Ceramic Tube Manufacturing Process . Most ceramic components are made through powder processing starting with ceramic powders. They show different shapes because of the firing/sintering of different. In addition to clay based materials, today ceramics include a multitude of products with a small fraction of clay or none at all. The transformation of raw materials into engineered ceramic products is a meticulous process. The clay is forced through a specially designed extrusion die,. When converting a plastic or metallic part to a ceramic material, you may require a. Less is often more in this game. Here’s a closer look at each step:. Unveiling the power of pressure. Pipes and tubes made from alunit® aluminum nitride ceramics ceramtec gmbh has succeeded in achieving series extrusion of exceptionally. Extrusion is a widely used technique in ceramic tube manufacturing.

from eureka.patsnap.com

Less is often more in this game. The transformation of raw materials into engineered ceramic products is a meticulous process. Extrusion is a widely used technique in ceramic tube manufacturing. They show different shapes because of the firing/sintering of different. In addition to clay based materials, today ceramics include a multitude of products with a small fraction of clay or none at all. Unveiling the power of pressure. Most ceramic components are made through powder processing starting with ceramic powders. The clay is forced through a specially designed extrusion die,. Pipes and tubes made from alunit® aluminum nitride ceramics ceramtec gmbh has succeeded in achieving series extrusion of exceptionally. Here’s a closer look at each step:.

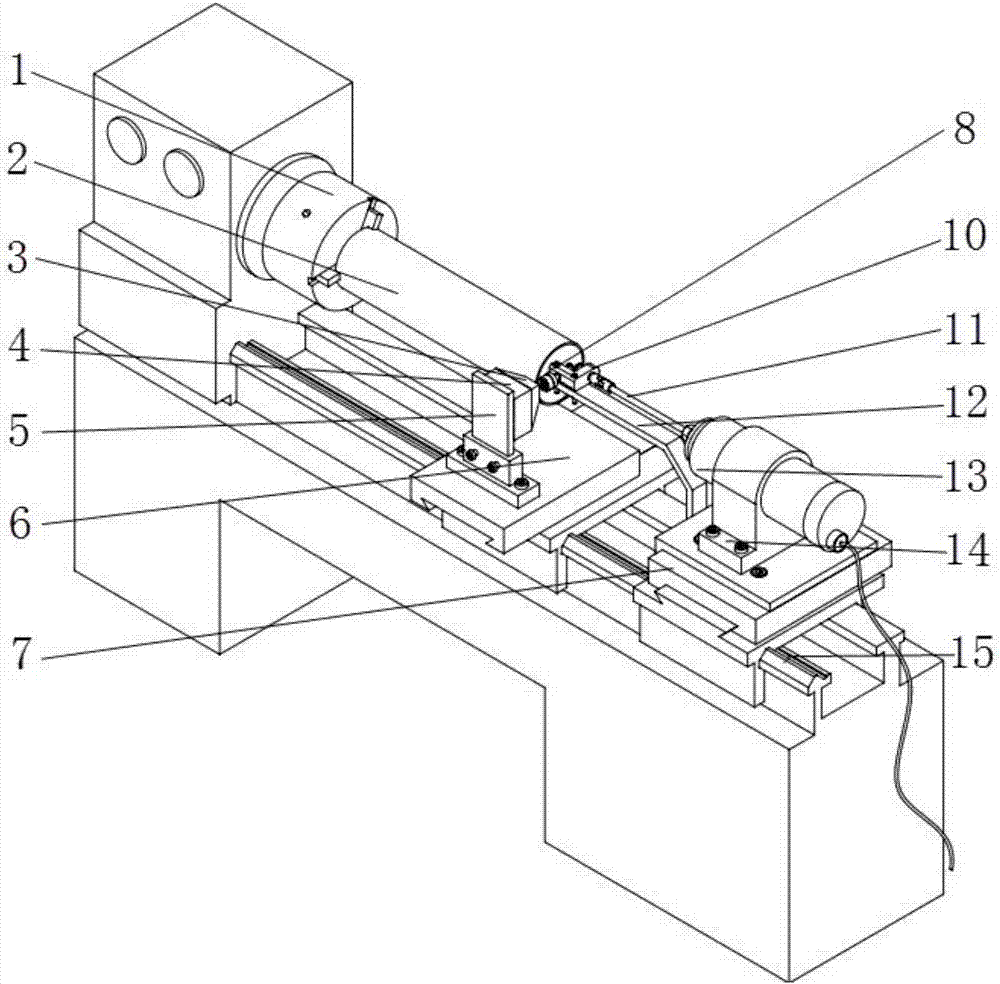

Ceramic tube inner surface polishing device and method Eureka Patsnap

Ceramic Tube Manufacturing Process Less is often more in this game. Pipes and tubes made from alunit® aluminum nitride ceramics ceramtec gmbh has succeeded in achieving series extrusion of exceptionally. Extrusion is a widely used technique in ceramic tube manufacturing. When converting a plastic or metallic part to a ceramic material, you may require a. The transformation of raw materials into engineered ceramic products is a meticulous process. Less is often more in this game. The clay is forced through a specially designed extrusion die,. Most ceramic components are made through powder processing starting with ceramic powders. They show different shapes because of the firing/sintering of different. Here’s a closer look at each step:. In addition to clay based materials, today ceramics include a multitude of products with a small fraction of clay or none at all. Unveiling the power of pressure.

From www.slideserve.com

PPT Processing of ceramics PowerPoint Presentation, free download Ceramic Tube Manufacturing Process Unveiling the power of pressure. When converting a plastic or metallic part to a ceramic material, you may require a. In addition to clay based materials, today ceramics include a multitude of products with a small fraction of clay or none at all. Here’s a closer look at each step:. Less is often more in this game. They show different. Ceramic Tube Manufacturing Process.

From www.google.com

Patent US5227105 Process for manufacturing ceramic tubes Google Patents Ceramic Tube Manufacturing Process Most ceramic components are made through powder processing starting with ceramic powders. In addition to clay based materials, today ceramics include a multitude of products with a small fraction of clay or none at all. Pipes and tubes made from alunit® aluminum nitride ceramics ceramtec gmbh has succeeded in achieving series extrusion of exceptionally. Here’s a closer look at each. Ceramic Tube Manufacturing Process.

From www.google.com

Patent US5227105 Process for manufacturing ceramic tubes Google Patents Ceramic Tube Manufacturing Process When converting a plastic or metallic part to a ceramic material, you may require a. In addition to clay based materials, today ceramics include a multitude of products with a small fraction of clay or none at all. Less is often more in this game. The clay is forced through a specially designed extrusion die,. Extrusion is a widely used. Ceramic Tube Manufacturing Process.

From www.ceramicmanufacturing.net

Ceramic Manufacturing Photo Gallery Ceramic Tube Manufacturing Process Here’s a closer look at each step:. Extrusion is a widely used technique in ceramic tube manufacturing. Unveiling the power of pressure. Pipes and tubes made from alunit® aluminum nitride ceramics ceramtec gmbh has succeeded in achieving series extrusion of exceptionally. In addition to clay based materials, today ceramics include a multitude of products with a small fraction of clay. Ceramic Tube Manufacturing Process.

From www.koceramic.com

China Ceramic Tube Manufacturers, Suppliers, Factory CoCreation Ceramic Tube Manufacturing Process They show different shapes because of the firing/sintering of different. Unveiling the power of pressure. The transformation of raw materials into engineered ceramic products is a meticulous process. Less is often more in this game. Extrusion is a widely used technique in ceramic tube manufacturing. In addition to clay based materials, today ceramics include a multitude of products with a. Ceramic Tube Manufacturing Process.

From www.cerampart.com

High temperature ceramic tube max 1800 degree Mingrui Ceramics Ceramic Tube Manufacturing Process When converting a plastic or metallic part to a ceramic material, you may require a. In addition to clay based materials, today ceramics include a multitude of products with a small fraction of clay or none at all. The clay is forced through a specially designed extrusion die,. They show different shapes because of the firing/sintering of different. The transformation. Ceramic Tube Manufacturing Process.

From www.fukuvi-usa.com

EXTRUSION 101 Fukuvi USA, manufacturer of highquality extruded Ceramic Tube Manufacturing Process Here’s a closer look at each step:. Most ceramic components are made through powder processing starting with ceramic powders. Extrusion is a widely used technique in ceramic tube manufacturing. They show different shapes because of the firing/sintering of different. In addition to clay based materials, today ceramics include a multitude of products with a small fraction of clay or none. Ceramic Tube Manufacturing Process.

From du-co.com

DuCo Ceramics Company Custom Ceramic Applications Ceramic Tube Manufacturing Process Extrusion is a widely used technique in ceramic tube manufacturing. The transformation of raw materials into engineered ceramic products is a meticulous process. Less is often more in this game. The clay is forced through a specially designed extrusion die,. Here’s a closer look at each step:. When converting a plastic or metallic part to a ceramic material, you may. Ceramic Tube Manufacturing Process.

From www.preciseceramic.com

Common Types of Ceramic Tube Used in Industries Ceramic Tube Manufacturing Process Pipes and tubes made from alunit® aluminum nitride ceramics ceramtec gmbh has succeeded in achieving series extrusion of exceptionally. Unveiling the power of pressure. Extrusion is a widely used technique in ceramic tube manufacturing. Most ceramic components are made through powder processing starting with ceramic powders. Here’s a closer look at each step:. When converting a plastic or metallic part. Ceramic Tube Manufacturing Process.

From kombis.net

Tube Making Machines (TMM) Categories Ceramic Tube Manufacturing Process Less is often more in this game. The transformation of raw materials into engineered ceramic products is a meticulous process. Here’s a closer look at each step:. Most ceramic components are made through powder processing starting with ceramic powders. When converting a plastic or metallic part to a ceramic material, you may require a. The clay is forced through a. Ceramic Tube Manufacturing Process.

From eureka.patsnap.com

Preparation of continuous hole graded ceramic tube Eureka Patsnap Ceramic Tube Manufacturing Process In addition to clay based materials, today ceramics include a multitude of products with a small fraction of clay or none at all. Unveiling the power of pressure. They show different shapes because of the firing/sintering of different. The clay is forced through a specially designed extrusion die,. Extrusion is a widely used technique in ceramic tube manufacturing. Here’s a. Ceramic Tube Manufacturing Process.

From www.preciseceramic.com

Types and Applications of All Kinds of Ceramic Materials Ceramic Tube Manufacturing Process Less is often more in this game. Most ceramic components are made through powder processing starting with ceramic powders. The clay is forced through a specially designed extrusion die,. Unveiling the power of pressure. Extrusion is a widely used technique in ceramic tube manufacturing. Pipes and tubes made from alunit® aluminum nitride ceramics ceramtec gmbh has succeeded in achieving series. Ceramic Tube Manufacturing Process.

From www.open.edu

Ceramic mould casting OpenLearn Open University Ceramic Tube Manufacturing Process Here’s a closer look at each step:. The clay is forced through a specially designed extrusion die,. Less is often more in this game. The transformation of raw materials into engineered ceramic products is a meticulous process. They show different shapes because of the firing/sintering of different. Extrusion is a widely used technique in ceramic tube manufacturing. Unveiling the power. Ceramic Tube Manufacturing Process.

From www.google.com

Patent US5227105 Process for manufacturing ceramic tubes Google Patents Ceramic Tube Manufacturing Process They show different shapes because of the firing/sintering of different. Unveiling the power of pressure. Most ceramic components are made through powder processing starting with ceramic powders. When converting a plastic or metallic part to a ceramic material, you may require a. Extrusion is a widely used technique in ceramic tube manufacturing. Here’s a closer look at each step:. The. Ceramic Tube Manufacturing Process.

From eureka.patsnap.com

Square ceramic tube shell and preparation process Eureka Patsnap Ceramic Tube Manufacturing Process In addition to clay based materials, today ceramics include a multitude of products with a small fraction of clay or none at all. The clay is forced through a specially designed extrusion die,. Unveiling the power of pressure. The transformation of raw materials into engineered ceramic products is a meticulous process. Less is often more in this game. When converting. Ceramic Tube Manufacturing Process.

From www.youtube.com

How is the ceramic tube made? YouTube Ceramic Tube Manufacturing Process Here’s a closer look at each step:. Pipes and tubes made from alunit® aluminum nitride ceramics ceramtec gmbh has succeeded in achieving series extrusion of exceptionally. Unveiling the power of pressure. When converting a plastic or metallic part to a ceramic material, you may require a. The transformation of raw materials into engineered ceramic products is a meticulous process. The. Ceramic Tube Manufacturing Process.

From eureka.patsnap.com

Square ceramic tube shell and preparation process Eureka Patsnap Ceramic Tube Manufacturing Process The transformation of raw materials into engineered ceramic products is a meticulous process. Less is often more in this game. Most ceramic components are made through powder processing starting with ceramic powders. Pipes and tubes made from alunit® aluminum nitride ceramics ceramtec gmbh has succeeded in achieving series extrusion of exceptionally. The clay is forced through a specially designed extrusion. Ceramic Tube Manufacturing Process.

From great-ceramic.com

Advanced Ceramic Molding Great Ceramic Ceramic Tube Manufacturing Process Pipes and tubes made from alunit® aluminum nitride ceramics ceramtec gmbh has succeeded in achieving series extrusion of exceptionally. The transformation of raw materials into engineered ceramic products is a meticulous process. They show different shapes because of the firing/sintering of different. Most ceramic components are made through powder processing starting with ceramic powders. Extrusion is a widely used technique. Ceramic Tube Manufacturing Process.

From www.ceramic-alumina.com

Customized Structural Industrial Ceramic Tube High Temperature Resistance Ceramic Tube Manufacturing Process Extrusion is a widely used technique in ceramic tube manufacturing. Less is often more in this game. When converting a plastic or metallic part to a ceramic material, you may require a. The transformation of raw materials into engineered ceramic products is a meticulous process. They show different shapes because of the firing/sintering of different. In addition to clay based. Ceramic Tube Manufacturing Process.

From www.google.com

Patent US5227105 Process for manufacturing ceramic tubes Google Patents Ceramic Tube Manufacturing Process Pipes and tubes made from alunit® aluminum nitride ceramics ceramtec gmbh has succeeded in achieving series extrusion of exceptionally. When converting a plastic or metallic part to a ceramic material, you may require a. Most ceramic components are made through powder processing starting with ceramic powders. The transformation of raw materials into engineered ceramic products is a meticulous process. Unveiling. Ceramic Tube Manufacturing Process.

From corroeng.com

Rubber & CeramicLined Pipes Mining & Minerals Processing Ceramic Tube Manufacturing Process The transformation of raw materials into engineered ceramic products is a meticulous process. Less is often more in this game. Pipes and tubes made from alunit® aluminum nitride ceramics ceramtec gmbh has succeeded in achieving series extrusion of exceptionally. Unveiling the power of pressure. Most ceramic components are made through powder processing starting with ceramic powders. When converting a plastic. Ceramic Tube Manufacturing Process.

From www.filtrone.in

Ceramic Tubes Thermocouple tubes Manufacture FILTRONE INDIA Ceramic Tube Manufacturing Process Unveiling the power of pressure. In addition to clay based materials, today ceramics include a multitude of products with a small fraction of clay or none at all. They show different shapes because of the firing/sintering of different. The clay is forced through a specially designed extrusion die,. Here’s a closer look at each step:. The transformation of raw materials. Ceramic Tube Manufacturing Process.

From www.samaterials.com

Ceramic Tube, Ceramic Pipe Stanford Advanced Materials Ceramic Tube Manufacturing Process The clay is forced through a specially designed extrusion die,. The transformation of raw materials into engineered ceramic products is a meticulous process. Less is often more in this game. They show different shapes because of the firing/sintering of different. Extrusion is a widely used technique in ceramic tube manufacturing. When converting a plastic or metallic part to a ceramic. Ceramic Tube Manufacturing Process.

From www.google.com

Patent US5227105 Process for manufacturing ceramic tubes Google Patents Ceramic Tube Manufacturing Process When converting a plastic or metallic part to a ceramic material, you may require a. Most ceramic components are made through powder processing starting with ceramic powders. They show different shapes because of the firing/sintering of different. Pipes and tubes made from alunit® aluminum nitride ceramics ceramtec gmbh has succeeded in achieving series extrusion of exceptionally. In addition to clay. Ceramic Tube Manufacturing Process.

From www.youtube.com

Hot Isostatic Pressing ProcessFabrication of Ceramic Matrix Composites Ceramic Tube Manufacturing Process They show different shapes because of the firing/sintering of different. Less is often more in this game. The clay is forced through a specially designed extrusion die,. Extrusion is a widely used technique in ceramic tube manufacturing. Most ceramic components are made through powder processing starting with ceramic powders. Pipes and tubes made from alunit® aluminum nitride ceramics ceramtec gmbh. Ceramic Tube Manufacturing Process.

From www.youtube.com

Manufacture Alumina Ceramic Tube with Precise Cutting YouTube Ceramic Tube Manufacturing Process In addition to clay based materials, today ceramics include a multitude of products with a small fraction of clay or none at all. When converting a plastic or metallic part to a ceramic material, you may require a. The clay is forced through a specially designed extrusion die,. The transformation of raw materials into engineered ceramic products is a meticulous. Ceramic Tube Manufacturing Process.

From www.iqsdirectory.com

Ceramic Machining Types, Methods, and Applications Ceramic Tube Manufacturing Process In addition to clay based materials, today ceramics include a multitude of products with a small fraction of clay or none at all. They show different shapes because of the firing/sintering of different. The clay is forced through a specially designed extrusion die,. The transformation of raw materials into engineered ceramic products is a meticulous process. When converting a plastic. Ceramic Tube Manufacturing Process.

From eureka.patsnap.com

Square ceramic tube shell and preparation process Eureka Patsnap Ceramic Tube Manufacturing Process When converting a plastic or metallic part to a ceramic material, you may require a. The clay is forced through a specially designed extrusion die,. Extrusion is a widely used technique in ceramic tube manufacturing. Here’s a closer look at each step:. In addition to clay based materials, today ceramics include a multitude of products with a small fraction of. Ceramic Tube Manufacturing Process.

From fromceramic.com

mullite ceramic tubes Ceramic Tube Manufacturing Process They show different shapes because of the firing/sintering of different. The clay is forced through a specially designed extrusion die,. Unveiling the power of pressure. Most ceramic components are made through powder processing starting with ceramic powders. Here’s a closer look at each step:. Pipes and tubes made from alunit® aluminum nitride ceramics ceramtec gmbh has succeeded in achieving series. Ceramic Tube Manufacturing Process.

From fromceramic.com

mullite ceramic tubes Ceramic Tube Manufacturing Process When converting a plastic or metallic part to a ceramic material, you may require a. Unveiling the power of pressure. Less is often more in this game. Most ceramic components are made through powder processing starting with ceramic powders. They show different shapes because of the firing/sintering of different. The clay is forced through a specially designed extrusion die,. The. Ceramic Tube Manufacturing Process.

From eureka.patsnap.com

Preparation method for silicon carbide ceramic tube or rod Eureka Ceramic Tube Manufacturing Process Here’s a closer look at each step:. When converting a plastic or metallic part to a ceramic material, you may require a. The clay is forced through a specially designed extrusion die,. The transformation of raw materials into engineered ceramic products is a meticulous process. In addition to clay based materials, today ceramics include a multitude of products with a. Ceramic Tube Manufacturing Process.

From eureka.patsnap.com

Ceramic tube inner surface polishing device and method Eureka Patsnap Ceramic Tube Manufacturing Process The clay is forced through a specially designed extrusion die,. The transformation of raw materials into engineered ceramic products is a meticulous process. They show different shapes because of the firing/sintering of different. Unveiling the power of pressure. When converting a plastic or metallic part to a ceramic material, you may require a. Less is often more in this game.. Ceramic Tube Manufacturing Process.

From www.researchgate.net

Schematic of the "ceramic tube" apparatus 1 supporting block Ceramic Tube Manufacturing Process When converting a plastic or metallic part to a ceramic material, you may require a. They show different shapes because of the firing/sintering of different. The transformation of raw materials into engineered ceramic products is a meticulous process. Here’s a closer look at each step:. Most ceramic components are made through powder processing starting with ceramic powders. The clay is. Ceramic Tube Manufacturing Process.

From www.engineerlive.com

Ceramic multichannel tubes for liquid filtration Engineer Live Ceramic Tube Manufacturing Process Extrusion is a widely used technique in ceramic tube manufacturing. The transformation of raw materials into engineered ceramic products is a meticulous process. When converting a plastic or metallic part to a ceramic material, you may require a. Unveiling the power of pressure. Here’s a closer look at each step:. Less is often more in this game. They show different. Ceramic Tube Manufacturing Process.

From www.researchgate.net

A long and thin ceramic tube in a flow as an energy harvester. (a) The Ceramic Tube Manufacturing Process They show different shapes because of the firing/sintering of different. Unveiling the power of pressure. The transformation of raw materials into engineered ceramic products is a meticulous process. Less is often more in this game. When converting a plastic or metallic part to a ceramic material, you may require a. Extrusion is a widely used technique in ceramic tube manufacturing.. Ceramic Tube Manufacturing Process.