Thrust Bearing In Vertical Pumps Are Related To . Thrust bearings—a thrust bearing is installed on the upper part of the motor, opposite to the shaft end. The majority of vertical turbine pump installations use a hollow shaft motor to manage thrust loads. Other danger signs include reduced speed, decreased. Image 3 depicts an angular contact ball bearing. Increased or erratic vibration of the driver is often the first symptom of an impending breakdown. Overhung vertical pumps supported by a thrust bearing located at the top of the machine are loaded with axial tensile force resulting from gravity loads. Through it’ s thrust bearing, must also be able to handle all of the vertical thrust imposed from the rotating assembly and not allow excessive downward movement that could result in. The thrust bearing, which is usually at the top of the vertical motor (figure 1), may consist of one or more angular contact bearings;

from www.bhsbearings.com

Increased or erratic vibration of the driver is often the first symptom of an impending breakdown. Thrust bearings—a thrust bearing is installed on the upper part of the motor, opposite to the shaft end. Overhung vertical pumps supported by a thrust bearing located at the top of the machine are loaded with axial tensile force resulting from gravity loads. Through it’ s thrust bearing, must also be able to handle all of the vertical thrust imposed from the rotating assembly and not allow excessive downward movement that could result in. The majority of vertical turbine pump installations use a hollow shaft motor to manage thrust loads. The thrust bearing, which is usually at the top of the vertical motor (figure 1), may consist of one or more angular contact bearings; Image 3 depicts an angular contact ball bearing. Other danger signs include reduced speed, decreased.

Custom Vertical Thrust Bearings Manufacturers, Suppliers

Thrust Bearing In Vertical Pumps Are Related To Increased or erratic vibration of the driver is often the first symptom of an impending breakdown. Thrust bearings—a thrust bearing is installed on the upper part of the motor, opposite to the shaft end. Increased or erratic vibration of the driver is often the first symptom of an impending breakdown. Overhung vertical pumps supported by a thrust bearing located at the top of the machine are loaded with axial tensile force resulting from gravity loads. Through it’ s thrust bearing, must also be able to handle all of the vertical thrust imposed from the rotating assembly and not allow excessive downward movement that could result in. Other danger signs include reduced speed, decreased. The thrust bearing, which is usually at the top of the vertical motor (figure 1), may consist of one or more angular contact bearings; The majority of vertical turbine pump installations use a hollow shaft motor to manage thrust loads. Image 3 depicts an angular contact ball bearing.

From binsfeld.com

Axial Thrust Measurement in Vertical Turbine Pump Binsfeld Thrust Bearing In Vertical Pumps Are Related To Thrust bearings—a thrust bearing is installed on the upper part of the motor, opposite to the shaft end. Other danger signs include reduced speed, decreased. Overhung vertical pumps supported by a thrust bearing located at the top of the machine are loaded with axial tensile force resulting from gravity loads. The majority of vertical turbine pump installations use a hollow. Thrust Bearing In Vertical Pumps Are Related To.

From www.ywsbearing.com

Manufacture quality 51201 thrust ball bearing for vertical pumps Buy Thrust Bearing In Vertical Pumps Are Related To Through it’ s thrust bearing, must also be able to handle all of the vertical thrust imposed from the rotating assembly and not allow excessive downward movement that could result in. Image 3 depicts an angular contact ball bearing. The thrust bearing, which is usually at the top of the vertical motor (figure 1), may consist of one or more. Thrust Bearing In Vertical Pumps Are Related To.

From www.ywsbearing.com

high load axial load 51224 thrust ball bearing for vertical pumps Buy Thrust Bearing In Vertical Pumps Are Related To Thrust bearings—a thrust bearing is installed on the upper part of the motor, opposite to the shaft end. Increased or erratic vibration of the driver is often the first symptom of an impending breakdown. Through it’ s thrust bearing, must also be able to handle all of the vertical thrust imposed from the rotating assembly and not allow excessive downward. Thrust Bearing In Vertical Pumps Are Related To.

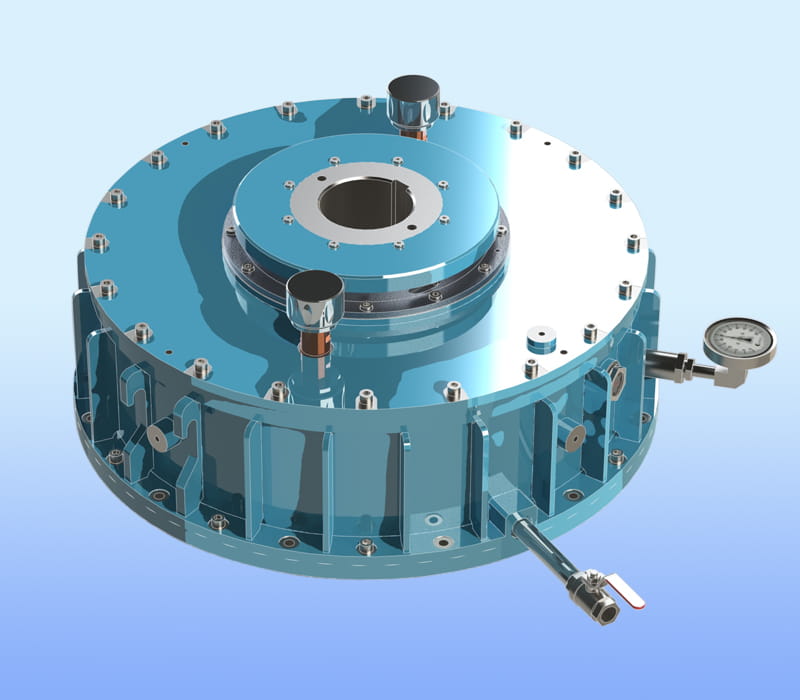

From haywardtyler.com

Upgrade the capacity of your BWCP thrust bearing Hayward Tyler Thrust Bearing In Vertical Pumps Are Related To Other danger signs include reduced speed, decreased. The thrust bearing, which is usually at the top of the vertical motor (figure 1), may consist of one or more angular contact bearings; The majority of vertical turbine pump installations use a hollow shaft motor to manage thrust loads. Thrust bearings—a thrust bearing is installed on the upper part of the motor,. Thrust Bearing In Vertical Pumps Are Related To.

From www.introtopumps.com

Vertical Turbine Pumps Intro To Pumps Thrust Bearing In Vertical Pumps Are Related To The thrust bearing, which is usually at the top of the vertical motor (figure 1), may consist of one or more angular contact bearings; Overhung vertical pumps supported by a thrust bearing located at the top of the machine are loaded with axial tensile force resulting from gravity loads. The majority of vertical turbine pump installations use a hollow shaft. Thrust Bearing In Vertical Pumps Are Related To.

From www.efficientplantmag.com

Understand Vertical Motor Bearings Efficient Plant Thrust Bearing In Vertical Pumps Are Related To Thrust bearings—a thrust bearing is installed on the upper part of the motor, opposite to the shaft end. Increased or erratic vibration of the driver is often the first symptom of an impending breakdown. Overhung vertical pumps supported by a thrust bearing located at the top of the machine are loaded with axial tensile force resulting from gravity loads. Through. Thrust Bearing In Vertical Pumps Are Related To.

From www.bhsbearings.com

Custom Vertical Thrust Bearings Manufacturers, Suppliers Thrust Bearing In Vertical Pumps Are Related To The majority of vertical turbine pump installations use a hollow shaft motor to manage thrust loads. Image 3 depicts an angular contact ball bearing. Overhung vertical pumps supported by a thrust bearing located at the top of the machine are loaded with axial tensile force resulting from gravity loads. Other danger signs include reduced speed, decreased. Increased or erratic vibration. Thrust Bearing In Vertical Pumps Are Related To.

From www.efficientplantmag.com

Understand Vertical Motor Bearings Efficient Plant Thrust Bearing In Vertical Pumps Are Related To Other danger signs include reduced speed, decreased. Through it’ s thrust bearing, must also be able to handle all of the vertical thrust imposed from the rotating assembly and not allow excessive downward movement that could result in. Increased or erratic vibration of the driver is often the first symptom of an impending breakdown. The majority of vertical turbine pump. Thrust Bearing In Vertical Pumps Are Related To.

From www.pump-zone.com

Centrifugal Pump Axial Thrust Pumps & Systems Thrust Bearing In Vertical Pumps Are Related To Increased or erratic vibration of the driver is often the first symptom of an impending breakdown. The majority of vertical turbine pump installations use a hollow shaft motor to manage thrust loads. The thrust bearing, which is usually at the top of the vertical motor (figure 1), may consist of one or more angular contact bearings; Thrust bearings—a thrust bearing. Thrust Bearing In Vertical Pumps Are Related To.

From www.marineengineersknowledge.com

Explained Thrust bearing working principle and where it is located Thrust Bearing In Vertical Pumps Are Related To The thrust bearing, which is usually at the top of the vertical motor (figure 1), may consist of one or more angular contact bearings; Overhung vertical pumps supported by a thrust bearing located at the top of the machine are loaded with axial tensile force resulting from gravity loads. Image 3 depicts an angular contact ball bearing. Thrust bearings—a thrust. Thrust Bearing In Vertical Pumps Are Related To.

From neptunopumps.com

Vertical Turbine Pumps (VTP) Neptuno Pumps Thrust Bearing In Vertical Pumps Are Related To Overhung vertical pumps supported by a thrust bearing located at the top of the machine are loaded with axial tensile force resulting from gravity loads. The majority of vertical turbine pump installations use a hollow shaft motor to manage thrust loads. Thrust bearings—a thrust bearing is installed on the upper part of the motor, opposite to the shaft end. Increased. Thrust Bearing In Vertical Pumps Are Related To.

From www.pumpsandsystems.com

Centrifugal Pump Axial Thrust Pumps & Systems Thrust Bearing In Vertical Pumps Are Related To Increased or erratic vibration of the driver is often the first symptom of an impending breakdown. Image 3 depicts an angular contact ball bearing. The majority of vertical turbine pump installations use a hollow shaft motor to manage thrust loads. Other danger signs include reduced speed, decreased. Through it’ s thrust bearing, must also be able to handle all of. Thrust Bearing In Vertical Pumps Are Related To.

From blog.softinway.com

An Overview of Vertical Pumps Turbomachinery blog Thrust Bearing In Vertical Pumps Are Related To Image 3 depicts an angular contact ball bearing. The majority of vertical turbine pump installations use a hollow shaft motor to manage thrust loads. The thrust bearing, which is usually at the top of the vertical motor (figure 1), may consist of one or more angular contact bearings; Through it’ s thrust bearing, must also be able to handle all. Thrust Bearing In Vertical Pumps Are Related To.

From www.pumpsandsystems.com

Selecting Bearing Systems in Vertical Motors Pumps & Systems Thrust Bearing In Vertical Pumps Are Related To The thrust bearing, which is usually at the top of the vertical motor (figure 1), may consist of one or more angular contact bearings; Image 3 depicts an angular contact ball bearing. Through it’ s thrust bearing, must also be able to handle all of the vertical thrust imposed from the rotating assembly and not allow excessive downward movement that. Thrust Bearing In Vertical Pumps Are Related To.

From www.youtube.com

Assembly 1 Thrust Bearing & Pump Install YouTube Thrust Bearing In Vertical Pumps Are Related To Increased or erratic vibration of the driver is often the first symptom of an impending breakdown. Overhung vertical pumps supported by a thrust bearing located at the top of the machine are loaded with axial tensile force resulting from gravity loads. Through it’ s thrust bearing, must also be able to handle all of the vertical thrust imposed from the. Thrust Bearing In Vertical Pumps Are Related To.

From www.youtube.com

Understanding Hydraulic Thrust Centrifugal Pumps and Compressors Thrust Bearing In Vertical Pumps Are Related To Through it’ s thrust bearing, must also be able to handle all of the vertical thrust imposed from the rotating assembly and not allow excessive downward movement that could result in. Increased or erratic vibration of the driver is often the first symptom of an impending breakdown. The thrust bearing, which is usually at the top of the vertical motor. Thrust Bearing In Vertical Pumps Are Related To.

From mechanic-info.blogspot.com

Mechanical Engineering Vertical Pump Thrust Bearing In Vertical Pumps Are Related To Thrust bearings—a thrust bearing is installed on the upper part of the motor, opposite to the shaft end. The thrust bearing, which is usually at the top of the vertical motor (figure 1), may consist of one or more angular contact bearings; Other danger signs include reduced speed, decreased. Through it’ s thrust bearing, must also be able to handle. Thrust Bearing In Vertical Pumps Are Related To.

From neptunopumps.com

Vertical Turbine Pumps (VTP) Neptuno Pumps Thrust Bearing In Vertical Pumps Are Related To Other danger signs include reduced speed, decreased. The thrust bearing, which is usually at the top of the vertical motor (figure 1), may consist of one or more angular contact bearings; Image 3 depicts an angular contact ball bearing. Through it’ s thrust bearing, must also be able to handle all of the vertical thrust imposed from the rotating assembly. Thrust Bearing In Vertical Pumps Are Related To.

From www.pumpsandsystems.com

Selecting Bearing Systems in Vertical Motors Pumps & Systems Thrust Bearing In Vertical Pumps Are Related To Thrust bearings—a thrust bearing is installed on the upper part of the motor, opposite to the shaft end. Other danger signs include reduced speed, decreased. Increased or erratic vibration of the driver is often the first symptom of an impending breakdown. Image 3 depicts an angular contact ball bearing. The thrust bearing, which is usually at the top of the. Thrust Bearing In Vertical Pumps Are Related To.

From www.pumpsandsystems.com

Back to Basics Pump Bearing Housing LubricationPart 2 Pumps & Systems Thrust Bearing In Vertical Pumps Are Related To The thrust bearing, which is usually at the top of the vertical motor (figure 1), may consist of one or more angular contact bearings; Image 3 depicts an angular contact ball bearing. Increased or erratic vibration of the driver is often the first symptom of an impending breakdown. Other danger signs include reduced speed, decreased. Thrust bearings—a thrust bearing is. Thrust Bearing In Vertical Pumps Are Related To.

From sddentebearing.en.made-in-china.com

51114 Pressure Thrust Ball Bearing for Vertical Water Pump China Thrust Bearing In Vertical Pumps Are Related To Increased or erratic vibration of the driver is often the first symptom of an impending breakdown. Thrust bearings—a thrust bearing is installed on the upper part of the motor, opposite to the shaft end. Through it’ s thrust bearing, must also be able to handle all of the vertical thrust imposed from the rotating assembly and not allow excessive downward. Thrust Bearing In Vertical Pumps Are Related To.

From www.introtopumps.com

Vertical Inline Pumps Intro to Pumps Thrust Bearing In Vertical Pumps Are Related To Thrust bearings—a thrust bearing is installed on the upper part of the motor, opposite to the shaft end. Increased or erratic vibration of the driver is often the first symptom of an impending breakdown. The majority of vertical turbine pump installations use a hollow shaft motor to manage thrust loads. Overhung vertical pumps supported by a thrust bearing located at. Thrust Bearing In Vertical Pumps Are Related To.

From www.ywsbearing.com

high load axial load 51224 thrust ball bearing for vertical pumps Buy Thrust Bearing In Vertical Pumps Are Related To Overhung vertical pumps supported by a thrust bearing located at the top of the machine are loaded with axial tensile force resulting from gravity loads. Thrust bearings—a thrust bearing is installed on the upper part of the motor, opposite to the shaft end. The thrust bearing, which is usually at the top of the vertical motor (figure 1), may consist. Thrust Bearing In Vertical Pumps Are Related To.

From www.ywsbearing.com

high load axial load 51224 thrust ball bearing for vertical pumps Buy Thrust Bearing In Vertical Pumps Are Related To Through it’ s thrust bearing, must also be able to handle all of the vertical thrust imposed from the rotating assembly and not allow excessive downward movement that could result in. Increased or erratic vibration of the driver is often the first symptom of an impending breakdown. Image 3 depicts an angular contact ball bearing. The thrust bearing, which is. Thrust Bearing In Vertical Pumps Are Related To.

From www.researchgate.net

3 Diagram of Thrust Bearing Loading Mechanism Download Scientific Thrust Bearing In Vertical Pumps Are Related To Through it’ s thrust bearing, must also be able to handle all of the vertical thrust imposed from the rotating assembly and not allow excessive downward movement that could result in. Overhung vertical pumps supported by a thrust bearing located at the top of the machine are loaded with axial tensile force resulting from gravity loads. The majority of vertical. Thrust Bearing In Vertical Pumps Are Related To.

From www.smeng.com.au

Thrust Bearing Ratings Submersible Motor Engineering Thrust Bearing In Vertical Pumps Are Related To Overhung vertical pumps supported by a thrust bearing located at the top of the machine are loaded with axial tensile force resulting from gravity loads. The thrust bearing, which is usually at the top of the vertical motor (figure 1), may consist of one or more angular contact bearings; Through it’ s thrust bearing, must also be able to handle. Thrust Bearing In Vertical Pumps Are Related To.

From www.batescrew.com

Turbine — Batescrew Pumps & Valves Australia Thrust Bearing In Vertical Pumps Are Related To Other danger signs include reduced speed, decreased. Image 3 depicts an angular contact ball bearing. Thrust bearings—a thrust bearing is installed on the upper part of the motor, opposite to the shaft end. The thrust bearing, which is usually at the top of the vertical motor (figure 1), may consist of one or more angular contact bearings; The majority of. Thrust Bearing In Vertical Pumps Are Related To.

From haywardtyler.com

Upgrade the capacity of your BWCP thrust bearing Hayward Tyler Thrust Bearing In Vertical Pumps Are Related To Image 3 depicts an angular contact ball bearing. Other danger signs include reduced speed, decreased. The majority of vertical turbine pump installations use a hollow shaft motor to manage thrust loads. Through it’ s thrust bearing, must also be able to handle all of the vertical thrust imposed from the rotating assembly and not allow excessive downward movement that could. Thrust Bearing In Vertical Pumps Are Related To.

From www.pumpsandsystems.com

Selecting Bearing Systems in Vertical Motors Pumps & Systems Thrust Bearing In Vertical Pumps Are Related To Image 3 depicts an angular contact ball bearing. The thrust bearing, which is usually at the top of the vertical motor (figure 1), may consist of one or more angular contact bearings; Thrust bearings—a thrust bearing is installed on the upper part of the motor, opposite to the shaft end. The majority of vertical turbine pump installations use a hollow. Thrust Bearing In Vertical Pumps Are Related To.

From www.pumpsandsystems.com

Steps to Successful Installation of Vertical Circulating Water Pumps Thrust Bearing In Vertical Pumps Are Related To The majority of vertical turbine pump installations use a hollow shaft motor to manage thrust loads. Image 3 depicts an angular contact ball bearing. Through it’ s thrust bearing, must also be able to handle all of the vertical thrust imposed from the rotating assembly and not allow excessive downward movement that could result in. Thrust bearings—a thrust bearing is. Thrust Bearing In Vertical Pumps Are Related To.

From www.youtube.com

Axial Displacement Of Turbine Thrust Bearing In Turbine YouTube Thrust Bearing In Vertical Pumps Are Related To Through it’ s thrust bearing, must also be able to handle all of the vertical thrust imposed from the rotating assembly and not allow excessive downward movement that could result in. The majority of vertical turbine pump installations use a hollow shaft motor to manage thrust loads. Image 3 depicts an angular contact ball bearing. Increased or erratic vibration of. Thrust Bearing In Vertical Pumps Are Related To.

From www.pumpsandsystems.com

Selecting Bearing Systems in Vertical Motors Pumps & Systems Thrust Bearing In Vertical Pumps Are Related To The majority of vertical turbine pump installations use a hollow shaft motor to manage thrust loads. Increased or erratic vibration of the driver is often the first symptom of an impending breakdown. Through it’ s thrust bearing, must also be able to handle all of the vertical thrust imposed from the rotating assembly and not allow excessive downward movement that. Thrust Bearing In Vertical Pumps Are Related To.

From introtopumps.com

Vertical Turbine Pumps Intro To Pumps Thrust Bearing In Vertical Pumps Are Related To The majority of vertical turbine pump installations use a hollow shaft motor to manage thrust loads. Image 3 depicts an angular contact ball bearing. Other danger signs include reduced speed, decreased. Increased or erratic vibration of the driver is often the first symptom of an impending breakdown. Thrust bearings—a thrust bearing is installed on the upper part of the motor,. Thrust Bearing In Vertical Pumps Are Related To.

From www.naglepumps.com

Vertical Submerged Bearing Pumps Nagle Pumps Inc. Thrust Bearing In Vertical Pumps Are Related To Overhung vertical pumps supported by a thrust bearing located at the top of the machine are loaded with axial tensile force resulting from gravity loads. The majority of vertical turbine pump installations use a hollow shaft motor to manage thrust loads. Other danger signs include reduced speed, decreased. Through it’ s thrust bearing, must also be able to handle all. Thrust Bearing In Vertical Pumps Are Related To.

From www.ywsbearing.com

high load axial load 51224 thrust ball bearing for vertical pumps Buy Thrust Bearing In Vertical Pumps Are Related To Thrust bearings—a thrust bearing is installed on the upper part of the motor, opposite to the shaft end. Image 3 depicts an angular contact ball bearing. Through it’ s thrust bearing, must also be able to handle all of the vertical thrust imposed from the rotating assembly and not allow excessive downward movement that could result in. Increased or erratic. Thrust Bearing In Vertical Pumps Are Related To.