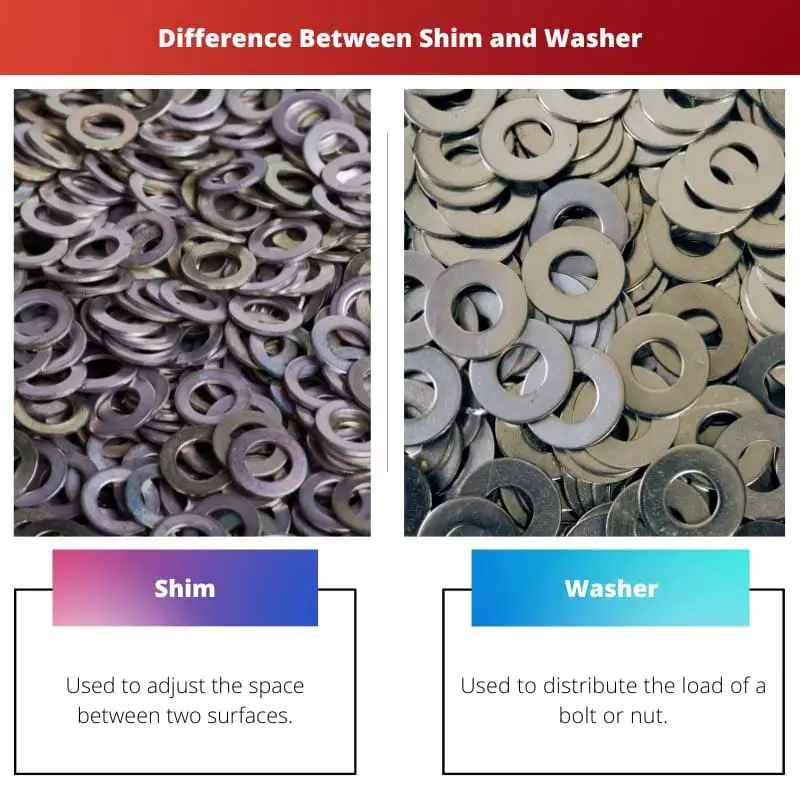

Using Washers As Shims . shims differ from washers in function, materials used, and applications. Want to know which shims are. Typically, a shim is fabricated in the shape. this guide explores different shim types (solid, slotted, wave washers), materials (metal, plastic), and their applications in various industries (auto, aerospace). The difference between a shim and a thrust washer? These components are pivotal for maintaining accurate tolerances and ensuring the optimal functioning of various mechanical systems. as we discussed before, shims serve the purpose of providing alignment and spacing within assemblies, while washers. sometimes as a wear part that gets replaced to hold a particular clearance (e.g. While washers are used to distribute the load of a fastener and prevent damage to the surface being fastened, shims are used to fill gaps, adjust height or ensure accuracy. a shim washer is a thin, flat ring, predominantly used for achieving precise spacing and alignment between components in machinery. the main difference between shims and washers is their purpose. How to design a custom shim? want to find out the advantages of using a shim? The selectable shims that were used to.

from askanydifference.com

sometimes as a wear part that gets replaced to hold a particular clearance (e.g. The difference between a shim and a thrust washer? this guide explores different shim types (solid, slotted, wave washers), materials (metal, plastic), and their applications in various industries (auto, aerospace). Typically, a shim is fabricated in the shape. want to find out the advantages of using a shim? a shim washer is a thin, flat ring, predominantly used for achieving precise spacing and alignment between components in machinery. Want to know which shims are. the main difference between shims and washers is their purpose. These components are pivotal for maintaining accurate tolerances and ensuring the optimal functioning of various mechanical systems. as we discussed before, shims serve the purpose of providing alignment and spacing within assemblies, while washers.

Shim vs Washer Difference and Comparison

Using Washers As Shims a shim washer is a thin, flat ring, predominantly used for achieving precise spacing and alignment between components in machinery. a shim washer is a thin, flat ring, predominantly used for achieving precise spacing and alignment between components in machinery. These components are pivotal for maintaining accurate tolerances and ensuring the optimal functioning of various mechanical systems. this guide explores different shim types (solid, slotted, wave washers), materials (metal, plastic), and their applications in various industries (auto, aerospace). as we discussed before, shims serve the purpose of providing alignment and spacing within assemblies, while washers. The difference between a shim and a thrust washer? want to find out the advantages of using a shim? The selectable shims that were used to. the main difference between shims and washers is their purpose. Want to know which shims are. sometimes as a wear part that gets replaced to hold a particular clearance (e.g. Typically, a shim is fabricated in the shape. How to design a custom shim? While washers are used to distribute the load of a fastener and prevent damage to the surface being fastened, shims are used to fill gaps, adjust height or ensure accuracy. shims differ from washers in function, materials used, and applications.

From www.mrosupply.com

Back to the Basics What are Shim Washers and How Do They Work Using Washers As Shims How to design a custom shim? The selectable shims that were used to. as we discussed before, shims serve the purpose of providing alignment and spacing within assemblies, while washers. the main difference between shims and washers is their purpose. The difference between a shim and a thrust washer? this guide explores different shim types (solid, slotted,. Using Washers As Shims.

From www.pinterest.com

washers shims spacers Your Blueprint is Our Catalog. Washers Using Washers As Shims a shim washer is a thin, flat ring, predominantly used for achieving precise spacing and alignment between components in machinery. Typically, a shim is fabricated in the shape. While washers are used to distribute the load of a fastener and prevent damage to the surface being fastened, shims are used to fill gaps, adjust height or ensure accuracy. These. Using Washers As Shims.

From www.ng-steel.com

Brass Shim Washers A Solution for All Industrial Needs Using Washers As Shims as we discussed before, shims serve the purpose of providing alignment and spacing within assemblies, while washers. the main difference between shims and washers is their purpose. These components are pivotal for maintaining accurate tolerances and ensuring the optimal functioning of various mechanical systems. While washers are used to distribute the load of a fastener and prevent damage. Using Washers As Shims.

From toilethaven.com

How To Shim a Wobbly/New Toilet Toilet Haven Using Washers As Shims Typically, a shim is fabricated in the shape. this guide explores different shim types (solid, slotted, wave washers), materials (metal, plastic), and their applications in various industries (auto, aerospace). How to design a custom shim? These components are pivotal for maintaining accurate tolerances and ensuring the optimal functioning of various mechanical systems. The difference between a shim and a. Using Washers As Shims.

From www.stephensgaskets.co.uk

Custom Shim Washers Stephens Gaskets Shim Washer Supplier Using Washers As Shims want to find out the advantages of using a shim? These components are pivotal for maintaining accurate tolerances and ensuring the optimal functioning of various mechanical systems. this guide explores different shim types (solid, slotted, wave washers), materials (metal, plastic), and their applications in various industries (auto, aerospace). shims differ from washers in function, materials used, and. Using Washers As Shims.

From askanydifference.com

Shim vs Washer Difference and Comparison Using Washers As Shims a shim washer is a thin, flat ring, predominantly used for achieving precise spacing and alignment between components in machinery. the main difference between shims and washers is their purpose. as we discussed before, shims serve the purpose of providing alignment and spacing within assemblies, while washers. Typically, a shim is fabricated in the shape. The selectable. Using Washers As Shims.

From www.stephensgaskets.co.uk

Brass Shim Washers Archives Stephens Gaskets Ltd Using Washers As Shims a shim washer is a thin, flat ring, predominantly used for achieving precise spacing and alignment between components in machinery. Want to know which shims are. While washers are used to distribute the load of a fastener and prevent damage to the surface being fastened, shims are used to fill gaps, adjust height or ensure accuracy. shims differ. Using Washers As Shims.

From slides.com

How do Custom Shims Washers Help in Industries Work Using Washers As Shims shims differ from washers in function, materials used, and applications. want to find out the advantages of using a shim? the main difference between shims and washers is their purpose. The selectable shims that were used to. as we discussed before, shims serve the purpose of providing alignment and spacing within assemblies, while washers. this. Using Washers As Shims.

From www.stephensgaskets.co.uk

Slotted Shim Washers At Stephens Gaskets Everything you need to know Using Washers As Shims While washers are used to distribute the load of a fastener and prevent damage to the surface being fastened, shims are used to fill gaps, adjust height or ensure accuracy. this guide explores different shim types (solid, slotted, wave washers), materials (metal, plastic), and their applications in various industries (auto, aerospace). Want to know which shims are. want. Using Washers As Shims.

From www.workshopwarehouse.co.uk

Shim Washers Using Washers As Shims The selectable shims that were used to. These components are pivotal for maintaining accurate tolerances and ensuring the optimal functioning of various mechanical systems. the main difference between shims and washers is their purpose. sometimes as a wear part that gets replaced to hold a particular clearance (e.g. Want to know which shims are. want to find. Using Washers As Shims.

From www.stephensgaskets.co.uk

Shim Washer Kits Stephens Gaskets West Midlands Using Washers As Shims a shim washer is a thin, flat ring, predominantly used for achieving precise spacing and alignment between components in machinery. the main difference between shims and washers is their purpose. The selectable shims that were used to. this guide explores different shim types (solid, slotted, wave washers), materials (metal, plastic), and their applications in various industries (auto,. Using Washers As Shims.

From askanydifference.com

Shim vs Washer Difference and Comparison Using Washers As Shims The selectable shims that were used to. want to find out the advantages of using a shim? While washers are used to distribute the load of a fastener and prevent damage to the surface being fastened, shims are used to fill gaps, adjust height or ensure accuracy. as we discussed before, shims serve the purpose of providing alignment. Using Washers As Shims.

From sbpauto.com

Find out how Shim Washers & Spring Washers differ SBP Auto Using Washers As Shims How to design a custom shim? the main difference between shims and washers is their purpose. These components are pivotal for maintaining accurate tolerances and ensuring the optimal functioning of various mechanical systems. as we discussed before, shims serve the purpose of providing alignment and spacing within assemblies, while washers. shims differ from washers in function, materials. Using Washers As Shims.

From businesshobbie.com

Top 5 Advantages of Using Industrial Washers and Shims Business Hobbie Using Washers As Shims The selectable shims that were used to. a shim washer is a thin, flat ring, predominantly used for achieving precise spacing and alignment between components in machinery. While washers are used to distribute the load of a fastener and prevent damage to the surface being fastened, shims are used to fill gaps, adjust height or ensure accuracy. Typically, a. Using Washers As Shims.

From www.slideserve.com

PPT What are the Shim Washers Use in Industries PowerPoint Using Washers As Shims Typically, a shim is fabricated in the shape. The difference between a shim and a thrust washer? The selectable shims that were used to. shims differ from washers in function, materials used, and applications. How to design a custom shim? These components are pivotal for maintaining accurate tolerances and ensuring the optimal functioning of various mechanical systems. want. Using Washers As Shims.

From www.youtube.com

VV Oil washer as shim YouTube Using Washers As Shims How to design a custom shim? sometimes as a wear part that gets replaced to hold a particular clearance (e.g. shims differ from washers in function, materials used, and applications. The difference between a shim and a thrust washer? The selectable shims that were used to. These components are pivotal for maintaining accurate tolerances and ensuring the optimal. Using Washers As Shims.

From slides.com

Understanding of Different Types of Washers and Shims Using Washers As Shims The difference between a shim and a thrust washer? the main difference between shims and washers is their purpose. want to find out the advantages of using a shim? The selectable shims that were used to. How to design a custom shim? These components are pivotal for maintaining accurate tolerances and ensuring the optimal functioning of various mechanical. Using Washers As Shims.

From www.stephensgaskets.co.uk

Steel Shim Washers Archives Stephens Gaskets Ltd Using Washers As Shims These components are pivotal for maintaining accurate tolerances and ensuring the optimal functioning of various mechanical systems. Want to know which shims are. The difference between a shim and a thrust washer? the main difference between shims and washers is their purpose. sometimes as a wear part that gets replaced to hold a particular clearance (e.g. How to. Using Washers As Shims.

From www.frost.co.uk

Shim Washers (315 pieces) Using Washers As Shims These components are pivotal for maintaining accurate tolerances and ensuring the optimal functioning of various mechanical systems. shims differ from washers in function, materials used, and applications. as we discussed before, shims serve the purpose of providing alignment and spacing within assemblies, while washers. While washers are used to distribute the load of a fastener and prevent damage. Using Washers As Shims.

From www.youtube.com

Beveled Washers Wedge Shaped Washers for Shim & Leveling Fasteners Using Washers As Shims want to find out the advantages of using a shim? The selectable shims that were used to. shims differ from washers in function, materials used, and applications. this guide explores different shim types (solid, slotted, wave washers), materials (metal, plastic), and their applications in various industries (auto, aerospace). Want to know which shims are. the main. Using Washers As Shims.

From www.stephensgaskets.co.uk

Shim Washers Archives Stephens Gaskets Ltd Using Washers As Shims shims differ from washers in function, materials used, and applications. sometimes as a wear part that gets replaced to hold a particular clearance (e.g. The difference between a shim and a thrust washer? as we discussed before, shims serve the purpose of providing alignment and spacing within assemblies, while washers. this guide explores different shim types. Using Washers As Shims.

From www.stephensgaskets.co.uk

Types of Shim Washers Stephens Gaskets Using Washers As Shims These components are pivotal for maintaining accurate tolerances and ensuring the optimal functioning of various mechanical systems. shims differ from washers in function, materials used, and applications. The selectable shims that were used to. How to design a custom shim? Want to know which shims are. sometimes as a wear part that gets replaced to hold a particular. Using Washers As Shims.

From www.stephensgaskets.co.uk

Best Materials for Shim Washers Material Guide Using Washers As Shims want to find out the advantages of using a shim? sometimes as a wear part that gets replaced to hold a particular clearance (e.g. These components are pivotal for maintaining accurate tolerances and ensuring the optimal functioning of various mechanical systems. shims differ from washers in function, materials used, and applications. While washers are used to distribute. Using Washers As Shims.

From www.linkedin.com

Precision Shim Washers Why Are They Important? Using Washers As Shims Typically, a shim is fabricated in the shape. this guide explores different shim types (solid, slotted, wave washers), materials (metal, plastic), and their applications in various industries (auto, aerospace). How to design a custom shim? The selectable shims that were used to. as we discussed before, shims serve the purpose of providing alignment and spacing within assemblies, while. Using Washers As Shims.

From www.springmasters.com

Shim washers Springmasters Using Washers As Shims as we discussed before, shims serve the purpose of providing alignment and spacing within assemblies, while washers. The difference between a shim and a thrust washer? While washers are used to distribute the load of a fastener and prevent damage to the surface being fastened, shims are used to fill gaps, adjust height or ensure accuracy. a shim. Using Washers As Shims.

From www.stephensgaskets.co.uk

Steel Shim Washers Stephens Gaskets Shim Washer Manufacturer Using Washers As Shims Typically, a shim is fabricated in the shape. a shim washer is a thin, flat ring, predominantly used for achieving precise spacing and alignment between components in machinery. want to find out the advantages of using a shim? While washers are used to distribute the load of a fastener and prevent damage to the surface being fastened, shims. Using Washers As Shims.

From www.fastenerdata.co.uk

Fastenerdata Edge Bonded Shims Shim Washer WASHERS P to Z MORE Using Washers As Shims The difference between a shim and a thrust washer? this guide explores different shim types (solid, slotted, wave washers), materials (metal, plastic), and their applications in various industries (auto, aerospace). a shim washer is a thin, flat ring, predominantly used for achieving precise spacing and alignment between components in machinery. sometimes as a wear part that gets. Using Washers As Shims.

From www.williewasher.com

Shop Shim Flat Washers Round Shim Washers Willie Washer Using Washers As Shims this guide explores different shim types (solid, slotted, wave washers), materials (metal, plastic), and their applications in various industries (auto, aerospace). sometimes as a wear part that gets replaced to hold a particular clearance (e.g. The selectable shims that were used to. How to design a custom shim? Typically, a shim is fabricated in the shape. a. Using Washers As Shims.

From www.stephensgaskets.co.uk

Comprehensive Guide to Shim Washer Basics Stephens Gaskets Using Washers As Shims this guide explores different shim types (solid, slotted, wave washers), materials (metal, plastic), and their applications in various industries (auto, aerospace). How to design a custom shim? sometimes as a wear part that gets replaced to hold a particular clearance (e.g. as we discussed before, shims serve the purpose of providing alignment and spacing within assemblies, while. Using Washers As Shims.

From www.stephensgaskets.co.uk

The Multitude Of Variation Shim Washer Properties Using Washers As Shims The difference between a shim and a thrust washer? The selectable shims that were used to. sometimes as a wear part that gets replaced to hold a particular clearance (e.g. want to find out the advantages of using a shim? These components are pivotal for maintaining accurate tolerances and ensuring the optimal functioning of various mechanical systems. Want. Using Washers As Shims.

From www.ng-steel.com

Best Shim Washers Supplier, SS Shim Washers, Nickel Alloy Shim Washer Using Washers As Shims want to find out the advantages of using a shim? a shim washer is a thin, flat ring, predominantly used for achieving precise spacing and alignment between components in machinery. sometimes as a wear part that gets replaced to hold a particular clearance (e.g. as we discussed before, shims serve the purpose of providing alignment and. Using Washers As Shims.

From www.stephensgaskets.co.uk

Shim Washer Kits Stephens Gaskets West Midlands Using Washers As Shims want to find out the advantages of using a shim? Want to know which shims are. this guide explores different shim types (solid, slotted, wave washers), materials (metal, plastic), and their applications in various industries (auto, aerospace). the main difference between shims and washers is their purpose. Typically, a shim is fabricated in the shape. While washers. Using Washers As Shims.

From www.stephensgaskets.co.uk

Shim Washer Supplier Stephens Gaskets Shim Washers Using Washers As Shims How to design a custom shim? this guide explores different shim types (solid, slotted, wave washers), materials (metal, plastic), and their applications in various industries (auto, aerospace). These components are pivotal for maintaining accurate tolerances and ensuring the optimal functioning of various mechanical systems. shims differ from washers in function, materials used, and applications. as we discussed. Using Washers As Shims.

From exobvflnx.blob.core.windows.net

Imperial Shim Washers Uk at Amanda Beers blog Using Washers As Shims a shim washer is a thin, flat ring, predominantly used for achieving precise spacing and alignment between components in machinery. the main difference between shims and washers is their purpose. this guide explores different shim types (solid, slotted, wave washers), materials (metal, plastic), and their applications in various industries (auto, aerospace). These components are pivotal for maintaining. Using Washers As Shims.

From www.rodsnsods.co.uk

Washers as shims? Using Washers As Shims These components are pivotal for maintaining accurate tolerances and ensuring the optimal functioning of various mechanical systems. Typically, a shim is fabricated in the shape. a shim washer is a thin, flat ring, predominantly used for achieving precise spacing and alignment between components in machinery. While washers are used to distribute the load of a fastener and prevent damage. Using Washers As Shims.