Filter Fabric Manufacturing Process . The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments,. A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use, (b). Polypropylene filter fabrics can be used for both liquid and air filtration. They are commonly used in wastewater treatment plants, chemical processing plants ,. Proper selection of filter media/membrane material in filtration processes is often the most important consideration for. We are proud to manufacture the world’s best filter fabrics for demanding process conditions.

from www.slideshare.net

The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments,. Polypropylene filter fabrics can be used for both liquid and air filtration. A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use, (b). We are proud to manufacture the world’s best filter fabrics for demanding process conditions. They are commonly used in wastewater treatment plants, chemical processing plants ,. Proper selection of filter media/membrane material in filtration processes is often the most important consideration for.

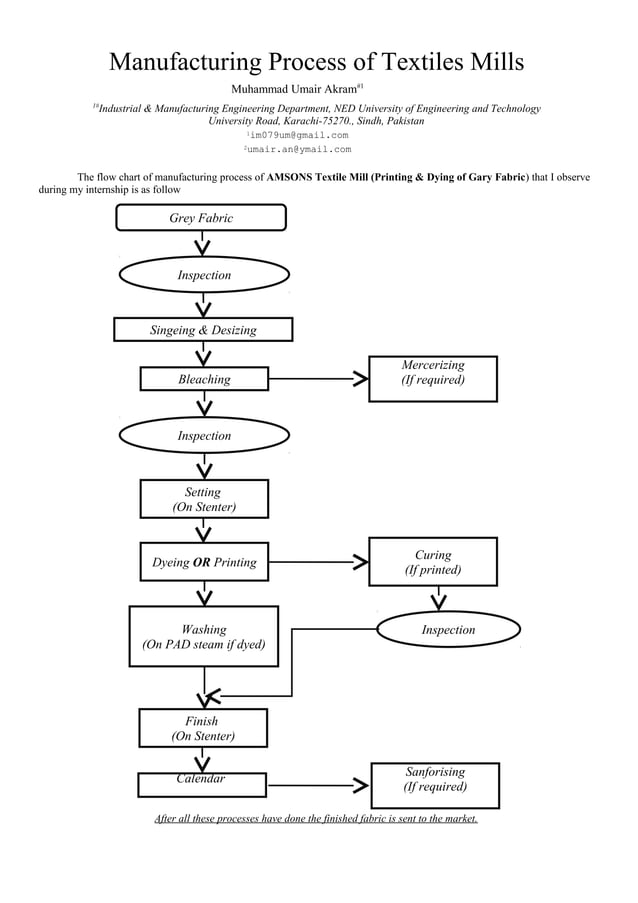

Manufacturing process of textile industries (Printing and dyeing

Filter Fabric Manufacturing Process Proper selection of filter media/membrane material in filtration processes is often the most important consideration for. We are proud to manufacture the world’s best filter fabrics for demanding process conditions. Proper selection of filter media/membrane material in filtration processes is often the most important consideration for. They are commonly used in wastewater treatment plants, chemical processing plants ,. The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments,. A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. Polypropylene filter fabrics can be used for both liquid and air filtration. Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use, (b).

From www.vrogue.co

Fabric Manufacturing Process Flow Chart vrogue.co Filter Fabric Manufacturing Process Proper selection of filter media/membrane material in filtration processes is often the most important consideration for. A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use, (b). They. Filter Fabric Manufacturing Process.

From www.slideshare.net

Manufacturing process of textile industries (Printing and dyeing Filter Fabric Manufacturing Process Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use, (b). Proper selection of filter media/membrane material in filtration processes is often the most important consideration for. The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments,. They are commonly used in wastewater treatment. Filter Fabric Manufacturing Process.

From www.textileproperty.com

Fabric Manufacturing Process Flow Chart A Comprehensive Look Filter Fabric Manufacturing Process Proper selection of filter media/membrane material in filtration processes is often the most important consideration for. A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. Polypropylene filter fabrics can be used for both liquid and air filtration. The melt blown process is a nonwoven manufacturing. Filter Fabric Manufacturing Process.

From www.slideserve.com

PPT Particulate Control2 Fabric Filters Particulate Scrubbers Filter Fabric Manufacturing Process A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. They are commonly used in wastewater treatment plants, chemical processing plants ,. Polypropylene filter fabrics can be used for both liquid and air filtration. We are proud to manufacture the world’s best filter fabrics for demanding. Filter Fabric Manufacturing Process.

From www.researchgate.net

Manufacturing process of nonwoven fabrics. Download Scientific Diagram Filter Fabric Manufacturing Process Proper selection of filter media/membrane material in filtration processes is often the most important consideration for. They are commonly used in wastewater treatment plants, chemical processing plants ,. A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. We are proud to manufacture the world’s best. Filter Fabric Manufacturing Process.

From www.edana.org

Nonwovens manufacturing process Filter Fabric Manufacturing Process Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use, (b). A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous. Filter Fabric Manufacturing Process.

From www.youtube.com

How it's made fabric Textile manufacturing process Best Video on Filter Fabric Manufacturing Process A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use, (b). The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous. Filter Fabric Manufacturing Process.

From www.acemechcorp.com

Meltblown Fabric Machine ACEMECH Machinery Filter Fabric Manufacturing Process They are commonly used in wastewater treatment plants, chemical processing plants ,. Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use, (b). We are proud to manufacture the world’s best filter fabrics for demanding process conditions. A wide range of fabrics for filtering a huge array of materials, for use across. Filter Fabric Manufacturing Process.

From www.slideserve.com

PPT FILTERATION OF FABRICS PowerPoint Presentation, free download Filter Fabric Manufacturing Process Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use, (b). They are commonly used in wastewater treatment plants, chemical processing plants ,. Proper selection of filter media/membrane material in filtration processes is often the most important consideration for. Polypropylene filter fabrics can be used for both liquid and air filtration. The. Filter Fabric Manufacturing Process.

From www.wingyuehk.com

Highperformance Fabric Manufacturing WingYue Filter Fabric Manufacturing Process Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use, (b). They are commonly used in wastewater treatment plants, chemical processing plants ,. The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments,. We are proud to manufacture the world’s best filter fabrics for. Filter Fabric Manufacturing Process.

From americanfabricfilter.com

Using Fabric Filters to Optimize Your Food and Beverage Processing Filter Fabric Manufacturing Process They are commonly used in wastewater treatment plants, chemical processing plants ,. A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use, (b). Polypropylene filter fabrics can be. Filter Fabric Manufacturing Process.

From www.slideserve.com

PPT FILTERATION OF FABRICS PowerPoint Presentation, free download Filter Fabric Manufacturing Process Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use, (b). Proper selection of filter media/membrane material in filtration processes is often the most important consideration for. They are commonly used in wastewater treatment plants, chemical processing plants ,. The melt blown process is a nonwoven manufacturing system involving direct conversion of. Filter Fabric Manufacturing Process.

From www.slideserve.com

PPT FILTERATION OF FABRICS PowerPoint Presentation, free download Filter Fabric Manufacturing Process They are commonly used in wastewater treatment plants, chemical processing plants ,. We are proud to manufacture the world’s best filter fabrics for demanding process conditions. The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments,. Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable. Filter Fabric Manufacturing Process.

From www.slideshare.net

Fabric filters Filter Fabric Manufacturing Process Polypropylene filter fabrics can be used for both liquid and air filtration. Proper selection of filter media/membrane material in filtration processes is often the most important consideration for. The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments,. Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain. Filter Fabric Manufacturing Process.

From www.textileandgarments.org

Brief Description of Fabric Manufacturing Process Filter Fabric Manufacturing Process We are proud to manufacture the world’s best filter fabrics for demanding process conditions. The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments,. Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use, (b). They are commonly used in wastewater treatment plants, chemical. Filter Fabric Manufacturing Process.

From www.slideserve.com

PPT Fabric Filters PowerPoint Presentation, free download ID2416656 Filter Fabric Manufacturing Process Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use, (b). A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. Proper selection of filter media/membrane material in filtration processes is often the most important consideration for. Polypropylene. Filter Fabric Manufacturing Process.

From www.pinterest.com

Flowchart of Fabric manufacturing process Flow chart, Bar chart, Chart Filter Fabric Manufacturing Process Proper selection of filter media/membrane material in filtration processes is often the most important consideration for. They are commonly used in wastewater treatment plants, chemical processing plants ,. A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. We are proud to manufacture the world’s best. Filter Fabric Manufacturing Process.

From www.slideserve.com

PPT FILTERATION OF FABRICS PowerPoint Presentation, free download Filter Fabric Manufacturing Process The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments,. Proper selection of filter media/membrane material in filtration processes is often the most important consideration for. They are commonly used in wastewater treatment plants, chemical processing plants ,. We are proud to manufacture the world’s best filter fabrics for demanding process conditions.. Filter Fabric Manufacturing Process.

From textiledetails.com

Complete 5 Textile Manufacturing Process In Details Textile Details Filter Fabric Manufacturing Process They are commonly used in wastewater treatment plants, chemical processing plants ,. The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments,. Polypropylene filter fabrics can be used for both liquid and air filtration. A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors,. Filter Fabric Manufacturing Process.

From www.youtube.com

NONWOVEN NEEDLE PUNCHING [FILTER FABRIC LINE ]PRODUCTION Filter Fabric Manufacturing Process Polypropylene filter fabrics can be used for both liquid and air filtration. They are commonly used in wastewater treatment plants, chemical processing plants ,. Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use, (b). Proper selection of filter media/membrane material in filtration processes is often the most important consideration for. The. Filter Fabric Manufacturing Process.

From www.textileproperty.com

Fabric Manufacturing Process Flow Chart A Comprehensive Look Filter Fabric Manufacturing Process A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments,. We are proud to manufacture the world’s best filter fabrics for demanding process conditions. They are commonly used. Filter Fabric Manufacturing Process.

From www.youtube.com

Fully Automatic Non Woven Fabric Production Line YouTube Filter Fabric Manufacturing Process The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments,. They are commonly used in wastewater treatment plants, chemical processing plants ,. A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. Polypropylene filter fabrics can be used. Filter Fabric Manufacturing Process.

From textiledetails.com

Complete 5 Textile Manufacturing Process In Details Textile Details Filter Fabric Manufacturing Process We are proud to manufacture the world’s best filter fabrics for demanding process conditions. Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use, (b). A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. Proper selection of. Filter Fabric Manufacturing Process.

From www.slideserve.com

PPT Particulate Control2 Fabric Filters Particulate Scrubbers Filter Fabric Manufacturing Process A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use, (b). The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous. Filter Fabric Manufacturing Process.

From textiletrainer.com

3 Easy Step of Nonwoven Fabric Manufacturing Process with Modern Filter Fabric Manufacturing Process They are commonly used in wastewater treatment plants, chemical processing plants ,. We are proud to manufacture the world’s best filter fabrics for demanding process conditions. Proper selection of filter media/membrane material in filtration processes is often the most important consideration for. A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors,. Filter Fabric Manufacturing Process.

From rattanfilters.com

Rattan Filters Products Filter Fabric Manufacturing Process A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. Proper selection of filter media/membrane material in filtration processes is often the most important consideration for. The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments,. Polypropylene filter. Filter Fabric Manufacturing Process.

From www.researchgate.net

Manufacturing process of nonwoven fabrics. Download Scientific Diagram Filter Fabric Manufacturing Process Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use, (b). A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. We are proud to manufacture the world’s best filter fabrics for demanding process conditions. Proper selection of. Filter Fabric Manufacturing Process.

From tapc.com.au

Fabric Filters Filter Fabric Manufacturing Process They are commonly used in wastewater treatment plants, chemical processing plants ,. The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments,. Polypropylene filter fabrics can be used for both liquid and air filtration. Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use,. Filter Fabric Manufacturing Process.

From www.slideserve.com

PPT Filter Fabric PowerPoint Presentation, free download ID1769906 Filter Fabric Manufacturing Process The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments,. They are commonly used in wastewater treatment plants, chemical processing plants ,. Polypropylene filter fabrics can be used for both liquid and air filtration. We are proud to manufacture the world’s best filter fabrics for demanding process conditions. Proper selection of filter. Filter Fabric Manufacturing Process.

From www.useon.com

Melt Blown Fabric Machine, Melt Blown Machine USEON Filter Fabric Manufacturing Process The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments,. A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. They are commonly used in wastewater treatment plants, chemical processing plants ,. Polypropylene filter fabrics can be used. Filter Fabric Manufacturing Process.

From www.linkedin.com

Fabric Manufacturing Process Step By Step Filter Fabric Manufacturing Process The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments,. A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. They are commonly used in wastewater treatment plants, chemical processing plants ,. Proper selection of filter media/membrane material. Filter Fabric Manufacturing Process.

From www.youtube.com

What is fabric in textile Fabric Manufacturing process flowchart Filter Fabric Manufacturing Process Polypropylene filter fabrics can be used for both liquid and air filtration. They are commonly used in wastewater treatment plants, chemical processing plants ,. We are proud to manufacture the world’s best filter fabrics for demanding process conditions. The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments,. Fabric finishing processes are. Filter Fabric Manufacturing Process.

From www.researchgate.net

Schematic process flow chart for making nettle fabric Download Filter Fabric Manufacturing Process We are proud to manufacture the world’s best filter fabrics for demanding process conditions. Polypropylene filter fabrics can be used for both liquid and air filtration. They are commonly used in wastewater treatment plants, chemical processing plants ,. A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector,. Filter Fabric Manufacturing Process.

From tapc.com.au

Fabric Filters Filter Fabric Manufacturing Process We are proud to manufacture the world’s best filter fabrics for demanding process conditions. Fabric finishing processes are designed essentially to ensure that the fabric will (a) remain dimensionally stable during use, (b). A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. They are commonly. Filter Fabric Manufacturing Process.

From emis.vito.be

Fabric filter EMIS Filter Fabric Manufacturing Process Proper selection of filter media/membrane material in filtration processes is often the most important consideration for. Polypropylene filter fabrics can be used for both liquid and air filtration. A wide range of fabrics for filtering a huge array of materials, for use across all industrial sectors, from the automotive sector, electronics and. The melt blown process is a nonwoven manufacturing. Filter Fabric Manufacturing Process.