How To Make Custom Turbo Manifold . Gather supporting modifications for your turbo kit. The more efficiently the manifold can get the gas away from the engine, the more gas the engine. Now i had to figure out the plenum. The most common pipe size wall thicknesses, or schedules, when building a turbo manifold are schedules 5, 10, and 40. This is how power is made. When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule 10 material can range between 0.049 and 0.120, as compared to tube size material where 16 gauge is 0.065 [*] regardless of the outside diameter. The cheapest intake solution is an aftermarket air filter attached directly to the. I liked the look of. The basic manifold was now ready. Now with the fully tacked manifold, place it on the motor and check that everything fits and there are no obstructions. The throttle body dictated the height of it.

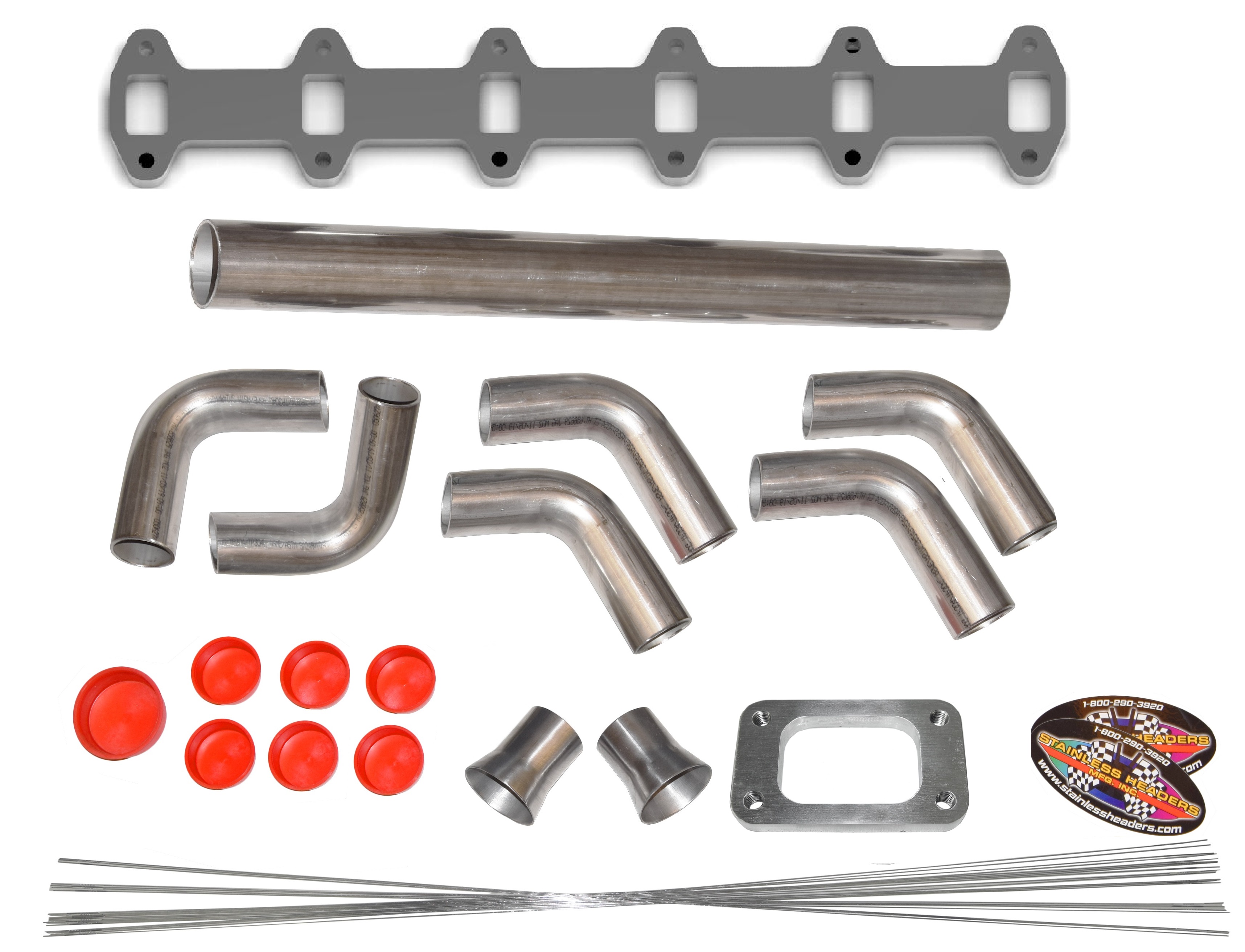

from www.stainlessheaders.com

Now with the fully tacked manifold, place it on the motor and check that everything fits and there are no obstructions. The most common pipe size wall thicknesses, or schedules, when building a turbo manifold are schedules 5, 10, and 40. The cheapest intake solution is an aftermarket air filter attached directly to the. The basic manifold was now ready. Gather supporting modifications for your turbo kit. This is how power is made. Now i had to figure out the plenum. When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule 10 material can range between 0.049 and 0.120, as compared to tube size material where 16 gauge is 0.065 [*] regardless of the outside diameter. The more efficiently the manifold can get the gas away from the engine, the more gas the engine. I liked the look of.

Custom Turbo Manifold Build Kits

How To Make Custom Turbo Manifold The cheapest intake solution is an aftermarket air filter attached directly to the. The throttle body dictated the height of it. The basic manifold was now ready. The more efficiently the manifold can get the gas away from the engine, the more gas the engine. This is how power is made. Now i had to figure out the plenum. When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule 10 material can range between 0.049 and 0.120, as compared to tube size material where 16 gauge is 0.065 [*] regardless of the outside diameter. Gather supporting modifications for your turbo kit. I liked the look of. Now with the fully tacked manifold, place it on the motor and check that everything fits and there are no obstructions. The most common pipe size wall thicknesses, or schedules, when building a turbo manifold are schedules 5, 10, and 40. The cheapest intake solution is an aftermarket air filter attached directly to the.

From www.youtube.com

BBG CUSTOM TURBO MANIFOLD FABRICATION VR V6 TURBO COMMODORE UTE PT How To Make Custom Turbo Manifold The throttle body dictated the height of it. Now i had to figure out the plenum. When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule 10 material can range between 0.049 and 0.120, as compared to tube size material where 16 gauge is 0.065 [*] regardless of the outside diameter. The cheapest intake solution is an. How To Make Custom Turbo Manifold.

From www.jdmbits.com

JDMbits Mazda Mx5 Miata Custom Turbo Manifold! How To Make Custom Turbo Manifold The most common pipe size wall thicknesses, or schedules, when building a turbo manifold are schedules 5, 10, and 40. Now with the fully tacked manifold, place it on the motor and check that everything fits and there are no obstructions. This is how power is made. Now i had to figure out the plenum. I liked the look of.. How To Make Custom Turbo Manifold.

From www.stainlessheaders.com

Custom Turbo Manifold Build Kits How To Make Custom Turbo Manifold This is how power is made. The cheapest intake solution is an aftermarket air filter attached directly to the. When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule 10 material can range between 0.049 and 0.120, as compared to tube size material where 16 gauge is 0.065 [*] regardless of the outside diameter. The most common. How To Make Custom Turbo Manifold.

From www.gpheaders.com

Custom Fabrication, Industry Leaders in Header and Exhaust Manifolds How To Make Custom Turbo Manifold When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule 10 material can range between 0.049 and 0.120, as compared to tube size material where 16 gauge is 0.065 [*] regardless of the outside diameter. The more efficiently the manifold can get the gas away from the engine, the more gas the engine. Now i had to. How To Make Custom Turbo Manifold.

From performance-supercar.com

Turbo/ Exhaust Manifolds Performance Supercar How To Make Custom Turbo Manifold When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule 10 material can range between 0.049 and 0.120, as compared to tube size material where 16 gauge is 0.065 [*] regardless of the outside diameter. This is how power is made. Now i had to figure out the plenum. I liked the look of. The basic manifold. How To Make Custom Turbo Manifold.

From www.stevesnovasite.com

5.3 turbo manifold on tci custom front end Chevy Nova Forum How To Make Custom Turbo Manifold When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule 10 material can range between 0.049 and 0.120, as compared to tube size material where 16 gauge is 0.065 [*] regardless of the outside diameter. The most common pipe size wall thicknesses, or schedules, when building a turbo manifold are schedules 5, 10, and 40. Gather supporting. How To Make Custom Turbo Manifold.

From performance-supercar.com

LS Topmount Single Turbo Manifold Performance Supercar How To Make Custom Turbo Manifold The more efficiently the manifold can get the gas away from the engine, the more gas the engine. Gather supporting modifications for your turbo kit. When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule 10 material can range between 0.049 and 0.120, as compared to tube size material where 16 gauge is 0.065 [*] regardless of. How To Make Custom Turbo Manifold.

From cliosport.net

Custom tubular turbo manifold Fab How To Make Custom Turbo Manifold I liked the look of. Now i had to figure out the plenum. Now with the fully tacked manifold, place it on the motor and check that everything fits and there are no obstructions. The basic manifold was now ready. This is how power is made. The cheapest intake solution is an aftermarket air filter attached directly to the. Gather. How To Make Custom Turbo Manifold.

From www.holley.com

How To Make Easy Turbocharged Power With Hooker BlackHeart Turbo LS How To Make Custom Turbo Manifold The throttle body dictated the height of it. Gather supporting modifications for your turbo kit. The basic manifold was now ready. The most common pipe size wall thicknesses, or schedules, when building a turbo manifold are schedules 5, 10, and 40. The more efficiently the manifold can get the gas away from the engine, the more gas the engine. Now. How To Make Custom Turbo Manifold.

From ls1tech.com

What's Up in the Forum Make Your Own LS1 Turbo Kit with Truck Manifolds How To Make Custom Turbo Manifold The more efficiently the manifold can get the gas away from the engine, the more gas the engine. Now i had to figure out the plenum. The basic manifold was now ready. Now with the fully tacked manifold, place it on the motor and check that everything fits and there are no obstructions. Gather supporting modifications for your turbo kit.. How To Make Custom Turbo Manifold.

From www.youtube.com

Custom Pie cut Turbo Exhaust Manifold BMW S54 YouTube How To Make Custom Turbo Manifold When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule 10 material can range between 0.049 and 0.120, as compared to tube size material where 16 gauge is 0.065 [*] regardless of the outside diameter. The most common pipe size wall thicknesses, or schedules, when building a turbo manifold are schedules 5, 10, and 40. Now i. How To Make Custom Turbo Manifold.

From www.fastspecialties.com

Custom fabricated turbo manifold Fast Specialties Performance Auto How To Make Custom Turbo Manifold I liked the look of. The cheapest intake solution is an aftermarket air filter attached directly to the. Now i had to figure out the plenum. This is how power is made. The more efficiently the manifold can get the gas away from the engine, the more gas the engine. Gather supporting modifications for your turbo kit. The most common. How To Make Custom Turbo Manifold.

From www.youtube.com

EG33 Swap Create your own Turbo Manifolds (Ep. 12) YouTube How To Make Custom Turbo Manifold Gather supporting modifications for your turbo kit. The most common pipe size wall thicknesses, or schedules, when building a turbo manifold are schedules 5, 10, and 40. Now with the fully tacked manifold, place it on the motor and check that everything fits and there are no obstructions. The basic manifold was now ready. I liked the look of. The. How To Make Custom Turbo Manifold.

From www.holley.com

How To Make Easy Turbocharged Power With Hooker BlackHeart Turbo LS How To Make Custom Turbo Manifold The basic manifold was now ready. The throttle body dictated the height of it. This is how power is made. The most common pipe size wall thicknesses, or schedules, when building a turbo manifold are schedules 5, 10, and 40. The cheapest intake solution is an aftermarket air filter attached directly to the. Gather supporting modifications for your turbo kit.. How To Make Custom Turbo Manifold.

From epc-racing.com

Custom Fabrication EPC Racing Spokane's Best Performance Shop How To Make Custom Turbo Manifold Gather supporting modifications for your turbo kit. The basic manifold was now ready. The more efficiently the manifold can get the gas away from the engine, the more gas the engine. The most common pipe size wall thicknesses, or schedules, when building a turbo manifold are schedules 5, 10, and 40. When referencing pipe sizes from 1/8 to 4, the. How To Make Custom Turbo Manifold.

From www.miataturbo.net

Custom turbo manifold, 1.8l (t25/28 flange) bottom mount Miata Turbo How To Make Custom Turbo Manifold I liked the look of. Gather supporting modifications for your turbo kit. The cheapest intake solution is an aftermarket air filter attached directly to the. The more efficiently the manifold can get the gas away from the engine, the more gas the engine. The most common pipe size wall thicknesses, or schedules, when building a turbo manifold are schedules 5,. How To Make Custom Turbo Manifold.

From www.youtube.com

How to make your own LSx Turbo Manifolds YouTube How To Make Custom Turbo Manifold The cheapest intake solution is an aftermarket air filter attached directly to the. This is how power is made. The most common pipe size wall thicknesses, or schedules, when building a turbo manifold are schedules 5, 10, and 40. Now i had to figure out the plenum. When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule. How To Make Custom Turbo Manifold.

From www.enginebasics.com

How to build your own turbo manifold Equal Length Divided Twin How To Make Custom Turbo Manifold The cheapest intake solution is an aftermarket air filter attached directly to the. I liked the look of. This is how power is made. When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule 10 material can range between 0.049 and 0.120, as compared to tube size material where 16 gauge is 0.065 [*] regardless of the. How To Make Custom Turbo Manifold.

From www.youtube.com

DIY Turbo Manifolds from Stock Cast Manifolds YouTube How To Make Custom Turbo Manifold The throttle body dictated the height of it. Now i had to figure out the plenum. I liked the look of. The basic manifold was now ready. The most common pipe size wall thicknesses, or schedules, when building a turbo manifold are schedules 5, 10, and 40. The more efficiently the manifold can get the gas away from the engine,. How To Make Custom Turbo Manifold.

From www.gpheaders.com

Custom Fabrication, Industry Leaders in Header and Exhaust Manifolds How To Make Custom Turbo Manifold This is how power is made. Now with the fully tacked manifold, place it on the motor and check that everything fits and there are no obstructions. The throttle body dictated the height of it. Gather supporting modifications for your turbo kit. When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule 10 material can range between. How To Make Custom Turbo Manifold.

From www.pinterest.com.mx

turbo manifold design log twin scroll Turbo, Custom metal fabrication How To Make Custom Turbo Manifold I liked the look of. The more efficiently the manifold can get the gas away from the engine, the more gas the engine. Now with the fully tacked manifold, place it on the motor and check that everything fits and there are no obstructions. This is how power is made. The throttle body dictated the height of it. The basic. How To Make Custom Turbo Manifold.

From speed.academy

How To Fabricate A Custom Intake Manifold Speed Academy How To Make Custom Turbo Manifold Now with the fully tacked manifold, place it on the motor and check that everything fits and there are no obstructions. Now i had to figure out the plenum. This is how power is made. I liked the look of. When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule 10 material can range between 0.049 and. How To Make Custom Turbo Manifold.

From performance-supercar.com

LS Topmount Twin Turbo Manifolds T4 Performance Supercar How To Make Custom Turbo Manifold Now i had to figure out the plenum. This is how power is made. I liked the look of. When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule 10 material can range between 0.049 and 0.120, as compared to tube size material where 16 gauge is 0.065 [*] regardless of the outside diameter. The more efficiently. How To Make Custom Turbo Manifold.

From www.jdmaster.net

1320 Performance Honda D series turbo manifold AC compatible T3 JDMaster How To Make Custom Turbo Manifold The cheapest intake solution is an aftermarket air filter attached directly to the. This is how power is made. The throttle body dictated the height of it. The basic manifold was now ready. Now with the fully tacked manifold, place it on the motor and check that everything fits and there are no obstructions. The more efficiently the manifold can. How To Make Custom Turbo Manifold.

From www.youtube.com

building your own turbo manifold. CLIO mk2 Tubular manifold fabrication How To Make Custom Turbo Manifold The throttle body dictated the height of it. I liked the look of. Gather supporting modifications for your turbo kit. Now i had to figure out the plenum. The most common pipe size wall thicknesses, or schedules, when building a turbo manifold are schedules 5, 10, and 40. The cheapest intake solution is an aftermarket air filter attached directly to. How To Make Custom Turbo Manifold.

From www.youtube.com

DIY Budget LS Turbo Manifold Build Part 3 YouTube How To Make Custom Turbo Manifold Now with the fully tacked manifold, place it on the motor and check that everything fits and there are no obstructions. The throttle body dictated the height of it. Now i had to figure out the plenum. I liked the look of. The cheapest intake solution is an aftermarket air filter attached directly to the. When referencing pipe sizes from. How To Make Custom Turbo Manifold.

From www.fastspecialties.com

Custom fabricated turbo manifold Fast Specialties Performance Auto How To Make Custom Turbo Manifold Now i had to figure out the plenum. I liked the look of. The basic manifold was now ready. When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule 10 material can range between 0.049 and 0.120, as compared to tube size material where 16 gauge is 0.065 [*] regardless of the outside diameter. Now with the. How To Make Custom Turbo Manifold.

From www.youtube.com

DIY turbo manifold fabrication. Custom tubular manifold from scratch How To Make Custom Turbo Manifold The cheapest intake solution is an aftermarket air filter attached directly to the. I liked the look of. This is how power is made. The more efficiently the manifold can get the gas away from the engine, the more gas the engine. The basic manifold was now ready. When referencing pipe sizes from 1/8 to 4, the actual thickness of. How To Make Custom Turbo Manifold.

From www.enginebasics.com

How to build your own turbo manifold Equal Length Divided Twin How To Make Custom Turbo Manifold The most common pipe size wall thicknesses, or schedules, when building a turbo manifold are schedules 5, 10, and 40. Now with the fully tacked manifold, place it on the motor and check that everything fits and there are no obstructions. This is how power is made. The more efficiently the manifold can get the gas away from the engine,. How To Make Custom Turbo Manifold.

From www.youtube.com

Aeroflow Performance LS Turbo Manifolds YouTube How To Make Custom Turbo Manifold Now i had to figure out the plenum. This is how power is made. Gather supporting modifications for your turbo kit. When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule 10 material can range between 0.049 and 0.120, as compared to tube size material where 16 gauge is 0.065 [*] regardless of the outside diameter. The. How To Make Custom Turbo Manifold.

From www.fastspecialties.com

Custom fabricated turbo manifold Fast Specialties Performance Auto How To Make Custom Turbo Manifold The throttle body dictated the height of it. Now i had to figure out the plenum. When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule 10 material can range between 0.049 and 0.120, as compared to tube size material where 16 gauge is 0.065 [*] regardless of the outside diameter. I liked the look of. Gather. How To Make Custom Turbo Manifold.

From www.holley.com

How To Make Easy Turbocharged Power With Hooker BlackHeart Turbo LS How To Make Custom Turbo Manifold The cheapest intake solution is an aftermarket air filter attached directly to the. Now with the fully tacked manifold, place it on the motor and check that everything fits and there are no obstructions. When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule 10 material can range between 0.049 and 0.120, as compared to tube size. How To Make Custom Turbo Manifold.

From gene.toyspeedmotorsports.com

Custom Turbo Manifold 3sgte Toyspeed Motorsports How To Make Custom Turbo Manifold Now with the fully tacked manifold, place it on the motor and check that everything fits and there are no obstructions. The cheapest intake solution is an aftermarket air filter attached directly to the. The throttle body dictated the height of it. This is how power is made. Gather supporting modifications for your turbo kit. The basic manifold was now. How To Make Custom Turbo Manifold.

From www.nopistons.com

Latest turbo manifold design... NoPistons Mazda Rx7 & Rx8 Rotary Forum How To Make Custom Turbo Manifold The basic manifold was now ready. The more efficiently the manifold can get the gas away from the engine, the more gas the engine. The most common pipe size wall thicknesses, or schedules, when building a turbo manifold are schedules 5, 10, and 40. Gather supporting modifications for your turbo kit. I liked the look of. The throttle body dictated. How To Make Custom Turbo Manifold.

From www.fastspecialties.com

Custom fabricated turbo manifold Fast Specialties Performance Auto How To Make Custom Turbo Manifold The cheapest intake solution is an aftermarket air filter attached directly to the. The more efficiently the manifold can get the gas away from the engine, the more gas the engine. This is how power is made. I liked the look of. When referencing pipe sizes from 1/8 to 4, the actual thickness of schedule 10 material can range between. How To Make Custom Turbo Manifold.