Pinion Internal Gear Ratio . when using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but. this is achieved by pinion enlargement (or correction as often termed), wherein the pinion teeth, still generated with a. 9 rows the following online calculator computes the basic dimensions and tooth profiles of a bevel gear pair (pinion and gear) based on their number of teeth and. the ratio of a singular pinion engaged with an internal gear is simply the number of teeth on the internal gear. The module of an internal gear is calculated using the formula m = c / (n + t), where c is the center distance, n. The internal gear ratio for each gear of all types of. gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift. the pinion gearbox calculator helps you to choose the ideal gearbox tuning.

from www.engineersedge.com

when using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but. the pinion gearbox calculator helps you to choose the ideal gearbox tuning. 9 rows the following online calculator computes the basic dimensions and tooth profiles of a bevel gear pair (pinion and gear) based on their number of teeth and. The module of an internal gear is calculated using the formula m = c / (n + t), where c is the center distance, n. the ratio of a singular pinion engaged with an internal gear is simply the number of teeth on the internal gear. this is achieved by pinion enlargement (or correction as often termed), wherein the pinion teeth, still generated with a. The internal gear ratio for each gear of all types of. gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift.

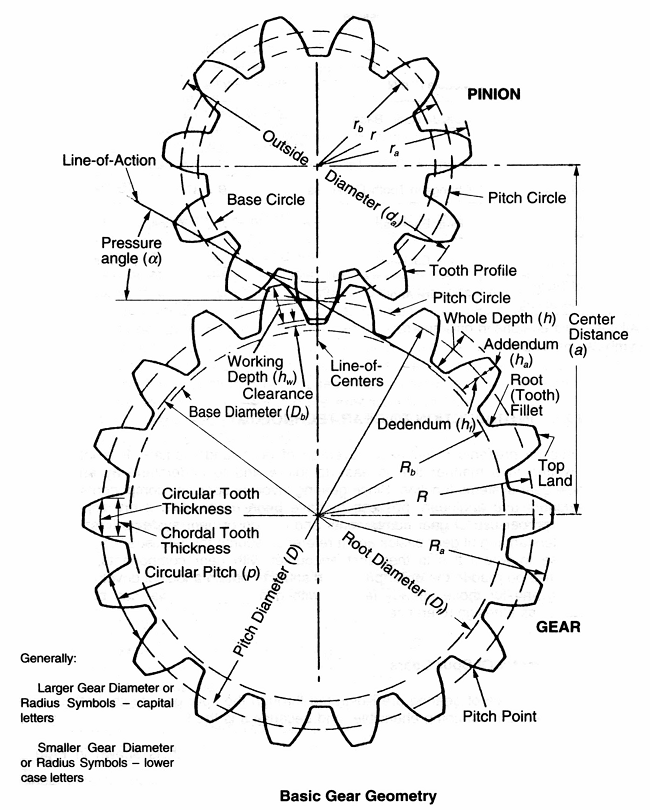

Gear Tooth Contact Stress Number Equation and Calculator

Pinion Internal Gear Ratio gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift. gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift. 9 rows the following online calculator computes the basic dimensions and tooth profiles of a bevel gear pair (pinion and gear) based on their number of teeth and. the ratio of a singular pinion engaged with an internal gear is simply the number of teeth on the internal gear. The module of an internal gear is calculated using the formula m = c / (n + t), where c is the center distance, n. the pinion gearbox calculator helps you to choose the ideal gearbox tuning. this is achieved by pinion enlargement (or correction as often termed), wherein the pinion teeth, still generated with a. The internal gear ratio for each gear of all types of. when using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but.

From www.cyclingabout.com

Why The New Pinion Smart Shift Gearbox Is A Big Deal (New Possibilities Pinion Internal Gear Ratio the ratio of a singular pinion engaged with an internal gear is simply the number of teeth on the internal gear. 9 rows the following online calculator computes the basic dimensions and tooth profiles of a bevel gear pair (pinion and gear) based on their number of teeth and. The internal gear ratio for each gear of all. Pinion Internal Gear Ratio.

From www.researchgate.net

Rack and pinion mechanism (a) 3D internal mechanism of SBPG (b Pinion Internal Gear Ratio this is achieved by pinion enlargement (or correction as often termed), wherein the pinion teeth, still generated with a. the pinion gearbox calculator helps you to choose the ideal gearbox tuning. 9 rows the following online calculator computes the basic dimensions and tooth profiles of a bevel gear pair (pinion and gear) based on their number of. Pinion Internal Gear Ratio.

From www.pirate4x4.com

Figure 6 Pinion Depth Pinion Internal Gear Ratio The internal gear ratio for each gear of all types of. gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift. the ratio of a singular pinion engaged with an internal gear is simply the number of teeth on the internal gear. 9 rows the. Pinion Internal Gear Ratio.

From www.researchgate.net

Power skiving for internal gear Download Scientific Diagram Pinion Internal Gear Ratio the pinion gearbox calculator helps you to choose the ideal gearbox tuning. gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift. the ratio of a singular pinion engaged with an internal gear is simply the number of teeth on the internal gear. The internal. Pinion Internal Gear Ratio.

From www.chegg.com

Solved As discussed in class (Lecture note of May 1st the Pinion Internal Gear Ratio this is achieved by pinion enlargement (or correction as often termed), wherein the pinion teeth, still generated with a. The internal gear ratio for each gear of all types of. the ratio of a singular pinion engaged with an internal gear is simply the number of teeth on the internal gear. when using internal ring gears, you. Pinion Internal Gear Ratio.

From www.quadratec.com

Ring and Pinion Gear Ratio Calculation Chart Quadratec Pinion Internal Gear Ratio when using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but. The internal gear ratio for each gear of all types of. the pinion gearbox calculator helps you to choose the ideal gearbox tuning. gear dimensions are determined in accordance with their specifications, such as module. Pinion Internal Gear Ratio.

From www.tec-science.com

External and internal toothing of gears tecscience Pinion Internal Gear Ratio when using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but. the ratio of a singular pinion engaged with an internal gear is simply the number of teeth on the internal gear. 9 rows the following online calculator computes the basic dimensions and tooth profiles of. Pinion Internal Gear Ratio.

From www.quadratec.com

Ring and Pinion Gear Ratio Calculation Chart Quadratec Pinion Internal Gear Ratio The module of an internal gear is calculated using the formula m = c / (n + t), where c is the center distance, n. 9 rows the following online calculator computes the basic dimensions and tooth profiles of a bevel gear pair (pinion and gear) based on their number of teeth and. this is achieved by pinion. Pinion Internal Gear Ratio.

From www.mopardiy.com

How to Select the Optimal Ring and Pinion Gears for a Dana Rear Pinion Internal Gear Ratio gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift. The module of an internal gear is calculated using the formula m = c / (n + t), where c is the center distance, n. the ratio of a singular pinion engaged with an internal gear. Pinion Internal Gear Ratio.

From www.xtremediesel.com

Ring and Pinion 101 XDP Blog Pinion Internal Gear Ratio The internal gear ratio for each gear of all types of. this is achieved by pinion enlargement (or correction as often termed), wherein the pinion teeth, still generated with a. the ratio of a singular pinion engaged with an internal gear is simply the number of teeth on the internal gear. 9 rows the following online calculator. Pinion Internal Gear Ratio.

From cyclemonkeylab.blogspot.com

The Monkey Lab Calculating Gear Ratios with Pinion Gearboxes Pinion Internal Gear Ratio the pinion gearbox calculator helps you to choose the ideal gearbox tuning. when using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but. 9 rows the following online calculator computes the basic dimensions and tooth profiles of a bevel gear pair (pinion and gear) based on. Pinion Internal Gear Ratio.

From www.mdpi.com

Applied Sciences Free FullText Investigation of Load Capacity of Pinion Internal Gear Ratio the ratio of a singular pinion engaged with an internal gear is simply the number of teeth on the internal gear. when using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but. 9 rows the following online calculator computes the basic dimensions and tooth profiles of. Pinion Internal Gear Ratio.

From www.largiader.com

Gearing comparison Pinion Internal Gear Ratio the pinion gearbox calculator helps you to choose the ideal gearbox tuning. The internal gear ratio for each gear of all types of. this is achieved by pinion enlargement (or correction as often termed), wherein the pinion teeth, still generated with a. gear dimensions are determined in accordance with their specifications, such as module (m), number of. Pinion Internal Gear Ratio.

From www.researchgate.net

(a) CAD model of meshed pinion and gear; (b) schematic demonstration of Pinion Internal Gear Ratio the pinion gearbox calculator helps you to choose the ideal gearbox tuning. 9 rows the following online calculator computes the basic dimensions and tooth profiles of a bevel gear pair (pinion and gear) based on their number of teeth and. The internal gear ratio for each gear of all types of. the ratio of a singular pinion. Pinion Internal Gear Ratio.

From ricdata.blogspot.com

20 Best Ring And Pinion Gear Ratio Chart Pinion Internal Gear Ratio gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift. when using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but. the pinion gearbox calculator helps you to choose the ideal gearbox tuning. . Pinion Internal Gear Ratio.

From www.reddit.com

Internal Gearing r/MechanicalEngineering Pinion Internal Gear Ratio the ratio of a singular pinion engaged with an internal gear is simply the number of teeth on the internal gear. 9 rows the following online calculator computes the basic dimensions and tooth profiles of a bevel gear pair (pinion and gear) based on their number of teeth and. the pinion gearbox calculator helps you to choose. Pinion Internal Gear Ratio.

From www.alamy.com

When meshing pair of gears, the smaller gear is called a pinion gear Pinion Internal Gear Ratio The module of an internal gear is calculated using the formula m = c / (n + t), where c is the center distance, n. 9 rows the following online calculator computes the basic dimensions and tooth profiles of a bevel gear pair (pinion and gear) based on their number of teeth and. The internal gear ratio for each. Pinion Internal Gear Ratio.

From www.engineersedge.com

Gear Tooth Contact Stress Number Equation and Calculator Pinion Internal Gear Ratio when using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but. this is achieved by pinion enlargement (or correction as often termed), wherein the pinion teeth, still generated with a. The module of an internal gear is calculated using the formula m = c / (n +. Pinion Internal Gear Ratio.

From www.zhygear.com

Worm Gears vs. Internal Gears ZHY Gear Pinion Internal Gear Ratio this is achieved by pinion enlargement (or correction as often termed), wherein the pinion teeth, still generated with a. The module of an internal gear is calculated using the formula m = c / (n + t), where c is the center distance, n. when using internal ring gears, you can develop a gear system with a high. Pinion Internal Gear Ratio.

From khkgears.net

Basic Gear Terminology and Calculation KHK Pinion Internal Gear Ratio the ratio of a singular pinion engaged with an internal gear is simply the number of teeth on the internal gear. 9 rows the following online calculator computes the basic dimensions and tooth profiles of a bevel gear pair (pinion and gear) based on their number of teeth and. gear dimensions are determined in accordance with their. Pinion Internal Gear Ratio.

From naveeddhriti.blogspot.com

Ring and pinion gear ratio chart NaveedDhriti Pinion Internal Gear Ratio gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift. the pinion gearbox calculator helps you to choose the ideal gearbox tuning. 9 rows the following online calculator computes the basic dimensions and tooth profiles of a bevel gear pair (pinion and gear) based on. Pinion Internal Gear Ratio.

From sbainvent.com

Gearing Systems S.B.A. Invent Pinion Internal Gear Ratio this is achieved by pinion enlargement (or correction as often termed), wherein the pinion teeth, still generated with a. The module of an internal gear is calculated using the formula m = c / (n + t), where c is the center distance, n. gear dimensions are determined in accordance with their specifications, such as module (m), number. Pinion Internal Gear Ratio.

From www.motorcyclespecs.co.za

Gear Ratios Pinion Internal Gear Ratio 9 rows the following online calculator computes the basic dimensions and tooth profiles of a bevel gear pair (pinion and gear) based on their number of teeth and. when using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but. The internal gear ratio for each gear of. Pinion Internal Gear Ratio.

From classicautoadvisors.com

Gear Ratios What Do They Mean Classic Auto Advisors Pinion Internal Gear Ratio gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift. the ratio of a singular pinion engaged with an internal gear is simply the number of teeth on the internal gear. The module of an internal gear is calculated using the formula m = c /. Pinion Internal Gear Ratio.

From www.pololu.com

Pololu 37D gearmotors helical pinion gear, new 1501 gear ratio, and Pinion Internal Gear Ratio 9 rows the following online calculator computes the basic dimensions and tooth profiles of a bevel gear pair (pinion and gear) based on their number of teeth and. The module of an internal gear is calculated using the formula m = c / (n + t), where c is the center distance, n. the ratio of a singular. Pinion Internal Gear Ratio.

From bikepacking.com

Pinion Gearbox Review A True Bike Transmission! Pinion Internal Gear Ratio this is achieved by pinion enlargement (or correction as often termed), wherein the pinion teeth, still generated with a. The module of an internal gear is calculated using the formula m = c / (n + t), where c is the center distance, n. gear dimensions are determined in accordance with their specifications, such as module (m), number. Pinion Internal Gear Ratio.

From sciencing.com

RackandPinion Gear Ratio Sciencing Pinion Internal Gear Ratio 9 rows the following online calculator computes the basic dimensions and tooth profiles of a bevel gear pair (pinion and gear) based on their number of teeth and. this is achieved by pinion enlargement (or correction as often termed), wherein the pinion teeth, still generated with a. The module of an internal gear is calculated using the formula. Pinion Internal Gear Ratio.

From atvhelper.com

ATV Gear Ratio A Complete Gear Ratio Guide AtvHelper Pinion Internal Gear Ratio when using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but. 9 rows the following online calculator computes the basic dimensions and tooth profiles of a bevel gear pair (pinion and gear) based on their number of teeth and. gear dimensions are determined in accordance with. Pinion Internal Gear Ratio.

From ctaxleservice.com

Why Change My Gear Ratio? CT Axle & Spindle Repair Pinion Internal Gear Ratio this is achieved by pinion enlargement (or correction as often termed), wherein the pinion teeth, still generated with a. when using internal ring gears, you can develop a gear system with a high reduction ratio in a compact space — but. the ratio of a singular pinion engaged with an internal gear is simply the number of. Pinion Internal Gear Ratio.

From www.tec-science.com

Transmission ratios of gears (Willis equation) tecscience Pinion Internal Gear Ratio The module of an internal gear is calculated using the formula m = c / (n + t), where c is the center distance, n. gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift. the ratio of a singular pinion engaged with an internal gear. Pinion Internal Gear Ratio.

From www.youtube.com

Rack and Pinion Mechanism Steering Ratio Size of Pinion Gear Easy Pinion Internal Gear Ratio 9 rows the following online calculator computes the basic dimensions and tooth profiles of a bevel gear pair (pinion and gear) based on their number of teeth and. this is achieved by pinion enlargement (or correction as often termed), wherein the pinion teeth, still generated with a. when using internal ring gears, you can develop a gear. Pinion Internal Gear Ratio.

From hobbygraderc.com

RC Pinion and Spur Gear Explained A Beginners Guide Pinion Internal Gear Ratio this is achieved by pinion enlargement (or correction as often termed), wherein the pinion teeth, still generated with a. The internal gear ratio for each gear of all types of. The module of an internal gear is calculated using the formula m = c / (n + t), where c is the center distance, n. the ratio of. Pinion Internal Gear Ratio.

From www.whoracing.org.uk

Gear Ratio Pinion Internal Gear Ratio gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift. The module of an internal gear is calculated using the formula m = c / (n + t), where c is the center distance, n. the pinion gearbox calculator helps you to choose the ideal gearbox. Pinion Internal Gear Ratio.

From haipernews.com

How To Calculate Gear Ratio Haiper Pinion Internal Gear Ratio this is achieved by pinion enlargement (or correction as often termed), wherein the pinion teeth, still generated with a. gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift. 9 rows the following online calculator computes the basic dimensions and tooth profiles of a bevel. Pinion Internal Gear Ratio.

From www.wikihow.com

4 Easy Ways to Determine Gear Ratio (with Pictures) Pinion Internal Gear Ratio the ratio of a singular pinion engaged with an internal gear is simply the number of teeth on the internal gear. this is achieved by pinion enlargement (or correction as often termed), wherein the pinion teeth, still generated with a. The module of an internal gear is calculated using the formula m = c / (n + t),. Pinion Internal Gear Ratio.