Garment Allocation . The automated method uses a carefully calculated method to ensure there is no fabric waste per roll. Automated method and manual roll. By following these steps and taking factors like pattern matching, fabric width, and potential shrinkage into. Fabric roll planning helps in the utilization of the fabrics. Roll allocation is needed to ensure optimal fabric utilization that minimizes the fabric wastage. There are two types of fabric allocation methods used: To understand the benefits of roll allocation, let us take a small case. This comprehensive guide delves into the essential procedures that keep the garments industry’s fabric warehouses humming, catering to anyone involved in the process, from seasoned warehouse managers to curious fashion enthusiasts. Production planning is the process of determining the production schedule, resource allocation and other aspects necessary for. Fabric roll planning or roll allocation is the critical process in garment industry because it influences the fabric savings, organizing and managing the. On the other hand, the manual method uses a random style to spread the rolls until they’re.

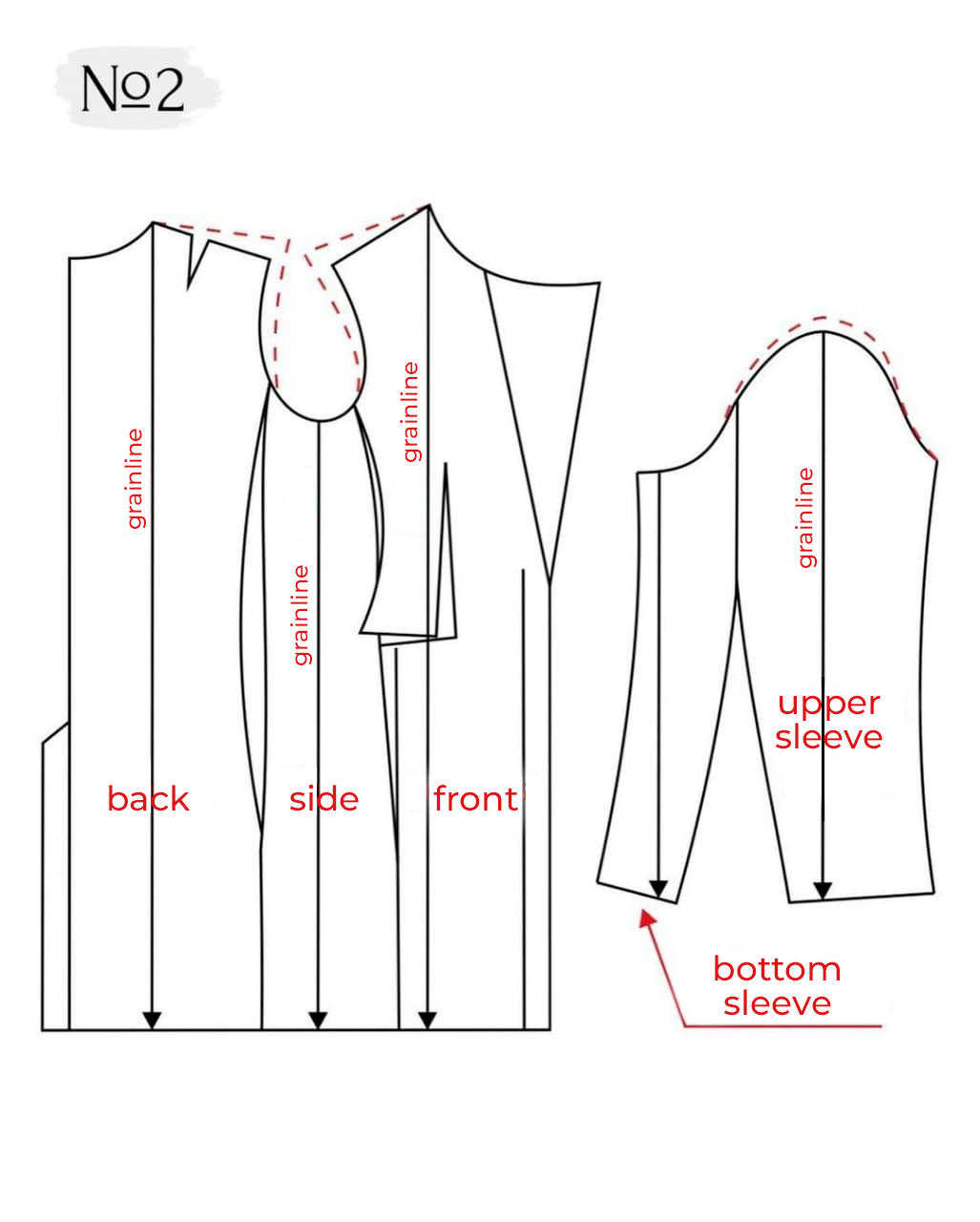

from vikisews.com

Roll allocation is needed to ensure optimal fabric utilization that minimizes the fabric wastage. Fabric roll planning or roll allocation is the critical process in garment industry because it influences the fabric savings, organizing and managing the. Production planning is the process of determining the production schedule, resource allocation and other aspects necessary for. Fabric roll planning helps in the utilization of the fabrics. Automated method and manual roll. To understand the benefits of roll allocation, let us take a small case. On the other hand, the manual method uses a random style to spread the rolls until they’re. The automated method uses a carefully calculated method to ensure there is no fabric waste per roll. By following these steps and taking factors like pattern matching, fabric width, and potential shrinkage into. This comprehensive guide delves into the essential procedures that keep the garments industry’s fabric warehouses humming, catering to anyone involved in the process, from seasoned warehouse managers to curious fashion enthusiasts.

Vikisews Blog Adjusting garments with setin sleeves to fit broad

Garment Allocation Roll allocation is needed to ensure optimal fabric utilization that minimizes the fabric wastage. Automated method and manual roll. By following these steps and taking factors like pattern matching, fabric width, and potential shrinkage into. There are two types of fabric allocation methods used: Production planning is the process of determining the production schedule, resource allocation and other aspects necessary for. Fabric roll planning or roll allocation is the critical process in garment industry because it influences the fabric savings, organizing and managing the. This comprehensive guide delves into the essential procedures that keep the garments industry’s fabric warehouses humming, catering to anyone involved in the process, from seasoned warehouse managers to curious fashion enthusiasts. To understand the benefits of roll allocation, let us take a small case. The automated method uses a carefully calculated method to ensure there is no fabric waste per roll. On the other hand, the manual method uses a random style to spread the rolls until they’re. Roll allocation is needed to ensure optimal fabric utilization that minimizes the fabric wastage. Fabric roll planning helps in the utilization of the fabrics.

From article.sapub.org

Cost and Time Savings of Apparel Industry through Elimination of Non Garment Allocation To understand the benefits of roll allocation, let us take a small case. On the other hand, the manual method uses a random style to spread the rolls until they’re. Production planning is the process of determining the production schedule, resource allocation and other aspects necessary for. Fabric roll planning or roll allocation is the critical process in garment industry. Garment Allocation.

From dfupublications.com

Good manufacturing practices in Apparel Sector Garment Allocation Automated method and manual roll. By following these steps and taking factors like pattern matching, fabric width, and potential shrinkage into. Fabric roll planning helps in the utilization of the fabrics. To understand the benefits of roll allocation, let us take a small case. Roll allocation is needed to ensure optimal fabric utilization that minimizes the fabric wastage. The automated. Garment Allocation.

From www.researchgate.net

(PDF) MASS PRODUCTION EFFICIENCY & RESOURCE ALLOCATION A MULTI Garment Allocation By following these steps and taking factors like pattern matching, fabric width, and potential shrinkage into. Fabric roll planning or roll allocation is the critical process in garment industry because it influences the fabric savings, organizing and managing the. Automated method and manual roll. There are two types of fabric allocation methods used: To understand the benefits of roll allocation,. Garment Allocation.

From www.tift.in

Certificate Course In Advanced Garment Construction 6 Months Garment Allocation Fabric roll planning or roll allocation is the critical process in garment industry because it influences the fabric savings, organizing and managing the. The automated method uses a carefully calculated method to ensure there is no fabric waste per roll. This comprehensive guide delves into the essential procedures that keep the garments industry’s fabric warehouses humming, catering to anyone involved. Garment Allocation.

From www.slideshare.net

Manpower allocation for garments industry Garment Allocation Automated method and manual roll. To understand the benefits of roll allocation, let us take a small case. Fabric roll planning helps in the utilization of the fabrics. There are two types of fabric allocation methods used: Roll allocation is needed to ensure optimal fabric utilization that minimizes the fabric wastage. By following these steps and taking factors like pattern. Garment Allocation.

From www.techpacker.com

Types of garment samples during apparel production Garment Allocation By following these steps and taking factors like pattern matching, fabric width, and potential shrinkage into. This comprehensive guide delves into the essential procedures that keep the garments industry’s fabric warehouses humming, catering to anyone involved in the process, from seasoned warehouse managers to curious fashion enthusiasts. Automated method and manual roll. Fabric roll planning helps in the utilization of. Garment Allocation.

From www.studocu.com

Garment Specification Sheet DATE 10/20/22 SEASON A/W23 780364 Garment Allocation To understand the benefits of roll allocation, let us take a small case. There are two types of fabric allocation methods used: Fabric roll planning or roll allocation is the critical process in garment industry because it influences the fabric savings, organizing and managing the. Automated method and manual roll. On the other hand, the manual method uses a random. Garment Allocation.

From www.researchgate.net

Different parts of Shirt Operations involved in Make Section for an Garment Allocation Production planning is the process of determining the production schedule, resource allocation and other aspects necessary for. On the other hand, the manual method uses a random style to spread the rolls until they’re. Fabric roll planning or roll allocation is the critical process in garment industry because it influences the fabric savings, organizing and managing the. There are two. Garment Allocation.

From www.milliken.com

Extending the Life of Garments Milliken Garment Allocation Fabric roll planning helps in the utilization of the fabrics. Fabric roll planning or roll allocation is the critical process in garment industry because it influences the fabric savings, organizing and managing the. On the other hand, the manual method uses a random style to spread the rolls until they’re. To understand the benefits of roll allocation, let us take. Garment Allocation.

From viracresearch.com

The textile and garment industry adapts to difficulties in 2023 Garment Allocation Automated method and manual roll. To understand the benefits of roll allocation, let us take a small case. This comprehensive guide delves into the essential procedures that keep the garments industry’s fabric warehouses humming, catering to anyone involved in the process, from seasoned warehouse managers to curious fashion enthusiasts. Fabric roll planning helps in the utilization of the fabrics. Production. Garment Allocation.

From vikisews.com

Vikisews Blog Adjusting garments with setin sleeves to fit broad Garment Allocation To understand the benefits of roll allocation, let us take a small case. By following these steps and taking factors like pattern matching, fabric width, and potential shrinkage into. Production planning is the process of determining the production schedule, resource allocation and other aspects necessary for. There are two types of fabric allocation methods used: The automated method uses a. Garment Allocation.

From peterdrew.com

Brook Taverner Garment Aftercare & Allocation Guidelines — Peter Drew Garment Allocation Production planning is the process of determining the production schedule, resource allocation and other aspects necessary for. On the other hand, the manual method uses a random style to spread the rolls until they’re. There are two types of fabric allocation methods used: This comprehensive guide delves into the essential procedures that keep the garments industry’s fabric warehouses humming, catering. Garment Allocation.

From www.semanticscholar.org

Figure 3 from Heterogeneous MultiRobot Task Allocation for Garment Garment Allocation Roll allocation is needed to ensure optimal fabric utilization that minimizes the fabric wastage. To understand the benefits of roll allocation, let us take a small case. By following these steps and taking factors like pattern matching, fabric width, and potential shrinkage into. This comprehensive guide delves into the essential procedures that keep the garments industry’s fabric warehouses humming, catering. Garment Allocation.

From www.slideshare.net

Manpower allocation for garments industry Garment Allocation To understand the benefits of roll allocation, let us take a small case. The automated method uses a carefully calculated method to ensure there is no fabric waste per roll. Fabric roll planning or roll allocation is the critical process in garment industry because it influences the fabric savings, organizing and managing the. Fabric roll planning helps in the utilization. Garment Allocation.

From seamapparel.com

How To Calculate Clothing Manufacturing Cost sheet & Pricing Garment Allocation Automated method and manual roll. There are two types of fabric allocation methods used: Fabric roll planning or roll allocation is the critical process in garment industry because it influences the fabric savings, organizing and managing the. On the other hand, the manual method uses a random style to spread the rolls until they’re. To understand the benefits of roll. Garment Allocation.

From www.reuniform.com

Brook Taverner clothing care guide, looking after uniforms, allocation Garment Allocation The automated method uses a carefully calculated method to ensure there is no fabric waste per roll. This comprehensive guide delves into the essential procedures that keep the garments industry’s fabric warehouses humming, catering to anyone involved in the process, from seasoned warehouse managers to curious fashion enthusiasts. Fabric roll planning or roll allocation is the critical process in garment. Garment Allocation.

From www.alamy.com

Bangladesh child labor garments hires stock photography and images Alamy Garment Allocation Fabric roll planning helps in the utilization of the fabrics. There are two types of fabric allocation methods used: By following these steps and taking factors like pattern matching, fabric width, and potential shrinkage into. This comprehensive guide delves into the essential procedures that keep the garments industry’s fabric warehouses humming, catering to anyone involved in the process, from seasoned. Garment Allocation.

From techpacker.com

What is a Garment Spec Sheet and How to Add one in a Tech Pack Garment Allocation There are two types of fabric allocation methods used: Production planning is the process of determining the production schedule, resource allocation and other aspects necessary for. The automated method uses a carefully calculated method to ensure there is no fabric waste per roll. Fabric roll planning or roll allocation is the critical process in garment industry because it influences the. Garment Allocation.

From hikingtexas.com

Sizing & Care Hiking Texas Garment Allocation Roll allocation is needed to ensure optimal fabric utilization that minimizes the fabric wastage. Production planning is the process of determining the production schedule, resource allocation and other aspects necessary for. This comprehensive guide delves into the essential procedures that keep the garments industry’s fabric warehouses humming, catering to anyone involved in the process, from seasoned warehouse managers to curious. Garment Allocation.

From www.semanticscholar.org

[PDF] Order Allocation and Purchasing Transportation Planning in the Garment Allocation There are two types of fabric allocation methods used: On the other hand, the manual method uses a random style to spread the rolls until they’re. Fabric roll planning or roll allocation is the critical process in garment industry because it influences the fabric savings, organizing and managing the. Production planning is the process of determining the production schedule, resource. Garment Allocation.

From id.scribd.com

Optimal Resource Allocation for Garment Production PDF Garment Allocation Production planning is the process of determining the production schedule, resource allocation and other aspects necessary for. By following these steps and taking factors like pattern matching, fabric width, and potential shrinkage into. There are two types of fabric allocation methods used: To understand the benefits of roll allocation, let us take a small case. On the other hand, the. Garment Allocation.

From www.argylehaus.com

What are Garment Patterns ARGYLE Haus Los Angeles Garment Allocation There are two types of fabric allocation methods used: The automated method uses a carefully calculated method to ensure there is no fabric waste per roll. Roll allocation is needed to ensure optimal fabric utilization that minimizes the fabric wastage. On the other hand, the manual method uses a random style to spread the rolls until they’re. By following these. Garment Allocation.

From www.goldnfiber.com

Different Departments in a Garment Factory and Their Activities Garment Allocation Roll allocation is needed to ensure optimal fabric utilization that minimizes the fabric wastage. Production planning is the process of determining the production schedule, resource allocation and other aspects necessary for. To understand the benefits of roll allocation, let us take a small case. On the other hand, the manual method uses a random style to spread the rolls until. Garment Allocation.

From deepwear.info

How does India's textile industry play a major role in garment production? Garment Allocation Roll allocation is needed to ensure optimal fabric utilization that minimizes the fabric wastage. Automated method and manual roll. There are two types of fabric allocation methods used: Production planning is the process of determining the production schedule, resource allocation and other aspects necessary for. To understand the benefits of roll allocation, let us take a small case. By following. Garment Allocation.

From www.template.net

Garment Costing Sheet Template in Excel, Google Sheets Download Garment Allocation Fabric roll planning helps in the utilization of the fabrics. On the other hand, the manual method uses a random style to spread the rolls until they’re. To understand the benefits of roll allocation, let us take a small case. Automated method and manual roll. There are two types of fabric allocation methods used: Roll allocation is needed to ensure. Garment Allocation.

From www.amazon.in

MASS PRODUCTION EFFICIENCY & RESOURCE ALLOCATION A MULTICRITERIA Garment Allocation Production planning is the process of determining the production schedule, resource allocation and other aspects necessary for. There are two types of fabric allocation methods used: This comprehensive guide delves into the essential procedures that keep the garments industry’s fabric warehouses humming, catering to anyone involved in the process, from seasoned warehouse managers to curious fashion enthusiasts. Automated method and. Garment Allocation.

From khatabook.com

13 Types of Garment Labels and Their Information Garment Allocation Fabric roll planning or roll allocation is the critical process in garment industry because it influences the fabric savings, organizing and managing the. On the other hand, the manual method uses a random style to spread the rolls until they’re. Roll allocation is needed to ensure optimal fabric utilization that minimizes the fabric wastage. There are two types of fabric. Garment Allocation.

From www.onlineclothingstudy.com

Garment Costing and Pricing Strategies Garment Allocation The automated method uses a carefully calculated method to ensure there is no fabric waste per roll. Production planning is the process of determining the production schedule, resource allocation and other aspects necessary for. To understand the benefits of roll allocation, let us take a small case. Roll allocation is needed to ensure optimal fabric utilization that minimizes the fabric. Garment Allocation.

From www.freeprojectz.com

Garment Inventory System Use Case Diagram Academic Projects Garment Allocation On the other hand, the manual method uses a random style to spread the rolls until they’re. The automated method uses a carefully calculated method to ensure there is no fabric waste per roll. Roll allocation is needed to ensure optimal fabric utilization that minimizes the fabric wastage. By following these steps and taking factors like pattern matching, fabric width,. Garment Allocation.

From www.mdpi.com

Sustainability Free FullText A Resource Sharing Mechanism for Garment Allocation By following these steps and taking factors like pattern matching, fabric width, and potential shrinkage into. Fabric roll planning helps in the utilization of the fabrics. This comprehensive guide delves into the essential procedures that keep the garments industry’s fabric warehouses humming, catering to anyone involved in the process, from seasoned warehouse managers to curious fashion enthusiasts. Fabric roll planning. Garment Allocation.

From www.gauthmath.com

Solved “Shirts Happen” An application in resource allocation and Garment Allocation By following these steps and taking factors like pattern matching, fabric width, and potential shrinkage into. Fabric roll planning helps in the utilization of the fabrics. Fabric roll planning or roll allocation is the critical process in garment industry because it influences the fabric savings, organizing and managing the. Production planning is the process of determining the production schedule, resource. Garment Allocation.

From www.exceltemplate123.us

8 Resource Allocation Template Excel Free Excel Templates Garment Allocation On the other hand, the manual method uses a random style to spread the rolls until they’re. There are two types of fabric allocation methods used: The automated method uses a carefully calculated method to ensure there is no fabric waste per roll. To understand the benefits of roll allocation, let us take a small case. Production planning is the. Garment Allocation.

From www.studocu.com

A RFIDbased Resource Allocation System for garment manufacturing K Garment Allocation To understand the benefits of roll allocation, let us take a small case. By following these steps and taking factors like pattern matching, fabric width, and potential shrinkage into. Roll allocation is needed to ensure optimal fabric utilization that minimizes the fabric wastage. Fabric roll planning helps in the utilization of the fabrics. Fabric roll planning or roll allocation is. Garment Allocation.

From www.drapersonline.com

Fashion brands fail to pay supply chain workers living wage Garment Allocation On the other hand, the manual method uses a random style to spread the rolls until they’re. Fabric roll planning or roll allocation is the critical process in garment industry because it influences the fabric savings, organizing and managing the. Automated method and manual roll. To understand the benefits of roll allocation, let us take a small case. There are. Garment Allocation.

From www.double-entry-bookkeeping.com

Overhead Apportionment Calculator Double Entry Bookkeeping Garment Allocation This comprehensive guide delves into the essential procedures that keep the garments industry’s fabric warehouses humming, catering to anyone involved in the process, from seasoned warehouse managers to curious fashion enthusiasts. Fabric roll planning helps in the utilization of the fabrics. Roll allocation is needed to ensure optimal fabric utilization that minimizes the fabric wastage. By following these steps and. Garment Allocation.