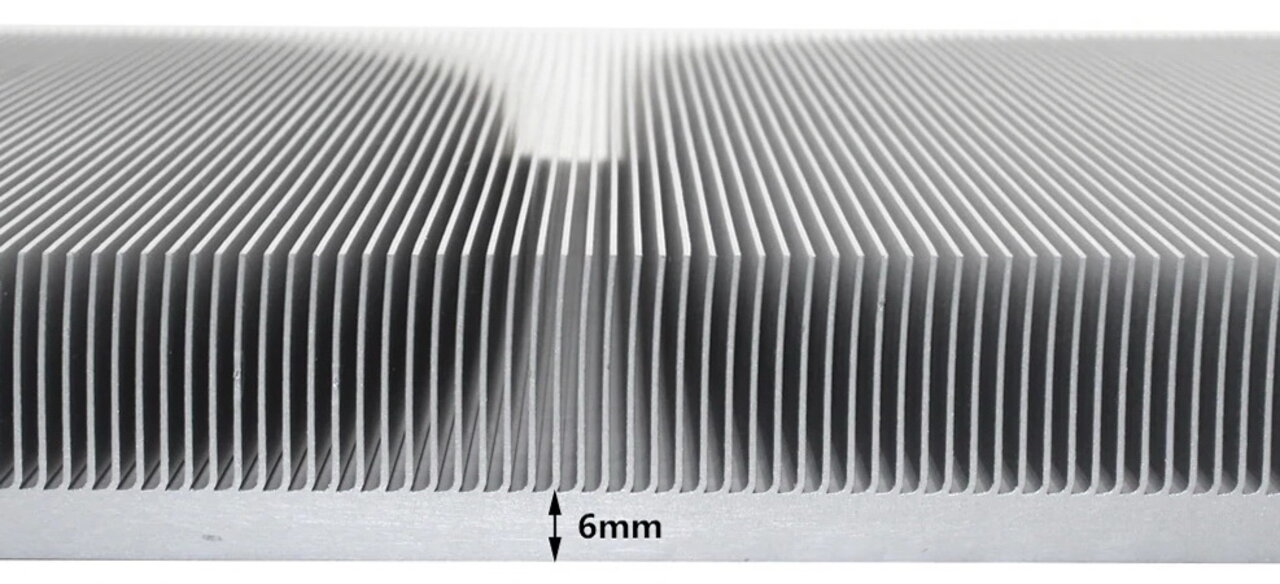

Heat Sink With Fins . Extrusion heat sinks & profiles for cost effective cooling solutions. The optimal heat sink location is on a hot spot, such as a powerful integrated circuit (ic) or a thermal spreader that collects heat from several sources. Extruding heat sinks enable the creation of shapes capable of. The image below demonstrates two mechanical heat sink types: Plate fins are flat, parallel fin structures that extend from a heat sink base, providing a large surface area for heat transfer. The fins on a heat sink are essential to the cooling medium, so having an accurate design and placement of the fins is critical. A pin (left) and a fin (right) type of heat sink. Pin fins are cylindrical or elongated protrusions that extend from a heat sink base, offering improved air circulation. Explore boyd's extensive heat sink selection, including board level, extruded aluminum, skived, folded, bonded, brazed, and zipper fin options. There are six dimensions that would need to be determined to design an appropriate heat sink for your needs. The fins on a heat sink are responsible for moving heat away from a component and into contact with air. Heat sinks are typically made of cnc machined aluminum or copper and have heat sink fins or pins that work to increase the surface area of the component, to facilitate the heat transfer to the surrounding fluid. Figure 1 shows a typical plate fin heat sink used to cool common electrical / electronic components such as leds used in lighting applications and mosfet used in digital circuits and microprocessors.

from www.finskiving.com

A pin (left) and a fin (right) type of heat sink. Plate fins are flat, parallel fin structures that extend from a heat sink base, providing a large surface area for heat transfer. The fins on a heat sink are essential to the cooling medium, so having an accurate design and placement of the fins is critical. The image below demonstrates two mechanical heat sink types: Explore boyd's extensive heat sink selection, including board level, extruded aluminum, skived, folded, bonded, brazed, and zipper fin options. The fins on a heat sink are responsible for moving heat away from a component and into contact with air. The optimal heat sink location is on a hot spot, such as a powerful integrated circuit (ic) or a thermal spreader that collects heat from several sources. Pin fins are cylindrical or elongated protrusions that extend from a heat sink base, offering improved air circulation. Extruding heat sinks enable the creation of shapes capable of. Heat sinks are typically made of cnc machined aluminum or copper and have heat sink fins or pins that work to increase the surface area of the component, to facilitate the heat transfer to the surrounding fluid.

Heat sink fin skiving technology,Fin skiving machines,heat sink fin

Heat Sink With Fins The optimal heat sink location is on a hot spot, such as a powerful integrated circuit (ic) or a thermal spreader that collects heat from several sources. Extrusion heat sinks & profiles for cost effective cooling solutions. Heat sinks are typically made of cnc machined aluminum or copper and have heat sink fins or pins that work to increase the surface area of the component, to facilitate the heat transfer to the surrounding fluid. Pin fins are cylindrical or elongated protrusions that extend from a heat sink base, offering improved air circulation. The fins on a heat sink are essential to the cooling medium, so having an accurate design and placement of the fins is critical. Extruding heat sinks enable the creation of shapes capable of. The fins on a heat sink are responsible for moving heat away from a component and into contact with air. The optimal heat sink location is on a hot spot, such as a powerful integrated circuit (ic) or a thermal spreader that collects heat from several sources. Explore boyd's extensive heat sink selection, including board level, extruded aluminum, skived, folded, bonded, brazed, and zipper fin options. Plate fins are flat, parallel fin structures that extend from a heat sink base, providing a large surface area for heat transfer. A pin (left) and a fin (right) type of heat sink. The image below demonstrates two mechanical heat sink types: There are six dimensions that would need to be determined to design an appropriate heat sink for your needs. Figure 1 shows a typical plate fin heat sink used to cool common electrical / electronic components such as leds used in lighting applications and mosfet used in digital circuits and microprocessors.

From www.lorithermal.com

Zipper Fin Heat Sink Advanced themal solution Lori Heat Sink With Fins A pin (left) and a fin (right) type of heat sink. The fins on a heat sink are responsible for moving heat away from a component and into contact with air. Figure 1 shows a typical plate fin heat sink used to cool common electrical / electronic components such as leds used in lighting applications and mosfet used in digital. Heat Sink With Fins.

From www.bhoomiheatsinks.com

Bonded Fin Heatsinks High Power force cooled heat sink. Heat Sink With Fins Explore boyd's extensive heat sink selection, including board level, extruded aluminum, skived, folded, bonded, brazed, and zipper fin options. The fins on a heat sink are essential to the cooling medium, so having an accurate design and placement of the fins is critical. Plate fins are flat, parallel fin structures that extend from a heat sink base, providing a large. Heat Sink With Fins.

From www.finskiving.com

Fin skiving machines, Heat sink Fins skiving machines, heat sink fin Heat Sink With Fins There are six dimensions that would need to be determined to design an appropriate heat sink for your needs. Figure 1 shows a typical plate fin heat sink used to cool common electrical / electronic components such as leds used in lighting applications and mosfet used in digital circuits and microprocessors. Extrusion heat sinks & profiles for cost effective cooling. Heat Sink With Fins.

From www.heatsinksmfg.com

Folded fin Heat Sinks, aluminum folded fin heat sink, folded fin Heat Sink With Fins Explore boyd's extensive heat sink selection, including board level, extruded aluminum, skived, folded, bonded, brazed, and zipper fin options. There are six dimensions that would need to be determined to design an appropriate heat sink for your needs. Extrusion heat sinks & profiles for cost effective cooling solutions. Heat sinks are typically made of cnc machined aluminum or copper and. Heat Sink With Fins.

From turkish.aluminiumdiecastingparts.com

Soldered Pin Fin Heat Sink With Copper Pipe Liquid Evaporate Technology Heat Sink With Fins The image below demonstrates two mechanical heat sink types: A pin (left) and a fin (right) type of heat sink. Extrusion heat sinks & profiles for cost effective cooling solutions. Pin fins are cylindrical or elongated protrusions that extend from a heat sink base, offering improved air circulation. The fins on a heat sink are responsible for moving heat away. Heat Sink With Fins.

From www.lorithermal.com

Plate Fin Heat Sink Manufacturer Lori Heat Sink With Fins Explore boyd's extensive heat sink selection, including board level, extruded aluminum, skived, folded, bonded, brazed, and zipper fin options. There are six dimensions that would need to be determined to design an appropriate heat sink for your needs. The fins on a heat sink are essential to the cooling medium, so having an accurate design and placement of the fins. Heat Sink With Fins.

From www.heatsinksmfg.com

Skived Heat Sink, Skived Fin HeatSinks, Custom Aluminum Heat Sink Heat Sink With Fins Extrusion heat sinks & profiles for cost effective cooling solutions. The optimal heat sink location is on a hot spot, such as a powerful integrated circuit (ic) or a thermal spreader that collects heat from several sources. A pin (left) and a fin (right) type of heat sink. Figure 1 shows a typical plate fin heat sink used to cool. Heat Sink With Fins.

From www.heatscape.com

double floating core heatsink heatscape Heat Sink With Fins Heat sinks are typically made of cnc machined aluminum or copper and have heat sink fins or pins that work to increase the surface area of the component, to facilitate the heat transfer to the surrounding fluid. Extrusion heat sinks & profiles for cost effective cooling solutions. Figure 1 shows a typical plate fin heat sink used to cool common. Heat Sink With Fins.

From www.goldconnhk.com

Skived Fin aluminum Heat Sinks _ Goldconn Heat Sink With Fins Figure 1 shows a typical plate fin heat sink used to cool common electrical / electronic components such as leds used in lighting applications and mosfet used in digital circuits and microprocessors. Plate fins are flat, parallel fin structures that extend from a heat sink base, providing a large surface area for heat transfer. Extrusion heat sinks & profiles for. Heat Sink With Fins.

From thermocoolcorp.com

Thermo Cool Folded Fins Heat Sink With Fins The fins on a heat sink are responsible for moving heat away from a component and into contact with air. Plate fins are flat, parallel fin structures that extend from a heat sink base, providing a large surface area for heat transfer. Heat sinks are typically made of cnc machined aluminum or copper and have heat sink fins or pins. Heat Sink With Fins.

From thermocoolcorp.com

Thermo Cool Skived fin heat sink Heat Sink With Fins A pin (left) and a fin (right) type of heat sink. The image below demonstrates two mechanical heat sink types: Plate fins are flat, parallel fin structures that extend from a heat sink base, providing a large surface area for heat transfer. Heat sinks are typically made of cnc machined aluminum or copper and have heat sink fins or pins. Heat Sink With Fins.

From www.lorithermal.com

Custom Aluminum Skived Fin Heat Sink, Greenhouse heat sink manufacturer Heat Sink With Fins Extruding heat sinks enable the creation of shapes capable of. Explore boyd's extensive heat sink selection, including board level, extruded aluminum, skived, folded, bonded, brazed, and zipper fin options. The optimal heat sink location is on a hot spot, such as a powerful integrated circuit (ic) or a thermal spreader that collects heat from several sources. The fins on a. Heat Sink With Fins.

From www.researchgate.net

(a) Porous heat sink. (b) Plain view of a vertical fins heat sink. (c Heat Sink With Fins Extruding heat sinks enable the creation of shapes capable of. Pin fins are cylindrical or elongated protrusions that extend from a heat sink base, offering improved air circulation. A pin (left) and a fin (right) type of heat sink. The fins on a heat sink are responsible for moving heat away from a component and into contact with air. Figure. Heat Sink With Fins.

From www.finskiving.com

Heat sink fin skiving technology,Fin skiving machines,heat sink fin Heat Sink With Fins There are six dimensions that would need to be determined to design an appropriate heat sink for your needs. A pin (left) and a fin (right) type of heat sink. Figure 1 shows a typical plate fin heat sink used to cool common electrical / electronic components such as leds used in lighting applications and mosfet used in digital circuits. Heat Sink With Fins.

From thermocoolcorp.com

Thermo Cool Bonded Fins Heat Sink With Fins The fins on a heat sink are essential to the cooling medium, so having an accurate design and placement of the fins is critical. Extrusion heat sinks & profiles for cost effective cooling solutions. Explore boyd's extensive heat sink selection, including board level, extruded aluminum, skived, folded, bonded, brazed, and zipper fin options. Extruding heat sinks enable the creation of. Heat Sink With Fins.

From www.lorithermal.com

Professional Finned Aluminum Heat Sink & Copper Heat Sink Manufacture Heat Sink With Fins Extruding heat sinks enable the creation of shapes capable of. Figure 1 shows a typical plate fin heat sink used to cool common electrical / electronic components such as leds used in lighting applications and mosfet used in digital circuits and microprocessors. The fins on a heat sink are responsible for moving heat away from a component and into contact. Heat Sink With Fins.

From www.indiamart.com

Straight Fin Heat Sink, Thickness 3 To 5 Mm at Rs 350/piece in Heat Sink With Fins Plate fins are flat, parallel fin structures that extend from a heat sink base, providing a large surface area for heat transfer. The image below demonstrates two mechanical heat sink types: Extruding heat sinks enable the creation of shapes capable of. The fins on a heat sink are essential to the cooling medium, so having an accurate design and placement. Heat Sink With Fins.

From river-level05319.en.made-in-china.com

China Aluminum Bonded Fin Heat Sinks China CNC Machined Aluminum Heat Heat Sink With Fins Figure 1 shows a typical plate fin heat sink used to cool common electrical / electronic components such as leds used in lighting applications and mosfet used in digital circuits and microprocessors. Extrusion heat sinks & profiles for cost effective cooling solutions. Pin fins are cylindrical or elongated protrusions that extend from a heat sink base, offering improved air circulation.. Heat Sink With Fins.

From www.researchgate.net

continuous rectangular fins heat sink. Download Scientific Diagram Heat Sink With Fins Extrusion heat sinks & profiles for cost effective cooling solutions. Extruding heat sinks enable the creation of shapes capable of. The fins on a heat sink are responsible for moving heat away from a component and into contact with air. Figure 1 shows a typical plate fin heat sink used to cool common electrical / electronic components such as leds. Heat Sink With Fins.

From www.lorithermal.com

Custom Aluminum Skived Fin Heat Sink, Greenhouse heat sink manufacturer Heat Sink With Fins Heat sinks are typically made of cnc machined aluminum or copper and have heat sink fins or pins that work to increase the surface area of the component, to facilitate the heat transfer to the surrounding fluid. The optimal heat sink location is on a hot spot, such as a powerful integrated circuit (ic) or a thermal spreader that collects. Heat Sink With Fins.

From www.lorithermal.com

Folded Fin Heat Sinks Aluminumlori Heat Sink Heat Sink With Fins Heat sinks are typically made of cnc machined aluminum or copper and have heat sink fins or pins that work to increase the surface area of the component, to facilitate the heat transfer to the surrounding fluid. Extruding heat sinks enable the creation of shapes capable of. Pin fins are cylindrical or elongated protrusions that extend from a heat sink. Heat Sink With Fins.

From thermocoolcorp.com

Thermo Cool Snapped Fins Heat Sink With Fins Plate fins are flat, parallel fin structures that extend from a heat sink base, providing a large surface area for heat transfer. Extrusion heat sinks & profiles for cost effective cooling solutions. The fins on a heat sink are essential to the cooling medium, so having an accurate design and placement of the fins is critical. Extruding heat sinks enable. Heat Sink With Fins.

From www.novarktechnologies.com

Copper Folded Fin Heat Sink ManufacturerNovark Heat Sink With Fins Extruding heat sinks enable the creation of shapes capable of. Heat sinks are typically made of cnc machined aluminum or copper and have heat sink fins or pins that work to increase the surface area of the component, to facilitate the heat transfer to the surrounding fluid. The fins on a heat sink are responsible for moving heat away from. Heat Sink With Fins.

From www.lorithermal.com

Folded Fin Heat Sinks Aluminumlori Heat Sink Heat Sink With Fins The image below demonstrates two mechanical heat sink types: The optimal heat sink location is on a hot spot, such as a powerful integrated circuit (ic) or a thermal spreader that collects heat from several sources. Extruding heat sinks enable the creation of shapes capable of. Explore boyd's extensive heat sink selection, including board level, extruded aluminum, skived, folded, bonded,. Heat Sink With Fins.

From www.kingkatech.com

Bonded Fins Heat Sink Kingka Heat Sink With Fins Plate fins are flat, parallel fin structures that extend from a heat sink base, providing a large surface area for heat transfer. The fins on a heat sink are responsible for moving heat away from a component and into contact with air. Extrusion heat sinks & profiles for cost effective cooling solutions. Figure 1 shows a typical plate fin heat. Heat Sink With Fins.

From www.qats.com

What are the benefits of using Pin Fin Heat Sinks in thermal management Heat Sink With Fins Explore boyd's extensive heat sink selection, including board level, extruded aluminum, skived, folded, bonded, brazed, and zipper fin options. Pin fins are cylindrical or elongated protrusions that extend from a heat sink base, offering improved air circulation. A pin (left) and a fin (right) type of heat sink. The fins on a heat sink are responsible for moving heat away. Heat Sink With Fins.

From heatsinkchina.com

kind of bonded fin heat sink type swaged heatsink Heat Sink With Fins Figure 1 shows a typical plate fin heat sink used to cool common electrical / electronic components such as leds used in lighting applications and mosfet used in digital circuits and microprocessors. Pin fins are cylindrical or elongated protrusions that extend from a heat sink base, offering improved air circulation. The fins on a heat sink are essential to the. Heat Sink With Fins.

From www.diabatix.com

Pin Fin Heat Sink Applications Enhancing Thermal Management for Heat Sink With Fins The fins on a heat sink are responsible for moving heat away from a component and into contact with air. Explore boyd's extensive heat sink selection, including board level, extruded aluminum, skived, folded, bonded, brazed, and zipper fin options. Plate fins are flat, parallel fin structures that extend from a heat sink base, providing a large surface area for heat. Heat Sink With Fins.

From www.aliexpress.com

Black Color 40mm*40mm*11mm DIY Cooler Aluminum Heatsink Cooling Fin Heat Sink With Fins Heat sinks are typically made of cnc machined aluminum or copper and have heat sink fins or pins that work to increase the surface area of the component, to facilitate the heat transfer to the surrounding fluid. The fins on a heat sink are responsible for moving heat away from a component and into contact with air. The fins on. Heat Sink With Fins.

From www.semanticscholar.org

Figure 2 from Improved thermal design of fin heat sink for highpower Heat Sink With Fins Heat sinks are typically made of cnc machined aluminum or copper and have heat sink fins or pins that work to increase the surface area of the component, to facilitate the heat transfer to the surrounding fluid. A pin (left) and a fin (right) type of heat sink. There are six dimensions that would need to be determined to design. Heat Sink With Fins.

From getecna.com

Bonded and Folded Fin Heat Sink Design Thermal Management Solutions Heat Sink With Fins The fins on a heat sink are responsible for moving heat away from a component and into contact with air. There are six dimensions that would need to be determined to design an appropriate heat sink for your needs. Heat sinks are typically made of cnc machined aluminum or copper and have heat sink fins or pins that work to. Heat Sink With Fins.

From www.aliexpress.com

40 x 40 x 20mm Aluminum Heat Sink IC Heatsink Cooling Fin For CPU LED Heat Sink With Fins Pin fins are cylindrical or elongated protrusions that extend from a heat sink base, offering improved air circulation. The optimal heat sink location is on a hot spot, such as a powerful integrated circuit (ic) or a thermal spreader that collects heat from several sources. Heat sinks are typically made of cnc machined aluminum or copper and have heat sink. Heat Sink With Fins.

From www.sparkfun.com

Heat Sink with Fins PRT09798 SparkFun Electronics Heat Sink With Fins The optimal heat sink location is on a hot spot, such as a powerful integrated circuit (ic) or a thermal spreader that collects heat from several sources. The fins on a heat sink are essential to the cooling medium, so having an accurate design and placement of the fins is critical. Extruding heat sinks enable the creation of shapes capable. Heat Sink With Fins.

From www.finskiving.com

Stacked fin heat sink Spanish Heat Sink With Fins Explore boyd's extensive heat sink selection, including board level, extruded aluminum, skived, folded, bonded, brazed, and zipper fin options. There are six dimensions that would need to be determined to design an appropriate heat sink for your needs. The fins on a heat sink are essential to the cooling medium, so having an accurate design and placement of the fins. Heat Sink With Fins.

From dgcoolwhist.en.made-in-china.com

China 40W/60W Round Aluminum Fins LED Heat Sink China Heat Sink, LED Heat Sink With Fins Heat sinks are typically made of cnc machined aluminum or copper and have heat sink fins or pins that work to increase the surface area of the component, to facilitate the heat transfer to the surrounding fluid. The image below demonstrates two mechanical heat sink types: Extrusion heat sinks & profiles for cost effective cooling solutions. Extruding heat sinks enable. Heat Sink With Fins.