Mold Casting Youtube . You can use it to cast many materials including polyurethane, epoxide, polyester, plaster, concrete, cement, wax, low melting alloys or soap. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. This mold material is suitable both for small, detailed casts and large objects (i.e statues). This video is a beginners guide to mold making for resin casting. Make concrete molds for wet casting, form liners, concrete stamps, and gfrc decorative structures and panels. The resulting cast will be an exact likeness of the shape of the hollow mold form. The shell molding (or shell casting) process is the industry standard for medium to. Resulting mold has a stable shape and is both chemically and thermally resistant. The goal here is to take the intimidation out of mold making. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. By the end of his.

from www.youtube.com

The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. This video is a beginners guide to mold making for resin casting. Make concrete molds for wet casting, form liners, concrete stamps, and gfrc decorative structures and panels. Resulting mold has a stable shape and is both chemically and thermally resistant. This mold material is suitable both for small, detailed casts and large objects (i.e statues). The shell molding (or shell casting) process is the industry standard for medium to. The resulting cast will be an exact likeness of the shape of the hollow mold form. The goal here is to take the intimidation out of mold making. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. By the end of his.

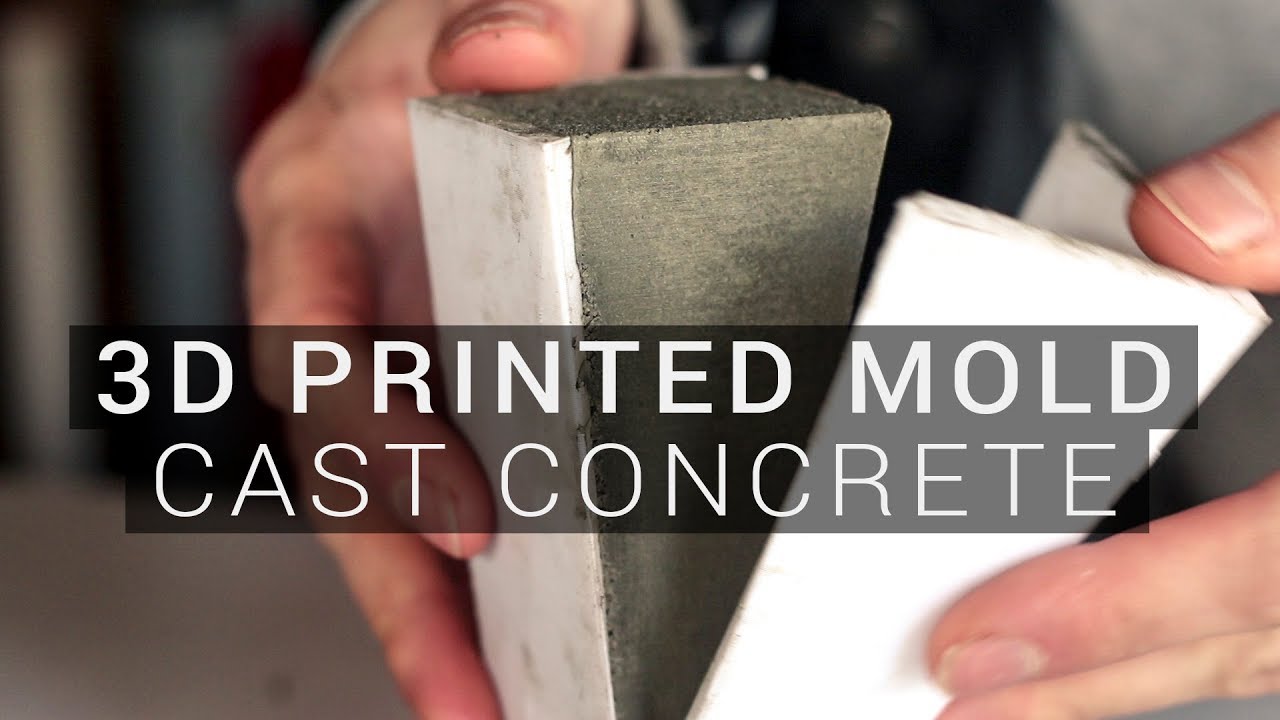

Cast Concrete with REUSABLE 3D Printed Molds YouTube

Mold Casting Youtube The shell molding (or shell casting) process is the industry standard for medium to. Make concrete molds for wet casting, form liners, concrete stamps, and gfrc decorative structures and panels. You can use it to cast many materials including polyurethane, epoxide, polyester, plaster, concrete, cement, wax, low melting alloys or soap. The goal here is to take the intimidation out of mold making. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. The shell molding (or shell casting) process is the industry standard for medium to. The resulting cast will be an exact likeness of the shape of the hollow mold form. Resulting mold has a stable shape and is both chemically and thermally resistant. This video is a beginners guide to mold making for resin casting. This mold material is suitable both for small, detailed casts and large objects (i.e statues). By the end of his.

From www.youtube.com

The beginner's guide to mold making and casting YouTube Mold Casting Youtube Resulting mold has a stable shape and is both chemically and thermally resistant. The resulting cast will be an exact likeness of the shape of the hollow mold form. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. This mold material is suitable both for small, detailed casts and large. Mold Casting Youtube.

From www.youtube.com

shell mold and core casting produciton line (resin coated sand) YouTube Mold Casting Youtube This video is a beginners guide to mold making for resin casting. You can use it to cast many materials including polyurethane, epoxide, polyester, plaster, concrete, cement, wax, low melting alloys or soap. By the end of his. Make concrete molds for wet casting, form liners, concrete stamps, and gfrc decorative structures and panels. Resulting mold has a stable shape. Mold Casting Youtube.

From www.youtube.com

How to make silicone molds for casting concrete YouTube Mold Casting Youtube Resulting mold has a stable shape and is both chemically and thermally resistant. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. Make concrete molds for wet casting, form liners, concrete stamps, and gfrc decorative structures and panels. This video is a beginners guide to mold making for resin casting.. Mold Casting Youtube.

From www.youtube.com

Casting in plaster molds YouTube Mold Casting Youtube Make concrete molds for wet casting, form liners, concrete stamps, and gfrc decorative structures and panels. The shell molding (or shell casting) process is the industry standard for medium to. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. Resulting mold has a stable shape and is. Mold Casting Youtube.

From www.youtube.com

Casting Metal Parts into 3D Printed Molds YouTube Mold Casting Youtube The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. Resulting mold has a stable shape and is both chemically and thermally resistant. By the end of his. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. Make. Mold Casting Youtube.

From www.youtube.com

Making Very Large Silicone Molds YouTube Mold Casting Youtube You can use it to cast many materials including polyurethane, epoxide, polyester, plaster, concrete, cement, wax, low melting alloys or soap. The shell molding (or shell casting) process is the industry standard for medium to. Resulting mold has a stable shape and is both chemically and thermally resistant. The easiest example of what a mold is, that almost everyone has. Mold Casting Youtube.

From www.youtube.com

Ch 5 Expendable Mold Casting YouTube Mold Casting Youtube By the end of his. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. This mold material is suitable both for small, detailed casts and large objects (i.e statues). You can use it to cast many materials including polyurethane, epoxide, polyester, plaster, concrete, cement, wax, low melting alloys or soap.. Mold Casting Youtube.

From www.leclairemfg.com

moldcastingequipment Le Claire Manufacturing Co Mold Casting Youtube The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. You can use it to cast many materials including polyurethane, epoxide, polyester, plaster, concrete, cement, wax, low melting alloys or soap. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was. Mold Casting Youtube.

From www.youtube.com

Make Melamine Molds For Resin Casting NV Woodwerks YouTube Mold Casting Youtube Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The shell molding (or shell casting) process is the industry standard for medium to. Resulting mold has a stable shape and is both chemically and thermally resistant. Make concrete molds for wet casting, form liners, concrete stamps, and. Mold Casting Youtube.

From www.youtube.com

DIY Casting lead into plaster mold YouTube Mold Casting Youtube The goal here is to take the intimidation out of mold making. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. By the end of his. Resulting mold has a stable shape and is both chemically and thermally resistant. This mold material is suitable both for small, detailed casts and. Mold Casting Youtube.

From www.youtube.com

Permanent gravity mold YouTube Mold Casting Youtube The goal here is to take the intimidation out of mold making. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The resulting cast will be an exact likeness of the shape of the hollow mold form. By the end of his. This mold material is suitable. Mold Casting Youtube.

From www.youtube.com

Open sand mold brass casting & steel mold copper coins Casting Copper Mold Casting Youtube Resulting mold has a stable shape and is both chemically and thermally resistant. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. You can use it to cast many materials including polyurethane, epoxide, polyester, plaster, concrete, cement, wax, low melting alloys or soap. This mold material is suitable both for. Mold Casting Youtube.

From www.youtube.com

Vacuum Molding Expandable Mold Casting Processes. YouTube Mold Casting Youtube You can use it to cast many materials including polyurethane, epoxide, polyester, plaster, concrete, cement, wax, low melting alloys or soap. This mold material is suitable both for small, detailed casts and large objects (i.e statues). The goal here is to take the intimidation out of mold making. Molds are negative forms that are used to shape casting materials, creating. Mold Casting Youtube.

From www.youtube.com

Die Casting Permanent Mold Casting Processes. YouTube Mold Casting Youtube This video is a beginners guide to mold making for resin casting. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The shell molding (or shell casting) process is the industry standard for medium to. The goal here is to take the intimidation out of mold making.. Mold Casting Youtube.

From www.youtube.com

Permanent Mold Casting, Gravity Casting,Permanent mold aluminum casting Mold Casting Youtube The goal here is to take the intimidation out of mold making. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. By the end of his. Make concrete molds for wet casting, form liners, concrete stamps, and gfrc decorative structures and panels. You can use it to. Mold Casting Youtube.

From www.youtube.com

Pouring Molten Aluminum into a 3D Printed Sand Casting Mold YouTube Mold Casting Youtube Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The resulting cast will be an exact likeness of the shape of the hollow mold form. The shell molding (or shell casting) process is the industry standard for medium to. The goal here is to take the intimidation. Mold Casting Youtube.

From www.youtube.com

Making a green sand mold Casting 2 YouTube Mold Casting Youtube Resulting mold has a stable shape and is both chemically and thermally resistant. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. This mold material is suitable both for small, detailed casts and large objects (i.e statues). The goal here is to take the intimidation out of mold making. Make. Mold Casting Youtube.

From www.youtube.com

How To Make a Two Part Mold Using Reusable imPRESSive Putty to make Mold Casting Youtube Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. By the end of his. Resulting mold has a stable shape and is both chemically and thermally resistant. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. The. Mold Casting Youtube.

From www.youtube.com

Advanced Resin Casting Techniques Intro to Using J Molds Part 2 YouTube Mold Casting Youtube The shell molding (or shell casting) process is the industry standard for medium to. Make concrete molds for wet casting, form liners, concrete stamps, and gfrc decorative structures and panels. The resulting cast will be an exact likeness of the shape of the hollow mold form. You can use it to cast many materials including polyurethane, epoxide, polyester, plaster, concrete,. Mold Casting Youtube.

From www.youtube.com

Machining a Custom Graphite Mold for Metal Casting MaterialMonday Mold Casting Youtube The resulting cast will be an exact likeness of the shape of the hollow mold form. Make concrete molds for wet casting, form liners, concrete stamps, and gfrc decorative structures and panels. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. By the end of his. The goal here is. Mold Casting Youtube.

From www.youtube.com

Plaster Moulding Process Plaster Mould Casting Process ENGINEERING Mold Casting Youtube By the end of his. This mold material is suitable both for small, detailed casts and large objects (i.e statues). The goal here is to take the intimidation out of mold making. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The easiest example of what a. Mold Casting Youtube.

From www.youtube.com

Shell Molding Expandable Mold Casting Processes YouTube Mold Casting Youtube This mold material is suitable both for small, detailed casts and large objects (i.e statues). By the end of his. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The shell molding (or shell casting) process is the industry standard for medium to. Make concrete molds for. Mold Casting Youtube.

From www.youtube.com

Cast Concrete with REUSABLE 3D Printed Molds YouTube Mold Casting Youtube Resulting mold has a stable shape and is both chemically and thermally resistant. The goal here is to take the intimidation out of mold making. By the end of his. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. You can use it to cast many materials including polyurethane, epoxide,. Mold Casting Youtube.

From www.youtube.com

Introduction to DIY metal casting in sand molds How to YouTube Mold Casting Youtube The goal here is to take the intimidation out of mold making. The shell molding (or shell casting) process is the industry standard for medium to. This video is a beginners guide to mold making for resin casting. Resulting mold has a stable shape and is both chemically and thermally resistant. The easiest example of what a mold is, that. Mold Casting Youtube.

From www.youtube.com

Carving and Casting Coin Molds By Hand YouTube Mold Casting Youtube Resulting mold has a stable shape and is both chemically and thermally resistant. You can use it to cast many materials including polyurethane, epoxide, polyester, plaster, concrete, cement, wax, low melting alloys or soap. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. The goal here is to take the. Mold Casting Youtube.

From www.youtube.com

3421 Expendable Mold Casting YouTube Mold Casting Youtube Resulting mold has a stable shape and is both chemically and thermally resistant. The resulting cast will be an exact likeness of the shape of the hollow mold form. By the end of his. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The shell molding (or. Mold Casting Youtube.

From www.youtube.com

LIVE How To Make Molds For Concrete Casting YouTube Mold Casting Youtube This mold material is suitable both for small, detailed casts and large objects (i.e statues). This video is a beginners guide to mold making for resin casting. The resulting cast will be an exact likeness of the shape of the hollow mold form. Resulting mold has a stable shape and is both chemically and thermally resistant. The goal here is. Mold Casting Youtube.

From www.youtube.com

Prop Shop Molding & Casting 101 Intro to Silicone Rubber YouTube Mold Casting Youtube The shell molding (or shell casting) process is the industry standard for medium to. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. Resulting mold has a stable shape and is both chemically and thermally resistant. Molds are negative forms that are used to shape casting materials, creating duplicates of. Mold Casting Youtube.

From www.youtube.com

Casting Metal the Basics YouTube Mold Casting Youtube You can use it to cast many materials including polyurethane, epoxide, polyester, plaster, concrete, cement, wax, low melting alloys or soap. This mold material is suitable both for small, detailed casts and large objects (i.e statues). This video is a beginners guide to mold making for resin casting. Resulting mold has a stable shape and is both chemically and thermally. Mold Casting Youtube.

From www.youtube.com

Polyurethane Casting Using 3D Printed Molds YouTube Mold Casting Youtube The shell molding (or shell casting) process is the industry standard for medium to. By the end of his. This mold material is suitable both for small, detailed casts and large objects (i.e statues). Resulting mold has a stable shape and is both chemically and thermally resistant. Molds are negative forms that are used to shape casting materials, creating duplicates. Mold Casting Youtube.

From www.youtube.com

Aluminium castingthermocol diy making processSand mold casting Mold Casting Youtube Make concrete molds for wet casting, form liners, concrete stamps, and gfrc decorative structures and panels. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. Molds are negative forms that are used to shape casting materials, creating duplicates of the model (object) the mold was made from. The resulting cast. Mold Casting Youtube.

From www.youtube.com

Casting Lead ingots in silicone molds YouTube Mold Casting Youtube The goal here is to take the intimidation out of mold making. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. This video is a beginners guide to mold making for resin casting. Resulting mold has a stable shape and is both chemically and thermally resistant. The resulting cast will. Mold Casting Youtube.

From www.youtube.com

Bronze Casting Pt. 1 "Making A Rubber Mold" YouTube Mold Casting Youtube The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. This mold material is suitable both for small, detailed casts and large objects (i.e statues). Resulting mold has a stable shape and is both chemically and thermally resistant. The shell molding (or shell casting) process is the industry standard for medium. Mold Casting Youtube.

From www.youtube.com

How to Silicone Mold & casting Flexible Foam YouTube Mold Casting Youtube By the end of his. This mold material is suitable both for small, detailed casts and large objects (i.e statues). Make concrete molds for wet casting, form liners, concrete stamps, and gfrc decorative structures and panels. The goal here is to take the intimidation out of mold making. Resulting mold has a stable shape and is both chemically and thermally. Mold Casting Youtube.

From www.youtube.com

The Basic Permanent Mold Casting Process YouTube Mold Casting Youtube You can use it to cast many materials including polyurethane, epoxide, polyester, plaster, concrete, cement, wax, low melting alloys or soap. This video is a beginners guide to mold making for resin casting. The easiest example of what a mold is, that almost everyone has used before, is an ice cube tray. By the end of his. Molds are negative. Mold Casting Youtube.