Process Control Vs Process Capability . It measures a process's ability to meet. Cp assesses the process spread relative to tolerances, assuming the process is centered on the target. Cpk considers the spread and centering, determining the capability to meet specifications even if the process could be more perfectly centered. While the difference between cp and cpk is subtle, it’s crucial. Process capability uses the process sigma value determined from either the moving range, range, or sigma control charts. The comparison is made by forming the ratio of the spread between. Understanding process capability index (cpk) is crucial in statistical process control (spc). In other words, it is the ability of the process to meet the design. Process capability is defined as a statistical measure of the inherent process variability of a given characteristic. Pp and ppk are used. Process capability is a statistical measurement of a process’s ability to produce parts within specified limits consistently.

from www.youtube.com

While the difference between cp and cpk is subtle, it’s crucial. The comparison is made by forming the ratio of the spread between. Cp assesses the process spread relative to tolerances, assuming the process is centered on the target. It measures a process's ability to meet. Understanding process capability index (cpk) is crucial in statistical process control (spc). Process capability uses the process sigma value determined from either the moving range, range, or sigma control charts. In other words, it is the ability of the process to meet the design. Process capability is a statistical measurement of a process’s ability to produce parts within specified limits consistently. Process capability is defined as a statistical measure of the inherent process variability of a given characteristic. Pp and ppk are used.

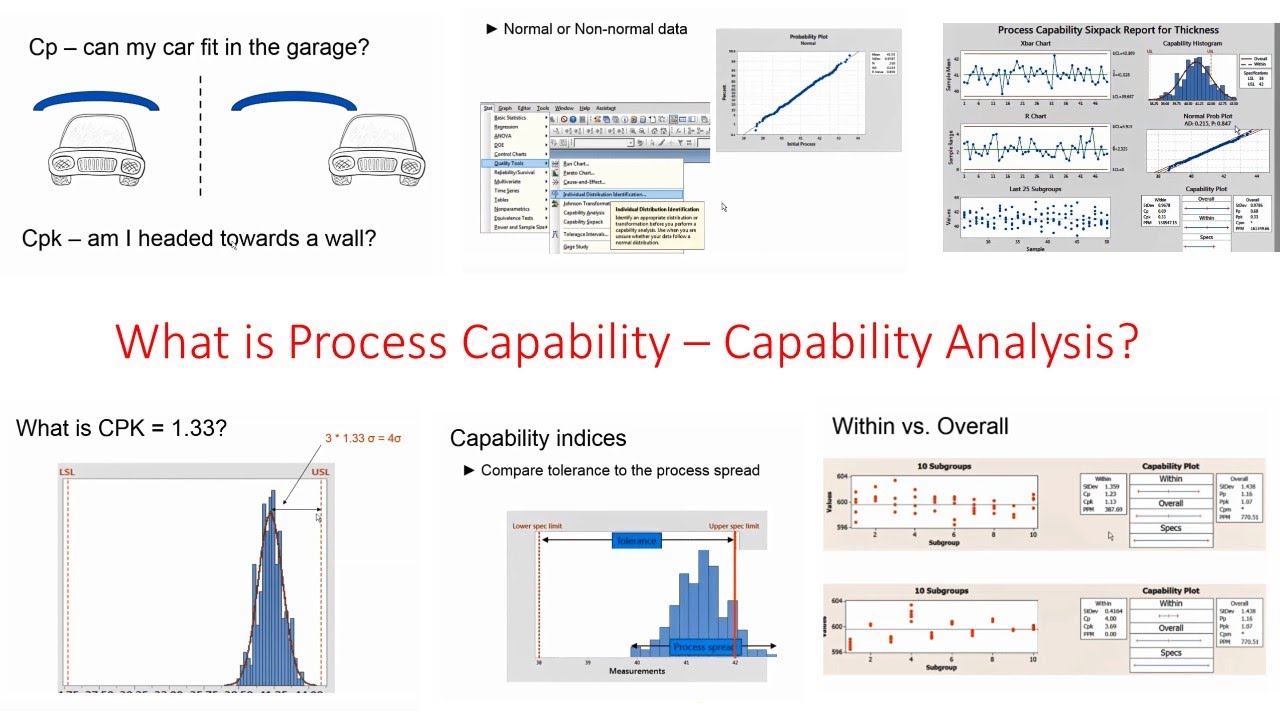

Process Capability, Capability indices, Cpk vs. Ppk, Capability Sixpack

Process Control Vs Process Capability Process capability uses the process sigma value determined from either the moving range, range, or sigma control charts. It measures a process's ability to meet. Understanding process capability index (cpk) is crucial in statistical process control (spc). Process capability is a statistical measurement of a process’s ability to produce parts within specified limits consistently. Pp and ppk are used. In other words, it is the ability of the process to meet the design. Cpk considers the spread and centering, determining the capability to meet specifications even if the process could be more perfectly centered. The comparison is made by forming the ratio of the spread between. While the difference between cp and cpk is subtle, it’s crucial. Process capability is defined as a statistical measure of the inherent process variability of a given characteristic. Cp assesses the process spread relative to tolerances, assuming the process is centered on the target. Process capability uses the process sigma value determined from either the moving range, range, or sigma control charts.

From gaselit.weebly.com

Process capability and process control gaselit Process Control Vs Process Capability Cp assesses the process spread relative to tolerances, assuming the process is centered on the target. It measures a process's ability to meet. In other words, it is the ability of the process to meet the design. While the difference between cp and cpk is subtle, it’s crucial. The comparison is made by forming the ratio of the spread between.. Process Control Vs Process Capability.

From www.diffzy.com

Process Capability vs. Machine Capability What's The Difference (With Process Control Vs Process Capability Cp assesses the process spread relative to tolerances, assuming the process is centered on the target. Process capability uses the process sigma value determined from either the moving range, range, or sigma control charts. Process capability is a statistical measurement of a process’s ability to produce parts within specified limits consistently. Process capability is defined as a statistical measure of. Process Control Vs Process Capability.

From www.sixleansigma.com

Six Sigma Measure 5 Perform Capability Analysis Process Control Vs Process Capability Pp and ppk are used. Process capability is a statistical measurement of a process’s ability to produce parts within specified limits consistently. Understanding process capability index (cpk) is crucial in statistical process control (spc). In other words, it is the ability of the process to meet the design. While the difference between cp and cpk is subtle, it’s crucial. Process. Process Control Vs Process Capability.

From www.quality-assurance-solutions.com

Understand Process Capability Process Control Vs Process Capability The comparison is made by forming the ratio of the spread between. Process capability is a statistical measurement of a process’s ability to produce parts within specified limits consistently. While the difference between cp and cpk is subtle, it’s crucial. Process capability is defined as a statistical measure of the inherent process variability of a given characteristic. Cpk considers the. Process Control Vs Process Capability.

From slideplayer.com

The Certified Quality Process Analyst Handbook Process Capability Process Control Vs Process Capability In other words, it is the ability of the process to meet the design. Cp assesses the process spread relative to tolerances, assuming the process is centered on the target. Process capability is a statistical measurement of a process’s ability to produce parts within specified limits consistently. Understanding process capability index (cpk) is crucial in statistical process control (spc). While. Process Control Vs Process Capability.

From nelofm.weebly.com

Process capability and process control nelofm Process Control Vs Process Capability Pp and ppk are used. Process capability is a statistical measurement of a process’s ability to produce parts within specified limits consistently. In other words, it is the ability of the process to meet the design. Cp assesses the process spread relative to tolerances, assuming the process is centered on the target. Understanding process capability index (cpk) is crucial in. Process Control Vs Process Capability.

From www.slideserve.com

PPT Chapter 8. Process Capability & Statistical Quality Control Process Control Vs Process Capability While the difference between cp and cpk is subtle, it’s crucial. Understanding process capability index (cpk) is crucial in statistical process control (spc). Process capability uses the process sigma value determined from either the moving range, range, or sigma control charts. Process capability is a statistical measurement of a process’s ability to produce parts within specified limits consistently. Cpk considers. Process Control Vs Process Capability.

From dokumen.tips

(PPT) 1 Process Capability Assessment. 2 Process Capability vs. Process Process Control Vs Process Capability In other words, it is the ability of the process to meet the design. Process capability is defined as a statistical measure of the inherent process variability of a given characteristic. It measures a process's ability to meet. Pp and ppk are used. Understanding process capability index (cpk) is crucial in statistical process control (spc). Cpk considers the spread and. Process Control Vs Process Capability.

From mavink.com

Process Capability Control Chart Process Control Vs Process Capability Understanding process capability index (cpk) is crucial in statistical process control (spc). Process capability is a statistical measurement of a process’s ability to produce parts within specified limits consistently. Pp and ppk are used. Cpk considers the spread and centering, determining the capability to meet specifications even if the process could be more perfectly centered. In other words, it is. Process Control Vs Process Capability.

From www.youtube.com

Process Capability, Capability indices, Cpk vs. Ppk, Capability Sixpack Process Control Vs Process Capability Process capability uses the process sigma value determined from either the moving range, range, or sigma control charts. Pp and ppk are used. While the difference between cp and cpk is subtle, it’s crucial. Process capability is defined as a statistical measure of the inherent process variability of a given characteristic. The comparison is made by forming the ratio of. Process Control Vs Process Capability.

From tech-publish-com.medium.com

Process Capability and its benefits by Mr. KP Medium Process Control Vs Process Capability Process capability uses the process sigma value determined from either the moving range, range, or sigma control charts. In other words, it is the ability of the process to meet the design. It measures a process's ability to meet. The comparison is made by forming the ratio of the spread between. Cpk considers the spread and centering, determining the capability. Process Control Vs Process Capability.

From inbodastx.weebly.com

Process capability and process control inbodastX Process Control Vs Process Capability Pp and ppk are used. Understanding process capability index (cpk) is crucial in statistical process control (spc). Process capability is defined as a statistical measure of the inherent process variability of a given characteristic. Process capability is a statistical measurement of a process’s ability to produce parts within specified limits consistently. The comparison is made by forming the ratio of. Process Control Vs Process Capability.

From accendoreliability.com

Relationship between Process Stability and Process Capability Process Control Vs Process Capability While the difference between cp and cpk is subtle, it’s crucial. Cp assesses the process spread relative to tolerances, assuming the process is centered on the target. The comparison is made by forming the ratio of the spread between. Pp and ppk are used. It measures a process's ability to meet. In other words, it is the ability of the. Process Control Vs Process Capability.

From www.slideserve.com

PPT Chapter 5 Quality PowerPoint Presentation, free download ID5716952 Process Control Vs Process Capability While the difference between cp and cpk is subtle, it’s crucial. In other words, it is the ability of the process to meet the design. Cpk considers the spread and centering, determining the capability to meet specifications even if the process could be more perfectly centered. It measures a process's ability to meet. Process capability uses the process sigma value. Process Control Vs Process Capability.

From irexmfg.com

iRex Process Capability Index Process Control Vs Process Capability Cp assesses the process spread relative to tolerances, assuming the process is centered on the target. Cpk considers the spread and centering, determining the capability to meet specifications even if the process could be more perfectly centered. Pp and ppk are used. Process capability is defined as a statistical measure of the inherent process variability of a given characteristic. It. Process Control Vs Process Capability.

From www.slideserve.com

PPT Process Capability Assessment PowerPoint Presentation, free Process Control Vs Process Capability Process capability is a statistical measurement of a process’s ability to produce parts within specified limits consistently. It measures a process's ability to meet. Understanding process capability index (cpk) is crucial in statistical process control (spc). Cp assesses the process spread relative to tolerances, assuming the process is centered on the target. Pp and ppk are used. Cpk considers the. Process Control Vs Process Capability.

From www.qualitygurus.com

Process Capability and Performance (Cp, Cpk, Pp, Ppk, Cpm) Quality Gurus Process Control Vs Process Capability It measures a process's ability to meet. Cpk considers the spread and centering, determining the capability to meet specifications even if the process could be more perfectly centered. While the difference between cp and cpk is subtle, it’s crucial. Process capability uses the process sigma value determined from either the moving range, range, or sigma control charts. Process capability is. Process Control Vs Process Capability.

From www.presentationeze.com

Process Capability What is Cp, Cpk, Pp, Ppk? PresentationEZE Process Control Vs Process Capability Cp assesses the process spread relative to tolerances, assuming the process is centered on the target. In other words, it is the ability of the process to meet the design. Cpk considers the spread and centering, determining the capability to meet specifications even if the process could be more perfectly centered. Process capability uses the process sigma value determined from. Process Control Vs Process Capability.

From www.slideserve.com

PPT Chapter 8. Process Capability & Statistical Quality Control Process Control Vs Process Capability Understanding process capability index (cpk) is crucial in statistical process control (spc). Process capability is a statistical measurement of a process’s ability to produce parts within specified limits consistently. Cpk considers the spread and centering, determining the capability to meet specifications even if the process could be more perfectly centered. Cp assesses the process spread relative to tolerances, assuming the. Process Control Vs Process Capability.

From www.youtube.com

Process Capability Analysis All Concepts Simplest Way To Learn Process Control Vs Process Capability It measures a process's ability to meet. While the difference between cp and cpk is subtle, it’s crucial. In other words, it is the ability of the process to meet the design. Understanding process capability index (cpk) is crucial in statistical process control (spc). Process capability is a statistical measurement of a process’s ability to produce parts within specified limits. Process Control Vs Process Capability.

From nelofm.weebly.com

Process capability and process control nelofm Process Control Vs Process Capability Understanding process capability index (cpk) is crucial in statistical process control (spc). Process capability is defined as a statistical measure of the inherent process variability of a given characteristic. Pp and ppk are used. Cp assesses the process spread relative to tolerances, assuming the process is centered on the target. Cpk considers the spread and centering, determining the capability to. Process Control Vs Process Capability.

From www.youtube.com

Process under Control and a Capable Process Process Control vs Process Control Vs Process Capability Understanding process capability index (cpk) is crucial in statistical process control (spc). While the difference between cp and cpk is subtle, it’s crucial. Process capability is a statistical measurement of a process’s ability to produce parts within specified limits consistently. The comparison is made by forming the ratio of the spread between. Cp assesses the process spread relative to tolerances,. Process Control Vs Process Capability.

From www.youtube.com

Lecture 12 Attribute Control Charts and Process Capability YouTube Process Control Vs Process Capability The comparison is made by forming the ratio of the spread between. It measures a process's ability to meet. Cpk considers the spread and centering, determining the capability to meet specifications even if the process could be more perfectly centered. While the difference between cp and cpk is subtle, it’s crucial. Pp and ppk are used. In other words, it. Process Control Vs Process Capability.

From www.slideserve.com

PPT Process Capability Assessment PowerPoint Presentation, free Process Control Vs Process Capability Process capability uses the process sigma value determined from either the moving range, range, or sigma control charts. Cpk considers the spread and centering, determining the capability to meet specifications even if the process could be more perfectly centered. Pp and ppk are used. Process capability is a statistical measurement of a process’s ability to produce parts within specified limits. Process Control Vs Process Capability.

From www.linkedin.com

Process vs Capability Process Control Vs Process Capability Cp assesses the process spread relative to tolerances, assuming the process is centered on the target. Cpk considers the spread and centering, determining the capability to meet specifications even if the process could be more perfectly centered. The comparison is made by forming the ratio of the spread between. Understanding process capability index (cpk) is crucial in statistical process control. Process Control Vs Process Capability.

From www.youtube.com

Process control, Process stability,Process capability YouTube Process Control Vs Process Capability It measures a process's ability to meet. Pp and ppk are used. Process capability is a statistical measurement of a process’s ability to produce parts within specified limits consistently. In other words, it is the ability of the process to meet the design. Process capability uses the process sigma value determined from either the moving range, range, or sigma control. Process Control Vs Process Capability.

From www.six-sigma-material.com

Process Capability Indices Process Control Vs Process Capability Cp assesses the process spread relative to tolerances, assuming the process is centered on the target. Pp and ppk are used. Process capability uses the process sigma value determined from either the moving range, range, or sigma control charts. While the difference between cp and cpk is subtle, it’s crucial. Process capability is defined as a statistical measure of the. Process Control Vs Process Capability.

From www.youtube.com

Process Capability (Cp, Cpk) Vs Process Performance (Pp, Ppk) YouTube Process Control Vs Process Capability In other words, it is the ability of the process to meet the design. Cp assesses the process spread relative to tolerances, assuming the process is centered on the target. Understanding process capability index (cpk) is crucial in statistical process control (spc). The comparison is made by forming the ratio of the spread between. Process capability uses the process sigma. Process Control Vs Process Capability.

From qidemy.com

What is Process Capability Analysis? Process Control Vs Process Capability Process capability uses the process sigma value determined from either the moving range, range, or sigma control charts. The comparison is made by forming the ratio of the spread between. Pp and ppk are used. Understanding process capability index (cpk) is crucial in statistical process control (spc). While the difference between cp and cpk is subtle, it’s crucial. Cpk considers. Process Control Vs Process Capability.

From gaselit.weebly.com

Process capability and process control gaselit Process Control Vs Process Capability It measures a process's ability to meet. Cpk considers the spread and centering, determining the capability to meet specifications even if the process could be more perfectly centered. Process capability is defined as a statistical measure of the inherent process variability of a given characteristic. Pp and ppk are used. Understanding process capability index (cpk) is crucial in statistical process. Process Control Vs Process Capability.

From www.slideserve.com

PPT Process Capability Assessment PowerPoint Presentation, free Process Control Vs Process Capability Process capability is a statistical measurement of a process’s ability to produce parts within specified limits consistently. Cp assesses the process spread relative to tolerances, assuming the process is centered on the target. Pp and ppk are used. While the difference between cp and cpk is subtle, it’s crucial. Process capability uses the process sigma value determined from either the. Process Control Vs Process Capability.

From insightdeal.in

Process Capability Insightdeal.in 2024 Process Control Vs Process Capability It measures a process's ability to meet. Process capability is defined as a statistical measure of the inherent process variability of a given characteristic. Process capability uses the process sigma value determined from either the moving range, range, or sigma control charts. Cp assesses the process spread relative to tolerances, assuming the process is centered on the target. Cpk considers. Process Control Vs Process Capability.

From horhalo.weebly.com

Process capability and process control horhalo Process Control Vs Process Capability Cp assesses the process spread relative to tolerances, assuming the process is centered on the target. It measures a process's ability to meet. Cpk considers the spread and centering, determining the capability to meet specifications even if the process could be more perfectly centered. Process capability is a statistical measurement of a process’s ability to produce parts within specified limits. Process Control Vs Process Capability.

From growthnatives.com

Process Performance vs. Process Capability Explained Process Control Vs Process Capability While the difference between cp and cpk is subtle, it’s crucial. Process capability is defined as a statistical measure of the inherent process variability of a given characteristic. It measures a process's ability to meet. Cp assesses the process spread relative to tolerances, assuming the process is centered on the target. Cpk considers the spread and centering, determining the capability. Process Control Vs Process Capability.

From www.presentationeze.com

Process Capability and Process Control PresentationEZE Process Control Vs Process Capability It measures a process's ability to meet. Process capability is a statistical measurement of a process’s ability to produce parts within specified limits consistently. Process capability is defined as a statistical measure of the inherent process variability of a given characteristic. While the difference between cp and cpk is subtle, it’s crucial. Cpk considers the spread and centering, determining the. Process Control Vs Process Capability.