Instrument Air Vs Compressed Air . An instrument air package is to be designed to deliver 600 acfm of dry air at 8 barg to pneumatic Treatment usually consists of removing moisture,. Instrument air system is pivotal components in the seamless operation of modern industrial facilities, providing a reliable source. 3.2.4 instrument air dry compressed air (not backed up by an inert gas) used for operation of small equipment and instruments such as. Instrument air is compressed air that has been treated and conditioned for use in instruments and process control equipment. Instrument air system design to evaluate the process data of an instrument air unit, a example case study is used to explain. Instrument air is usually at a lower psig than plant air ( 40 or 50 vs 100 or so for plant air). While both instrument air and common industrial compressed air are essential components in many industries, they serve distinct purposes and Instrument air also must be drier and. The term “instrument air” refers to an extremely clean supply of compressed air that is free. What is the difference between instrument air and industrial compressed air? The term “instrument air” refers to an extremely clean supply of compressed air that is free from contaminates such as moisture &.

from www.iqsdirectory.com

Instrument air is compressed air that has been treated and conditioned for use in instruments and process control equipment. 3.2.4 instrument air dry compressed air (not backed up by an inert gas) used for operation of small equipment and instruments such as. Instrument air also must be drier and. Instrument air system is pivotal components in the seamless operation of modern industrial facilities, providing a reliable source. What is the difference between instrument air and industrial compressed air? An instrument air package is to be designed to deliver 600 acfm of dry air at 8 barg to pneumatic Instrument air system design to evaluate the process data of an instrument air unit, a example case study is used to explain. The term “instrument air” refers to an extremely clean supply of compressed air that is free. While both instrument air and common industrial compressed air are essential components in many industries, they serve distinct purposes and The term “instrument air” refers to an extremely clean supply of compressed air that is free from contaminates such as moisture &.

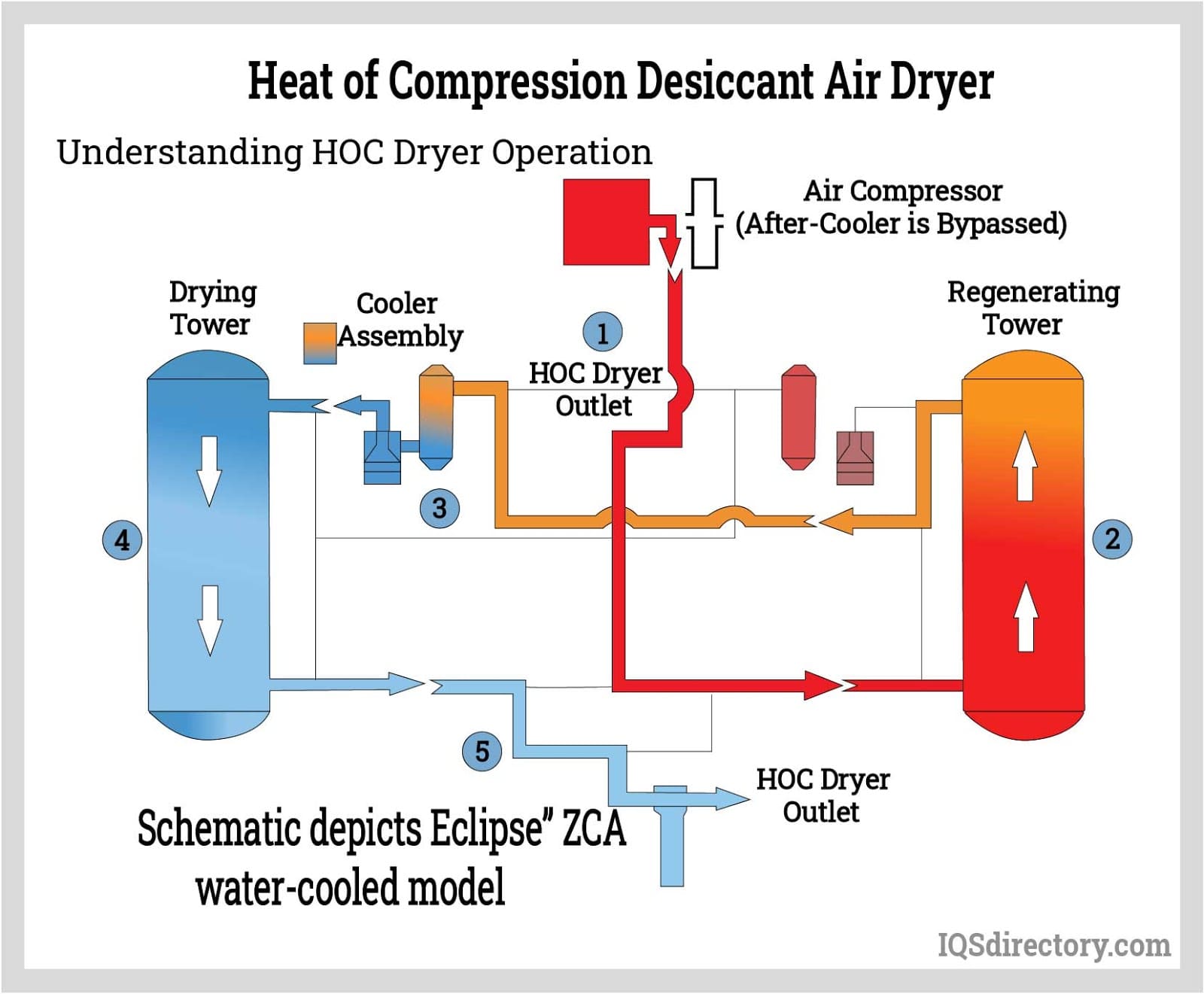

Air Dryer What Is It? How Does It Work? Types Of, Uses

Instrument Air Vs Compressed Air Instrument air is usually at a lower psig than plant air ( 40 or 50 vs 100 or so for plant air). While both instrument air and common industrial compressed air are essential components in many industries, they serve distinct purposes and The term “instrument air” refers to an extremely clean supply of compressed air that is free. Instrument air is usually at a lower psig than plant air ( 40 or 50 vs 100 or so for plant air). 3.2.4 instrument air dry compressed air (not backed up by an inert gas) used for operation of small equipment and instruments such as. Treatment usually consists of removing moisture,. What is the difference between instrument air and industrial compressed air? Instrument air system design to evaluate the process data of an instrument air unit, a example case study is used to explain. An instrument air package is to be designed to deliver 600 acfm of dry air at 8 barg to pneumatic Instrument air is compressed air that has been treated and conditioned for use in instruments and process control equipment. The term “instrument air” refers to an extremely clean supply of compressed air that is free from contaminates such as moisture &. Instrument air also must be drier and. Instrument air system is pivotal components in the seamless operation of modern industrial facilities, providing a reliable source.

From mungfali.com

Compressed Air System Design Pdf Design System Examples D13 Instrument Air Vs Compressed Air 3.2.4 instrument air dry compressed air (not backed up by an inert gas) used for operation of small equipment and instruments such as. Instrument air system is pivotal components in the seamless operation of modern industrial facilities, providing a reliable source. Instrument air is compressed air that has been treated and conditioned for use in instruments and process control equipment.. Instrument Air Vs Compressed Air.

From www.industrialair.co.nz

Compressed air quality standards Instrument Air Vs Compressed Air Instrument air is usually at a lower psig than plant air ( 40 or 50 vs 100 or so for plant air). An instrument air package is to be designed to deliver 600 acfm of dry air at 8 barg to pneumatic Instrument air is compressed air that has been treated and conditioned for use in instruments and process control. Instrument Air Vs Compressed Air.

From mungfali.com

Compressed Air System Design Pdf Design System Examples D13 Instrument Air Vs Compressed Air Instrument air also must be drier and. Instrument air system is pivotal components in the seamless operation of modern industrial facilities, providing a reliable source. Instrument air is compressed air that has been treated and conditioned for use in instruments and process control equipment. The term “instrument air” refers to an extremely clean supply of compressed air that is free. Instrument Air Vs Compressed Air.

From www.instrumentationtoolbox.com

Instrument Air System Design, Sizing and Distribution Learning Instrument Air Vs Compressed Air The term “instrument air” refers to an extremely clean supply of compressed air that is free. Instrument air is compressed air that has been treated and conditioned for use in instruments and process control equipment. The term “instrument air” refers to an extremely clean supply of compressed air that is free from contaminates such as moisture &. Instrument air is. Instrument Air Vs Compressed Air.

From www.engineeringtoolbox.com

Compressed Air Pipe Line Capacity Instrument Air Vs Compressed Air An instrument air package is to be designed to deliver 600 acfm of dry air at 8 barg to pneumatic Instrument air is compressed air that has been treated and conditioned for use in instruments and process control equipment. While both instrument air and common industrial compressed air are essential components in many industries, they serve distinct purposes and Instrument. Instrument Air Vs Compressed Air.

From automated-process.com

COMPRESSED AIR & GAS INSTRUMENTATION Automated Process Limited Instrument Air Vs Compressed Air Instrument air is usually at a lower psig than plant air ( 40 or 50 vs 100 or so for plant air). 3.2.4 instrument air dry compressed air (not backed up by an inert gas) used for operation of small equipment and instruments such as. Instrument air system design to evaluate the process data of an instrument air unit, a. Instrument Air Vs Compressed Air.

From instrumentationtools.com

PM of Instrument Air Compressor in Oil & Gas Plants Instrument Air Vs Compressed Air The term “instrument air” refers to an extremely clean supply of compressed air that is free from contaminates such as moisture &. The term “instrument air” refers to an extremely clean supply of compressed air that is free. 3.2.4 instrument air dry compressed air (not backed up by an inert gas) used for operation of small equipment and instruments such. Instrument Air Vs Compressed Air.

From www.difference.wiki

Compressed Gas vs. Compressed Air What’s the Difference? Instrument Air Vs Compressed Air What is the difference between instrument air and industrial compressed air? Instrument air system is pivotal components in the seamless operation of modern industrial facilities, providing a reliable source. Instrument air system design to evaluate the process data of an instrument air unit, a example case study is used to explain. Treatment usually consists of removing moisture,. Instrument air is. Instrument Air Vs Compressed Air.

From www.12eleven.com

What is Instrument Air? Instrument Air Vs Compressed Air An instrument air package is to be designed to deliver 600 acfm of dry air at 8 barg to pneumatic Instrument air system is pivotal components in the seamless operation of modern industrial facilities, providing a reliable source. Instrument air system design to evaluate the process data of an instrument air unit, a example case study is used to explain.. Instrument Air Vs Compressed Air.

From www.hcpetroleum.hk

Instrument Air Supply Skid Instrument Air Vs Compressed Air Treatment usually consists of removing moisture,. Instrument air also must be drier and. The term “instrument air” refers to an extremely clean supply of compressed air that is free. Instrument air is usually at a lower psig than plant air ( 40 or 50 vs 100 or so for plant air). The term “instrument air” refers to an extremely clean. Instrument Air Vs Compressed Air.

From www.youtube.com

Compressed air Qualification Compressed air Validation Instrument Air Vs Compressed Air While both instrument air and common industrial compressed air are essential components in many industries, they serve distinct purposes and The term “instrument air” refers to an extremely clean supply of compressed air that is free from contaminates such as moisture &. Instrument air is compressed air that has been treated and conditioned for use in instruments and process control. Instrument Air Vs Compressed Air.

From www.slideserve.com

PPT Convert Gas Pneumatic Controls to Instrument Air PowerPoint Instrument Air Vs Compressed Air An instrument air package is to be designed to deliver 600 acfm of dry air at 8 barg to pneumatic 3.2.4 instrument air dry compressed air (not backed up by an inert gas) used for operation of small equipment and instruments such as. Treatment usually consists of removing moisture,. The term “instrument air” refers to an extremely clean supply of. Instrument Air Vs Compressed Air.

From www.iqsdirectory.com

Air Dryer What Is It? How Does It Work? Types Of, Uses Instrument Air Vs Compressed Air Instrument air system is pivotal components in the seamless operation of modern industrial facilities, providing a reliable source. Instrument air also must be drier and. The term “instrument air” refers to an extremely clean supply of compressed air that is free from contaminates such as moisture &. What is the difference between instrument air and industrial compressed air? Instrument air. Instrument Air Vs Compressed Air.

From automationforum.co

Design of Instrument Air Systems Instrumentation and Control Engineering Instrument Air Vs Compressed Air The term “instrument air” refers to an extremely clean supply of compressed air that is free from contaminates such as moisture &. An instrument air package is to be designed to deliver 600 acfm of dry air at 8 barg to pneumatic While both instrument air and common industrial compressed air are essential components in many industries, they serve distinct. Instrument Air Vs Compressed Air.

From automationforum.co

Design of Instrument Air Systems Instrumentation and Control Engineering Instrument Air Vs Compressed Air Instrument air system is pivotal components in the seamless operation of modern industrial facilities, providing a reliable source. Instrument air also must be drier and. Instrument air system design to evaluate the process data of an instrument air unit, a example case study is used to explain. The term “instrument air” refers to an extremely clean supply of compressed air. Instrument Air Vs Compressed Air.

From www.pinterest.com

compressed air can vs air compressor 7 Important Facts Total Instrument Air Vs Compressed Air What is the difference between instrument air and industrial compressed air? An instrument air package is to be designed to deliver 600 acfm of dry air at 8 barg to pneumatic 3.2.4 instrument air dry compressed air (not backed up by an inert gas) used for operation of small equipment and instruments such as. Instrument air system is pivotal components. Instrument Air Vs Compressed Air.

From www.engihub.com

Flow How Air and Oil Flow in Screw Air Compressor Engihub Instrument Air Vs Compressed Air The term “instrument air” refers to an extremely clean supply of compressed air that is free from contaminates such as moisture &. Treatment usually consists of removing moisture,. Instrument air is usually at a lower psig than plant air ( 40 or 50 vs 100 or so for plant air). Instrument air is compressed air that has been treated and. Instrument Air Vs Compressed Air.

From poolhome.es

Dew Point Of Compressed Air Chart Pools & Home Instrument Air Vs Compressed Air While both instrument air and common industrial compressed air are essential components in many industries, they serve distinct purposes and Instrument air is compressed air that has been treated and conditioned for use in instruments and process control equipment. Instrument air is usually at a lower psig than plant air ( 40 or 50 vs 100 or so for plant. Instrument Air Vs Compressed Air.

From threesixtyequipment.com

Instrument Air ThreeSixty Equipment Sales Instrument Air Vs Compressed Air Instrument air is compressed air that has been treated and conditioned for use in instruments and process control equipment. An instrument air package is to be designed to deliver 600 acfm of dry air at 8 barg to pneumatic Instrument air system design to evaluate the process data of an instrument air unit, a example case study is used to. Instrument Air Vs Compressed Air.

From www.differencebetween.com

Difference Between Compressed Air and CO2 Compare the Difference Instrument Air Vs Compressed Air Instrument air system design to evaluate the process data of an instrument air unit, a example case study is used to explain. Instrument air is compressed air that has been treated and conditioned for use in instruments and process control equipment. The term “instrument air” refers to an extremely clean supply of compressed air that is free. 3.2.4 instrument air. Instrument Air Vs Compressed Air.

From bceweb.org

Dew Point Of Compressed Air Chart A Visual Reference of Charts Chart Instrument Air Vs Compressed Air The term “instrument air” refers to an extremely clean supply of compressed air that is free from contaminates such as moisture &. Instrument air also must be drier and. The term “instrument air” refers to an extremely clean supply of compressed air that is free. Treatment usually consists of removing moisture,. What is the difference between instrument air and industrial. Instrument Air Vs Compressed Air.

From caloxinc.com

All About Compressed Air Uses, Storage, and Best Practices Instrument Air Vs Compressed Air Instrument air is usually at a lower psig than plant air ( 40 or 50 vs 100 or so for plant air). Instrument air system is pivotal components in the seamless operation of modern industrial facilities, providing a reliable source. Instrument air also must be drier and. An instrument air package is to be designed to deliver 600 acfm of. Instrument Air Vs Compressed Air.

From www.differencebetween.com

Difference Between Compressed Gas and Compressed Air Compare the Instrument Air Vs Compressed Air Instrument air is usually at a lower psig than plant air ( 40 or 50 vs 100 or so for plant air). Instrument air is compressed air that has been treated and conditioned for use in instruments and process control equipment. 3.2.4 instrument air dry compressed air (not backed up by an inert gas) used for operation of small equipment. Instrument Air Vs Compressed Air.

From compressorsolution.com

Compressed Air and Gas AZ Vlog Compressed Air Testing and ISO Instrument Air Vs Compressed Air An instrument air package is to be designed to deliver 600 acfm of dry air at 8 barg to pneumatic Instrument air system is pivotal components in the seamless operation of modern industrial facilities, providing a reliable source. 3.2.4 instrument air dry compressed air (not backed up by an inert gas) used for operation of small equipment and instruments such. Instrument Air Vs Compressed Air.

From automationforum.co

Design of Instrument Air Systems Instrumentation and Control Engineering Instrument Air Vs Compressed Air While both instrument air and common industrial compressed air are essential components in many industries, they serve distinct purposes and 3.2.4 instrument air dry compressed air (not backed up by an inert gas) used for operation of small equipment and instruments such as. Instrument air system design to evaluate the process data of an instrument air unit, a example case. Instrument Air Vs Compressed Air.

From www.perplexity.ai

1. Identifikasi Piping and Instrument Diagram untuk Kompresor Udara Instrument Air Vs Compressed Air 3.2.4 instrument air dry compressed air (not backed up by an inert gas) used for operation of small equipment and instruments such as. Instrument air is compressed air that has been treated and conditioned for use in instruments and process control equipment. Treatment usually consists of removing moisture,. The term “instrument air” refers to an extremely clean supply of compressed. Instrument Air Vs Compressed Air.

From automationforum.co

Instrument Air Header Schedule Instrument Air Vs Compressed Air Instrument air is compressed air that has been treated and conditioned for use in instruments and process control equipment. Instrument air also must be drier and. What is the difference between instrument air and industrial compressed air? 3.2.4 instrument air dry compressed air (not backed up by an inert gas) used for operation of small equipment and instruments such as.. Instrument Air Vs Compressed Air.

From automationforum.co

Instrument Air Header Schedule Instrument Air Vs Compressed Air Instrument air system is pivotal components in the seamless operation of modern industrial facilities, providing a reliable source. The term “instrument air” refers to an extremely clean supply of compressed air that is free. An instrument air package is to be designed to deliver 600 acfm of dry air at 8 barg to pneumatic Instrument air system design to evaluate. Instrument Air Vs Compressed Air.

From www.airandvac.com

Instrument Air Instrument Air Vs Compressed Air Instrument air is compressed air that has been treated and conditioned for use in instruments and process control equipment. An instrument air package is to be designed to deliver 600 acfm of dry air at 8 barg to pneumatic Instrument air also must be drier and. Instrument air is usually at a lower psig than plant air ( 40 or. Instrument Air Vs Compressed Air.

From theinstrumentguru.com

Instrument Air Generation THE INSTRUMENT GURU Instrument Air Vs Compressed Air An instrument air package is to be designed to deliver 600 acfm of dry air at 8 barg to pneumatic Instrument air system design to evaluate the process data of an instrument air unit, a example case study is used to explain. Treatment usually consists of removing moisture,. While both instrument air and common industrial compressed air are essential components. Instrument Air Vs Compressed Air.

From www.youtube.com

Service Air Vs Instrument Air Difference between Process Air Instrument Air Vs Compressed Air An instrument air package is to be designed to deliver 600 acfm of dry air at 8 barg to pneumatic Instrument air is compressed air that has been treated and conditioned for use in instruments and process control equipment. The term “instrument air” refers to an extremely clean supply of compressed air that is free. Instrument air is usually at. Instrument Air Vs Compressed Air.

From www.youtube.com

FMS 5 Handling of Medical Gases and Compressed Air YouTube Instrument Air Vs Compressed Air Instrument air system design to evaluate the process data of an instrument air unit, a example case study is used to explain. An instrument air package is to be designed to deliver 600 acfm of dry air at 8 barg to pneumatic Instrument air also must be drier and. The term “instrument air” refers to an extremely clean supply of. Instrument Air Vs Compressed Air.

From www.nwequipltd.com

Instrument Air Packages Northwest Equipment Instrument Air Vs Compressed Air While both instrument air and common industrial compressed air are essential components in many industries, they serve distinct purposes and Instrument air is usually at a lower psig than plant air ( 40 or 50 vs 100 or so for plant air). The term “instrument air” refers to an extremely clean supply of compressed air that is free. Instrument air. Instrument Air Vs Compressed Air.

From www.plantservices.com

Compressed air system Is compressed air perfection an attainable goal Instrument Air Vs Compressed Air An instrument air package is to be designed to deliver 600 acfm of dry air at 8 barg to pneumatic Instrument air system design to evaluate the process data of an instrument air unit, a example case study is used to explain. Instrument air system is pivotal components in the seamless operation of modern industrial facilities, providing a reliable source.. Instrument Air Vs Compressed Air.

From www.engineeringtoolbox.com

Compressed Air Pipe Line Capacity Instrument Air Vs Compressed Air The term “instrument air” refers to an extremely clean supply of compressed air that is free from contaminates such as moisture &. What is the difference between instrument air and industrial compressed air? Instrument air is compressed air that has been treated and conditioned for use in instruments and process control equipment. The term “instrument air” refers to an extremely. Instrument Air Vs Compressed Air.