Nut Bolt Design . Bolts find application due to ease in following. A bolt head with no marking indicates a grade 2 bolt, 3 markings indicates a grade 5 bolt, and 6 markings indicates a grade 8 bolt (the simple shortcut is to take the number of radial lines. Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. The process of tightening a fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced in the fastener. These effects result from the way the joint is loaded, as well as how. New specifications for structural joints using astm a325 or a490 bolts, one based on allowable stress principles and the other on a load factor. With its external thread, a bolt fits into a nut’s internal thread. Geometry and classification of fasteners. They connect by threading a bolt through aligned holes in two or.

from www.youtube.com

With its external thread, a bolt fits into a nut’s internal thread. A bolt head with no marking indicates a grade 2 bolt, 3 markings indicates a grade 5 bolt, and 6 markings indicates a grade 8 bolt (the simple shortcut is to take the number of radial lines. Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. Geometry and classification of fasteners. Bolts find application due to ease in following. New specifications for structural joints using astm a325 or a490 bolts, one based on allowable stress principles and the other on a load factor. The process of tightening a fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced in the fastener. These effects result from the way the joint is loaded, as well as how. They connect by threading a bolt through aligned holes in two or.

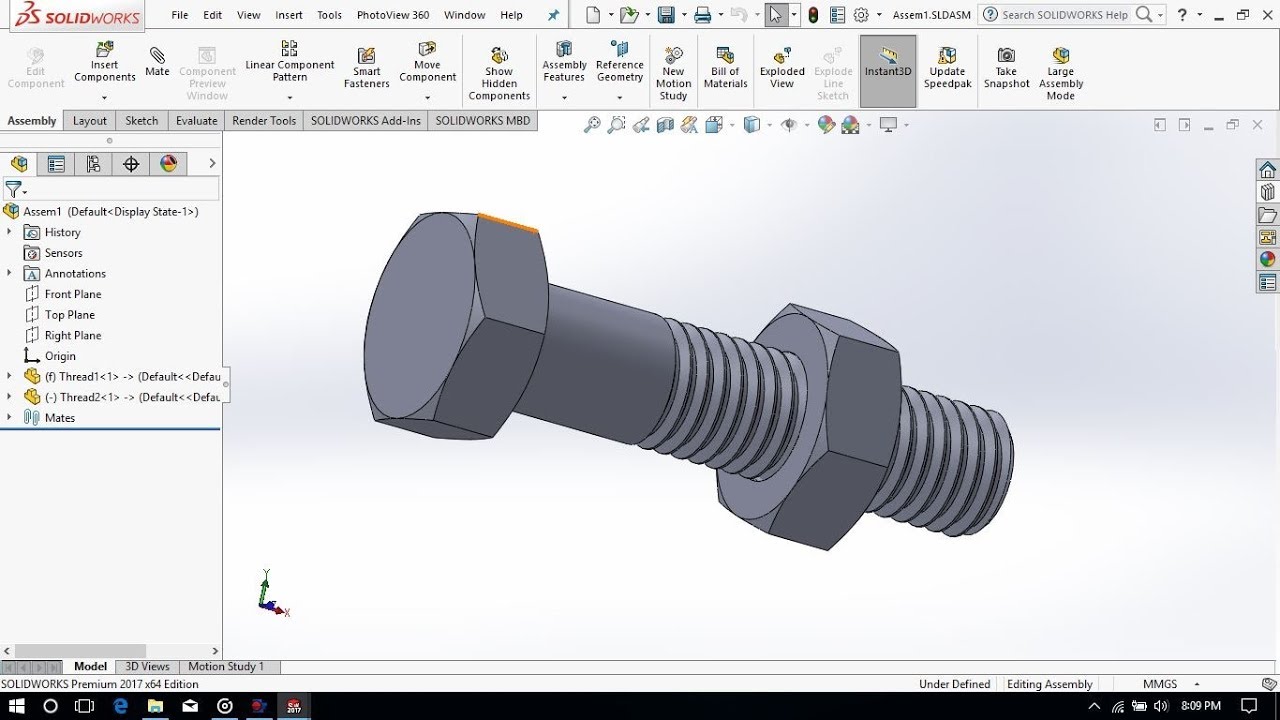

How to Design M10 Nut & Bolt in SolidWorks YouTube

Nut Bolt Design Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. Geometry and classification of fasteners. The process of tightening a fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced in the fastener. Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. With its external thread, a bolt fits into a nut’s internal thread. New specifications for structural joints using astm a325 or a490 bolts, one based on allowable stress principles and the other on a load factor. These effects result from the way the joint is loaded, as well as how. A bolt head with no marking indicates a grade 2 bolt, 3 markings indicates a grade 5 bolt, and 6 markings indicates a grade 8 bolt (the simple shortcut is to take the number of radial lines. Bolts find application due to ease in following. They connect by threading a bolt through aligned holes in two or.

From paintingvalley.com

Nut And Bolt Drawing at Explore collection of Nut Nut Bolt Design Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. These effects result from the way the joint is loaded, as well as how. Geometry and classification of fasteners. New specifications for structural joints using astm a325 or a490 bolts, one based on allowable stress principles and the. Nut Bolt Design.

From www.dreamstime.com

Bolt. Vector Illustration for Technical Design. Stock Vector Nut Bolt Design A bolt head with no marking indicates a grade 2 bolt, 3 markings indicates a grade 5 bolt, and 6 markings indicates a grade 8 bolt (the simple shortcut is to take the number of radial lines. With its external thread, a bolt fits into a nut’s internal thread. They connect by threading a bolt through aligned holes in two. Nut Bolt Design.

From www.youtube.com

Solidworks Tutorials Nut Bolt Design & Assembly The Cadd Sandy Nut Bolt Design Bolts find application due to ease in following. Geometry and classification of fasteners. These effects result from the way the joint is loaded, as well as how. The process of tightening a fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced in the fastener. A bolt head with no marking indicates. Nut Bolt Design.

From www.mechanicalbooster.com

Difference Between Nuts and Bolts Mechanical Booster Nut Bolt Design Geometry and classification of fasteners. Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. They connect by threading a bolt through aligned holes in two or. New specifications for structural joints using astm a325 or a490 bolts, one based on allowable stress principles and the other on. Nut Bolt Design.

From stock.adobe.com

screw bolt with nut silhouette icon vector Stock Vector Adobe Stock Nut Bolt Design New specifications for structural joints using astm a325 or a490 bolts, one based on allowable stress principles and the other on a load factor. A bolt head with no marking indicates a grade 2 bolt, 3 markings indicates a grade 5 bolt, and 6 markings indicates a grade 8 bolt (the simple shortcut is to take the number of radial. Nut Bolt Design.

From www.youtube.com

How to Design M10 Nut & Bolt in SolidWorks YouTube Nut Bolt Design Bolts find application due to ease in following. Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. New specifications for structural joints using astm a325 or a490 bolts, one based on allowable stress principles and the other on a load factor. A bolt head with no marking. Nut Bolt Design.

From fastfixtechnology.com

A reliable locking performance using a two nut design Nut Bolt Design With its external thread, a bolt fits into a nut’s internal thread. They connect by threading a bolt through aligned holes in two or. New specifications for structural joints using astm a325 or a490 bolts, one based on allowable stress principles and the other on a load factor. The process of tightening a fastener involves turning, advance of the lead. Nut Bolt Design.

From cadbull.com

Nutbolt design in AutoCAD 2D drawing, dwg file, CAD file Cadbull Nut Bolt Design Geometry and classification of fasteners. With its external thread, a bolt fits into a nut’s internal thread. The process of tightening a fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced in the fastener. These effects result from the way the joint is loaded, as well as how. Loads can be. Nut Bolt Design.

From grabcad.com

Free CAD Designs, Files & 3D Models The GrabCAD Community Library Nut Bolt Design Bolts find application due to ease in following. These effects result from the way the joint is loaded, as well as how. New specifications for structural joints using astm a325 or a490 bolts, one based on allowable stress principles and the other on a load factor. With its external thread, a bolt fits into a nut’s internal thread. The process. Nut Bolt Design.

From www.youtube.com

How to Calculate Bolt Value/Strength of Bolt Bolted Connection Nut Bolt Design Geometry and classification of fasteners. Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. They connect by threading a bolt through aligned holes in two or. These effects result from the way the joint is loaded, as well as how. With its external thread, a bolt fits. Nut Bolt Design.

From cadbull.com

Nuts and bolts design in detail AutoCAD drawing, dwg file, CAD file Nut Bolt Design Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. These effects result from the way the joint is loaded, as well as how. They connect by threading a bolt through aligned holes in two or. A bolt head with no marking indicates a grade 2 bolt, 3. Nut Bolt Design.

From cadbull.com

3d model of Nut and bolt detail elevation layout file Cadbull Nut Bolt Design With its external thread, a bolt fits into a nut’s internal thread. These effects result from the way the joint is loaded, as well as how. Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. A bolt head with no marking indicates a grade 2 bolt, 3. Nut Bolt Design.

From pngtree.com

Nuts And Bolts Vector Art PNG, Bolt And Nut, Bolt, Nut, Bolt Vector PNG Nut Bolt Design Geometry and classification of fasteners. A bolt head with no marking indicates a grade 2 bolt, 3 markings indicates a grade 5 bolt, and 6 markings indicates a grade 8 bolt (the simple shortcut is to take the number of radial lines. These effects result from the way the joint is loaded, as well as how. With its external thread,. Nut Bolt Design.

From www.vecteezy.com

Bolt and nut icon vector logo design illustration 9458876 Vector Art at Nut Bolt Design A bolt head with no marking indicates a grade 2 bolt, 3 markings indicates a grade 5 bolt, and 6 markings indicates a grade 8 bolt (the simple shortcut is to take the number of radial lines. With its external thread, a bolt fits into a nut’s internal thread. Bolts find application due to ease in following. Geometry and classification. Nut Bolt Design.

From www.reddit.com

Types of Nuts, Bolts, Screws r/coolguides Nut Bolt Design With its external thread, a bolt fits into a nut’s internal thread. A bolt head with no marking indicates a grade 2 bolt, 3 markings indicates a grade 5 bolt, and 6 markings indicates a grade 8 bolt (the simple shortcut is to take the number of radial lines. These effects result from the way the joint is loaded, as. Nut Bolt Design.

From www.educationalstuffs.in

Different types of Nuts ENGINEERING DRAWING Nut Bolt Design New specifications for structural joints using astm a325 or a490 bolts, one based on allowable stress principles and the other on a load factor. A bolt head with no marking indicates a grade 2 bolt, 3 markings indicates a grade 5 bolt, and 6 markings indicates a grade 8 bolt (the simple shortcut is to take the number of radial. Nut Bolt Design.

From www.youtube.com

Solidworks Tutorial 055 Nut & Bolt Design WIth Assembly YouTube Nut Bolt Design Bolts find application due to ease in following. A bolt head with no marking indicates a grade 2 bolt, 3 markings indicates a grade 5 bolt, and 6 markings indicates a grade 8 bolt (the simple shortcut is to take the number of radial lines. The process of tightening a fastener involves turning, advance of the lead screw, and torque,. Nut Bolt Design.

From www.vectorstock.com

Bolt nut and screw set Royalty Free Vector Image Nut Bolt Design A bolt head with no marking indicates a grade 2 bolt, 3 markings indicates a grade 5 bolt, and 6 markings indicates a grade 8 bolt (the simple shortcut is to take the number of radial lines. With its external thread, a bolt fits into a nut’s internal thread. These effects result from the way the joint is loaded, as. Nut Bolt Design.

From www.iqsdirectory.com

Types of Bolts Types, Components, and Fastener Terms Nut Bolt Design New specifications for structural joints using astm a325 or a490 bolts, one based on allowable stress principles and the other on a load factor. These effects result from the way the joint is loaded, as well as how. A bolt head with no marking indicates a grade 2 bolt, 3 markings indicates a grade 5 bolt, and 6 markings indicates. Nut Bolt Design.

From www.iqsdirectory.com

Types of Bolts Types, Components, and Fastener Terms Nut Bolt Design Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. These effects result from the way the joint is loaded, as well as how. Bolts find application due to ease in following. The process of tightening a fastener involves turning, advance of the lead screw, and torque, turning. Nut Bolt Design.

From www.youtube.com

Hexagonal nut bolt assembly drawing in hindi (Engineering drawing Nut Bolt Design A bolt head with no marking indicates a grade 2 bolt, 3 markings indicates a grade 5 bolt, and 6 markings indicates a grade 8 bolt (the simple shortcut is to take the number of radial lines. The process of tightening a fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced. Nut Bolt Design.

From mungfali.com

Different Types Of Nuts For Bolts Nut Bolt Design New specifications for structural joints using astm a325 or a490 bolts, one based on allowable stress principles and the other on a load factor. The process of tightening a fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced in the fastener. Bolts find application due to ease in following. They connect. Nut Bolt Design.

From www.youtube.com

Nut and Bolt Design in SolidWorks Thread Feature, Assembly and Nut Bolt Design These effects result from the way the joint is loaded, as well as how. Geometry and classification of fasteners. New specifications for structural joints using astm a325 or a490 bolts, one based on allowable stress principles and the other on a load factor. Loads can be applied to bolted joints in a number of different ways, each of which produces. Nut Bolt Design.

From www.youtube.com

⚡ SOLIDWORKS TUTORIAL 31 Design of Bolt and Nut assembly with Nut Bolt Design Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. The process of tightening a fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced in the fastener. Geometry and classification of fasteners. They connect by threading a bolt through. Nut Bolt Design.

From www.dreamstime.com

Bolt and nut stock vector. Illustration of engineering 49772668 Nut Bolt Design Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. With its external thread, a bolt fits into a nut’s internal thread. These effects result from the way the joint is loaded, as well as how. New specifications for structural joints using astm a325 or a490 bolts, one. Nut Bolt Design.

From www.dreamstime.com

Bolt with nut stock vector. Illustration of design, work 176321213 Nut Bolt Design These effects result from the way the joint is loaded, as well as how. Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. They connect by threading a bolt through aligned holes in two or. The process of tightening a fastener involves turning, advance of the lead. Nut Bolt Design.

From www.youtube.com

How to Design Nut Bolt with Animation in NX Unigraphics C for CAD Nut Bolt Design Geometry and classification of fasteners. Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. With its external thread, a bolt fits into a nut’s internal thread. They connect by threading a bolt through aligned holes in two or. The process of tightening a fastener involves turning, advance. Nut Bolt Design.

From www.vecteezy.com

Screw hex bolt set vector design illustration set isolated on white Nut Bolt Design Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. With its external thread, a bolt fits into a nut’s internal thread. These effects result from the way the joint is loaded, as well as how. New specifications for structural joints using astm a325 or a490 bolts, one. Nut Bolt Design.

From www.engineersedge.com

Fastener Nut Types Nut Bolt Design Geometry and classification of fasteners. They connect by threading a bolt through aligned holes in two or. The process of tightening a fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced in the fastener. With its external thread, a bolt fits into a nut’s internal thread. A bolt head with no. Nut Bolt Design.

From www.cadcrowd.com

NutBolt download free 3D model by tintinsuz Cad Crowd Nut Bolt Design The process of tightening a fastener involves turning, advance of the lead screw, and torque, turning moment, so that preload, tension, is produced in the fastener. New specifications for structural joints using astm a325 or a490 bolts, one based on allowable stress principles and the other on a load factor. These effects result from the way the joint is loaded,. Nut Bolt Design.

From www.vectorstock.com

Bolt and nut set all view isometric Royalty Free Vector Nut Bolt Design Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. A bolt head with no marking indicates a grade 2 bolt, 3 markings indicates a grade 5 bolt, and 6 markings indicates a grade 8 bolt (the simple shortcut is to take the number of radial lines. They. Nut Bolt Design.

From savree.com

Flange Nuts and Bolts Explained (Fasteners) saVRee Nut Bolt Design A bolt head with no marking indicates a grade 2 bolt, 3 markings indicates a grade 5 bolt, and 6 markings indicates a grade 8 bolt (the simple shortcut is to take the number of radial lines. Geometry and classification of fasteners. Bolts find application due to ease in following. They connect by threading a bolt through aligned holes in. Nut Bolt Design.

From elchoroukhost.net

Bolt Nut Dimensions Table Elcho Table Nut Bolt Design They connect by threading a bolt through aligned holes in two or. New specifications for structural joints using astm a325 or a490 bolts, one based on allowable stress principles and the other on a load factor. Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. Geometry and. Nut Bolt Design.

From www.researchgate.net

2D sketches of bolt, nut, and bolted joint (a) bolt (and its bearing Nut Bolt Design With its external thread, a bolt fits into a nut’s internal thread. Bolts find application due to ease in following. Loads can be applied to bolted joints in a number of different ways, each of which produces unique effects on the joint. They connect by threading a bolt through aligned holes in two or. Geometry and classification of fasteners. A. Nut Bolt Design.

From pngtree.com

Nuts And Bolts Vector Art PNG, Icon Of Bolt And Nut, Design, Screw Nut Bolt Design These effects result from the way the joint is loaded, as well as how. With its external thread, a bolt fits into a nut’s internal thread. They connect by threading a bolt through aligned holes in two or. A bolt head with no marking indicates a grade 2 bolt, 3 markings indicates a grade 5 bolt, and 6 markings indicates. Nut Bolt Design.