How Strong Is Wire Welding . Tensile strength represents the maximum force applied. It acts as a filler material, creating a strong bond between metal pieces. Welding wire is essential in various welding processes. Generally, the strength of a weld deposit made with a solid gmaw electrode is limited to the strength of the electrode. This welding method requires a special gun to weld, which is. Not very efficient for welding thin metals. There is no weld type that is the strongest universally across all welding applications. We have identified 8 types of particularly strong welds: In industrial applications, flux core welds must meet minimum tensile and yield strength. The strongest weld depends upon the base metal. The wire welding method is also as common as stick welding. As far as performance is concerned, both wire types produce sound welds with good weld bead appearances when applied correctly and used within the proper parameter.

from www.repairerdrivennews.com

Welding wire is essential in various welding processes. We have identified 8 types of particularly strong welds: The strongest weld depends upon the base metal. Tensile strength represents the maximum force applied. As far as performance is concerned, both wire types produce sound welds with good weld bead appearances when applied correctly and used within the proper parameter. Generally, the strength of a weld deposit made with a solid gmaw electrode is limited to the strength of the electrode. The wire welding method is also as common as stick welding. In industrial applications, flux core welds must meet minimum tensile and yield strength. This welding method requires a special gun to weld, which is. There is no weld type that is the strongest universally across all welding applications.

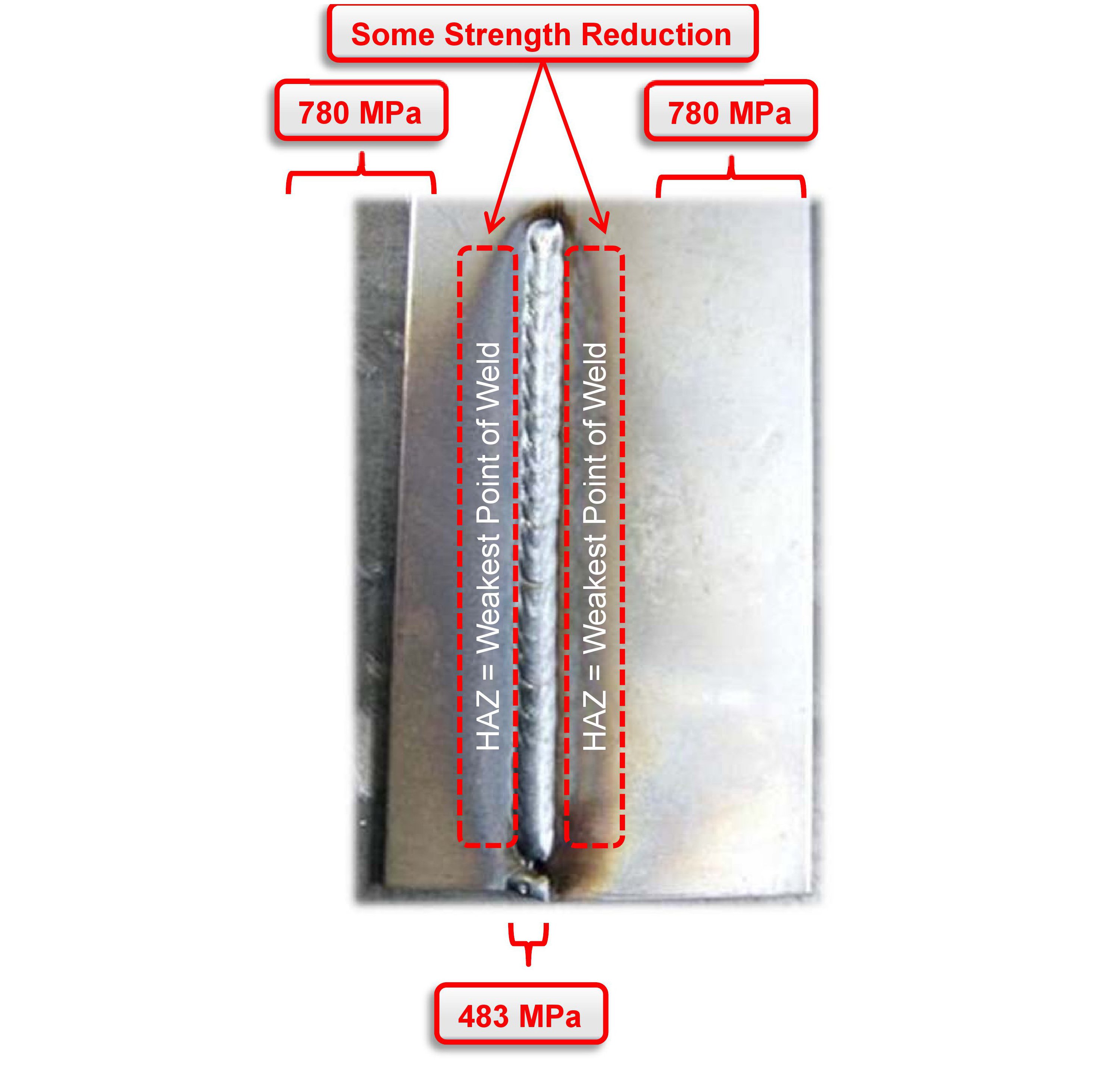

Honda explains why staple 70 ksi welding wire won’t work for higher

How Strong Is Wire Welding This welding method requires a special gun to weld, which is. Generally, the strength of a weld deposit made with a solid gmaw electrode is limited to the strength of the electrode. It acts as a filler material, creating a strong bond between metal pieces. The strongest weld depends upon the base metal. Tensile strength represents the maximum force applied. There is no weld type that is the strongest universally across all welding applications. As far as performance is concerned, both wire types produce sound welds with good weld bead appearances when applied correctly and used within the proper parameter. In industrial applications, flux core welds must meet minimum tensile and yield strength. We have identified 8 types of particularly strong welds: This welding method requires a special gun to weld, which is. Not very efficient for welding thin metals. Welding wire is essential in various welding processes. The wire welding method is also as common as stick welding.

From makemoneywelding.com

MIG Welding Wire Essentials A Guide to Types & Uses How Strong Is Wire Welding Generally, the strength of a weld deposit made with a solid gmaw electrode is limited to the strength of the electrode. The wire welding method is also as common as stick welding. We have identified 8 types of particularly strong welds: This welding method requires a special gun to weld, which is. Tensile strength represents the maximum force applied. As. How Strong Is Wire Welding.

From hogaki.com

HZXVOGEN 1KG Mig welding Flux Core Wire Gasless Wires Iron Welding How Strong Is Wire Welding This welding method requires a special gun to weld, which is. Not very efficient for welding thin metals. The strongest weld depends upon the base metal. The wire welding method is also as common as stick welding. In industrial applications, flux core welds must meet minimum tensile and yield strength. As far as performance is concerned, both wire types produce. How Strong Is Wire Welding.

From www.youtube.com

Installing the Welding Wire Welding 101 from MetalMan YouTube How Strong Is Wire Welding This welding method requires a special gun to weld, which is. The wire welding method is also as common as stick welding. There is no weld type that is the strongest universally across all welding applications. It acts as a filler material, creating a strong bond between metal pieces. Not very efficient for welding thin metals. Tensile strength represents the. How Strong Is Wire Welding.

From www.hollyfab.com

Common Welding Methods How Strong Is Wire Welding This welding method requires a special gun to weld, which is. Tensile strength represents the maximum force applied. The strongest weld depends upon the base metal. In industrial applications, flux core welds must meet minimum tensile and yield strength. There is no weld type that is the strongest universally across all welding applications. Welding wire is essential in various welding. How Strong Is Wire Welding.

From www.nevatiasteel.com

MIG Welding Wire Excellent For Welding Process Nevatia Steel How Strong Is Wire Welding Not very efficient for welding thin metals. Welding wire is essential in various welding processes. Generally, the strength of a weld deposit made with a solid gmaw electrode is limited to the strength of the electrode. There is no weld type that is the strongest universally across all welding applications. The strongest weld depends upon the base metal. This welding. How Strong Is Wire Welding.

From weldguru.com

Arc Welding Explained What Is It & How Does It Work? Weld Guru How Strong Is Wire Welding Generally, the strength of a weld deposit made with a solid gmaw electrode is limited to the strength of the electrode. The wire welding method is also as common as stick welding. Tensile strength represents the maximum force applied. Not very efficient for welding thin metals. We have identified 8 types of particularly strong welds: As far as performance is. How Strong Is Wire Welding.

From www.thefabricator.com

Tips for welding wire drum storage, handling, and setup How Strong Is Wire Welding The wire welding method is also as common as stick welding. The strongest weld depends upon the base metal. This welding method requires a special gun to weld, which is. There is no weld type that is the strongest universally across all welding applications. As far as performance is concerned, both wire types produce sound welds with good weld bead. How Strong Is Wire Welding.

From www.codinter.com

TIG vs. MIG Welding Which one to use in every case Codinter Americas How Strong Is Wire Welding Welding wire is essential in various welding processes. It acts as a filler material, creating a strong bond between metal pieces. This welding method requires a special gun to weld, which is. In industrial applications, flux core welds must meet minimum tensile and yield strength. There is no weld type that is the strongest universally across all welding applications. The. How Strong Is Wire Welding.

From blog.thepipingmart.com

How to MIG Weld Stainless Steel How Strong Is Wire Welding The strongest weld depends upon the base metal. There is no weld type that is the strongest universally across all welding applications. Welding wire is essential in various welding processes. Tensile strength represents the maximum force applied. In industrial applications, flux core welds must meet minimum tensile and yield strength. It acts as a filler material, creating a strong bond. How Strong Is Wire Welding.

From blog.thepipingmart.com

3 Best MIG Welding Wire for Mild Steel Projects How Strong Is Wire Welding Generally, the strength of a weld deposit made with a solid gmaw electrode is limited to the strength of the electrode. The strongest weld depends upon the base metal. As far as performance is concerned, both wire types produce sound welds with good weld bead appearances when applied correctly and used within the proper parameter. There is no weld type. How Strong Is Wire Welding.

From www.technoxmachine.com

MIG vs TIG Welding Types, Materials, and Applications A Guide How Strong Is Wire Welding Not very efficient for welding thin metals. In industrial applications, flux core welds must meet minimum tensile and yield strength. The strongest weld depends upon the base metal. We have identified 8 types of particularly strong welds: The wire welding method is also as common as stick welding. As far as performance is concerned, both wire types produce sound welds. How Strong Is Wire Welding.

From bmxracingthailand.com

How Much Can 1 Inch Of Weld Hold? Update How Strong Is Wire Welding In industrial applications, flux core welds must meet minimum tensile and yield strength. Not very efficient for welding thin metals. It acts as a filler material, creating a strong bond between metal pieces. The wire welding method is also as common as stick welding. There is no weld type that is the strongest universally across all welding applications. We have. How Strong Is Wire Welding.

From www.ebay.com

MTB Galvanized Welded Wire Mesh Garden Economy Fence 48" X50'2"x3 How Strong Is Wire Welding In industrial applications, flux core welds must meet minimum tensile and yield strength. There is no weld type that is the strongest universally across all welding applications. The wire welding method is also as common as stick welding. The strongest weld depends upon the base metal. Welding wire is essential in various welding processes. Generally, the strength of a weld. How Strong Is Wire Welding.

From blog.thepipingmart.com

How To Weld Copper Wire? How Strong Is Wire Welding Welding wire is essential in various welding processes. Generally, the strength of a weld deposit made with a solid gmaw electrode is limited to the strength of the electrode. As far as performance is concerned, both wire types produce sound welds with good weld bead appearances when applied correctly and used within the proper parameter. Not very efficient for welding. How Strong Is Wire Welding.

From www.oceanproperty.co.th

What Is FluxCore Arc Welding (FCAW) How Does It Work?, 53 OFF How Strong Is Wire Welding Not very efficient for welding thin metals. Tensile strength represents the maximum force applied. There is no weld type that is the strongest universally across all welding applications. It acts as a filler material, creating a strong bond between metal pieces. This welding method requires a special gun to weld, which is. Welding wire is essential in various welding processes.. How Strong Is Wire Welding.

From yeswelder.com

How to MIG weld different metal thicknesses YesWelder How Strong Is Wire Welding We have identified 8 types of particularly strong welds: Generally, the strength of a weld deposit made with a solid gmaw electrode is limited to the strength of the electrode. There is no weld type that is the strongest universally across all welding applications. The wire welding method is also as common as stick welding. Welding wire is essential in. How Strong Is Wire Welding.

From www.hotrod.com

MIG Welding Guide Learn How to MIG Weld Like a Professional Hot Rod How Strong Is Wire Welding As far as performance is concerned, both wire types produce sound welds with good weld bead appearances when applied correctly and used within the proper parameter. The strongest weld depends upon the base metal. In industrial applications, flux core welds must meet minimum tensile and yield strength. We have identified 8 types of particularly strong welds: Generally, the strength of. How Strong Is Wire Welding.

From www.youtube.com

🔥 Learn How to Flux Core Weld FCAW Basics MIG Monday YouTube How Strong Is Wire Welding Tensile strength represents the maximum force applied. In industrial applications, flux core welds must meet minimum tensile and yield strength. This welding method requires a special gun to weld, which is. We have identified 8 types of particularly strong welds: There is no weld type that is the strongest universally across all welding applications. It acts as a filler material,. How Strong Is Wire Welding.

From workshopinsider.com

Insider's Guide to Electric Resistance Welding (ERW) Insider How Strong Is Wire Welding The strongest weld depends upon the base metal. In industrial applications, flux core welds must meet minimum tensile and yield strength. It acts as a filler material, creating a strong bond between metal pieces. There is no weld type that is the strongest universally across all welding applications. We have identified 8 types of particularly strong welds: This welding method. How Strong Is Wire Welding.

From weldingwatch.com

How To Wire Feed Weld [StepbyStep Guide] WeldingWatch How Strong Is Wire Welding Not very efficient for welding thin metals. It acts as a filler material, creating a strong bond between metal pieces. We have identified 8 types of particularly strong welds: The wire welding method is also as common as stick welding. Welding wire is essential in various welding processes. In industrial applications, flux core welds must meet minimum tensile and yield. How Strong Is Wire Welding.

From www.repairerdrivennews.com

Honda explains why staple 70 ksi welding wire won’t work for higher How Strong Is Wire Welding Generally, the strength of a weld deposit made with a solid gmaw electrode is limited to the strength of the electrode. Tensile strength represents the maximum force applied. Welding wire is essential in various welding processes. We have identified 8 types of particularly strong welds: It acts as a filler material, creating a strong bond between metal pieces. The strongest. How Strong Is Wire Welding.

From www.twi-global.com

What is Welding? Definition, Processes and Types of Welds TWI How Strong Is Wire Welding Tensile strength represents the maximum force applied. Not very efficient for welding thin metals. Generally, the strength of a weld deposit made with a solid gmaw electrode is limited to the strength of the electrode. There is no weld type that is the strongest universally across all welding applications. We have identified 8 types of particularly strong welds: This welding. How Strong Is Wire Welding.

From www.thefabricator.com

Common problems in wire welding How Strong Is Wire Welding The wire welding method is also as common as stick welding. Tensile strength represents the maximum force applied. It acts as a filler material, creating a strong bond between metal pieces. In industrial applications, flux core welds must meet minimum tensile and yield strength. Not very efficient for welding thin metals. We have identified 8 types of particularly strong welds:. How Strong Is Wire Welding.

From www.engineeringinhindi.com

Why Use Flux in Welding Enhancing the Welding Process How Strong Is Wire Welding As far as performance is concerned, both wire types produce sound welds with good weld bead appearances when applied correctly and used within the proper parameter. We have identified 8 types of particularly strong welds: This welding method requires a special gun to weld, which is. It acts as a filler material, creating a strong bond between metal pieces. The. How Strong Is Wire Welding.

From blog.thepipingmart.com

Differences Between Carbon Steel and Mild Steel Welding Wire How Strong Is Wire Welding As far as performance is concerned, both wire types produce sound welds with good weld bead appearances when applied correctly and used within the proper parameter. The strongest weld depends upon the base metal. This welding method requires a special gun to weld, which is. Generally, the strength of a weld deposit made with a solid gmaw electrode is limited. How Strong Is Wire Welding.

From bancrofteng.com

GMAW Welding, MIG or Wire Welding Problems Bancroft Engineering How Strong Is Wire Welding It acts as a filler material, creating a strong bond between metal pieces. There is no weld type that is the strongest universally across all welding applications. Welding wire is essential in various welding processes. This welding method requires a special gun to weld, which is. As far as performance is concerned, both wire types produce sound welds with good. How Strong Is Wire Welding.

From weldguru.com

TIG Welding Stainless Steel A Beginners Guide Weld Guru How Strong Is Wire Welding This welding method requires a special gun to weld, which is. The wire welding method is also as common as stick welding. In industrial applications, flux core welds must meet minimum tensile and yield strength. Not very efficient for welding thin metals. The strongest weld depends upon the base metal. Tensile strength represents the maximum force applied. We have identified. How Strong Is Wire Welding.

From www.lazada.com.ph

Mitsushi 2.5kg/142pcs 2.5mm/32.mm*50cm Electrode Welding Rod for How Strong Is Wire Welding Welding wire is essential in various welding processes. It acts as a filler material, creating a strong bond between metal pieces. This welding method requires a special gun to weld, which is. The wire welding method is also as common as stick welding. Tensile strength represents the maximum force applied. The strongest weld depends upon the base metal. Not very. How Strong Is Wire Welding.

From joiwgzwyp.blob.core.windows.net

What Is Mig Welding Wire Made Out Of at Leticia Myers blog How Strong Is Wire Welding Welding wire is essential in various welding processes. We have identified 8 types of particularly strong welds: This welding method requires a special gun to weld, which is. Not very efficient for welding thin metals. Generally, the strength of a weld deposit made with a solid gmaw electrode is limited to the strength of the electrode. It acts as a. How Strong Is Wire Welding.

From www.cruxweld.com

The Difference between Soldering and Brazing with Welding [The How Strong Is Wire Welding Not very efficient for welding thin metals. The wire welding method is also as common as stick welding. There is no weld type that is the strongest universally across all welding applications. Generally, the strength of a weld deposit made with a solid gmaw electrode is limited to the strength of the electrode. The strongest weld depends upon the base. How Strong Is Wire Welding.

From weldguru.com

MIG vs Stick Welding Which is Better? (Pros & Cons) How Strong Is Wire Welding The wire welding method is also as common as stick welding. Generally, the strength of a weld deposit made with a solid gmaw electrode is limited to the strength of the electrode. The strongest weld depends upon the base metal. In industrial applications, flux core welds must meet minimum tensile and yield strength. We have identified 8 types of particularly. How Strong Is Wire Welding.

From weldingpros.net

Best MIG Welding Wire Reviews and Comparison Table 2024 How Strong Is Wire Welding Tensile strength represents the maximum force applied. The strongest weld depends upon the base metal. Generally, the strength of a weld deposit made with a solid gmaw electrode is limited to the strength of the electrode. It acts as a filler material, creating a strong bond between metal pieces. Not very efficient for welding thin metals. As far as performance. How Strong Is Wire Welding.

From www.youtube.com

How to cad weld ground rod part 2 full cadweld YouTube How Strong Is Wire Welding We have identified 8 types of particularly strong welds: Not very efficient for welding thin metals. This welding method requires a special gun to weld, which is. The wire welding method is also as common as stick welding. It acts as a filler material, creating a strong bond between metal pieces. Welding wire is essential in various welding processes. In. How Strong Is Wire Welding.

From www.youtube.com

Do you know the flux cored wire welding method? Do you know what flat How Strong Is Wire Welding In industrial applications, flux core welds must meet minimum tensile and yield strength. Tensile strength represents the maximum force applied. Not very efficient for welding thin metals. There is no weld type that is the strongest universally across all welding applications. It acts as a filler material, creating a strong bond between metal pieces. Generally, the strength of a weld. How Strong Is Wire Welding.

From www.mdpi.com

Metals Free FullText Research on Parameters of WireFilling Laser How Strong Is Wire Welding Generally, the strength of a weld deposit made with a solid gmaw electrode is limited to the strength of the electrode. Welding wire is essential in various welding processes. As far as performance is concerned, both wire types produce sound welds with good weld bead appearances when applied correctly and used within the proper parameter. In industrial applications, flux core. How Strong Is Wire Welding.