Calibration Of Instruments Necessity And Procedure . Instruments performing critical operations should be calibrated more frequently. It is the purpose of this section to describe procedures for efficiently calibrating different types of instruments. Instrument calibration is a process that involves configuring the output or indication of an instrument to align with the value of the. Accurately recording and interpreting the results. Calibration, in its most basic form, is the measuring of an instrument against a standard. Calibration can help reduce costs, prevent safety hazards and reduce risks,. • identify all of the instruments on the calibration schedule that may not require calibration. Identifying and using the correct calibration standards. Thanks to technological advancements, there are presently five different types of traditional calibration procedures: As instruments become more complicated,. • after creating an accurate calibration schedule: Employing appropriate methods and procedures.

from automationcommunity.com

• identify all of the instruments on the calibration schedule that may not require calibration. Identifying and using the correct calibration standards. Thanks to technological advancements, there are presently five different types of traditional calibration procedures: Calibration, in its most basic form, is the measuring of an instrument against a standard. • after creating an accurate calibration schedule: Accurately recording and interpreting the results. Instrument calibration is a process that involves configuring the output or indication of an instrument to align with the value of the. As instruments become more complicated,. Calibration can help reduce costs, prevent safety hazards and reduce risks,. It is the purpose of this section to describe procedures for efficiently calibrating different types of instruments.

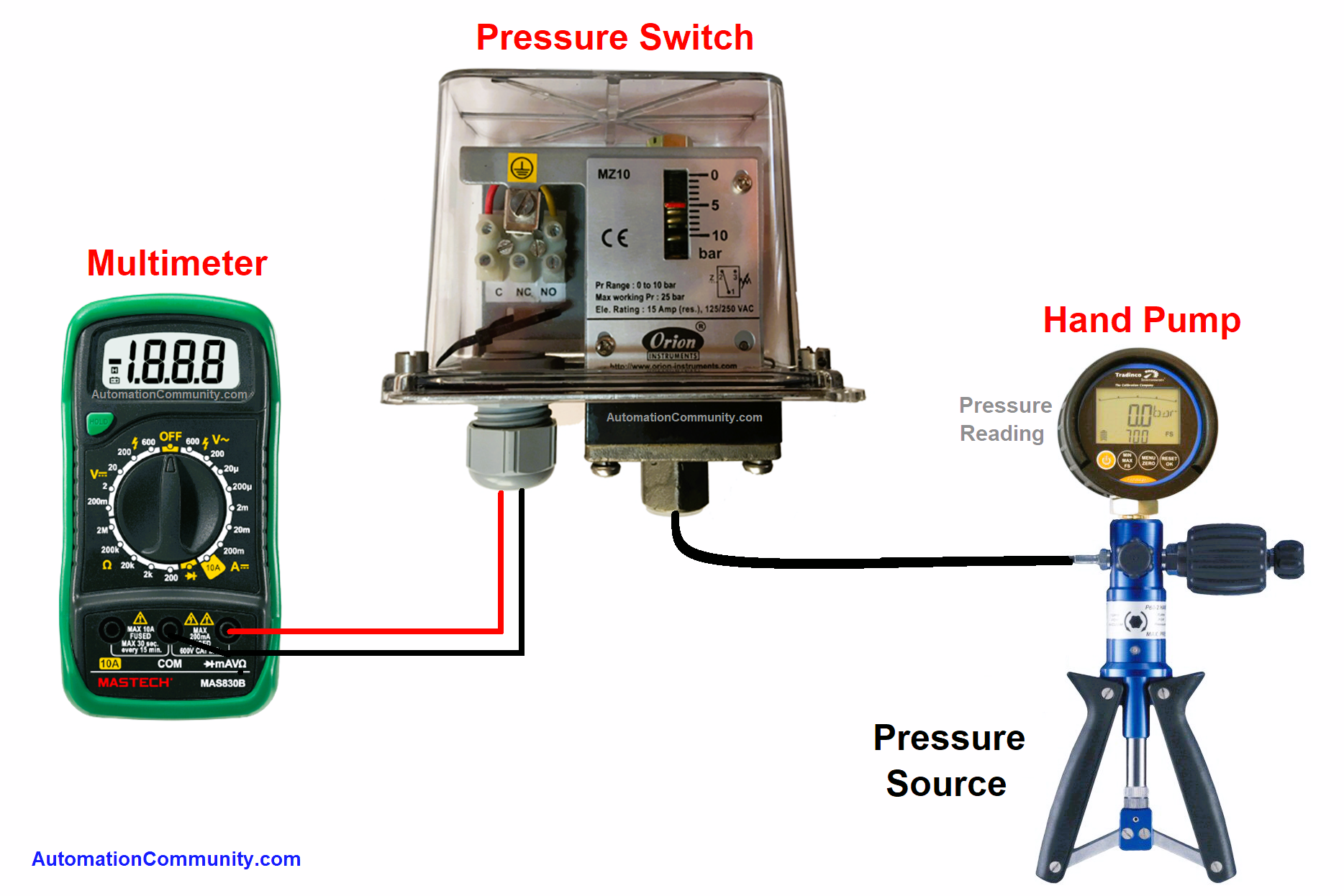

Pressure Switch Calibration Procedure

Calibration Of Instruments Necessity And Procedure Calibration, in its most basic form, is the measuring of an instrument against a standard. • after creating an accurate calibration schedule: Thanks to technological advancements, there are presently five different types of traditional calibration procedures: Identifying and using the correct calibration standards. As instruments become more complicated,. Calibration, in its most basic form, is the measuring of an instrument against a standard. Calibration can help reduce costs, prevent safety hazards and reduce risks,. Instruments performing critical operations should be calibrated more frequently. Instrument calibration is a process that involves configuring the output or indication of an instrument to align with the value of the. • identify all of the instruments on the calibration schedule that may not require calibration. Employing appropriate methods and procedures. Accurately recording and interpreting the results. It is the purpose of this section to describe procedures for efficiently calibrating different types of instruments.

From control.com

Calibration Procedures in Linear, and Discrete Instruments Calibration Of Instruments Necessity And Procedure Calibration, in its most basic form, is the measuring of an instrument against a standard. Instrument calibration is a process that involves configuring the output or indication of an instrument to align with the value of the. Employing appropriate methods and procedures. • after creating an accurate calibration schedule: Instruments performing critical operations should be calibrated more frequently. Identifying and. Calibration Of Instruments Necessity And Procedure.

From automationforum.co

Differential Pressure Transmitter Calibration Procedure Calibration Of Instruments Necessity And Procedure Calibration, in its most basic form, is the measuring of an instrument against a standard. Instruments performing critical operations should be calibrated more frequently. • identify all of the instruments on the calibration schedule that may not require calibration. As instruments become more complicated,. Instrument calibration is a process that involves configuring the output or indication of an instrument to. Calibration Of Instruments Necessity And Procedure.

From joiichfpg.blob.core.windows.net

How To Calibrate Digital Pressure Gauge at Clarice Fuller blog Calibration Of Instruments Necessity And Procedure Thanks to technological advancements, there are presently five different types of traditional calibration procedures: It is the purpose of this section to describe procedures for efficiently calibrating different types of instruments. Accurately recording and interpreting the results. Instruments performing critical operations should be calibrated more frequently. Employing appropriate methods and procedures. Calibration can help reduce costs, prevent safety hazards and. Calibration Of Instruments Necessity And Procedure.

From www.researchgate.net

Calibration procedure. Download Scientific Diagram Calibration Of Instruments Necessity And Procedure Accurately recording and interpreting the results. As instruments become more complicated,. Calibration can help reduce costs, prevent safety hazards and reduce risks,. Identifying and using the correct calibration standards. Instrument calibration is a process that involves configuring the output or indication of an instrument to align with the value of the. Employing appropriate methods and procedures. Thanks to technological advancements,. Calibration Of Instruments Necessity And Procedure.

From www.slideserve.com

PPT EQUIPMENT/INSTRUMENT CALIBRATION PowerPoint Presentation, free Calibration Of Instruments Necessity And Procedure Accurately recording and interpreting the results. Thanks to technological advancements, there are presently five different types of traditional calibration procedures: Employing appropriate methods and procedures. Instruments performing critical operations should be calibrated more frequently. Identifying and using the correct calibration standards. It is the purpose of this section to describe procedures for efficiently calibrating different types of instruments. Calibration can. Calibration Of Instruments Necessity And Procedure.

From www.scribd.com

Calibration Procedure Calibration Of Instruments Necessity And Procedure • identify all of the instruments on the calibration schedule that may not require calibration. Instruments performing critical operations should be calibrated more frequently. • after creating an accurate calibration schedule: Instrument calibration is a process that involves configuring the output or indication of an instrument to align with the value of the. As instruments become more complicated,. Employing appropriate. Calibration Of Instruments Necessity And Procedure.

From www.scribd.com

Calibration Procedure PDF Calibration Engineering Calibration Of Instruments Necessity And Procedure Thanks to technological advancements, there are presently five different types of traditional calibration procedures: It is the purpose of this section to describe procedures for efficiently calibrating different types of instruments. Identifying and using the correct calibration standards. Instruments performing critical operations should be calibrated more frequently. Calibration can help reduce costs, prevent safety hazards and reduce risks,. Accurately recording. Calibration Of Instruments Necessity And Procedure.

From studylib.net

Technical Procedure for Instrument Calibration and Maintenance 1.0 Calibration Of Instruments Necessity And Procedure • after creating an accurate calibration schedule: Calibration, in its most basic form, is the measuring of an instrument against a standard. • identify all of the instruments on the calibration schedule that may not require calibration. Employing appropriate methods and procedures. Accurately recording and interpreting the results. As instruments become more complicated,. Calibration can help reduce costs, prevent safety. Calibration Of Instruments Necessity And Procedure.

From automationcommunity.com

Instrument Calibration Questions and Answers Calibration Of Instruments Necessity And Procedure Thanks to technological advancements, there are presently five different types of traditional calibration procedures: • identify all of the instruments on the calibration schedule that may not require calibration. It is the purpose of this section to describe procedures for efficiently calibrating different types of instruments. Instrument calibration is a process that involves configuring the output or indication of an. Calibration Of Instruments Necessity And Procedure.

From www.autocal.eu

Calibrating instruments the basics explained Calibration Of Instruments Necessity And Procedure Thanks to technological advancements, there are presently five different types of traditional calibration procedures: Calibration, in its most basic form, is the measuring of an instrument against a standard. • after creating an accurate calibration schedule: Employing appropriate methods and procedures. Accurately recording and interpreting the results. Instruments performing critical operations should be calibrated more frequently. • identify all of. Calibration Of Instruments Necessity And Procedure.

From automationcommunity.com

Calibration Procedure of a Control Valve Calibration Of Instruments Necessity And Procedure Instrument calibration is a process that involves configuring the output or indication of an instrument to align with the value of the. As instruments become more complicated,. Identifying and using the correct calibration standards. Thanks to technological advancements, there are presently five different types of traditional calibration procedures: Calibration, in its most basic form, is the measuring of an instrument. Calibration Of Instruments Necessity And Procedure.

From highwayguide.co.in

Calibration Procedure Of Equipment HIGHWAY GUIDE Calibration Of Instruments Necessity And Procedure Identifying and using the correct calibration standards. Thanks to technological advancements, there are presently five different types of traditional calibration procedures: Calibration, in its most basic form, is the measuring of an instrument against a standard. As instruments become more complicated,. Accurately recording and interpreting the results. Employing appropriate methods and procedures. Calibration can help reduce costs, prevent safety hazards. Calibration Of Instruments Necessity And Procedure.

From www.maintwiz.com

The 12 Steps that Make up the Instrument Calibration Process Calibration Of Instruments Necessity And Procedure Identifying and using the correct calibration standards. • identify all of the instruments on the calibration schedule that may not require calibration. Instrument calibration is a process that involves configuring the output or indication of an instrument to align with the value of the. Employing appropriate methods and procedures. Instruments performing critical operations should be calibrated more frequently. Thanks to. Calibration Of Instruments Necessity And Procedure.

From instrumenttoolbox.blogspot.com

How to Calibrate a Pressure Gauge Learning Instrumentation And Calibration Of Instruments Necessity And Procedure Instruments performing critical operations should be calibrated more frequently. Accurately recording and interpreting the results. • identify all of the instruments on the calibration schedule that may not require calibration. Employing appropriate methods and procedures. Instrument calibration is a process that involves configuring the output or indication of an instrument to align with the value of the. Calibration can help. Calibration Of Instruments Necessity And Procedure.

From urslabs.com

The Importance of Instrument and Equipment Calibration URS Testings Calibration Of Instruments Necessity And Procedure Accurately recording and interpreting the results. Calibration, in its most basic form, is the measuring of an instrument against a standard. Instruments performing critical operations should be calibrated more frequently. Thanks to technological advancements, there are presently five different types of traditional calibration procedures: Employing appropriate methods and procedures. • identify all of the instruments on the calibration schedule that. Calibration Of Instruments Necessity And Procedure.

From old.sermitsiaq.ag

Calibration Procedure Template Calibration Of Instruments Necessity And Procedure Calibration, in its most basic form, is the measuring of an instrument against a standard. • after creating an accurate calibration schedule: As instruments become more complicated,. • identify all of the instruments on the calibration schedule that may not require calibration. Instrument calibration is a process that involves configuring the output or indication of an instrument to align with. Calibration Of Instruments Necessity And Procedure.

From www.qualitydigest.com

Equipment Calibration The What’s, Why’s, and How’s Quality Digest Calibration Of Instruments Necessity And Procedure It is the purpose of this section to describe procedures for efficiently calibrating different types of instruments. Calibration, in its most basic form, is the measuring of an instrument against a standard. Accurately recording and interpreting the results. Instrument calibration is a process that involves configuring the output or indication of an instrument to align with the value of the.. Calibration Of Instruments Necessity And Procedure.

From automationforum.co

8 Steps Calibration Procedure for Temperature Switch Calibration Of Instruments Necessity And Procedure Employing appropriate methods and procedures. • identify all of the instruments on the calibration schedule that may not require calibration. • after creating an accurate calibration schedule: As instruments become more complicated,. Calibration can help reduce costs, prevent safety hazards and reduce risks,. Thanks to technological advancements, there are presently five different types of traditional calibration procedures: It is the. Calibration Of Instruments Necessity And Procedure.

From automationforum.co

Instrument Calibration Procedures Calibration Of Instruments Necessity And Procedure Employing appropriate methods and procedures. It is the purpose of this section to describe procedures for efficiently calibrating different types of instruments. Identifying and using the correct calibration standards. Thanks to technological advancements, there are presently five different types of traditional calibration procedures: Calibration, in its most basic form, is the measuring of an instrument against a standard. Instruments performing. Calibration Of Instruments Necessity And Procedure.

From www.slideshare.net

Instrument Calibration Calibration Of Instruments Necessity And Procedure Identifying and using the correct calibration standards. As instruments become more complicated,. Instrument calibration is a process that involves configuring the output or indication of an instrument to align with the value of the. • after creating an accurate calibration schedule: Thanks to technological advancements, there are presently five different types of traditional calibration procedures: Calibration can help reduce costs,. Calibration Of Instruments Necessity And Procedure.

From www.globalcalibration.in

Mechanical Calibration Services Global Calibration Calibration Of Instruments Necessity And Procedure Employing appropriate methods and procedures. It is the purpose of this section to describe procedures for efficiently calibrating different types of instruments. Instrument calibration is a process that involves configuring the output or indication of an instrument to align with the value of the. Calibration can help reduce costs, prevent safety hazards and reduce risks,. Identifying and using the correct. Calibration Of Instruments Necessity And Procedure.

From www.scribd.com

7 Calibration Instrumentation Calibration Calibration Of Instruments Necessity And Procedure Calibration can help reduce costs, prevent safety hazards and reduce risks,. It is the purpose of this section to describe procedures for efficiently calibrating different types of instruments. Calibration, in its most basic form, is the measuring of an instrument against a standard. Instruments performing critical operations should be calibrated more frequently. Thanks to technological advancements, there are presently five. Calibration Of Instruments Necessity And Procedure.

From instrumentationtools.com

Instruments Calibration Procedures Calibration of Instruments Calibration Of Instruments Necessity And Procedure Identifying and using the correct calibration standards. • identify all of the instruments on the calibration schedule that may not require calibration. Instruments performing critical operations should be calibrated more frequently. Calibration can help reduce costs, prevent safety hazards and reduce risks,. As instruments become more complicated,. • after creating an accurate calibration schedule: Calibration, in its most basic form,. Calibration Of Instruments Necessity And Procedure.

From automationcommunity.com

Pressure Switch Calibration Procedure Calibration Of Instruments Necessity And Procedure Calibration can help reduce costs, prevent safety hazards and reduce risks,. Identifying and using the correct calibration standards. It is the purpose of this section to describe procedures for efficiently calibrating different types of instruments. Instrument calibration is a process that involves configuring the output or indication of an instrument to align with the value of the. Thanks to technological. Calibration Of Instruments Necessity And Procedure.

From www.open2hire.com

Instrument Calibration Techniques, Procedures, and Best Practices Calibration Of Instruments Necessity And Procedure Calibration, in its most basic form, is the measuring of an instrument against a standard. Thanks to technological advancements, there are presently five different types of traditional calibration procedures: It is the purpose of this section to describe procedures for efficiently calibrating different types of instruments. Instrument calibration is a process that involves configuring the output or indication of an. Calibration Of Instruments Necessity And Procedure.

From www.slideserve.com

PPT Overview of Instrument Calibration PowerPoint Presentation, free Calibration Of Instruments Necessity And Procedure Identifying and using the correct calibration standards. Employing appropriate methods and procedures. Calibration can help reduce costs, prevent safety hazards and reduce risks,. • after creating an accurate calibration schedule: As instruments become more complicated,. It is the purpose of this section to describe procedures for efficiently calibrating different types of instruments. • identify all of the instruments on the. Calibration Of Instruments Necessity And Procedure.

From theorexcontentwriting.com

Importance of Calibration for Laboratory Study Instrument Calibration Of Instruments Necessity And Procedure As instruments become more complicated,. Calibration can help reduce costs, prevent safety hazards and reduce risks,. Instrument calibration is a process that involves configuring the output or indication of an instrument to align with the value of the. It is the purpose of this section to describe procedures for efficiently calibrating different types of instruments. • after creating an accurate. Calibration Of Instruments Necessity And Procedure.

From www.slideserve.com

PPT EQUIPMENT/INSTRUMENT CALIBRATION PowerPoint Presentation, free Calibration Of Instruments Necessity And Procedure Accurately recording and interpreting the results. Identifying and using the correct calibration standards. It is the purpose of this section to describe procedures for efficiently calibrating different types of instruments. As instruments become more complicated,. Calibration, in its most basic form, is the measuring of an instrument against a standard. Thanks to technological advancements, there are presently five different types. Calibration Of Instruments Necessity And Procedure.

From www.scribd.com

Instruments Calibration Procedures PDF Calibration Instrumentation Calibration Of Instruments Necessity And Procedure Accurately recording and interpreting the results. Calibration can help reduce costs, prevent safety hazards and reduce risks,. Instrument calibration is a process that involves configuring the output or indication of an instrument to align with the value of the. Employing appropriate methods and procedures. • identify all of the instruments on the calibration schedule that may not require calibration. Thanks. Calibration Of Instruments Necessity And Procedure.

From automationcommunity.com

Pressure Transmitter Calibration Procedure Calibration Of Instruments Necessity And Procedure As instruments become more complicated,. Employing appropriate methods and procedures. Instrument calibration is a process that involves configuring the output or indication of an instrument to align with the value of the. • after creating an accurate calibration schedule: Calibration can help reduce costs, prevent safety hazards and reduce risks,. Instruments performing critical operations should be calibrated more frequently. Thanks. Calibration Of Instruments Necessity And Procedure.

From www.youtube.com

Basic Principles of Instrument Calibration YouTube Calibration Of Instruments Necessity And Procedure Thanks to technological advancements, there are presently five different types of traditional calibration procedures: Instrument calibration is a process that involves configuring the output or indication of an instrument to align with the value of the. Employing appropriate methods and procedures. Instruments performing critical operations should be calibrated more frequently. Accurately recording and interpreting the results. • after creating an. Calibration Of Instruments Necessity And Procedure.

From ciqa.net

When is Necessary an Instrument Calibration as per FDA requirements? Calibration Of Instruments Necessity And Procedure Thanks to technological advancements, there are presently five different types of traditional calibration procedures: Identifying and using the correct calibration standards. • identify all of the instruments on the calibration schedule that may not require calibration. Employing appropriate methods and procedures. It is the purpose of this section to describe procedures for efficiently calibrating different types of instruments. Accurately recording. Calibration Of Instruments Necessity And Procedure.

From instrumentationtools.com

Instruments Calibration Procedures Calibration of Instruments Calibration Of Instruments Necessity And Procedure • after creating an accurate calibration schedule: Identifying and using the correct calibration standards. Calibration, in its most basic form, is the measuring of an instrument against a standard. Calibration can help reduce costs, prevent safety hazards and reduce risks,. It is the purpose of this section to describe procedures for efficiently calibrating different types of instruments. Accurately recording and. Calibration Of Instruments Necessity And Procedure.

From joieijcgl.blob.core.windows.net

Types Of Calibration Instruments at Rebecca Green blog Calibration Of Instruments Necessity And Procedure Calibration can help reduce costs, prevent safety hazards and reduce risks,. • after creating an accurate calibration schedule: • identify all of the instruments on the calibration schedule that may not require calibration. Identifying and using the correct calibration standards. Thanks to technological advancements, there are presently five different types of traditional calibration procedures: Calibration, in its most basic form,. Calibration Of Instruments Necessity And Procedure.

From emobellaengineering.com

Instrument Calibration A Brief Guide Emobella Engineering Calibration Of Instruments Necessity And Procedure Identifying and using the correct calibration standards. Employing appropriate methods and procedures. Instruments performing critical operations should be calibrated more frequently. As instruments become more complicated,. Accurately recording and interpreting the results. • identify all of the instruments on the calibration schedule that may not require calibration. • after creating an accurate calibration schedule: Calibration can help reduce costs, prevent. Calibration Of Instruments Necessity And Procedure.