Tool Standardization Procedure . Without standards, there can be no improvement. Identification and understanding of the concept for the. Lean management practitioners know what a powerful tool standardization is for continuously improving processes. Key components of effective process standardization. The benefits of standardized work include documentation of. Planning stage or conceptualization of the tool. This paper describes possible approaches to process standardization procedures using the example of a project. How well a part meets the specified tolerances is a function of cnc machine tool accuracy. This guide describes the recommendations for defining standards for software development tools and processes. In this article we will discuss the selected tool and standardization. While the design and construction of a machine tool is determined by its ability to hold tolerances, all cnc machine tools are subject to

from www.sketchbubble.com

This paper describes possible approaches to process standardization procedures using the example of a project. This guide describes the recommendations for defining standards for software development tools and processes. Planning stage or conceptualization of the tool. Key components of effective process standardization. In this article we will discuss the selected tool and standardization. The benefits of standardized work include documentation of. How well a part meets the specified tolerances is a function of cnc machine tool accuracy. Identification and understanding of the concept for the. Lean management practitioners know what a powerful tool standardization is for continuously improving processes. While the design and construction of a machine tool is determined by its ability to hold tolerances, all cnc machine tools are subject to

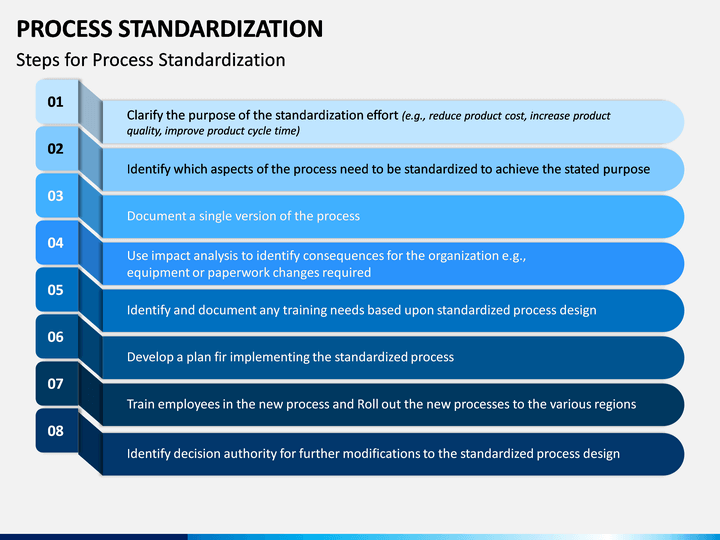

Process Standardization PowerPoint and Google Slides Template PPT Slides

Tool Standardization Procedure This guide describes the recommendations for defining standards for software development tools and processes. Identification and understanding of the concept for the. While the design and construction of a machine tool is determined by its ability to hold tolerances, all cnc machine tools are subject to This guide describes the recommendations for defining standards for software development tools and processes. Planning stage or conceptualization of the tool. In this article we will discuss the selected tool and standardization. How well a part meets the specified tolerances is a function of cnc machine tool accuracy. Key components of effective process standardization. Lean management practitioners know what a powerful tool standardization is for continuously improving processes. This paper describes possible approaches to process standardization procedures using the example of a project. The benefits of standardized work include documentation of. Without standards, there can be no improvement.

From www.animalia-life.club

Standardization Tool Standardization Procedure Planning stage or conceptualization of the tool. While the design and construction of a machine tool is determined by its ability to hold tolerances, all cnc machine tools are subject to Lean management practitioners know what a powerful tool standardization is for continuously improving processes. This guide describes the recommendations for defining standards for software development tools and processes. Without. Tool Standardization Procedure.

From www.suntecdata.com

How To Leverage Data Standardization For Enhanced Business Insights Tool Standardization Procedure While the design and construction of a machine tool is determined by its ability to hold tolerances, all cnc machine tools are subject to Planning stage or conceptualization of the tool. Key components of effective process standardization. Identification and understanding of the concept for the. Without standards, there can be no improvement. The benefits of standardized work include documentation of.. Tool Standardization Procedure.

From cimatri.com

A through Z of IT Standard Operating Procedures [Template] Cimatri Tool Standardization Procedure In this article we will discuss the selected tool and standardization. The benefits of standardized work include documentation of. How well a part meets the specified tolerances is a function of cnc machine tool accuracy. Lean management practitioners know what a powerful tool standardization is for continuously improving processes. This paper describes possible approaches to process standardization procedures using the. Tool Standardization Procedure.

From www.exactbuyer.com

Data Standardization Tool Comparison Choose the Best Data Tool Standardization Procedure While the design and construction of a machine tool is determined by its ability to hold tolerances, all cnc machine tools are subject to The benefits of standardized work include documentation of. How well a part meets the specified tolerances is a function of cnc machine tool accuracy. In this article we will discuss the selected tool and standardization. This. Tool Standardization Procedure.

From www.youtube.com

Standardization of Psychological Tests YouTube Tool Standardization Procedure Without standards, there can be no improvement. Planning stage or conceptualization of the tool. Lean management practitioners know what a powerful tool standardization is for continuously improving processes. The benefits of standardized work include documentation of. This paper describes possible approaches to process standardization procedures using the example of a project. This guide describes the recommendations for defining standards for. Tool Standardization Procedure.

From www.semanticscholar.org

Figure 1 from Developing a Procedure Model for Business Process Tool Standardization Procedure How well a part meets the specified tolerances is a function of cnc machine tool accuracy. Lean management practitioners know what a powerful tool standardization is for continuously improving processes. Identification and understanding of the concept for the. While the design and construction of a machine tool is determined by its ability to hold tolerances, all cnc machine tools are. Tool Standardization Procedure.

From www.researchgate.net

(PDF) Age Standardization Procedure Direct Method Tool Standardization Procedure How well a part meets the specified tolerances is a function of cnc machine tool accuracy. This guide describes the recommendations for defining standards for software development tools and processes. Planning stage or conceptualization of the tool. Identification and understanding of the concept for the. This paper describes possible approaches to process standardization procedures using the example of a project.. Tool Standardization Procedure.

From www.suntecdata.com

How To Leverage Data Standardization For Enhanced Business Insights Tool Standardization Procedure While the design and construction of a machine tool is determined by its ability to hold tolerances, all cnc machine tools are subject to Without standards, there can be no improvement. This guide describes the recommendations for defining standards for software development tools and processes. The benefits of standardized work include documentation of. Identification and understanding of the concept for. Tool Standardization Procedure.

From www.animalia-life.club

Standardization Tool Standardization Procedure The benefits of standardized work include documentation of. Identification and understanding of the concept for the. This paper describes possible approaches to process standardization procedures using the example of a project. This guide describes the recommendations for defining standards for software development tools and processes. Without standards, there can be no improvement. While the design and construction of a machine. Tool Standardization Procedure.

From blog.paperturn.com

A Beginner’s Guide to Process Standardization — Paperturn Blog Tool Standardization Procedure In this article we will discuss the selected tool and standardization. The benefits of standardized work include documentation of. Planning stage or conceptualization of the tool. How well a part meets the specified tolerances is a function of cnc machine tool accuracy. Identification and understanding of the concept for the. This paper describes possible approaches to process standardization procedures using. Tool Standardization Procedure.

From www.manifest.ly

Process Standardization A Complete Guide Tool Standardization Procedure Key components of effective process standardization. Lean management practitioners know what a powerful tool standardization is for continuously improving processes. The benefits of standardized work include documentation of. While the design and construction of a machine tool is determined by its ability to hold tolerances, all cnc machine tools are subject to Identification and understanding of the concept for the.. Tool Standardization Procedure.

From nhasachquocte.com

Mua Sách Process Mapping and Process Improvement Standardization Tool Standardization Procedure In this article we will discuss the selected tool and standardization. Planning stage or conceptualization of the tool. This guide describes the recommendations for defining standards for software development tools and processes. This paper describes possible approaches to process standardization procedures using the example of a project. Lean management practitioners know what a powerful tool standardization is for continuously improving. Tool Standardization Procedure.

From www.slideserve.com

PPT International Standardization for QMS PowerPoint Presentation Tool Standardization Procedure In this article we will discuss the selected tool and standardization. Without standards, there can be no improvement. This guide describes the recommendations for defining standards for software development tools and processes. The benefits of standardized work include documentation of. This paper describes possible approaches to process standardization procedures using the example of a project. Key components of effective process. Tool Standardization Procedure.

From www.slideteam.net

Organizational Process Standardization Procedure Model Presentation Tool Standardization Procedure Lean management practitioners know what a powerful tool standardization is for continuously improving processes. Key components of effective process standardization. This paper describes possible approaches to process standardization procedures using the example of a project. In this article we will discuss the selected tool and standardization. This guide describes the recommendations for defining standards for software development tools and processes.. Tool Standardization Procedure.

From www.inprolink.com

The Role of Standardization in Continuous Improvement Intact Prolink Tool Standardization Procedure Identification and understanding of the concept for the. This paper describes possible approaches to process standardization procedures using the example of a project. Planning stage or conceptualization of the tool. This guide describes the recommendations for defining standards for software development tools and processes. Lean management practitioners know what a powerful tool standardization is for continuously improving processes. In this. Tool Standardization Procedure.

From www.predictiveanalyticstoday.com

Guidelines for Preparing Standard Operating Procedures in 2022 Tool Standardization Procedure Key components of effective process standardization. The benefits of standardized work include documentation of. This guide describes the recommendations for defining standards for software development tools and processes. How well a part meets the specified tolerances is a function of cnc machine tool accuracy. Planning stage or conceptualization of the tool. This paper describes possible approaches to process standardization procedures. Tool Standardization Procedure.

From www.sweetprocess.com

Process Standardization (Definition, Types, Examples, and Tips) Tool Standardization Procedure While the design and construction of a machine tool is determined by its ability to hold tolerances, all cnc machine tools are subject to This paper describes possible approaches to process standardization procedures using the example of a project. The benefits of standardized work include documentation of. How well a part meets the specified tolerances is a function of cnc. Tool Standardization Procedure.

From www.sketchbubble.com

Process Standardization PowerPoint and Google Slides Template PPT Slides Tool Standardization Procedure This guide describes the recommendations for defining standards for software development tools and processes. Without standards, there can be no improvement. This paper describes possible approaches to process standardization procedures using the example of a project. How well a part meets the specified tolerances is a function of cnc machine tool accuracy. While the design and construction of a machine. Tool Standardization Procedure.

From www.quality-assurance-solutions.com

5s Implementation in the Office Tool Standardization Procedure In this article we will discuss the selected tool and standardization. This paper describes possible approaches to process standardization procedures using the example of a project. This guide describes the recommendations for defining standards for software development tools and processes. Without standards, there can be no improvement. While the design and construction of a machine tool is determined by its. Tool Standardization Procedure.

From www2.mdpi.com

Information Free FullText Standardization Procedure for Data Exchange Tool Standardization Procedure Lean management practitioners know what a powerful tool standardization is for continuously improving processes. The benefits of standardized work include documentation of. Key components of effective process standardization. This guide describes the recommendations for defining standards for software development tools and processes. Identification and understanding of the concept for the. This paper describes possible approaches to process standardization procedures using. Tool Standardization Procedure.

From www.bytesroute.com

The Business Process Standardization Definition Tool Standardization Procedure Planning stage or conceptualization of the tool. Identification and understanding of the concept for the. The benefits of standardized work include documentation of. Lean management practitioners know what a powerful tool standardization is for continuously improving processes. How well a part meets the specified tolerances is a function of cnc machine tool accuracy. This guide describes the recommendations for defining. Tool Standardization Procedure.

From www.youtube.com

HRIS a monitoring and standardization tool YouTube Tool Standardization Procedure Without standards, there can be no improvement. Key components of effective process standardization. Planning stage or conceptualization of the tool. While the design and construction of a machine tool is determined by its ability to hold tolerances, all cnc machine tools are subject to Identification and understanding of the concept for the. How well a part meets the specified tolerances. Tool Standardization Procedure.

From www.sketchbubble.com

Process Standardization PowerPoint and Google Slides Template PPT Slides Tool Standardization Procedure Lean management practitioners know what a powerful tool standardization is for continuously improving processes. Without standards, there can be no improvement. While the design and construction of a machine tool is determined by its ability to hold tolerances, all cnc machine tools are subject to In this article we will discuss the selected tool and standardization. This guide describes the. Tool Standardization Procedure.

From www.youtube.com

Construction of Research Tool and Standardization Procedure YouTube Tool Standardization Procedure How well a part meets the specified tolerances is a function of cnc machine tool accuracy. Planning stage or conceptualization of the tool. The benefits of standardized work include documentation of. In this article we will discuss the selected tool and standardization. Without standards, there can be no improvement. Lean management practitioners know what a powerful tool standardization is for. Tool Standardization Procedure.

From www.sexizpix.com

Standard Operating Procedure Template Word Business Form Letter Tool Standardization Procedure Planning stage or conceptualization of the tool. This paper describes possible approaches to process standardization procedures using the example of a project. This guide describes the recommendations for defining standards for software development tools and processes. Without standards, there can be no improvement. Identification and understanding of the concept for the. How well a part meets the specified tolerances is. Tool Standardization Procedure.

From www.scribd.com

Marker Standardization Procedure PDF Salary Employment Tool Standardization Procedure How well a part meets the specified tolerances is a function of cnc machine tool accuracy. Without standards, there can be no improvement. Lean management practitioners know what a powerful tool standardization is for continuously improving processes. This paper describes possible approaches to process standardization procedures using the example of a project. Planning stage or conceptualization of the tool. The. Tool Standardization Procedure.

From www.manifest.ly

Process Standardization A Complete Guide Tool Standardization Procedure Identification and understanding of the concept for the. This paper describes possible approaches to process standardization procedures using the example of a project. How well a part meets the specified tolerances is a function of cnc machine tool accuracy. Key components of effective process standardization. This guide describes the recommendations for defining standards for software development tools and processes. Without. Tool Standardization Procedure.

From winpro.com.sg

Improve Lack Of Standardization In IT Policy And Procedure Tool Standardization Procedure Key components of effective process standardization. Identification and understanding of the concept for the. This guide describes the recommendations for defining standards for software development tools and processes. Lean management practitioners know what a powerful tool standardization is for continuously improving processes. In this article we will discuss the selected tool and standardization. The benefits of standardized work include documentation. Tool Standardization Procedure.

From www.slideteam.net

Organizational Activities And Process Standardization Presentation Tool Standardization Procedure Without standards, there can be no improvement. Lean management practitioners know what a powerful tool standardization is for continuously improving processes. Planning stage or conceptualization of the tool. This paper describes possible approaches to process standardization procedures using the example of a project. In this article we will discuss the selected tool and standardization. Key components of effective process standardization.. Tool Standardization Procedure.

From www.youtube.com

What is Standardization? Definition, Process, Areas of Tool Standardization Procedure This guide describes the recommendations for defining standards for software development tools and processes. In this article we will discuss the selected tool and standardization. This paper describes possible approaches to process standardization procedures using the example of a project. While the design and construction of a machine tool is determined by its ability to hold tolerances, all cnc machine. Tool Standardization Procedure.

From www.researchgate.net

(PDF) STANDARDIZATION AS TOOL TO ENHANCE EDUCATIONAL ACCREDITATION Tool Standardization Procedure Planning stage or conceptualization of the tool. Key components of effective process standardization. In this article we will discuss the selected tool and standardization. Identification and understanding of the concept for the. The benefits of standardized work include documentation of. Lean management practitioners know what a powerful tool standardization is for continuously improving processes. While the design and construction of. Tool Standardization Procedure.

From www.semanticscholar.org

Figure 1 from A Process Standardization Approach to Enhance Design Tool Standardization Procedure How well a part meets the specified tolerances is a function of cnc machine tool accuracy. In this article we will discuss the selected tool and standardization. Lean management practitioners know what a powerful tool standardization is for continuously improving processes. This guide describes the recommendations for defining standards for software development tools and processes. Without standards, there can be. Tool Standardization Procedure.

From news.subharti.org

Online Guest Lecture on “Preparation of Research Tool and Tool Standardization Procedure This paper describes possible approaches to process standardization procedures using the example of a project. While the design and construction of a machine tool is determined by its ability to hold tolerances, all cnc machine tools are subject to Without standards, there can be no improvement. How well a part meets the specified tolerances is a function of cnc machine. Tool Standardization Procedure.

From www.arenasolutions.com

ISO (International Organization for Standardization) Definition Arena Tool Standardization Procedure Lean management practitioners know what a powerful tool standardization is for continuously improving processes. Planning stage or conceptualization of the tool. Without standards, there can be no improvement. Key components of effective process standardization. While the design and construction of a machine tool is determined by its ability to hold tolerances, all cnc machine tools are subject to This paper. Tool Standardization Procedure.

From greenprojectmanagement.org

ISO Standards in Action Tool Standardization Procedure In this article we will discuss the selected tool and standardization. Planning stage or conceptualization of the tool. How well a part meets the specified tolerances is a function of cnc machine tool accuracy. Lean management practitioners know what a powerful tool standardization is for continuously improving processes. Without standards, there can be no improvement. Identification and understanding of the. Tool Standardization Procedure.