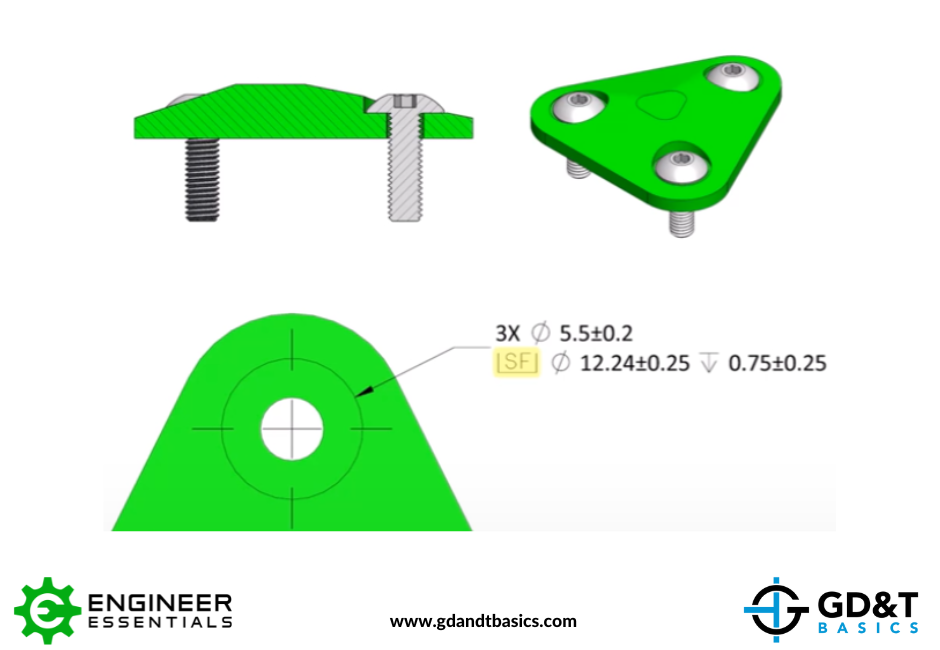

Counterbore And Spotface . Counterbore holes, on the other hand, are. spotfaces provide a flat, accurately located surface, which is essential for fasteners to sit flush with the workpiece’s surface. Spotfaces position the parts accurately and spread the loads. spotface and counterbore are essential machining features that contribute significantly to manufacturing complex assemblies, ensuring the secure and precise connection between mating parts. Accommodating fastener heads, some of their subtle differences professionals often cause professionals to confuse them with each other. unlike counterbore holes, spotface holes do not have a larger diameter than the hole they surround. though a spotface and a counterbore are very similar, a spotface only provides a flat mounting surface, where a counterbore provides a. It creates a flat surface for mounting bolt heads and washers. Instead, they are designed to clean up and flatten the surface around the hole, ensuring proper alignment and contact with mating components. a spotface hole or shallow counterbore is a hole in a workpiece. While their core purpose is the same: Understanding the difference between these holes in machining is crucial to carefully selecting the right hole that meets the specific requirements of your.

from ar.inspiredpencil.com

While their core purpose is the same: It creates a flat surface for mounting bolt heads and washers. Accommodating fastener heads, some of their subtle differences professionals often cause professionals to confuse them with each other. though a spotface and a counterbore are very similar, a spotface only provides a flat mounting surface, where a counterbore provides a. Understanding the difference between these holes in machining is crucial to carefully selecting the right hole that meets the specific requirements of your. Spotfaces position the parts accurately and spread the loads. Instead, they are designed to clean up and flatten the surface around the hole, ensuring proper alignment and contact with mating components. Counterbore holes, on the other hand, are. spotfaces provide a flat, accurately located surface, which is essential for fasteners to sit flush with the workpiece’s surface. unlike counterbore holes, spotface holes do not have a larger diameter than the hole they surround.

Spot Face Vs Counterbore

Counterbore And Spotface While their core purpose is the same: Instead, they are designed to clean up and flatten the surface around the hole, ensuring proper alignment and contact with mating components. While their core purpose is the same: spotface and counterbore are essential machining features that contribute significantly to manufacturing complex assemblies, ensuring the secure and precise connection between mating parts. unlike counterbore holes, spotface holes do not have a larger diameter than the hole they surround. spotfaces provide a flat, accurately located surface, which is essential for fasteners to sit flush with the workpiece’s surface. though a spotface and a counterbore are very similar, a spotface only provides a flat mounting surface, where a counterbore provides a. Accommodating fastener heads, some of their subtle differences professionals often cause professionals to confuse them with each other. a spotface hole or shallow counterbore is a hole in a workpiece. Understanding the difference between these holes in machining is crucial to carefully selecting the right hole that meets the specific requirements of your. It creates a flat surface for mounting bolt heads and washers. Counterbore holes, on the other hand, are. Spotfaces position the parts accurately and spread the loads.

From www.youtube.com

Counter boring and spot facing YouTube Counterbore And Spotface though a spotface and a counterbore are very similar, a spotface only provides a flat mounting surface, where a counterbore provides a. Counterbore holes, on the other hand, are. a spotface hole or shallow counterbore is a hole in a workpiece. It creates a flat surface for mounting bolt heads and washers. While their core purpose is the. Counterbore And Spotface.

From www.theengineeringknowledge.com

What is Countersink vs. Counterbore Holes in Machining The Counterbore And Spotface While their core purpose is the same: spotfaces provide a flat, accurately located surface, which is essential for fasteners to sit flush with the workpiece’s surface. spotface and counterbore are essential machining features that contribute significantly to manufacturing complex assemblies, ensuring the secure and precise connection between mating parts. Spotfaces position the parts accurately and spread the loads.. Counterbore And Spotface.

From ar.inspiredpencil.com

Spot Face Vs Counterbore Counterbore And Spotface unlike counterbore holes, spotface holes do not have a larger diameter than the hole they surround. a spotface hole or shallow counterbore is a hole in a workpiece. Spotfaces position the parts accurately and spread the loads. spotfaces provide a flat, accurately located surface, which is essential for fasteners to sit flush with the workpiece’s surface. Instead,. Counterbore And Spotface.

From www.madearia.com

Spotface Vs. Counterbore in Machining Parts Counterbore And Spotface Counterbore holes, on the other hand, are. Instead, they are designed to clean up and flatten the surface around the hole, ensuring proper alignment and contact with mating components. While their core purpose is the same: Spotfaces position the parts accurately and spread the loads. unlike counterbore holes, spotface holes do not have a larger diameter than the hole. Counterbore And Spotface.

From www.chegg.com

ó ☺ ☺ ☺ DRILLED HOLE (BLIND) COUNTERBORE SPOTFACE Counterbore And Spotface Spotfaces position the parts accurately and spread the loads. While their core purpose is the same: a spotface hole or shallow counterbore is a hole in a workpiece. It creates a flat surface for mounting bolt heads and washers. spotface and counterbore are essential machining features that contribute significantly to manufacturing complex assemblies, ensuring the secure and precise. Counterbore And Spotface.

From ar.inspiredpencil.com

Spot Face Vs Counterbore Counterbore And Spotface It creates a flat surface for mounting bolt heads and washers. Understanding the difference between these holes in machining is crucial to carefully selecting the right hole that meets the specific requirements of your. though a spotface and a counterbore are very similar, a spotface only provides a flat mounting surface, where a counterbore provides a. Counterbore holes, on. Counterbore And Spotface.

From www.slideserve.com

PPT Chapter 10 cont. PowerPoint Presentation, free download ID1984589 Counterbore And Spotface spotface and counterbore are essential machining features that contribute significantly to manufacturing complex assemblies, ensuring the secure and precise connection between mating parts. unlike counterbore holes, spotface holes do not have a larger diameter than the hole they surround. Spotfaces position the parts accurately and spread the loads. Instead, they are designed to clean up and flatten the. Counterbore And Spotface.

From ar.inspiredpencil.com

Spot Face Vs Counterbore Counterbore And Spotface Instead, they are designed to clean up and flatten the surface around the hole, ensuring proper alignment and contact with mating components. spotface and counterbore are essential machining features that contribute significantly to manufacturing complex assemblies, ensuring the secure and precise connection between mating parts. Understanding the difference between these holes in machining is crucial to carefully selecting the. Counterbore And Spotface.

From ar.inspiredpencil.com

Spot Face Vs Counterbore Counterbore And Spotface spotfaces provide a flat, accurately located surface, which is essential for fasteners to sit flush with the workpiece’s surface. Spotfaces position the parts accurately and spread the loads. Accommodating fastener heads, some of their subtle differences professionals often cause professionals to confuse them with each other. It creates a flat surface for mounting bolt heads and washers. unlike. Counterbore And Spotface.

From www.finepowertools.com

Counterbore vs Countersink. Differences, Strength & Uses Counterbore And Spotface Spotfaces position the parts accurately and spread the loads. though a spotface and a counterbore are very similar, a spotface only provides a flat mounting surface, where a counterbore provides a. unlike counterbore holes, spotface holes do not have a larger diameter than the hole they surround. It creates a flat surface for mounting bolt heads and washers.. Counterbore And Spotface.

From www.mscdirect.com

Reverse Counterbores (Spot Facers) Counterbore And Spotface Accommodating fastener heads, some of their subtle differences professionals often cause professionals to confuse them with each other. unlike counterbore holes, spotface holes do not have a larger diameter than the hole they surround. Instead, they are designed to clean up and flatten the surface around the hole, ensuring proper alignment and contact with mating components. While their core. Counterbore And Spotface.

From thecontentauthority.com

Counterbore vs Spotface Decoding Common Word MixUps Counterbore And Spotface Counterbore holes, on the other hand, are. spotfaces provide a flat, accurately located surface, which is essential for fasteners to sit flush with the workpiece’s surface. Accommodating fastener heads, some of their subtle differences professionals often cause professionals to confuse them with each other. Instead, they are designed to clean up and flatten the surface around the hole, ensuring. Counterbore And Spotface.

From maindifference.net

Counterbore vs. Spotface What's the Difference? Main Difference Counterbore And Spotface unlike counterbore holes, spotface holes do not have a larger diameter than the hole they surround. spotface and counterbore are essential machining features that contribute significantly to manufacturing complex assemblies, ensuring the secure and precise connection between mating parts. Counterbore holes, on the other hand, are. Accommodating fastener heads, some of their subtle differences professionals often cause professionals. Counterbore And Spotface.

From www.jurassictools.com

SKF Dormer G120 3/8 spot face cutter 1/4 pilot HSS 4 fluted counterbore Counterbore And Spotface Instead, they are designed to clean up and flatten the surface around the hole, ensuring proper alignment and contact with mating components. spotfaces provide a flat, accurately located surface, which is essential for fasteners to sit flush with the workpiece’s surface. spotface and counterbore are essential machining features that contribute significantly to manufacturing complex assemblies, ensuring the secure. Counterbore And Spotface.

From www.cnccookbook.com

Ultimate Guide to Spotface vs Counterbore CNCCookbook Be A Better CNC'er Counterbore And Spotface Instead, they are designed to clean up and flatten the surface around the hole, ensuring proper alignment and contact with mating components. While their core purpose is the same: Counterbore holes, on the other hand, are. though a spotface and a counterbore are very similar, a spotface only provides a flat mounting surface, where a counterbore provides a. . Counterbore And Spotface.

From www.wisc-online.com

Spotface Example OER Counterbore And Spotface spotface and counterbore are essential machining features that contribute significantly to manufacturing complex assemblies, ensuring the secure and precise connection between mating parts. It creates a flat surface for mounting bolt heads and washers. While their core purpose is the same: spotfaces provide a flat, accurately located surface, which is essential for fasteners to sit flush with the. Counterbore And Spotface.

From www.jurassictools.com

Clarkson 33mm spot face cutter 21mm pilot for M20 capheads HSS 2 fluted Counterbore And Spotface though a spotface and a counterbore are very similar, a spotface only provides a flat mounting surface, where a counterbore provides a. unlike counterbore holes, spotface holes do not have a larger diameter than the hole they surround. spotface and counterbore are essential machining features that contribute significantly to manufacturing complex assemblies, ensuring the secure and precise. Counterbore And Spotface.

From www.madearia.com

Spotface Vs. Counterbore in Machining Parts Counterbore And Spotface spotfaces provide a flat, accurately located surface, which is essential for fasteners to sit flush with the workpiece’s surface. spotface and counterbore are essential machining features that contribute significantly to manufacturing complex assemblies, ensuring the secure and precise connection between mating parts. While their core purpose is the same: Instead, they are designed to clean up and flatten. Counterbore And Spotface.

From chansmachining.com

Spotface vs. Counterbore Holes in Machining What’re The Differences Counterbore And Spotface Spotfaces position the parts accurately and spread the loads. spotface and counterbore are essential machining features that contribute significantly to manufacturing complex assemblies, ensuring the secure and precise connection between mating parts. Understanding the difference between these holes in machining is crucial to carefully selecting the right hole that meets the specific requirements of your. unlike counterbore holes,. Counterbore And Spotface.

From www.slideserve.com

PPT Holes PowerPoint Presentation, free download ID2107959 Counterbore And Spotface Spotfaces position the parts accurately and spread the loads. spotfaces provide a flat, accurately located surface, which is essential for fasteners to sit flush with the workpiece’s surface. spotface and counterbore are essential machining features that contribute significantly to manufacturing complex assemblies, ensuring the secure and precise connection between mating parts. Instead, they are designed to clean up. Counterbore And Spotface.

From www.madearia.com

Spotface Vs. Counterbore in Machining Parts Counterbore And Spotface Spotfaces position the parts accurately and spread the loads. Understanding the difference between these holes in machining is crucial to carefully selecting the right hole that meets the specific requirements of your. While their core purpose is the same: unlike counterbore holes, spotface holes do not have a larger diameter than the hole they surround. Accommodating fastener heads, some. Counterbore And Spotface.

From slidetodoc.com

Basic Machine Processes Competency D 403 00 Identify Counterbore And Spotface a spotface hole or shallow counterbore is a hole in a workpiece. Spotfaces position the parts accurately and spread the loads. Counterbore holes, on the other hand, are. It creates a flat surface for mounting bolt heads and washers. spotfaces provide a flat, accurately located surface, which is essential for fasteners to sit flush with the workpiece’s surface.. Counterbore And Spotface.

From lomas.co.uk

Spotface / Counterbores Lomas Engineering Cutting Tools Counterbore And Spotface Counterbore holes, on the other hand, are. a spotface hole or shallow counterbore is a hole in a workpiece. While their core purpose is the same: Understanding the difference between these holes in machining is crucial to carefully selecting the right hole that meets the specific requirements of your. Instead, they are designed to clean up and flatten the. Counterbore And Spotface.

From at-machining.com

Spotface Vs. Counterbore Holes in Machining Exploring Their Counterbore And Spotface though a spotface and a counterbore are very similar, a spotface only provides a flat mounting surface, where a counterbore provides a. Instead, they are designed to clean up and flatten the surface around the hole, ensuring proper alignment and contact with mating components. Accommodating fastener heads, some of their subtle differences professionals often cause professionals to confuse them. Counterbore And Spotface.

From www.thehandymansdaughter.com

Countersink vs Counterbore The Handyman's Daughter Counterbore And Spotface Accommodating fastener heads, some of their subtle differences professionals often cause professionals to confuse them with each other. spotface and counterbore are essential machining features that contribute significantly to manufacturing complex assemblies, ensuring the secure and precise connection between mating parts. It creates a flat surface for mounting bolt heads and washers. Counterbore holes, on the other hand, are.. Counterbore And Spotface.

From ar.inspiredpencil.com

Standard Countersink Hole Counterbore And Spotface spotface and counterbore are essential machining features that contribute significantly to manufacturing complex assemblies, ensuring the secure and precise connection between mating parts. Spotfaces position the parts accurately and spread the loads. Accommodating fastener heads, some of their subtle differences professionals often cause professionals to confuse them with each other. While their core purpose is the same: Counterbore holes,. Counterbore And Spotface.

From www.thehandymansdaughter.com

Countersink vs Counterbore The Handyman's Daughter Counterbore And Spotface Counterbore holes, on the other hand, are. Instead, they are designed to clean up and flatten the surface around the hole, ensuring proper alignment and contact with mating components. spotface and counterbore are essential machining features that contribute significantly to manufacturing complex assemblies, ensuring the secure and precise connection between mating parts. unlike counterbore holes, spotface holes do. Counterbore And Spotface.

From pcbprime.com

Countersink vs Counterbore for PCBs Counterbore And Spotface Counterbore holes, on the other hand, are. unlike counterbore holes, spotface holes do not have a larger diameter than the hole they surround. Spotfaces position the parts accurately and spread the loads. spotfaces provide a flat, accurately located surface, which is essential for fasteners to sit flush with the workpiece’s surface. though a spotface and a counterbore. Counterbore And Spotface.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Counterbore And Spotface spotface and counterbore are essential machining features that contribute significantly to manufacturing complex assemblies, ensuring the secure and precise connection between mating parts. It creates a flat surface for mounting bolt heads and washers. unlike counterbore holes, spotface holes do not have a larger diameter than the hole they surround. a spotface hole or shallow counterbore is. Counterbore And Spotface.

From chansmachining.com

Spotface vs. Counterbore Holes in Machining What’re The Differences Counterbore And Spotface spotfaces provide a flat, accurately located surface, which is essential for fasteners to sit flush with the workpiece’s surface. While their core purpose is the same: spotface and counterbore are essential machining features that contribute significantly to manufacturing complex assemblies, ensuring the secure and precise connection between mating parts. It creates a flat surface for mounting bolt heads. Counterbore And Spotface.

From www.machinistguides.com

Spotfaces All About Machinist Guides Counterbore And Spotface Understanding the difference between these holes in machining is crucial to carefully selecting the right hole that meets the specific requirements of your. It creates a flat surface for mounting bolt heads and washers. though a spotface and a counterbore are very similar, a spotface only provides a flat mounting surface, where a counterbore provides a. spotface and. Counterbore And Spotface.

From www.askdifference.com

Counterbore vs. Spotface — What’s the Difference? Counterbore And Spotface spotfaces provide a flat, accurately located surface, which is essential for fasteners to sit flush with the workpiece’s surface. a spotface hole or shallow counterbore is a hole in a workpiece. Instead, they are designed to clean up and flatten the surface around the hole, ensuring proper alignment and contact with mating components. Counterbore holes, on the other. Counterbore And Spotface.

From www.famictech.com

WhatsNew8 Professional Edition Automation Studio™ Counterbore And Spotface a spotface hole or shallow counterbore is a hole in a workpiece. Accommodating fastener heads, some of their subtle differences professionals often cause professionals to confuse them with each other. Counterbore holes, on the other hand, are. spotface and counterbore are essential machining features that contribute significantly to manufacturing complex assemblies, ensuring the secure and precise connection between. Counterbore And Spotface.

From ar.inspiredpencil.com

Spot Face Vs Counterbore Counterbore And Spotface Accommodating fastener heads, some of their subtle differences professionals often cause professionals to confuse them with each other. though a spotface and a counterbore are very similar, a spotface only provides a flat mounting surface, where a counterbore provides a. spotfaces provide a flat, accurately located surface, which is essential for fasteners to sit flush with the workpiece’s. Counterbore And Spotface.

From www.differencebetween.net

Difference Between Counterbore and Countersink Difference Between Counterbore And Spotface unlike counterbore holes, spotface holes do not have a larger diameter than the hole they surround. While their core purpose is the same: spotfaces provide a flat, accurately located surface, which is essential for fasteners to sit flush with the workpiece’s surface. Accommodating fastener heads, some of their subtle differences professionals often cause professionals to confuse them with. Counterbore And Spotface.