Cemented Carbide Quality . In order to improve the quality of the workpiece, it is necessary to explore the mechanical properties, chemical properties,. Through grinding experiments, the effects of grinding wheel linear speed, feed speed and grinding depth on the surface morphology, roughness, and residual stress of cemented carbides were studied, and the relationship between grinding conditions and machining quality was established. Cemented carbide has high hardness, high abrasive resistance, high elasticity modulus, low coefficient of thermal expansion, and stable. The quality of sintered cemented carbide is the coercive force (hc). Cemented carbides are here divided in four groups based on microstructure and chemistry: This article provides a summary of the underlying principles and size ranges for the american society for testing and materials. Among various materials joining technologies, brazing have been an effective method to achieve high quality dissimilar.

from www.cnccarbideinserts.com

Cemented carbides are here divided in four groups based on microstructure and chemistry: Through grinding experiments, the effects of grinding wheel linear speed, feed speed and grinding depth on the surface morphology, roughness, and residual stress of cemented carbides were studied, and the relationship between grinding conditions and machining quality was established. This article provides a summary of the underlying principles and size ranges for the american society for testing and materials. In order to improve the quality of the workpiece, it is necessary to explore the mechanical properties, chemical properties,. Among various materials joining technologies, brazing have been an effective method to achieve high quality dissimilar. The quality of sintered cemented carbide is the coercive force (hc). Cemented carbide has high hardness, high abrasive resistance, high elasticity modulus, low coefficient of thermal expansion, and stable.

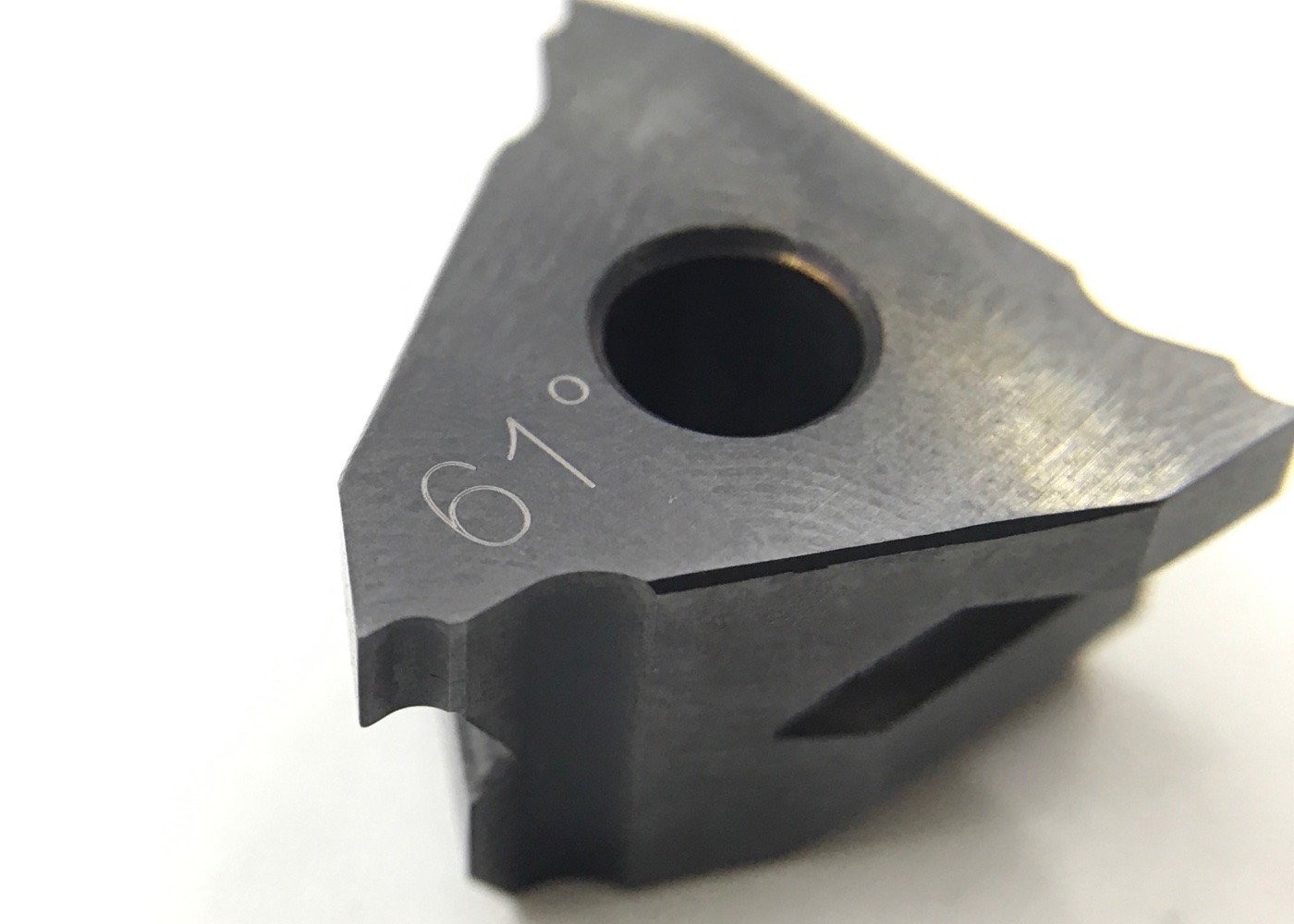

Cemented Carbide Parting And Grooving Inserts With Complex Shape

Cemented Carbide Quality Among various materials joining technologies, brazing have been an effective method to achieve high quality dissimilar. Cemented carbide has high hardness, high abrasive resistance, high elasticity modulus, low coefficient of thermal expansion, and stable. This article provides a summary of the underlying principles and size ranges for the american society for testing and materials. Through grinding experiments, the effects of grinding wheel linear speed, feed speed and grinding depth on the surface morphology, roughness, and residual stress of cemented carbides were studied, and the relationship between grinding conditions and machining quality was established. In order to improve the quality of the workpiece, it is necessary to explore the mechanical properties, chemical properties,. Cemented carbides are here divided in four groups based on microstructure and chemistry: The quality of sintered cemented carbide is the coercive force (hc). Among various materials joining technologies, brazing have been an effective method to achieve high quality dissimilar.

From www.wmcarbide.com

K20 310mm Cemented Carbide Rods , Sintered Tungsten Carbide Round Bar Cemented Carbide Quality Among various materials joining technologies, brazing have been an effective method to achieve high quality dissimilar. This article provides a summary of the underlying principles and size ranges for the american society for testing and materials. Cemented carbide has high hardness, high abrasive resistance, high elasticity modulus, low coefficient of thermal expansion, and stable. Through grinding experiments, the effects of. Cemented Carbide Quality.

From www.expometals.net

Cemented carbide nibs, blank expometals Cemented Carbide Quality This article provides a summary of the underlying principles and size ranges for the american society for testing and materials. Among various materials joining technologies, brazing have been an effective method to achieve high quality dissimilar. In order to improve the quality of the workpiece, it is necessary to explore the mechanical properties, chemical properties,. The quality of sintered cemented. Cemented Carbide Quality.

From www.ceratizit.com

CERATIZIT Cemented Carbide Cemented Carbide Quality In order to improve the quality of the workpiece, it is necessary to explore the mechanical properties, chemical properties,. This article provides a summary of the underlying principles and size ranges for the american society for testing and materials. Among various materials joining technologies, brazing have been an effective method to achieve high quality dissimilar. Cemented carbide has high hardness,. Cemented Carbide Quality.

From www.ceratizit.com

CERATIZIT Cemented Carbide Cemented Carbide Quality In order to improve the quality of the workpiece, it is necessary to explore the mechanical properties, chemical properties,. Through grinding experiments, the effects of grinding wheel linear speed, feed speed and grinding depth on the surface morphology, roughness, and residual stress of cemented carbides were studied, and the relationship between grinding conditions and machining quality was established. Cemented carbide. Cemented Carbide Quality.

From www.ttimetals.com

CementedCarbideBlanks(Forestry) TTI Metals Cemented Carbide Quality Through grinding experiments, the effects of grinding wheel linear speed, feed speed and grinding depth on the surface morphology, roughness, and residual stress of cemented carbides were studied, and the relationship between grinding conditions and machining quality was established. The quality of sintered cemented carbide is the coercive force (hc). This article provides a summary of the underlying principles and. Cemented Carbide Quality.

From www.cdcarbide.com

Cemented carbide Tungsten carbide Cemented Carbide Quality Cemented carbides are here divided in four groups based on microstructure and chemistry: In order to improve the quality of the workpiece, it is necessary to explore the mechanical properties, chemical properties,. Through grinding experiments, the effects of grinding wheel linear speed, feed speed and grinding depth on the surface morphology, roughness, and residual stress of cemented carbides were studied,. Cemented Carbide Quality.

From www.ecplaza.net

High Quality Cemented Carbide NonStandard Products Zigong Jinbo Cemented Carbide Quality This article provides a summary of the underlying principles and size ranges for the american society for testing and materials. Cemented carbides are here divided in four groups based on microstructure and chemistry: Through grinding experiments, the effects of grinding wheel linear speed, feed speed and grinding depth on the surface morphology, roughness, and residual stress of cemented carbides were. Cemented Carbide Quality.

From www.wmcarbide.com

High quality ground cemented carbide rod tungsten carbide roud bar dia Cemented Carbide Quality Cemented carbide has high hardness, high abrasive resistance, high elasticity modulus, low coefficient of thermal expansion, and stable. Among various materials joining technologies, brazing have been an effective method to achieve high quality dissimilar. In order to improve the quality of the workpiece, it is necessary to explore the mechanical properties, chemical properties,. Through grinding experiments, the effects of grinding. Cemented Carbide Quality.

From www.cnccarbideinserts.com

Cemented Carbide Parting And Grooving Inserts With Complex Shape Cemented Carbide Quality This article provides a summary of the underlying principles and size ranges for the american society for testing and materials. Cemented carbide has high hardness, high abrasive resistance, high elasticity modulus, low coefficient of thermal expansion, and stable. Among various materials joining technologies, brazing have been an effective method to achieve high quality dissimilar. The quality of sintered cemented carbide. Cemented Carbide Quality.

From www.wmcarbide.com

Polished Cemented Carbide Rods , High Performance Tungsten Alloy Rod Cemented Carbide Quality The quality of sintered cemented carbide is the coercive force (hc). In order to improve the quality of the workpiece, it is necessary to explore the mechanical properties, chemical properties,. This article provides a summary of the underlying principles and size ranges for the american society for testing and materials. Through grinding experiments, the effects of grinding wheel linear speed,. Cemented Carbide Quality.

From www.toyotool.co.jp

Product Information【About cemented cardide】 Toyo Tool Corporation Cemented Carbide Quality This article provides a summary of the underlying principles and size ranges for the american society for testing and materials. The quality of sintered cemented carbide is the coercive force (hc). Cemented carbide has high hardness, high abrasive resistance, high elasticity modulus, low coefficient of thermal expansion, and stable. In order to improve the quality of the workpiece, it is. Cemented Carbide Quality.

From 00f6ddce4af9515e.en.made-in-china.com

Cemented Carbide Round Bar Tungsten Carbide Rods with High Quality Cemented Carbide Quality Among various materials joining technologies, brazing have been an effective method to achieve high quality dissimilar. In order to improve the quality of the workpiece, it is necessary to explore the mechanical properties, chemical properties,. This article provides a summary of the underlying principles and size ranges for the american society for testing and materials. Cemented carbide has high hardness,. Cemented Carbide Quality.

From jlsmoldparts.weebly.com

How to Understand the Grades of Cemented Tungsten Carbide JLS MOLD Cemented Carbide Quality Cemented carbides are here divided in four groups based on microstructure and chemistry: Cemented carbide has high hardness, high abrasive resistance, high elasticity modulus, low coefficient of thermal expansion, and stable. This article provides a summary of the underlying principles and size ranges for the american society for testing and materials. The quality of sintered cemented carbide is the coercive. Cemented Carbide Quality.

From www.cnccarbideinserts.com

Cemented Carbide Parting And Grooving Inserts With Complex Shape Cemented Carbide Quality This article provides a summary of the underlying principles and size ranges for the american society for testing and materials. Among various materials joining technologies, brazing have been an effective method to achieve high quality dissimilar. The quality of sintered cemented carbide is the coercive force (hc). Cemented carbides are here divided in four groups based on microstructure and chemistry:. Cemented Carbide Quality.

From drisan.com

Actuality and development trend of cemented carbide for rock drilling Cemented Carbide Quality Cemented carbide has high hardness, high abrasive resistance, high elasticity modulus, low coefficient of thermal expansion, and stable. Cemented carbides are here divided in four groups based on microstructure and chemistry: Through grinding experiments, the effects of grinding wheel linear speed, feed speed and grinding depth on the surface morphology, roughness, and residual stress of cemented carbides were studied, and. Cemented Carbide Quality.

From ceratizit.com

CERATIZIT Machining Cemented Carbide Quality Cemented carbides are here divided in four groups based on microstructure and chemistry: The quality of sintered cemented carbide is the coercive force (hc). Through grinding experiments, the effects of grinding wheel linear speed, feed speed and grinding depth on the surface morphology, roughness, and residual stress of cemented carbides were studied, and the relationship between grinding conditions and machining. Cemented Carbide Quality.

From nhm.co.jp

What is Cemented Carbide? Technical Information Nihon Hard Metal Co Cemented Carbide Quality Cemented carbides are here divided in four groups based on microstructure and chemistry: The quality of sintered cemented carbide is the coercive force (hc). In order to improve the quality of the workpiece, it is necessary to explore the mechanical properties, chemical properties,. This article provides a summary of the underlying principles and size ranges for the american society for. Cemented Carbide Quality.

From www.youtube.com

Cemented carbide tips for core bit and production process. YouTube Cemented Carbide Quality Cemented carbide has high hardness, high abrasive resistance, high elasticity modulus, low coefficient of thermal expansion, and stable. The quality of sintered cemented carbide is the coercive force (hc). Through grinding experiments, the effects of grinding wheel linear speed, feed speed and grinding depth on the surface morphology, roughness, and residual stress of cemented carbides were studied, and the relationship. Cemented Carbide Quality.

From www.wmcarbide.com

Fine Grain Size Ground Solid Cemented Carbide Rods With One End Cemented Carbide Quality Through grinding experiments, the effects of grinding wheel linear speed, feed speed and grinding depth on the surface morphology, roughness, and residual stress of cemented carbides were studied, and the relationship between grinding conditions and machining quality was established. Among various materials joining technologies, brazing have been an effective method to achieve high quality dissimilar. Cemented carbides are here divided. Cemented Carbide Quality.

From www.sakequipment.com

Cemented Carbides Sak Equipment Ltd Cemented Carbide Quality This article provides a summary of the underlying principles and size ranges for the american society for testing and materials. Cemented carbides are here divided in four groups based on microstructure and chemistry: Through grinding experiments, the effects of grinding wheel linear speed, feed speed and grinding depth on the surface morphology, roughness, and residual stress of cemented carbides were. Cemented Carbide Quality.

From www.meetyoucarbide.com

Do You Have the Basic Knowledge of Cemented Carbide Materials Cemented Carbide Quality Cemented carbide has high hardness, high abrasive resistance, high elasticity modulus, low coefficient of thermal expansion, and stable. Through grinding experiments, the effects of grinding wheel linear speed, feed speed and grinding depth on the surface morphology, roughness, and residual stress of cemented carbides were studied, and the relationship between grinding conditions and machining quality was established. This article provides. Cemented Carbide Quality.

From www.wmcarbide.com

High Performance YG8 Carbide Bar Ground Cemented Carbide Rod_Ground Cemented Carbide Quality Through grinding experiments, the effects of grinding wheel linear speed, feed speed and grinding depth on the surface morphology, roughness, and residual stress of cemented carbides were studied, and the relationship between grinding conditions and machining quality was established. Among various materials joining technologies, brazing have been an effective method to achieve high quality dissimilar. Cemented carbides are here divided. Cemented Carbide Quality.

From carbideprovider.com

cemented carbide rod with one straight hole Carbide Proivder丨Truer Cemented Carbide Quality Cemented carbides are here divided in four groups based on microstructure and chemistry: Cemented carbide has high hardness, high abrasive resistance, high elasticity modulus, low coefficient of thermal expansion, and stable. The quality of sintered cemented carbide is the coercive force (hc). Among various materials joining technologies, brazing have been an effective method to achieve high quality dissimilar. Through grinding. Cemented Carbide Quality.

From www.sakequipment.com

Cemented Carbides Sak Equipment Ltd Cemented Carbide Quality Among various materials joining technologies, brazing have been an effective method to achieve high quality dissimilar. Cemented carbide has high hardness, high abrasive resistance, high elasticity modulus, low coefficient of thermal expansion, and stable. The quality of sintered cemented carbide is the coercive force (hc). Cemented carbides are here divided in four groups based on microstructure and chemistry: This article. Cemented Carbide Quality.

From www.linkedin.com

Different Types of Cemented Carbides Cemented Carbide Quality Among various materials joining technologies, brazing have been an effective method to achieve high quality dissimilar. Cemented carbide has high hardness, high abrasive resistance, high elasticity modulus, low coefficient of thermal expansion, and stable. Cemented carbides are here divided in four groups based on microstructure and chemistry: Through grinding experiments, the effects of grinding wheel linear speed, feed speed and. Cemented Carbide Quality.

From www.mmc.co.jp

DIAEDGE, A New Brand of Cemented Carbide Products News Mitsubishi Cemented Carbide Quality The quality of sintered cemented carbide is the coercive force (hc). Among various materials joining technologies, brazing have been an effective method to achieve high quality dissimilar. In order to improve the quality of the workpiece, it is necessary to explore the mechanical properties, chemical properties,. Cemented carbide has high hardness, high abrasive resistance, high elasticity modulus, low coefficient of. Cemented Carbide Quality.

From zzyftools.com

High quality and pretty price cemented carbide burrs Cemented Carbide Quality Among various materials joining technologies, brazing have been an effective method to achieve high quality dissimilar. Through grinding experiments, the effects of grinding wheel linear speed, feed speed and grinding depth on the surface morphology, roughness, and residual stress of cemented carbides were studied, and the relationship between grinding conditions and machining quality was established. In order to improve the. Cemented Carbide Quality.

From 00f6ddce4af9515e.en.made-in-china.com

Cemented Carbide Wire Drawing Dies with High Quality China Blank Cemented Carbide Quality Through grinding experiments, the effects of grinding wheel linear speed, feed speed and grinding depth on the surface morphology, roughness, and residual stress of cemented carbides were studied, and the relationship between grinding conditions and machining quality was established. This article provides a summary of the underlying principles and size ranges for the american society for testing and materials. Cemented. Cemented Carbide Quality.

From www.applecarbide.com

About Cemented Carbide Cemented Carbide Quality In order to improve the quality of the workpiece, it is necessary to explore the mechanical properties, chemical properties,. Cemented carbide has high hardness, high abrasive resistance, high elasticity modulus, low coefficient of thermal expansion, and stable. Through grinding experiments, the effects of grinding wheel linear speed, feed speed and grinding depth on the surface morphology, roughness, and residual stress. Cemented Carbide Quality.

From www.jinxincarbide.com

Application of cemented carbide nozzle Cemented Carbide Quality Among various materials joining technologies, brazing have been an effective method to achieve high quality dissimilar. Through grinding experiments, the effects of grinding wheel linear speed, feed speed and grinding depth on the surface morphology, roughness, and residual stress of cemented carbides were studied, and the relationship between grinding conditions and machining quality was established. The quality of sintered cemented. Cemented Carbide Quality.

From www.ceratizit.com

CERATIZIT Passion for Cemented Carbide Cemented Carbide Quality Cemented carbide has high hardness, high abrasive resistance, high elasticity modulus, low coefficient of thermal expansion, and stable. This article provides a summary of the underlying principles and size ranges for the american society for testing and materials. Cemented carbides are here divided in four groups based on microstructure and chemistry: Among various materials joining technologies, brazing have been an. Cemented Carbide Quality.

From www.ceratizit.com

CERATIZIT Cemented Carbide Cemented Carbide Quality This article provides a summary of the underlying principles and size ranges for the american society for testing and materials. Cemented carbide has high hardness, high abrasive resistance, high elasticity modulus, low coefficient of thermal expansion, and stable. In order to improve the quality of the workpiece, it is necessary to explore the mechanical properties, chemical properties,. Through grinding experiments,. Cemented Carbide Quality.

From ceramics.org

Video 100 years of cemented carbide The American Ceramic Society Cemented Carbide Quality The quality of sintered cemented carbide is the coercive force (hc). This article provides a summary of the underlying principles and size ranges for the american society for testing and materials. Cemented carbide has high hardness, high abrasive resistance, high elasticity modulus, low coefficient of thermal expansion, and stable. Through grinding experiments, the effects of grinding wheel linear speed, feed. Cemented Carbide Quality.

From www.ceratizit.com

CERATIZIT Cemented Carbide Cemented Carbide Quality Through grinding experiments, the effects of grinding wheel linear speed, feed speed and grinding depth on the surface morphology, roughness, and residual stress of cemented carbides were studied, and the relationship between grinding conditions and machining quality was established. The quality of sintered cemented carbide is the coercive force (hc). This article provides a summary of the underlying principles and. Cemented Carbide Quality.

From www.researchgate.net

SEM image of cemented carbide Download Scientific Diagram Cemented Carbide Quality The quality of sintered cemented carbide is the coercive force (hc). This article provides a summary of the underlying principles and size ranges for the american society for testing and materials. In order to improve the quality of the workpiece, it is necessary to explore the mechanical properties, chemical properties,. Through grinding experiments, the effects of grinding wheel linear speed,. Cemented Carbide Quality.