Carbide Inserts Process . — the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. — carbide inserts are an essential component of modern machining operations, helping to achieve precision, efficiency, and cost. Additionally, it has a higher tendency for vibration. Learn more about carbide inserts, and. — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. A larger nose angle provides increased strength, but it also requires more machine power. regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity.

from www.carbidetoolinserts.com

— the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. Additionally, it has a higher tendency for vibration. regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. — carbide inserts are an essential component of modern machining operations, helping to achieve precision, efficiency, and cost. — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. A larger nose angle provides increased strength, but it also requires more machine power. Learn more about carbide inserts, and.

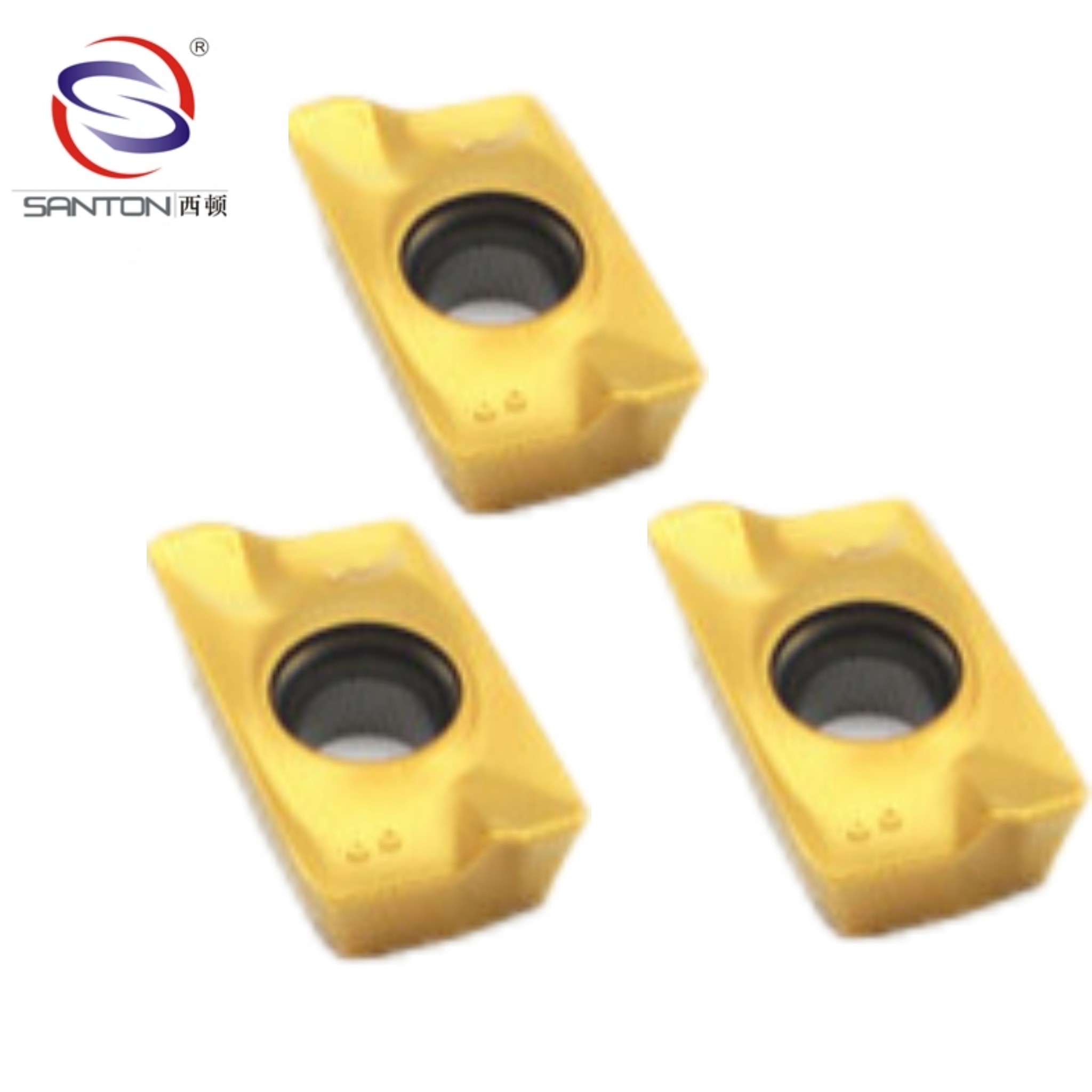

YG6A CNC Carbide Inserts to process steel, cast iron,rock, plastic, etc

Carbide Inserts Process — carbide inserts are an essential component of modern machining operations, helping to achieve precision, efficiency, and cost. Learn more about carbide inserts, and. — the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. — carbide inserts are an essential component of modern machining operations, helping to achieve precision, efficiency, and cost. regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. A larger nose angle provides increased strength, but it also requires more machine power. — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. Additionally, it has a higher tendency for vibration.

From estool.en.made-in-china.com

Cemented Turning Insert Snmm250924Tr Yc1325 (SNMM866) HeavyDuty Roughing Process CNC Lathe Carbide Inserts Process — the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. Additionally, it has a higher tendency for vibration. — carbide inserts are an essential component of modern machining operations, helping to achieve precision, efficiency, and cost. regardless of component size, material or design, the carbide insert. Carbide Inserts Process.

From spikejean.exblog.jp

Cutting Edge Geometry Effects On Tungsten Carbide Inserts Coating Process MILLING INSERTS Carbide Inserts Process — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. Additionally, it has a higher tendency for vibration. — carbide inserts are an essential component of modern machining operations, helping to achieve precision, efficiency, and cost. Learn more about carbide inserts, and. — the nose. Carbide Inserts Process.

From sigmatiz.com

Identify the best turning insert & carbide inserts Sigmatiz Carbide Inserts Process — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. Additionally, it has a higher tendency for vibration. A larger nose angle provides increased strength, but it also requires more machine power. — the nose radius of a turning insert plays a major role in reducing. Carbide Inserts Process.

From www.aliexpress.com

Carbide Turning Tips,Tungsten Carbide Inserts for SCLCR/SCKCR Steel Process 10pcs CCMT09T308 HM Carbide Inserts Process — the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. Learn more about carbide inserts, and. Additionally, it has a higher tendency for vibration. regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. A. Carbide Inserts Process.

From www.alibaba.com

Inserts Carbide Cnmg,Cemented Carbide Inserts,Carbide Cutting Inserts Buy Inserts Carbide Carbide Inserts Process — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. — the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. A larger nose angle provides increased strength, but it also requires more machine power. Additionally,. Carbide Inserts Process.

From tungstencarbide.en.made-in-china.com

Standard Carbide Inserts for Scarfing Process China Scarfing Inserts and Scarfing Tools Carbide Inserts Process A larger nose angle provides increased strength, but it also requires more machine power. regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. — the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. Additionally,. Carbide Inserts Process.

From www.researchgate.net

Carbide inserts before machining Download Scientific Diagram Carbide Inserts Process — the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. — carbide inserts are an essential component of modern machining operations, helping to achieve precision, efficiency, and cost. A larger nose angle provides increased strength, but it also requires more machine power. regardless of component size,. Carbide Inserts Process.

From www.carbide-part.com

How carbide inserts are made? Yizemold Carbide Inserts Process Additionally, it has a higher tendency for vibration. A larger nose angle provides increased strength, but it also requires more machine power. — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. Learn more about carbide inserts, and. — the nose radius of a turning insert. Carbide Inserts Process.

From www.dreamstime.com

Insert Carbide Tip Attach at Holding Shaft for Cnc Machining Center or Milling Machine for Carbide Inserts Process Learn more about carbide inserts, and. — the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. regardless of component size, material or design, the. Carbide Inserts Process.

From www.wodenco.com

How to Select the Right Carbide Inserts The Ultimate Guide Wodenco Carbide Inserts Process — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. Additionally, it has a higher tendency for vibration. A larger nose angle provides increased strength, but it also requires more machine power. — carbide inserts are an essential component of modern machining operations, helping to achieve. Carbide Inserts Process.

From www.icarbide.com

how to understand milling carbide inserts icarbide Carbide Inserts Process — the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. — carbide inserts are an essential component of modern machining operations, helping to achieve precision, efficiency, and cost. — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw. Carbide Inserts Process.

From www.wodenco.com

How to Select the Right Carbide Inserts The Ultimate Guide Wodenco Carbide Inserts Process — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Learn more about carbide inserts, and. — the nose radius of a turning. Carbide Inserts Process.

From www.cnc-tool.com

CNC Solid Carbide Inserts S21 Carbide Inserts Process Additionally, it has a higher tendency for vibration. — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. — carbide inserts are an. Carbide Inserts Process.

From www.youtube.com

Carbide turning inserts pressing YouTube Carbide Inserts Process — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. Learn more about carbide inserts, and. — carbide inserts are an essential component of modern machining operations, helping to achieve precision, efficiency, and cost. — the nose radius of a turning insert plays a major. Carbide Inserts Process.

From www.aliexpress.com

Original Carbide Inserts XSEQ1202 XSEQ12T3 XSEQ12T4 YBG302 XSEQ 1202 12T4 12T3 Milling Lathe Carbide Inserts Process A larger nose angle provides increased strength, but it also requires more machine power. Learn more about carbide inserts, and. — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. — carbide inserts are an essential component of modern machining operations, helping to achieve precision, efficiency,. Carbide Inserts Process.

From brmeccanicaitaly.com

Cutting tools and carbide Inserts Milling Inserts,Grooving Inserts,Drilling... Carbide Inserts Process — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. A larger nose angle provides increased strength, but it also requires more machine power. — the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. . Carbide Inserts Process.

From huanatools.com

How to choose the right carbide turning insert Huana Tools Carbide Inserts Process — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. Learn more about carbide inserts, and. A larger nose angle provides increased strength, but it also requires more machine power. regardless of component size, material or design, the carbide insert grade you use can make all. Carbide Inserts Process.

From huanatools.com

How To Make The Carbide Inserts? Huana Tools Carbide Inserts Process A larger nose angle provides increased strength, but it also requires more machine power. — the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. Learn. Carbide Inserts Process.

From scmtstools.en.made-in-china.com

Mtstools CNC Carbide Insert Tnga160408 for CNC Process China Milling Cutter and CNC Carbide Inserts Process regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Learn more about carbide inserts, and. — the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. A larger nose angle provides increased strength, but it. Carbide Inserts Process.

From www.carbidetoolinserts.com

YG6A CNC Carbide Inserts to process steel, cast iron,rock, plastic, etc Carbide Inserts Process — carbide inserts are an essential component of modern machining operations, helping to achieve precision, efficiency, and cost. Learn more about carbide inserts, and. Additionally, it has a higher tendency for vibration. regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. — in this. Carbide Inserts Process.

From www.wodenco.com

How to Select the Right Carbide Inserts The Ultimate Guide Wodenco Carbide Inserts Process — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. — carbide inserts are an essential component of modern machining operations, helping to achieve precision, efficiency, and cost. Learn more about carbide inserts, and. — the nose radius of a turning insert plays a major. Carbide Inserts Process.

From www.mmc-carbide.com

What is Carbide? Technical Info / Cutting Formula MITSUBISHI MATERIALS CORPORATION Carbide Inserts Process Additionally, it has a higher tendency for vibration. Learn more about carbide inserts, and. — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity.. Carbide Inserts Process.

From tungstencarbide.en.made-in-china.com

PENTA24 series Carbide Inserts for Grooving or Parting process China Grooving Inserts and Carbide Inserts Process — carbide inserts are an essential component of modern machining operations, helping to achieve precision, efficiency, and cost. Additionally, it has a higher tendency for vibration. — the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. — in this detailed guide, we will look at the. Carbide Inserts Process.

From www.estoolcarbide.com

How To Understand The Type Of Carbide Inserts Carbide Inserts Process — the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. Learn more about carbide inserts, and. regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. A larger nose angle provides increased strength, but it. Carbide Inserts Process.

From tungstencarbide.en.made-in-china.com

Carbide Inserts for turning process China carbide inserts and Indexable inserts Carbide Inserts Process — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. A larger nose angle provides increased strength, but it also requires more machine power. — the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. Learn. Carbide Inserts Process.

From www.alibaba.com

Tdgu 400 Ct5320 Carbide Insert For Cnc Machining Process Buy Carbide Inserts,Milling Carbide Carbide Inserts Process — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. A larger nose angle provides increased strength, but it also requires more machine power. Additionally, it has a higher tendency for vibration. Learn more about carbide inserts, and. — the nose radius of a turning insert. Carbide Inserts Process.

From huanatools.com

Complete application of carbide Inserts Huana Tools Carbide Inserts Process A larger nose angle provides increased strength, but it also requires more machine power. regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. — the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. Additionally,. Carbide Inserts Process.

From www.alibaba.com

Znht 03804 Ct5320 Carbide Insert For Milling And Slotting Process Buy Carbide Inserts Carbide Inserts Process — carbide inserts are an essential component of modern machining operations, helping to achieve precision, efficiency, and cost. regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Additionally, it has a higher tendency for vibration. A larger nose angle provides increased strength, but it also. Carbide Inserts Process.

From www.carbidetoolinserts.com

YG6A CNC Carbide Inserts to process steel, cast iron,rock, plastic, etc Carbide Inserts Process A larger nose angle provides increased strength, but it also requires more machine power. — the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. — carbide inserts are an essential component of modern machining operations, helping to achieve precision, efficiency, and cost. — in this detailed. Carbide Inserts Process.

From toolnotes.com

Carbide Insert Identification Systems ToolNotes Carbide Inserts Process Learn more about carbide inserts, and. — the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Additionally, it has a higher tendency for vibration. . Carbide Inserts Process.

From www.acarbide.com

Carbide Inserts AGrade Carbide Carbide Inserts Process — carbide inserts are an essential component of modern machining operations, helping to achieve precision, efficiency, and cost. regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Learn more about carbide inserts, and. — the nose radius of a turning insert plays a major. Carbide Inserts Process.

From rdbarrett.co.uk

How to Identify Carbide Inserts R.D. Barrett Carbide Inserts Process — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. — carbide inserts are an essential component of modern machining operations, helping to. Carbide Inserts Process.

From www.icarbide.com

High Performance Carbide Inserts icarbide Carbide Inserts Process Learn more about carbide inserts, and. Additionally, it has a higher tendency for vibration. — carbide inserts are an essential component of modern machining operations, helping to achieve precision, efficiency, and cost. A larger nose angle provides increased strength, but it also requires more machine power. — in this detailed guide, we will look at the entire process. Carbide Inserts Process.

From www.youtube.com

How carbide inserts are made by Sandvik Coromant YouTube Carbide Inserts Process Learn more about carbide inserts, and. — the nose radius of a turning insert plays a major role in reducing vibration and enhancing the workpiece’s surface finish. — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. regardless of component size, material or design, the. Carbide Inserts Process.

From www.bddrill.com.au

Carbide Inserts HighQuality Cutting Tools for Precision Machining Carbide Inserts Process Learn more about carbide inserts, and. Additionally, it has a higher tendency for vibration. — in this detailed guide, we will look at the entire process of creating carbide inserts, from raw materials to the finished. A larger nose angle provides increased strength, but it also requires more machine power. — carbide inserts are an essential component of. Carbide Inserts Process.