Plug Gage Tolerance Classes . The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. This illustrates the thread class, allowance and the basic pitch diameter for both unified inch screw threads and m series metric screw threads and how the classes relate to each other. Standard plug and ring gage classes for product tolerances. Plug, pin and ring gages. Gage tolerance selection, the 10% gage rule. Indicating gaging is typically mastered at maximum material condition. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. Cylindrical plug gage go member. The chart of product tolerances for plain plug and ring gages may be. Classes of threads are differentiated by the amount of tolerance and allowance specified. Plug gages are precision ground cylindrical measuring devices.

from extrudesign.com

This illustrates the thread class, allowance and the basic pitch diameter for both unified inch screw threads and m series metric screw threads and how the classes relate to each other. Indicating gaging is typically mastered at maximum material condition. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. The chart of product tolerances for plain plug and ring gages may be. Cylindrical plug gage go member. Classes of threads are differentiated by the amount of tolerance and allowance specified. Standard plug and ring gage classes for product tolerances. Plug, pin and ring gages. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Plug gages are precision ground cylindrical measuring devices.

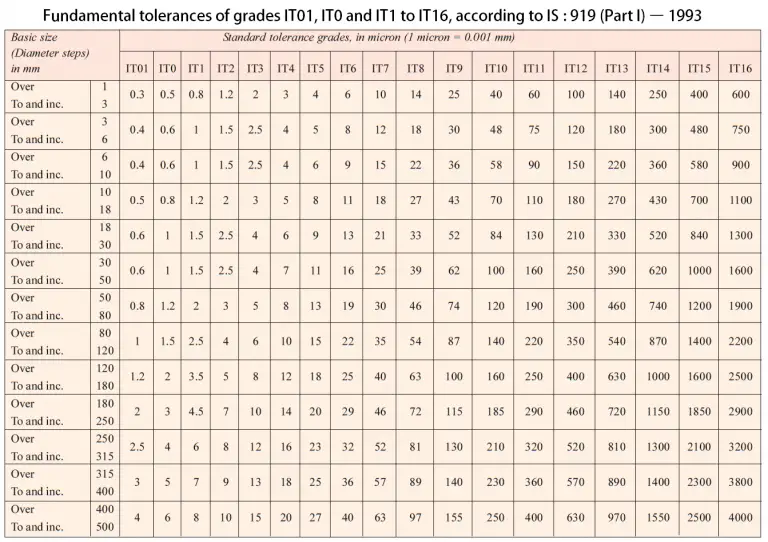

How to Calculate tolerance values for shaft or a hole? ExtruDesign

Plug Gage Tolerance Classes Plug, pin and ring gages. Standard plug and ring gage classes for product tolerances. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Plug, pin and ring gages. Plug gages are precision ground cylindrical measuring devices. Cylindrical plug gage go member. This illustrates the thread class, allowance and the basic pitch diameter for both unified inch screw threads and m series metric screw threads and how the classes relate to each other. Indicating gaging is typically mastered at maximum material condition. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. Classes of threads are differentiated by the amount of tolerance and allowance specified. The chart of product tolerances for plain plug and ring gages may be. Gage tolerance selection, the 10% gage rule.

From titangage.com

Thread Ring & Setting Plug Gages Titan Gage Plug Gage Tolerance Classes Plug gages are precision ground cylindrical measuring devices. Classes of threads are differentiated by the amount of tolerance and allowance specified. Indicating gaging is typically mastered at maximum material condition. This illustrates the thread class, allowance and the basic pitch diameter for both unified inch screw threads and m series metric screw threads and how the classes relate to each. Plug Gage Tolerance Classes.

From willrich.com

Gagemakers Tolerance Chart Willich Precision Instruments Plug Gage Tolerance Classes Plug gages are precision ground cylindrical measuring devices. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Gage tolerance selection, the 10% gage rule. Plug, pin and ring gages. Classes. Plug Gage Tolerance Classes.

From www.scribd.com

10. Gage Tolerances PDF Plug Gage Tolerance Classes The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Plug gages are precision ground cylindrical measuring devices. Standard plug and ring gage classes for product tolerances. Gage tolerance selection, the 10% gage rule. Plug, pin and ring gages. This illustrates the thread class, allowance and the basic pitch diameter. Plug Gage Tolerance Classes.

From www.ebay.com

SHARS M2 x 0.4 Thread Plug Gage GO and NO GO Class ANSI/ASME B1.16M Plug Gage Tolerance Classes Cylindrical plug gage go member. Classes of threads are differentiated by the amount of tolerance and allowance specified. Plug, pin and ring gages. Plug gages are precision ground cylindrical measuring devices. Indicating gaging is typically mastered at maximum material condition. The chart of product tolerances for plain plug and ring gages may be. The differences between classes of gages like. Plug Gage Tolerance Classes.

From mavink.com

Gage Makers Tolerance Chart Plug Gage Tolerance Classes Indicating gaging is typically mastered at maximum material condition. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. This illustrates the thread class, allowance and the basic pitch diameter for both unified inch screw threads and m series metric screw threads and how the classes relate to each other.. Plug Gage Tolerance Classes.

From extrudesign.com

How to Calculate tolerance values for shaft or a hole? ExtruDesign Plug Gage Tolerance Classes Standard plug and ring gage classes for product tolerances. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. Gage tolerance selection, the 10% gage rule. Classes of threads are differentiated by the amount of tolerance and allowance specified. This illustrates the thread class, allowance and the basic pitch diameter for. Plug Gage Tolerance Classes.

From vermontgage.com

Product and Technical Support Resources Vermont Gage Plug Gage Tolerance Classes The chart of product tolerances for plain plug and ring gages may be. Plug, pin and ring gages. Cylindrical plug gage go member. Classes of threads are differentiated by the amount of tolerance and allowance specified. Indicating gaging is typically mastered at maximum material condition. This illustrates the thread class, allowance and the basic pitch diameter for both unified inch. Plug Gage Tolerance Classes.

From exogszodf.blob.core.windows.net

Plug Gauge Tolerance Standards at Tracy Benedetti blog Plug Gage Tolerance Classes Plug, pin and ring gages. Gage tolerance selection, the 10% gage rule. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Classes of threads are differentiated by the amount of. Plug Gage Tolerance Classes.

From www.researchgate.net

17 Tolerance Class with Attributes Download Table Plug Gage Tolerance Classes Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. Gage tolerance selection, the 10% gage rule. Indicating gaging is typically mastered at maximum material condition. The chart of product tolerances for plain plug and ring gages may be. This illustrates the thread class, allowance and the basic pitch diameter for. Plug Gage Tolerance Classes.

From solutions.travers.com

Gage Classes Which To Use, When? Plug Gage Tolerance Classes Gage tolerance selection, the 10% gage rule. Indicating gaging is typically mastered at maximum material condition. This illustrates the thread class, allowance and the basic pitch diameter for both unified inch screw threads and m series metric screw threads and how the classes relate to each other. Standard plug and ring gage classes for product tolerances. The chart of product. Plug Gage Tolerance Classes.

From mavink.com

Plug Gauge Tolerance Chart Plug Gage Tolerance Classes The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Plug gages are precision ground cylindrical measuring devices. Gage tolerance selection, the 10% gage rule. Cylindrical plug gage go member. Plug, pin and ring gages. This illustrates the thread class, allowance and the basic pitch diameter for both unified inch. Plug Gage Tolerance Classes.

From www.sumipol.com

THREAD LIMIT PLUG GAUGE (ISO TYPE JIS / GPNP) Sumipol Plug Gage Tolerance Classes Classes of threads are differentiated by the amount of tolerance and allowance specified. Standard plug and ring gage classes for product tolerances. The chart of product tolerances for plain plug and ring gages may be. This illustrates the thread class, allowance and the basic pitch diameter for both unified inch screw threads and m series metric screw threads and how. Plug Gage Tolerance Classes.

From www.shars.com

1/428 Go/No Go Double End Thread Plug Gage Plug Gage Tolerance Classes Gage tolerance selection, the 10% gage rule. Standard plug and ring gage classes for product tolerances. Indicating gaging is typically mastered at maximum material condition. The chart of product tolerances for plain plug and ring gages may be. Plug, pin and ring gages. Cylindrical plug gage go member. Plug gages are precision ground cylindrical measuring devices. The differences between classes. Plug Gage Tolerance Classes.

From www.judgetool.com

DELTRONIC TP25 Plug Gage Sets 25 Gages in .0001" (Tenth) Steps Plug Gage Tolerance Classes Cylindrical plug gage go member. Standard plug and ring gage classes for product tolerances. Classes of threads are differentiated by the amount of tolerance and allowance specified. Gage tolerance selection, the 10% gage rule. Plug, pin and ring gages. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Indicating. Plug Gage Tolerance Classes.

From mungfali.com

Gage Block Tolerance Chart Plug Gage Tolerance Classes The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Indicating gaging is typically mastered at maximum material condition. Plug, pin and ring gages. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. Cylindrical plug gage go member. The chart. Plug Gage Tolerance Classes.

From bceweb.org

Plug Gauge Tolerance Chart A Visual Reference of Charts Chart Master Plug Gage Tolerance Classes Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. Classes of threads are differentiated by the amount of tolerance and allowance specified. Plug, pin and ring gages. Standard plug and ring gage classes for product tolerances. Cylindrical plug gage go member. The chart of product tolerances for plain plug and. Plug Gage Tolerance Classes.

From www.shars.com

5/1618 Go/No Go Double End Thread Plug Gage Plug Gage Tolerance Classes Cylindrical plug gage go member. This illustrates the thread class, allowance and the basic pitch diameter for both unified inch screw threads and m series metric screw threads and how the classes relate to each other. Indicating gaging is typically mastered at maximum material condition. Classes of threads are differentiated by the amount of tolerance and allowance specified. The chart. Plug Gage Tolerance Classes.

From mungfali.com

Plain Plug Gauge Tolerance Chart Plug Gage Tolerance Classes Plug gages are precision ground cylindrical measuring devices. Cylindrical plug gage go member. Indicating gaging is typically mastered at maximum material condition. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Classes of threads are differentiated by the amount of tolerance and allowance specified. Tolerance direction cylindrical ring gage. Plug Gage Tolerance Classes.

From tillescenter.org

Tolerance Class ZZ 0.208 Gage Diameter Vermont Gage Steel NoGo Plug Plug Gage Tolerance Classes The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Cylindrical plug gage go member. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. The chart of product tolerances for plain plug and ring gages may be. Plug gages are. Plug Gage Tolerance Classes.

From grmetrology.com

Plug Gage Calibration GR Metrology Plug Gage Tolerance Classes Standard plug and ring gage classes for product tolerances. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Indicating gaging is typically mastered at maximum material condition. Classes of threads. Plug Gage Tolerance Classes.

From www.youtube.com

How To Use Thread Plug Gages Technical Series 101 YouTube Plug Gage Tolerance Classes Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. Standard plug and ring gage classes for product tolerances. This illustrates the thread class, allowance and the basic pitch diameter for both unified inch screw threads and m series metric screw threads and how the classes relate to each other. The. Plug Gage Tolerance Classes.

From exogszodf.blob.core.windows.net

Plug Gauge Tolerance Standards at Tracy Benedetti blog Plug Gage Tolerance Classes The chart of product tolerances for plain plug and ring gages may be. Plug gages are precision ground cylindrical measuring devices. Plug, pin and ring gages. Cylindrical plug gage go member. Gage tolerance selection, the 10% gage rule. This illustrates the thread class, allowance and the basic pitch diameter for both unified inch screw threads and m series metric screw. Plug Gage Tolerance Classes.

From bceweb.org

Plug Gauge Tolerance Chart A Visual Reference of Charts Chart Master Plug Gage Tolerance Classes Classes of threads are differentiated by the amount of tolerance and allowance specified. Gage tolerance selection, the 10% gage rule. Plug gages are precision ground cylindrical measuring devices. Standard plug and ring gage classes for product tolerances. This illustrates the thread class, allowance and the basic pitch diameter for both unified inch screw threads and m series metric screw threads. Plug Gage Tolerance Classes.

From vdocuments.mx

Meyer Gage 2014 Pricing Catalog · .060” are marked with size and Plug Gage Tolerance Classes Gage tolerance selection, the 10% gage rule. This illustrates the thread class, allowance and the basic pitch diameter for both unified inch screw threads and m series metric screw threads and how the classes relate to each other. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Standard plug. Plug Gage Tolerance Classes.

From nabgauge.com

PLAIN PLUG AND RING GAUGES (CLASS Z, Y, X, XX) Northern Gauge Plug Gage Tolerance Classes Plug, pin and ring gages. Standard plug and ring gage classes for product tolerances. Classes of threads are differentiated by the amount of tolerance and allowance specified. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Tolerance direction cylindrical ring gage go member is to the minus side, nogo. Plug Gage Tolerance Classes.

From www.walmart.com

DOACT Thread Plug Gauge, Steel Gage For The Test Thread Tolerance Class Plug Gage Tolerance Classes Classes of threads are differentiated by the amount of tolerance and allowance specified. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. This illustrates the thread class, allowance and the basic pitch diameter for both unified inch screw threads and m series metric screw threads and how the classes. Plug Gage Tolerance Classes.

From www.judgetool.com

Thread Plug Gages STI (HELICOIL) Titanium Nitride Coated (Inch Plug Gage Tolerance Classes Cylindrical plug gage go member. Classes of threads are differentiated by the amount of tolerance and allowance specified. Standard plug and ring gage classes for product tolerances. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. The chart of product tolerances for plain plug and ring gages may be.. Plug Gage Tolerance Classes.

From www.qualitymag.com

Thread Classes and Setting Plug Gages 20191001 Quality Magazine Plug Gage Tolerance Classes The chart of product tolerances for plain plug and ring gages may be. Classes of threads are differentiated by the amount of tolerance and allowance specified. Cylindrical plug gage go member. This illustrates the thread class, allowance and the basic pitch diameter for both unified inch screw threads and m series metric screw threads and how the classes relate to. Plug Gage Tolerance Classes.

From www.bharatagritech.com

Thread Classes And Setting Plug Gages 20191001 Quality, 59 OFF Plug Gage Tolerance Classes Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. Standard plug and ring gage classes for product tolerances. Gage tolerance selection, the 10% gage rule. Plug gages are precision ground cylindrical measuring devices. Cylindrical plug gage go member. Classes of threads are differentiated by the amount of tolerance and allowance. Plug Gage Tolerance Classes.

From mavink.com

Plug Gauge Tolerance Chart Plug Gage Tolerance Classes Standard plug and ring gage classes for product tolerances. Cylindrical plug gage go member. This illustrates the thread class, allowance and the basic pitch diameter for both unified inch screw threads and m series metric screw threads and how the classes relate to each other. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is. Plug Gage Tolerance Classes.

From www.ebay.com

Steel Go Plug Gage, Tolerance Class Zz, 23.01Mm Gage Diameter eBay Plug Gage Tolerance Classes Cylindrical plug gage go member. Standard plug and ring gage classes for product tolerances. Plug, pin and ring gages. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Plug gages are precision ground cylindrical measuring devices. Tolerance direction cylindrical ring gage go member is to the minus side, nogo. Plug Gage Tolerance Classes.

From basicstomechanicalengineering.blogspot.com

Mechanical Engineering Basics International Tolerance Grade Plug Gage Tolerance Classes Gage tolerance selection, the 10% gage rule. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. The chart of product tolerances for plain plug and ring gages may be. Plug, pin and ring gages. This illustrates the thread class, allowance and the basic pitch diameter for both unified inch. Plug Gage Tolerance Classes.

From exovsazwm.blob.core.windows.net

Metric Thread Plug Gauge Standard Tolerances at Alvin McGee blog Plug Gage Tolerance Classes Plug, pin and ring gages. This illustrates the thread class, allowance and the basic pitch diameter for both unified inch screw threads and m series metric screw threads and how the classes relate to each other. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Indicating gaging is typically. Plug Gage Tolerance Classes.

From www.qualitymag.com

Thread Classes and Setting Plug Gages 20191001 Quality Magazine Plug Gage Tolerance Classes Plug gages are precision ground cylindrical measuring devices. The differences between classes of gages like class z gage and class zz gage is the deviation allowed in the. Classes of threads are differentiated by the amount of tolerance and allowance specified. Cylindrical plug gage go member. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member. Plug Gage Tolerance Classes.

From www.judgetool.com

APM14x1NG Thread Plug Gages METRIC Hardened Steel Judge Tool & Gage Plug Gage Tolerance Classes Cylindrical plug gage go member. Plug, pin and ring gages. Standard plug and ring gage classes for product tolerances. Gage tolerance selection, the 10% gage rule. Indicating gaging is typically mastered at maximum material condition. Tolerance direction cylindrical ring gage go member is to the minus side, nogo member is to the plus side. The chart of product tolerances for. Plug Gage Tolerance Classes.