Pump Maintenance Procedures . This focuses on components that are leading indicator of potential failure. Regular and effective pump maintenance is essential in maximizing pump life and performance. In this article, we explore various. Routine maintenance is the process of setting a schedule to inspect, log, and repair components. The solution to maintaining reliable pump operations is a robust. By integrating these recommended procedures into your regular pump maintenance regimen, you can guarantee the seamless operation of your. Maintenance programs for centrifugal pumps can be grouped into three categories: By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. Routine, quarterly, and annual maintenance. This comprehensive maintenance checklist provides a structured approach to safeguarding the efficiency and reliability of your centrifugal pump system. Pumps supporting process do not change with them.

from dacworldwide.com

Routine, quarterly, and annual maintenance. Pumps supporting process do not change with them. Regular and effective pump maintenance is essential in maximizing pump life and performance. By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. The solution to maintaining reliable pump operations is a robust. By integrating these recommended procedures into your regular pump maintenance regimen, you can guarantee the seamless operation of your. Routine maintenance is the process of setting a schedule to inspect, log, and repair components. This focuses on components that are leading indicator of potential failure. Maintenance programs for centrifugal pumps can be grouped into three categories: This comprehensive maintenance checklist provides a structured approach to safeguarding the efficiency and reliability of your centrifugal pump system.

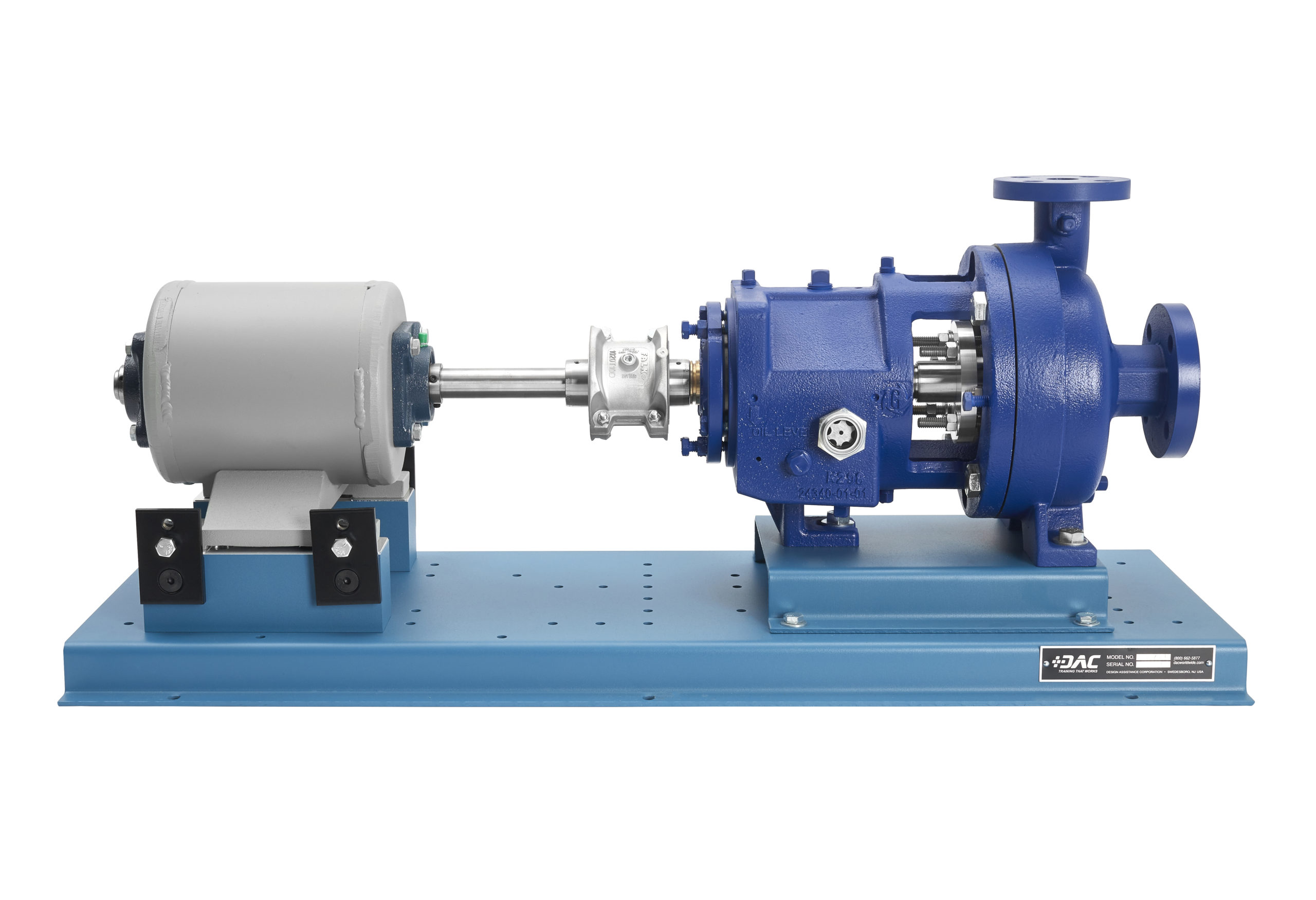

Pump Maintenance and Alignment Training System Plus HandsOn

Pump Maintenance Procedures By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. This focuses on components that are leading indicator of potential failure. By integrating these recommended procedures into your regular pump maintenance regimen, you can guarantee the seamless operation of your. This comprehensive maintenance checklist provides a structured approach to safeguarding the efficiency and reliability of your centrifugal pump system. Routine maintenance is the process of setting a schedule to inspect, log, and repair components. In this article, we explore various. Routine, quarterly, and annual maintenance. Regular and effective pump maintenance is essential in maximizing pump life and performance. Pumps supporting process do not change with them. Maintenance programs for centrifugal pumps can be grouped into three categories: The solution to maintaining reliable pump operations is a robust.

From dxppacific.com

3 Types of Pump Maintenance Which is Best? DXP Pacific Pump Maintenance Procedures The solution to maintaining reliable pump operations is a robust. This focuses on components that are leading indicator of potential failure. By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. Routine, quarterly, and annual maintenance. This comprehensive maintenance checklist provides a structured approach to safeguarding the efficiency and reliability of your centrifugal. Pump Maintenance Procedures.

From www.scribd.com

Pump Maintenance Procedures 1 PDF Bearing (Mechanical) Wear Pump Maintenance Procedures Regular and effective pump maintenance is essential in maximizing pump life and performance. By integrating these recommended procedures into your regular pump maintenance regimen, you can guarantee the seamless operation of your. In this article, we explore various. This focuses on components that are leading indicator of potential failure. The solution to maintaining reliable pump operations is a robust. This. Pump Maintenance Procedures.

From dacworldwide.com

Pump Maintenance and Alignment Training System Plus HandsOn Pump Maintenance Procedures This focuses on components that are leading indicator of potential failure. Routine, quarterly, and annual maintenance. By integrating these recommended procedures into your regular pump maintenance regimen, you can guarantee the seamless operation of your. By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. The solution to maintaining reliable pump operations is. Pump Maintenance Procedures.

From www.chamco.com

8 Industrial Pump Maintenance Tips to Extend The Lifespan of Your Pump Pump Maintenance Procedures By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. By integrating these recommended procedures into your regular pump maintenance regimen, you can guarantee the seamless operation of your. Routine, quarterly, and annual maintenance. Maintenance programs for centrifugal pumps can be grouped into three categories: Routine maintenance is the process of setting a. Pump Maintenance Procedures.

From www.pumpsandsystems.com

Checklist for Successful Pump Installation Pumps & Systems Pump Maintenance Procedures In this article, we explore various. This comprehensive maintenance checklist provides a structured approach to safeguarding the efficiency and reliability of your centrifugal pump system. Routine maintenance is the process of setting a schedule to inspect, log, and repair components. By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. Routine, quarterly, and. Pump Maintenance Procedures.

From www.slideserve.com

PPT Fire Engine Maintenance PowerPoint Presentation, free download Pump Maintenance Procedures Pumps supporting process do not change with them. Routine, quarterly, and annual maintenance. In this article, we explore various. By integrating these recommended procedures into your regular pump maintenance regimen, you can guarantee the seamless operation of your. The solution to maintaining reliable pump operations is a robust. This focuses on components that are leading indicator of potential failure. Maintenance. Pump Maintenance Procedures.

From www.open2hire.com

Oil and Gas Pump Maintenance Procedures PDF Pump Maintenance Procedures Routine, quarterly, and annual maintenance. Maintenance programs for centrifugal pumps can be grouped into three categories: This focuses on components that are leading indicator of potential failure. By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. The solution to maintaining reliable pump operations is a robust. Pumps supporting process do not change. Pump Maintenance Procedures.

From servicepump.com

Your Complete Guide to Maintaining Pump Systems Service Pump & Supply Pump Maintenance Procedures Maintenance programs for centrifugal pumps can be grouped into three categories: This focuses on components that are leading indicator of potential failure. By integrating these recommended procedures into your regular pump maintenance regimen, you can guarantee the seamless operation of your. In this article, we explore various. Pumps supporting process do not change with them. By following best practices, you. Pump Maintenance Procedures.

From servicepump.com

Free Infographic How to Perform Routine Centrifugal Pump Maintenance Pump Maintenance Procedures This focuses on components that are leading indicator of potential failure. Regular and effective pump maintenance is essential in maximizing pump life and performance. Routine, quarterly, and annual maintenance. By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. This comprehensive maintenance checklist provides a structured approach to safeguarding the efficiency and reliability. Pump Maintenance Procedures.

From www.scribd.com

Pump Maintenance PDF Bearing (Mechanical) Pump Pump Maintenance Procedures Routine, quarterly, and annual maintenance. In this article, we explore various. By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. The solution to maintaining reliable pump operations is a robust. This focuses on components that are leading indicator of potential failure. Maintenance programs for centrifugal pumps can be grouped into three categories:. Pump Maintenance Procedures.

From www.pumptec.com

Pump Maintenance Checklist Pumptec Pump Maintenance Procedures In this article, we explore various. Routine maintenance is the process of setting a schedule to inspect, log, and repair components. By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. By integrating these recommended procedures into your regular pump maintenance regimen, you can guarantee the seamless operation of your. Regular and effective. Pump Maintenance Procedures.

From aps-online.net

Preventive Maintenance (PM) Procedure Writing Services APS Pump Maintenance Procedures Routine maintenance is the process of setting a schedule to inspect, log, and repair components. Pumps supporting process do not change with them. In this article, we explore various. By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. This comprehensive maintenance checklist provides a structured approach to safeguarding the efficiency and reliability. Pump Maintenance Procedures.

From heatingny.com

Routine Pump Maintenance Controlled Combustion What is Involved? Pump Maintenance Procedures This focuses on components that are leading indicator of potential failure. This comprehensive maintenance checklist provides a structured approach to safeguarding the efficiency and reliability of your centrifugal pump system. Pumps supporting process do not change with them. Routine, quarterly, and annual maintenance. Regular and effective pump maintenance is essential in maximizing pump life and performance. In this article, we. Pump Maintenance Procedures.

From forumautomation.com

Electrical pumps Maintenance checklist Field Instrumentation Pump Maintenance Procedures By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. This focuses on components that are leading indicator of potential failure. The solution to maintaining reliable pump operations is a robust. Routine, quarterly, and annual maintenance. This comprehensive maintenance checklist provides a structured approach to safeguarding the efficiency and reliability of your centrifugal. Pump Maintenance Procedures.

From safetyculture.com

Free Pump Maintenance Checklist PDF SafetyCulture Pump Maintenance Procedures Routine, quarterly, and annual maintenance. Regular and effective pump maintenance is essential in maximizing pump life and performance. By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. In this article, we explore various. Maintenance programs for centrifugal pumps can be grouped into three categories: This comprehensive maintenance checklist provides a structured approach. Pump Maintenance Procedures.

From www.youtube.com

Centrifugal Pump Repair and Maintenance Procedure Part 1 YouTube Pump Maintenance Procedures In this article, we explore various. The solution to maintaining reliable pump operations is a robust. By integrating these recommended procedures into your regular pump maintenance regimen, you can guarantee the seamless operation of your. Regular and effective pump maintenance is essential in maximizing pump life and performance. This comprehensive maintenance checklist provides a structured approach to safeguarding the efficiency. Pump Maintenance Procedures.

From issuu.com

Pump Maintenance Checklist by Jeffery Mason Issuu Pump Maintenance Procedures In this article, we explore various. The solution to maintaining reliable pump operations is a robust. By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. Regular and effective pump maintenance is essential in maximizing pump life and performance. Routine, quarterly, and annual maintenance. By integrating these recommended procedures into your regular pump. Pump Maintenance Procedures.

From www.castlepumps.com

Centrifugal Pump Maintenance Schedule Castle Pumps Pump Maintenance Procedures This comprehensive maintenance checklist provides a structured approach to safeguarding the efficiency and reliability of your centrifugal pump system. By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. By integrating these recommended procedures into your regular pump maintenance regimen, you can guarantee the seamless operation of your. Pumps supporting process do not. Pump Maintenance Procedures.

From www.youtube.com

Basic Pump Maintenance Strategies & Techniques w/ TPC Online inar Pump Maintenance Procedures This comprehensive maintenance checklist provides a structured approach to safeguarding the efficiency and reliability of your centrifugal pump system. The solution to maintaining reliable pump operations is a robust. Routine, quarterly, and annual maintenance. Pumps supporting process do not change with them. This focuses on components that are leading indicator of potential failure. By integrating these recommended procedures into your. Pump Maintenance Procedures.

From www.slideserve.com

PPT to Diaphragm Pumps PowerPoint Presentation, free download Pump Maintenance Procedures Pumps supporting process do not change with them. By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. Regular and effective pump maintenance is essential in maximizing pump life and performance. This focuses on components that are leading indicator of potential failure. In this article, we explore various. By integrating these recommended procedures. Pump Maintenance Procedures.

From www.sampletemplates.com

FREE 25+ Maintenance Checklist Samples & Templates in MS Word PDF Pump Maintenance Procedures Routine maintenance is the process of setting a schedule to inspect, log, and repair components. Routine, quarterly, and annual maintenance. The solution to maintaining reliable pump operations is a robust. Maintenance programs for centrifugal pumps can be grouped into three categories: Regular and effective pump maintenance is essential in maximizing pump life and performance. By integrating these recommended procedures into. Pump Maintenance Procedures.

From www.youtube.com

centrifugal pump parts and work centrifugal pump maintenance Pump Maintenance Procedures The solution to maintaining reliable pump operations is a robust. By integrating these recommended procedures into your regular pump maintenance regimen, you can guarantee the seamless operation of your. Routine maintenance is the process of setting a schedule to inspect, log, and repair components. By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your. Pump Maintenance Procedures.

From www.rasmech.com

Centrifugal Pump Maintenance Checklist RasMech Pump Maintenance Procedures Pumps supporting process do not change with them. Maintenance programs for centrifugal pumps can be grouped into three categories: This comprehensive maintenance checklist provides a structured approach to safeguarding the efficiency and reliability of your centrifugal pump system. Routine maintenance is the process of setting a schedule to inspect, log, and repair components. Regular and effective pump maintenance is essential. Pump Maintenance Procedures.

From schoolcraftpublishing.com

Quick Reference Guide Pump Repair and Maintenance Pump Maintenance Procedures The solution to maintaining reliable pump operations is a robust. This comprehensive maintenance checklist provides a structured approach to safeguarding the efficiency and reliability of your centrifugal pump system. Routine maintenance is the process of setting a schedule to inspect, log, and repair components. By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your. Pump Maintenance Procedures.

From www.youtube.com

Centrifugal Pump Repair and Maintenance Procedure Part 2 YouTube Pump Maintenance Procedures Routine maintenance is the process of setting a schedule to inspect, log, and repair components. By integrating these recommended procedures into your regular pump maintenance regimen, you can guarantee the seamless operation of your. This focuses on components that are leading indicator of potential failure. The solution to maintaining reliable pump operations is a robust. Regular and effective pump maintenance. Pump Maintenance Procedures.

From www.youtube.com

How to Keep your Pumps Running Smoothly (Basic Pump Maintenance) TPC Pump Maintenance Procedures Routine, quarterly, and annual maintenance. By integrating these recommended procedures into your regular pump maintenance regimen, you can guarantee the seamless operation of your. This focuses on components that are leading indicator of potential failure. In this article, we explore various. By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. This comprehensive. Pump Maintenance Procedures.

From dxppacific.com

The Importance of Preventative Maintenance for Extended Pump Life DXP Pump Maintenance Procedures This comprehensive maintenance checklist provides a structured approach to safeguarding the efficiency and reliability of your centrifugal pump system. The solution to maintaining reliable pump operations is a robust. Routine maintenance is the process of setting a schedule to inspect, log, and repair components. By integrating these recommended procedures into your regular pump maintenance regimen, you can guarantee the seamless. Pump Maintenance Procedures.

From cortecheng.com

Centrifugal Pump Maintenance Procedures for Industrial Pumps DXP Cortech Pump Maintenance Procedures This comprehensive maintenance checklist provides a structured approach to safeguarding the efficiency and reliability of your centrifugal pump system. In this article, we explore various. Routine, quarterly, and annual maintenance. Regular and effective pump maintenance is essential in maximizing pump life and performance. By integrating these recommended procedures into your regular pump maintenance regimen, you can guarantee the seamless operation. Pump Maintenance Procedures.

From www.researchgate.net

1 Process flowchart of pump maintenance activities. Download Pump Maintenance Procedures In this article, we explore various. Regular and effective pump maintenance is essential in maximizing pump life and performance. The solution to maintaining reliable pump operations is a robust. This focuses on components that are leading indicator of potential failure. Maintenance programs for centrifugal pumps can be grouped into three categories: This comprehensive maintenance checklist provides a structured approach to. Pump Maintenance Procedures.

From www.pumptec.com

Pump Maintenance Checklist Pumptec Pump Maintenance Procedures By following best practices, you can maximize performance, minimize downtime, and extend the lifespan of your equipment. Routine maintenance is the process of setting a schedule to inspect, log, and repair components. The solution to maintaining reliable pump operations is a robust. Pumps supporting process do not change with them. Routine, quarterly, and annual maintenance. Regular and effective pump maintenance. Pump Maintenance Procedures.

From www.slideserve.com

PPT MAINTENANCE PROCEDURES PowerPoint Presentation, free download Pump Maintenance Procedures The solution to maintaining reliable pump operations is a robust. Pumps supporting process do not change with them. Maintenance programs for centrifugal pumps can be grouped into three categories: In this article, we explore various. This comprehensive maintenance checklist provides a structured approach to safeguarding the efficiency and reliability of your centrifugal pump system. This focuses on components that are. Pump Maintenance Procedures.

From mungfali.com

Centrifugal Pump Maintenance Pump Maintenance Procedures In this article, we explore various. This comprehensive maintenance checklist provides a structured approach to safeguarding the efficiency and reliability of your centrifugal pump system. This focuses on components that are leading indicator of potential failure. Routine, quarterly, and annual maintenance. Maintenance programs for centrifugal pumps can be grouped into three categories: By following best practices, you can maximize performance,. Pump Maintenance Procedures.

From mavink.com

Preventive Maintenance Checklist For Pumps Pump Maintenance Procedures Routine maintenance is the process of setting a schedule to inspect, log, and repair components. Pumps supporting process do not change with them. The solution to maintaining reliable pump operations is a robust. This comprehensive maintenance checklist provides a structured approach to safeguarding the efficiency and reliability of your centrifugal pump system. Maintenance programs for centrifugal pumps can be grouped. Pump Maintenance Procedures.

From www.slideshare.net

Maintenance of Pumps Pump Maintenance Procedures Routine maintenance is the process of setting a schedule to inspect, log, and repair components. Maintenance programs for centrifugal pumps can be grouped into three categories: By integrating these recommended procedures into your regular pump maintenance regimen, you can guarantee the seamless operation of your. Regular and effective pump maintenance is essential in maximizing pump life and performance. This focuses. Pump Maintenance Procedures.