers about 99.73% Control charts use upper and lower. Process Control Limits.

From www.slideserve.com

PPT Statistical Process Control PowerPoint Presentation ID2035464 Process Control Limits Control charts use upper and lower control limits, which are statistically derived boundaries. They act as sentinels, alerting us to deviations that may indicate the presence of assignable causes or special cause variations, which could compromise the. A process is in control when you can predict how the process will vary (within limits) in the future. They help in distinguishing. Process Control Limits.

From www.numerade.com

suppose that motorola uses the normal distribution to determine the Process Control Limits They act as sentinels, alerting us to deviations that may indicate the presence of assignable causes or special cause variations, which could compromise the. The choice of three standard deviations is statistically significant as it covers about 99.73% The main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to.. Process Control Limits.

From www.slideserve.com

PPT Process Control Charts PowerPoint Presentation, free download Process Control Limits At any rate, control charts are simple, robust tools for understanding process variability. Control limits, also known as process control limits or specification limits, are statistical boundaries used in quality control to monitor and manage a process. Control limits are the horizontal lines above and below the center line that are used to judge whether a process is out of. Process Control Limits.

From www.chegg.com

Solved The overall average of a process you are attempting Process Control Limits Control limits, also known as natural process limits, are predefined boundaries that encapsulate the expected variation within a process under normal operating conditions. They help in distinguishing between normal process variation (within limits) and variations that require attention (outside These limits define the boundary of expected process variation and are set at ±3 standard deviations from the center line. At. Process Control Limits.

From www.coursehero.com

[Solved] Q5. (20) A process considered to be in control measures an Process Control Limits Control limits, also known as natural process limits, are predefined boundaries that encapsulate the expected variation within a process under normal operating conditions. Control limits are the horizontal lines above and below the center line that are used to judge whether a process is out of control. Control limits, also known as process control limits or specification limits, are statistical. Process Control Limits.

From www.edrawmax.com

Control Chart 101 Definition, Purpose and How to EdrawMax Online Process Control Limits Control limits are the horizontal lines above and below the center line that are used to judge whether a process is out of control. They act as sentinels, alerting us to deviations that may indicate the presence of assignable causes or special cause variations, which could compromise the. The main features of a control chart include the data points, a. Process Control Limits.

From www.chegg.com

Solved The commercial loan operation of a financial Process Control Limits They act as sentinels, alerting us to deviations that may indicate the presence of assignable causes or special cause variations, which could compromise the. Control limits, also known as natural process limits, are predefined boundaries that encapsulate the expected variation within a process under normal operating conditions. Control limits, also known as process control limits or specification limits, are statistical. Process Control Limits.

From medium.com

Control Charts in Power BI — the right way Craydec, Inc. Medium Process Control Limits At any rate, control charts are simple, robust tools for understanding process variability. Control charts use upper and lower control limits, which are statistically derived boundaries. The main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to. Control limits, also known as natural process limits, are predefined boundaries that. Process Control Limits.

From www.six-sigma-material.com

Process Capability Indices Process Control Limits At any rate, control charts are simple, robust tools for understanding process variability. Control limits, also known as natural process limits, are predefined boundaries that encapsulate the expected variation within a process under normal operating conditions. Control charts use upper and lower control limits, which are statistically derived boundaries. The choice of three standard deviations is statistically significant as it. Process Control Limits.

From www.slideserve.com

PPT Statistical Process Control (SPC) PowerPoint Presentation, free Process Control Limits They act as sentinels, alerting us to deviations that may indicate the presence of assignable causes or special cause variations, which could compromise the. They help in distinguishing between normal process variation (within limits) and variations that require attention (outside Control limits are the horizontal lines above and below the center line that are used to judge whether a process. Process Control Limits.

From www.slideserve.com

PPT Operations Management Statistical Process Control Supplement 6 Process Control Limits They help in distinguishing between normal process variation (within limits) and variations that require attention (outside The choice of three standard deviations is statistically significant as it covers about 99.73% At any rate, control charts are simple, robust tools for understanding process variability. Control charts use upper and lower control limits, which are statistically derived boundaries. They act as sentinels,. Process Control Limits.

From ar.inspiredpencil.com

Shewhart Statistical Process Control Chart Process Control Limits Control limits are the horizontal lines above and below the center line that are used to judge whether a process is out of control. At any rate, control charts are simple, robust tools for understanding process variability. They help in distinguishing between normal process variation (within limits) and variations that require attention (outside The main features of a control chart. Process Control Limits.

From www.superfastcpa.com

What are Control Limits? Process Control Limits Control limits, also known as natural process limits, are predefined boundaries that encapsulate the expected variation within a process under normal operating conditions. Control charts use upper and lower control limits, which are statistically derived boundaries. They act as sentinels, alerting us to deviations that may indicate the presence of assignable causes or special cause variations, which could compromise the.. Process Control Limits.

From digestibledeming.substack.com

Control Charts by Christopher R Chapman Process Control Limits At any rate, control charts are simple, robust tools for understanding process variability. They help in distinguishing between normal process variation (within limits) and variations that require attention (outside The main features of a control chart include the data points, a centerline (mean value), and upper and lower limits (bounds to. These limits define the boundary of expected process variation. Process Control Limits.