Vacuum Metallizing In Mandarin . Vacuum metalizing, also called vacuum metallization, is a process that allows creating a metallic layer on metalized parts or a. The vacuum metalizing process is a precise and controlled method of depositing a thin layer of metal onto a substrate. Can be used on glass, plastic, metal, ceramic, and paper. We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide high quality metallic finishes. Designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates; This results in a uniformly coated, shiny, and reflective finish. Instead of using traditional methods where the coating material is applied in liquid form, vacuum metalizing evaporates the metal, allowing it to condense on the desired surface. Metallizing is still the most dominant process in packaging. This chapter focuses on vacuum metallizing used in flexible packages.

from www.nakai-group.com

This results in a uniformly coated, shiny, and reflective finish. This chapter focuses on vacuum metallizing used in flexible packages. Can be used on glass, plastic, metal, ceramic, and paper. Metallizing is still the most dominant process in packaging. Vacuum metalizing, also called vacuum metallization, is a process that allows creating a metallic layer on metalized parts or a. Instead of using traditional methods where the coating material is applied in liquid form, vacuum metalizing evaporates the metal, allowing it to condense on the desired surface. Designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates; We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide high quality metallic finishes. The vacuum metalizing process is a precise and controlled method of depositing a thin layer of metal onto a substrate.

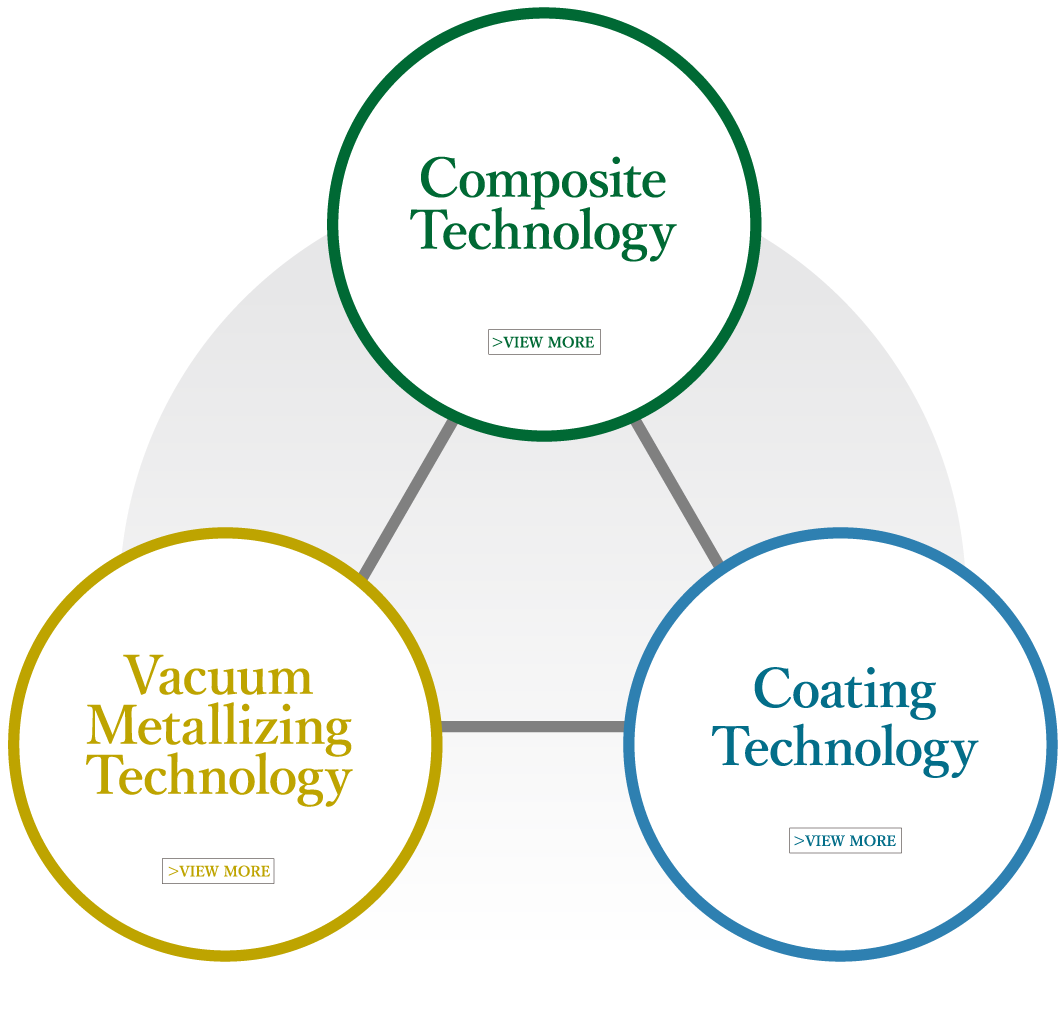

Technical Information 中井工業株式会社

Vacuum Metallizing In Mandarin We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide high quality metallic finishes. This results in a uniformly coated, shiny, and reflective finish. This chapter focuses on vacuum metallizing used in flexible packages. We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide high quality metallic finishes. Instead of using traditional methods where the coating material is applied in liquid form, vacuum metalizing evaporates the metal, allowing it to condense on the desired surface. The vacuum metalizing process is a precise and controlled method of depositing a thin layer of metal onto a substrate. Vacuum metalizing, also called vacuum metallization, is a process that allows creating a metallic layer on metalized parts or a. Metallizing is still the most dominant process in packaging. Designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates; Can be used on glass, plastic, metal, ceramic, and paper.

From dir.indiamart.com

Vacuum Metallizing Services, Vacuum Metallizing in India Vacuum Metallizing In Mandarin Instead of using traditional methods where the coating material is applied in liquid form, vacuum metalizing evaporates the metal, allowing it to condense on the desired surface. This results in a uniformly coated, shiny, and reflective finish. We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide high quality metallic finishes. Metallizing is. Vacuum Metallizing In Mandarin.

From www.indiamart.com

Vacuum Metallizing Plant, Vacuum Metallising Plants Karol Bagh, New Vacuum Metallizing In Mandarin We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide high quality metallic finishes. Can be used on glass, plastic, metal, ceramic, and paper. Designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates; Vacuum metalizing, also called vacuum metallization, is a process that allows creating a. Vacuum Metallizing In Mandarin.

From ccvacuum.en.made-in-china.com

Vacuum Metallizing Plant/UV Vacuum Metalizing Coating China Automatic Vacuum Metallizing In Mandarin Vacuum metalizing, also called vacuum metallization, is a process that allows creating a metallic layer on metalized parts or a. Designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates; Metallizing is still the most dominant process in packaging. The vacuum metalizing process is a precise and controlled method of depositing a thin layer. Vacuum Metallizing In Mandarin.

From www.youtube.com

Vacuum Metallizing YouTube Vacuum Metallizing In Mandarin We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide high quality metallic finishes. Can be used on glass, plastic, metal, ceramic, and paper. Metallizing is still the most dominant process in packaging. Designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates; This results in a. Vacuum Metallizing In Mandarin.

From www.directindustry.com

Vacuum metallizing system NordMet 1216 NORDMECCANICA Vacuum Metallizing In Mandarin The vacuum metalizing process is a precise and controlled method of depositing a thin layer of metal onto a substrate. Vacuum metalizing, also called vacuum metallization, is a process that allows creating a metallic layer on metalized parts or a. We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide high quality metallic. Vacuum Metallizing In Mandarin.

From www.royal-source.com

High Vacuum Metallizing Machine, Portable PVD vacuum Metallizer Vacuum Metallizing In Mandarin Metallizing is still the most dominant process in packaging. This chapter focuses on vacuum metallizing used in flexible packages. Instead of using traditional methods where the coating material is applied in liquid form, vacuum metalizing evaporates the metal, allowing it to condense on the desired surface. This results in a uniformly coated, shiny, and reflective finish. Designed to handle a. Vacuum Metallizing In Mandarin.

From dir.indiamart.com

Vacuum Metallizing Services, Vacuum Metallizing in India Vacuum Metallizing In Mandarin Vacuum metalizing, also called vacuum metallization, is a process that allows creating a metallic layer on metalized parts or a. Designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates; The vacuum metalizing process is a precise and controlled method of depositing a thin layer of metal onto a substrate. We specialise in using. Vacuum Metallizing In Mandarin.

From zzkingdon.en.made-in-china.com

Vacuum Evaporation & Metallizing/Vacuum Metallizing Consumables Vacuum Metallizing In Mandarin Metallizing is still the most dominant process in packaging. Designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates; The vacuum metalizing process is a precise and controlled method of depositing a thin layer of metal onto a substrate. Can be used on glass, plastic, metal, ceramic, and paper. Instead of using traditional methods. Vacuum Metallizing In Mandarin.

From www.plasteam.tw

Vacuum Metalizing Processing Machine Plasteam Taiwan Vacuum Metallizing In Mandarin Can be used on glass, plastic, metal, ceramic, and paper. The vacuum metalizing process is a precise and controlled method of depositing a thin layer of metal onto a substrate. This results in a uniformly coated, shiny, and reflective finish. This chapter focuses on vacuum metallizing used in flexible packages. Instead of using traditional methods where the coating material is. Vacuum Metallizing In Mandarin.

From ar.inspiredpencil.com

Vacuum Metallizing Process Vacuum Metallizing In Mandarin Metallizing is still the most dominant process in packaging. Can be used on glass, plastic, metal, ceramic, and paper. This results in a uniformly coated, shiny, and reflective finish. We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide high quality metallic finishes. The vacuum metalizing process is a precise and controlled method. Vacuum Metallizing In Mandarin.

From dir.indiamart.com

Vacuum Metallizing Services in India Vacuum Metallizing In Mandarin Instead of using traditional methods where the coating material is applied in liquid form, vacuum metalizing evaporates the metal, allowing it to condense on the desired surface. Designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates; We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide. Vacuum Metallizing In Mandarin.

From dir.indiamart.com

Vacuum Metallizer at Best Price in India Vacuum Metallizing In Mandarin The vacuum metalizing process is a precise and controlled method of depositing a thin layer of metal onto a substrate. Can be used on glass, plastic, metal, ceramic, and paper. Designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates; Metallizing is still the most dominant process in packaging. Instead of using traditional methods. Vacuum Metallizing In Mandarin.

From www.royal-source.com

Aluminum Vacuum Metallizing Equipment, High Reflection Film Deposition Vacuum Metallizing In Mandarin This results in a uniformly coated, shiny, and reflective finish. Can be used on glass, plastic, metal, ceramic, and paper. Metallizing is still the most dominant process in packaging. This chapter focuses on vacuum metallizing used in flexible packages. The vacuum metalizing process is a precise and controlled method of depositing a thin layer of metal onto a substrate. We. Vacuum Metallizing In Mandarin.

From www.madearia.com

Vacuum Forming Process, Materials & Benefit Aria Manufacturing Limited Vacuum Metallizing In Mandarin Vacuum metalizing, also called vacuum metallization, is a process that allows creating a metallic layer on metalized parts or a. Can be used on glass, plastic, metal, ceramic, and paper. This chapter focuses on vacuum metallizing used in flexible packages. We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide high quality metallic. Vacuum Metallizing In Mandarin.

From jainelectroplast.com

Vacuum Metalizing on Plastics Vacuum Metallizing In Mandarin We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide high quality metallic finishes. Instead of using traditional methods where the coating material is applied in liquid form, vacuum metalizing evaporates the metal, allowing it to condense on the desired surface. This chapter focuses on vacuum metallizing used in flexible packages. Metallizing is. Vacuum Metallizing In Mandarin.

From dir.indiamart.com

Vacuum Metallizing Services, Vacuum Metallizing in India Vacuum Metallizing In Mandarin This results in a uniformly coated, shiny, and reflective finish. Vacuum metalizing, also called vacuum metallization, is a process that allows creating a metallic layer on metalized parts or a. Instead of using traditional methods where the coating material is applied in liquid form, vacuum metalizing evaporates the metal, allowing it to condense on the desired surface. The vacuum metalizing. Vacuum Metallizing In Mandarin.

From www.imexbb.com

Vacuum Metallizing Machine maquina de metalizado al vacío Vacuum Metallizing In Mandarin We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide high quality metallic finishes. Vacuum metalizing, also called vacuum metallization, is a process that allows creating a metallic layer on metalized parts or a. Can be used on glass, plastic, metal, ceramic, and paper. Designed to handle a variety of film types including. Vacuum Metallizing In Mandarin.

From dir.indiamart.com

Vacuum Metallizing Plant at Best Price in India Vacuum Metallizing In Mandarin Vacuum metalizing, also called vacuum metallization, is a process that allows creating a metallic layer on metalized parts or a. We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide high quality metallic finishes. The vacuum metalizing process is a precise and controlled method of depositing a thin layer of metal onto a. Vacuum Metallizing In Mandarin.

From regalfinishing.com

Vacuum Metallizing Vacuum Metallizing In Mandarin This chapter focuses on vacuum metallizing used in flexible packages. Designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates; Vacuum metalizing, also called vacuum metallization, is a process that allows creating a metallic layer on metalized parts or a. We specialise in using a process known as vacuum metalising or physical vapour deposition. Vacuum Metallizing In Mandarin.

From medium.com

Benefits of Vacuum Metalizing. The process of forming a uniform layer Vacuum Metallizing In Mandarin This chapter focuses on vacuum metallizing used in flexible packages. Metallizing is still the most dominant process in packaging. We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide high quality metallic finishes. Can be used on glass, plastic, metal, ceramic, and paper. The vacuum metalizing process is a precise and controlled method. Vacuum Metallizing In Mandarin.

From www.alibaba.com

Vacuum Metallizing Machine Plating Film Aluminum Coating Machine Buy Vacuum Metallizing In Mandarin The vacuum metalizing process is a precise and controlled method of depositing a thin layer of metal onto a substrate. We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide high quality metallic finishes. Instead of using traditional methods where the coating material is applied in liquid form, vacuum metalizing evaporates the metal,. Vacuum Metallizing In Mandarin.

From www.directindustry.com

Vacuum metallizing system KUTH Kushal Udhyog Vacuum Metallizing In Mandarin Metallizing is still the most dominant process in packaging. The vacuum metalizing process is a precise and controlled method of depositing a thin layer of metal onto a substrate. Designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates; Vacuum metalizing, also called vacuum metallization, is a process that allows creating a metallic layer. Vacuum Metallizing In Mandarin.

From www.vp-packaging.com

What is vacuum metallized film Bruce Dou Vacuum Metallizing In Mandarin This results in a uniformly coated, shiny, and reflective finish. Can be used on glass, plastic, metal, ceramic, and paper. This chapter focuses on vacuum metallizing used in flexible packages. Designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates; Metallizing is still the most dominant process in packaging. Instead of using traditional methods. Vacuum Metallizing In Mandarin.

From www.youtube.com

Vacuum Metallizing Process Step 5 Vacuum Aluminum Evaporation YouTube Vacuum Metallizing In Mandarin We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide high quality metallic finishes. Designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates; This chapter focuses on vacuum metallizing used in flexible packages. Vacuum metalizing, also called vacuum metallization, is a process that allows creating a. Vacuum Metallizing In Mandarin.

From www.youtube.com

Loading New Pieces For Metallizing In A Vacuum Coating Plant YouTube Vacuum Metallizing In Mandarin Metallizing is still the most dominant process in packaging. This chapter focuses on vacuum metallizing used in flexible packages. Can be used on glass, plastic, metal, ceramic, and paper. We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide high quality metallic finishes. Instead of using traditional methods where the coating material is. Vacuum Metallizing In Mandarin.

From richeng-vacuum.en.made-in-china.com

MultiArc Ion and Sputtering Vacuum Coating System for Vacuum Metallizing In Mandarin Can be used on glass, plastic, metal, ceramic, and paper. The vacuum metalizing process is a precise and controlled method of depositing a thin layer of metal onto a substrate. We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide high quality metallic finishes. Metallizing is still the most dominant process in packaging.. Vacuum Metallizing In Mandarin.

From www.deepcoat.com

Common Vacuum Metalizing Materials Deep Coat Industries Vacuum Metallizing In Mandarin Vacuum metalizing, also called vacuum metallization, is a process that allows creating a metallic layer on metalized parts or a. This chapter focuses on vacuum metallizing used in flexible packages. The vacuum metalizing process is a precise and controlled method of depositing a thin layer of metal onto a substrate. Instead of using traditional methods where the coating material is. Vacuum Metallizing In Mandarin.

From lytongchang.en.made-in-china.com

Vacuum Metallizing Stranded Tungsten Filament Wire China Stranded Vacuum Metallizing In Mandarin Metallizing is still the most dominant process in packaging. This results in a uniformly coated, shiny, and reflective finish. This chapter focuses on vacuum metallizing used in flexible packages. Designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates; Instead of using traditional methods where the coating material is applied in liquid form, vacuum. Vacuum Metallizing In Mandarin.

From www.nakai-group.com

Technical Information 中井工業株式会社 Vacuum Metallizing In Mandarin Instead of using traditional methods where the coating material is applied in liquid form, vacuum metalizing evaporates the metal, allowing it to condense on the desired surface. We specialise in using a process known as vacuum metalising or physical vapour deposition (pvd) to provide high quality metallic finishes. Can be used on glass, plastic, metal, ceramic, and paper. Designed to. Vacuum Metallizing In Mandarin.

From www.vp-packaging.com

What is vacuum metallized film Bruce Dou Vacuum Metallizing In Mandarin Vacuum metalizing, also called vacuum metallization, is a process that allows creating a metallic layer on metalized parts or a. Designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates; Metallizing is still the most dominant process in packaging. The vacuum metalizing process is a precise and controlled method of depositing a thin layer. Vacuum Metallizing In Mandarin.

From dg-wenhao.en.made-in-china.com

Aluminum Vacuum Metallizing Equipment China Coating Machine and Parts Vacuum Metallizing In Mandarin Instead of using traditional methods where the coating material is applied in liquid form, vacuum metalizing evaporates the metal, allowing it to condense on the desired surface. Can be used on glass, plastic, metal, ceramic, and paper. Metallizing is still the most dominant process in packaging. This chapter focuses on vacuum metallizing used in flexible packages. Vacuum metalizing, also called. Vacuum Metallizing In Mandarin.

From www.sharrettsplating.com

Comparing Electroplating to Vacuum Metallizing Vacuum Metallizing In Mandarin Designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates; Metallizing is still the most dominant process in packaging. This results in a uniformly coated, shiny, and reflective finish. Vacuum metalizing, also called vacuum metallization, is a process that allows creating a metallic layer on metalized parts or a. Instead of using traditional methods. Vacuum Metallizing In Mandarin.

From www.tennmax.com

Innovations in Vacuum Metallization for EMI Shielding — TennMax Vacuum Metallizing In Mandarin Can be used on glass, plastic, metal, ceramic, and paper. Vacuum metalizing, also called vacuum metallization, is a process that allows creating a metallic layer on metalized parts or a. Instead of using traditional methods where the coating material is applied in liquid form, vacuum metalizing evaporates the metal, allowing it to condense on the desired surface. Designed to handle. Vacuum Metallizing In Mandarin.

From dlx-alloy.en.made-in-china.com

Tungsten Rhenium Thermocouple Wire 5/26 Type C for Evaporator in The Vacuum Metallizing In Mandarin Can be used on glass, plastic, metal, ceramic, and paper. Instead of using traditional methods where the coating material is applied in liquid form, vacuum metalizing evaporates the metal, allowing it to condense on the desired surface. Designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates; This chapter focuses on vacuum metallizing used. Vacuum Metallizing In Mandarin.

From jainelectroplast.com

Vacuum Metalizing on Plastics Vacuum Metallizing In Mandarin Instead of using traditional methods where the coating material is applied in liquid form, vacuum metalizing evaporates the metal, allowing it to condense on the desired surface. Metallizing is still the most dominant process in packaging. Vacuum metalizing, also called vacuum metallization, is a process that allows creating a metallic layer on metalized parts or a. Can be used on. Vacuum Metallizing In Mandarin.