Holding Down Bolts In Ship . Support weight of the engine. After a vessel has been through bad weather, the bolts should be checked as soon as possible. The holding down bolts keeps the bedplate in position with the bottom structure of the ship. Holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are hydraulically tensioned. When this occurs two options are: A rough method of checking holding. The bedplate must be strong enough to withstand the. Check for loose holding down bolts and tighten as per the manual if found loose. To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to. It is mounted on chocks and secured to the floor using holding down bolts for stability. Also, check for shearing and fretting on the holding down bolts. Interfere with engine hold down bolts. • slot the transverse bracket to permit inserting the bolt. Purpose of holding down bolts: Secure engine rigidly in all sea.

from studylib.net

Arrangement of holding down bolts and chocks should be: When this occurs two options are: The holding down bolts keeps the bedplate in position with the bottom structure of the ship. A rough method of checking holding. During dynamic analysis, one should consider the overturning moment, sliding forces on the equipment and ensure that there are sufficient anchoring points. Purpose of holding down bolts: Interfere with engine hold down bolts. Check for loose holding down bolts and tighten as per the manual if found loose. • slot the transverse bracket to permit inserting the bolt. Support weight of the engine.

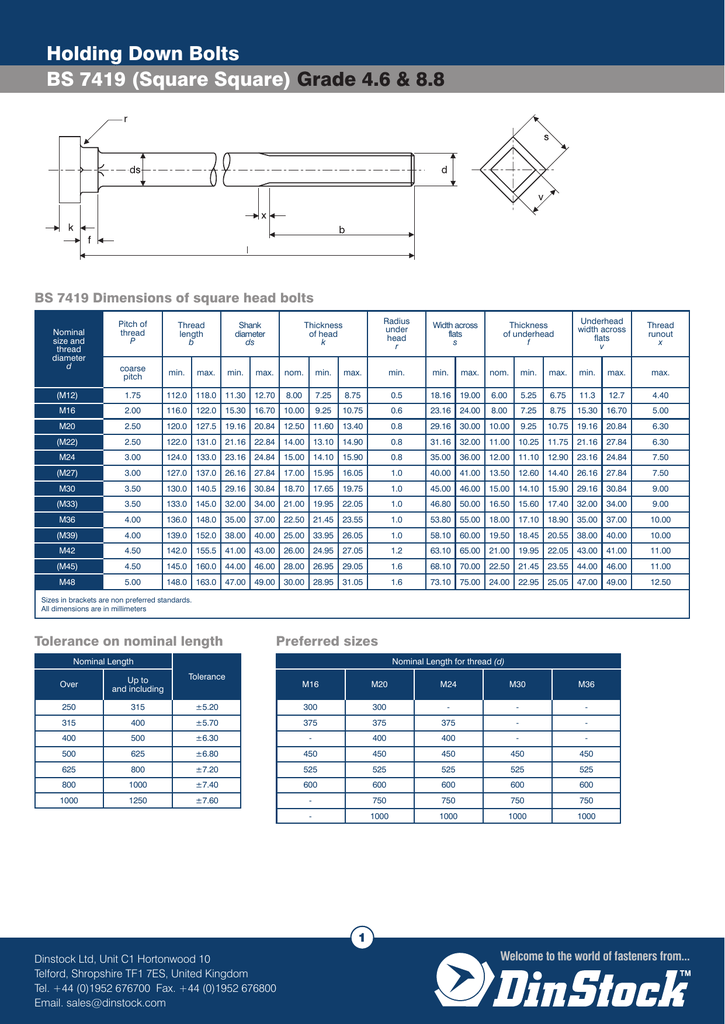

Holding Down Bolts

Holding Down Bolts In Ship Also, check for shearing and fretting on the holding down bolts. • slot the transverse bracket to permit inserting the bolt. Also, check for shearing and fretting on the holding down bolts. The holding down bolts keeps the bedplate in position with the bottom structure of the ship. After a vessel has been through bad weather, the bolts should be checked as soon as possible. It is mounted on chocks and secured to the floor using holding down bolts for stability. Interfere with engine hold down bolts. A rough method of checking holding. To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to. Secure engine rigidly in all sea. Check for loose holding down bolts and tighten as per the manual if found loose. The bedplate must be strong enough to withstand the. During dynamic analysis, one should consider the overturning moment, sliding forces on the equipment and ensure that there are sufficient anchoring points. Support weight of the engine. Purpose of holding down bolts: Holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are hydraulically tensioned.

From www.marineengineersknowledge.com

SIDE AND END CHOCKING, POURED RESIN CHOCKS Marine engineers knowledge Holding Down Bolts In Ship The holding down bolts keeps the bedplate in position with the bottom structure of the ship. After a vessel has been through bad weather, the bolts should be checked as soon as possible. Holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are hydraulically tensioned. When this occurs two options are: Interfere. Holding Down Bolts In Ship.

From www.youtube.com

The Space Shuttle HoldDown Bolts YouTube Holding Down Bolts In Ship Check for loose holding down bolts and tighten as per the manual if found loose. The holding down bolts keeps the bedplate in position with the bottom structure of the ship. During dynamic analysis, one should consider the overturning moment, sliding forces on the equipment and ensure that there are sufficient anchoring points. Secure engine rigidly in all sea. The. Holding Down Bolts In Ship.

From andrewsfasteners.uk

BS 7419 Holding down bolts Basic dimensions Andrews Fasteners Holding Down Bolts In Ship The bedplate must be strong enough to withstand the. After a vessel has been through bad weather, the bolts should be checked as soon as possible. A rough method of checking holding. Also, check for shearing and fretting on the holding down bolts. It is mounted on chocks and secured to the floor using holding down bolts for stability. During. Holding Down Bolts In Ship.

From www.encon.co.uk

Holding Down Bolts Encon Construction Products Holding Down Bolts In Ship Purpose of holding down bolts: Check for loose holding down bolts and tighten as per the manual if found loose. During dynamic analysis, one should consider the overturning moment, sliding forces on the equipment and ensure that there are sufficient anchoring points. • slot the transverse bracket to permit inserting the bolt. Also, check for shearing and fretting on the. Holding Down Bolts In Ship.

From www.rcfboltnut.co.uk

Holding Down Bolts Heavy Duty Bolts RCF Bolt & Nut Holding Down Bolts In Ship Also, check for shearing and fretting on the holding down bolts. Support weight of the engine. A rough method of checking holding. Holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are hydraulically tensioned. After a vessel has been through bad weather, the bolts should be checked as soon as possible. During. Holding Down Bolts In Ship.

From www.scribd.com

Holding Down Bolts PDF Screw Propeller Holding Down Bolts In Ship • slot the transverse bracket to permit inserting the bolt. Holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are hydraulically tensioned. Support weight of the engine. When this occurs two options are: After a vessel has been through bad weather, the bolts should be checked as soon as possible. Interfere with. Holding Down Bolts In Ship.

From www.boltbox.co.uk

News BoltBox Holding Down Bolts In Ship Interfere with engine hold down bolts. During dynamic analysis, one should consider the overturning moment, sliding forces on the equipment and ensure that there are sufficient anchoring points. The bedplate must be strong enough to withstand the. It is mounted on chocks and secured to the floor using holding down bolts for stability. Secure engine rigidly in all sea. A. Holding Down Bolts In Ship.

From www.steels-supplier.com

Anchor Bolt and holding down bolt Holding Down Bolts In Ship The holding down bolts keeps the bedplate in position with the bottom structure of the ship. To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to. It is mounted on chocks and secured to the floor using holding down bolts for stability. Also, check for shearing and fretting on the holding down bolts.. Holding Down Bolts In Ship.

From www.swiftfix.co.uk

Holding Down Bolts Holding Down Bolts In Ship Interfere with engine hold down bolts. Arrangement of holding down bolts and chocks should be: The holding down bolts keeps the bedplate in position with the bottom structure of the ship. A rough method of checking holding. Purpose of holding down bolts: Also, check for shearing and fretting on the holding down bolts. Secure engine rigidly in all sea. When. Holding Down Bolts In Ship.

From brooksforgings.co.uk

Holding Down Bolts, Structural Bolts, Construction Bolts, Foundation Bolts UK Manufacturer Holding Down Bolts In Ship Support weight of the engine. The holding down bolts keeps the bedplate in position with the bottom structure of the ship. Holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are hydraulically tensioned. Interfere with engine hold down bolts. Check for loose holding down bolts and tighten as per the manual if. Holding Down Bolts In Ship.

From shop.classic-boat-supplies.com.au

Brass Hold Down Bolts Davey Boat Fittings Classic Boat Supplies Australia Holding Down Bolts In Ship To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to. Also, check for shearing and fretting on the holding down bolts. Arrangement of holding down bolts and chocks should be: The bedplate must be strong enough to withstand the. During dynamic analysis, one should consider the overturning moment, sliding forces on the equipment. Holding Down Bolts In Ship.

From actech.com.au

Holding Down Bolts Actech International Holding Down Bolts In Ship Check for loose holding down bolts and tighten as per the manual if found loose. Arrangement of holding down bolts and chocks should be: To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to. Support weight of the engine. Holding down bolts for modern main propulsion slow speed engines are of the 'long. Holding Down Bolts In Ship.

From www.groupkdt.com

hold down bolts Group KDT Holding Down Bolts In Ship • slot the transverse bracket to permit inserting the bolt. Holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are hydraulically tensioned. Check for loose holding down bolts and tighten as per the manual if found loose. Secure engine rigidly in all sea. The holding down bolts keeps the bedplate in position. Holding Down Bolts In Ship.

From www.vrogue.co

Anchor Bolt And Holding Down Bolt vrogue.co Holding Down Bolts In Ship During dynamic analysis, one should consider the overturning moment, sliding forces on the equipment and ensure that there are sufficient anchoring points. Holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are hydraulically tensioned. Check for loose holding down bolts and tighten as per the manual if found loose. The bedplate must. Holding Down Bolts In Ship.

From marineengineeringonline.com

Resin Chocks Marine Diesel Engines Holding Down Bolts In Ship To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to. It is mounted on chocks and secured to the floor using holding down bolts for stability. • slot the transverse bracket to permit inserting the bolt. The holding down bolts keeps the bedplate in position with the bottom structure of the ship. Purpose. Holding Down Bolts In Ship.

From www.boltbox.co.uk

Tips Steel Construction Holding Down Bolts Diagram, Drawings Holding Down Blots BoltBox Holding Down Bolts In Ship The bedplate must be strong enough to withstand the. Check for loose holding down bolts and tighten as per the manual if found loose. A rough method of checking holding. When this occurs two options are: During dynamic analysis, one should consider the overturning moment, sliding forces on the equipment and ensure that there are sufficient anchoring points. Support weight. Holding Down Bolts In Ship.

From exobyfbxm.blob.core.windows.net

Holding Down Bolts Engine at Gilbert Dotson blog Holding Down Bolts In Ship • slot the transverse bracket to permit inserting the bolt. Holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are hydraulically tensioned. During dynamic analysis, one should consider the overturning moment, sliding forces on the equipment and ensure that there are sufficient anchoring points. Arrangement of holding down bolts and chocks should. Holding Down Bolts In Ship.

From www.allfasteners.com.au

Hold Down Anchor Bolts Holding Down Bolts In Ship To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to. Arrangement of holding down bolts and chocks should be: A rough method of checking holding. The holding down bolts keeps the bedplate in position with the bottom structure of the ship. • slot the transverse bracket to permit inserting the bolt. Also, check. Holding Down Bolts In Ship.

From sgseafarers.com

Holding Down Bolt SINGAPORE SEAFARERS Holding Down Bolts In Ship The bedplate must be strong enough to withstand the. Interfere with engine hold down bolts. Secure engine rigidly in all sea. When this occurs two options are: It is mounted on chocks and secured to the floor using holding down bolts for stability. Arrangement of holding down bolts and chocks should be: Support weight of the engine. The holding down. Holding Down Bolts In Ship.

From sailorsdiaries.blogspot.com

HOLDING DOWN BOLTS ARRANGEMENT Holding Down Bolts In Ship After a vessel has been through bad weather, the bolts should be checked as soon as possible. Interfere with engine hold down bolts. Check for loose holding down bolts and tighten as per the manual if found loose. • slot the transverse bracket to permit inserting the bolt. Holding down bolts for modern main propulsion slow speed engines are of. Holding Down Bolts In Ship.

From www.allfasteners.com.au

12 Bolt Set Hold Down Bolt Assembly Holding Down Bolts In Ship It is mounted on chocks and secured to the floor using holding down bolts for stability. • slot the transverse bracket to permit inserting the bolt. Secure engine rigidly in all sea. Interfere with engine hold down bolts. Also, check for shearing and fretting on the holding down bolts. Purpose of holding down bolts: During dynamic analysis, one should consider. Holding Down Bolts In Ship.

From www.youtube.com

CHOCKS HOLDING DOWN BOLTTYPE OF CHOCKSMARINE ENGINE(PART1) YouTube Holding Down Bolts In Ship The holding down bolts keeps the bedplate in position with the bottom structure of the ship. Check for loose holding down bolts and tighten as per the manual if found loose. Also, check for shearing and fretting on the holding down bolts. • slot the transverse bracket to permit inserting the bolt. A rough method of checking holding. Interfere with. Holding Down Bolts In Ship.

From yujincometal.com

생산/제품 CO., LTD. Holding Down Bolts In Ship During dynamic analysis, one should consider the overturning moment, sliding forces on the equipment and ensure that there are sufficient anchoring points. Support weight of the engine. Also, check for shearing and fretting on the holding down bolts. The holding down bolts keeps the bedplate in position with the bottom structure of the ship. Interfere with engine hold down bolts.. Holding Down Bolts In Ship.

From www.youtube.com

Marine EngineeringHolding Down BoltsHydraulic JackRetighteningMain EngineProcedures YouTube Holding Down Bolts In Ship The holding down bolts keeps the bedplate in position with the bottom structure of the ship. Also, check for shearing and fretting on the holding down bolts. A rough method of checking holding. When this occurs two options are: The bedplate must be strong enough to withstand the. • slot the transverse bracket to permit inserting the bolt. Support weight. Holding Down Bolts In Ship.

From www.allfasteners.com.au

4 Bolt Set Hold Down Bolt Assembly Holding Down Bolts In Ship When this occurs two options are: During dynamic analysis, one should consider the overturning moment, sliding forces on the equipment and ensure that there are sufficient anchoring points. To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to. Secure engine rigidly in all sea. Check for loose holding down bolts and tighten as. Holding Down Bolts In Ship.

From www.boltbox.co.uk

Holding Down Bolts, Nuts, Accessories Bolt Box BoltBox Holding Down Bolts In Ship During dynamic analysis, one should consider the overturning moment, sliding forces on the equipment and ensure that there are sufficient anchoring points. Check for loose holding down bolts and tighten as per the manual if found loose. It is mounted on chocks and secured to the floor using holding down bolts for stability. To provide a clamping force through friction. Holding Down Bolts In Ship.

From www.youtube.com

How to Set up Holding Down Bolts YouTube Holding Down Bolts In Ship Purpose of holding down bolts: When this occurs two options are: Holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are hydraulically tensioned. During dynamic analysis, one should consider the overturning moment, sliding forces on the equipment and ensure that there are sufficient anchoring points. Arrangement of holding down bolts and chocks. Holding Down Bolts In Ship.

From studylib.net

Holding Down Bolts Holding Down Bolts In Ship When this occurs two options are: Interfere with engine hold down bolts. Arrangement of holding down bolts and chocks should be: It is mounted on chocks and secured to the floor using holding down bolts for stability. The holding down bolts keeps the bedplate in position with the bottom structure of the ship. Check for loose holding down bolts and. Holding Down Bolts In Ship.

From www.boltbox.co.uk

Fastening Holding Down Bolts Correctly BoltBox BoltBox Holding Down Bolts In Ship It is mounted on chocks and secured to the floor using holding down bolts for stability. When this occurs two options are: Also, check for shearing and fretting on the holding down bolts. To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to. The holding down bolts keeps the bedplate in position with. Holding Down Bolts In Ship.

From www.linkedin.com

Fabricated Holding Down Bolts Holding Down Bolts In Ship Holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are hydraulically tensioned. Support weight of the engine. Purpose of holding down bolts: A rough method of checking holding. The bedplate must be strong enough to withstand the. Interfere with engine hold down bolts. The holding down bolts keeps the bedplate in position. Holding Down Bolts In Ship.

From marineengineeringonline.com

Holding Down Bolts Marine Diesel Engines Holding Down Bolts In Ship To provide a clamping force through friction between bedplate, chock and the ship’s structure in order to. Support weight of the engine. Also, check for shearing and fretting on the holding down bolts. Holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are hydraulically tensioned. During dynamic analysis, one should consider the. Holding Down Bolts In Ship.

From steels-supplier.com

Anchor Bolt and holding down bolt Holding Down Bolts In Ship The holding down bolts keeps the bedplate in position with the bottom structure of the ship. Secure engine rigidly in all sea. During dynamic analysis, one should consider the overturning moment, sliding forces on the equipment and ensure that there are sufficient anchoring points. After a vessel has been through bad weather, the bolts should be checked as soon as. Holding Down Bolts In Ship.

From www.boltbox.co.uk

Holding Down Bolts, Nuts, Accessories Bolt Box BoltBox Holding Down Bolts In Ship The holding down bolts keeps the bedplate in position with the bottom structure of the ship. Also, check for shearing and fretting on the holding down bolts. • slot the transverse bracket to permit inserting the bolt. During dynamic analysis, one should consider the overturning moment, sliding forces on the equipment and ensure that there are sufficient anchoring points. Interfere. Holding Down Bolts In Ship.

From www.brooksforgings.co.uk

Holding Down Bolts, Structural Bolts, Construction Bolts, Foundation Bolts UK Manufacturer Holding Down Bolts In Ship Also, check for shearing and fretting on the holding down bolts. Holding down bolts for modern main propulsion slow speed engines are of the 'long sleeve' type, and are hydraulically tensioned. Purpose of holding down bolts: During dynamic analysis, one should consider the overturning moment, sliding forces on the equipment and ensure that there are sufficient anchoring points. To provide. Holding Down Bolts In Ship.

From www.siteright.net

Holding Down Bolts Holding Down Bolts In Ship A rough method of checking holding. Check for loose holding down bolts and tighten as per the manual if found loose. It is mounted on chocks and secured to the floor using holding down bolts for stability. Support weight of the engine. Purpose of holding down bolts: During dynamic analysis, one should consider the overturning moment, sliding forces on the. Holding Down Bolts In Ship.