Eye Bolt Inspection Checklist . always inspect eye bolt before use. Never use eye bolt that shows signs of wear or damage. Always choose the right type of eye bolt for the job, install it correctly, and regularly inspect it to avoid accidents and injuries. This meticulous testing regimen ensures the reliability and safety of these systems under various working conditions. It lists 7 areas to inspect, including last inspection. the care, use and inspection of eyebolts is especially necessary when in service eyebolts are transferred from job to job. this document provides a checklist for inspecting eye bolts with criteria for rejection. Use an eye bolt inspection checklist to ensure all aspects are covered. for eye bolts, we strictly follow the bs 7883:2005 standard, recommending testing at least every 12 months. Class a1 categorised anchor points, on the other hand, adhere to bs en795 standards, necessitating testing every 6 months. safety should always be a top priority when using eye bolts in lifting operations. routine inspections are key to maintaining safety. Never use eye bolt if eye or shank is bent or elongated. Proper installation and inspection are essential in ensuring their safety and effectiveness.

from mungfali.com

for eye bolts, we strictly follow the bs 7883:2005 standard, recommending testing at least every 12 months. Always choose the right type of eye bolt for the job, install it correctly, and regularly inspect it to avoid accidents and injuries. always inspect eye bolt before use. routine inspections are key to maintaining safety. Use an eye bolt inspection checklist to ensure all aspects are covered. Never use eye bolt that shows signs of wear or damage. Class a1 categorised anchor points, on the other hand, adhere to bs en795 standards, necessitating testing every 6 months. This meticulous testing regimen ensures the reliability and safety of these systems under various working conditions. this document provides a checklist for inspecting eye bolts with criteria for rejection. Never use eye bolt if eye or shank is bent or elongated.

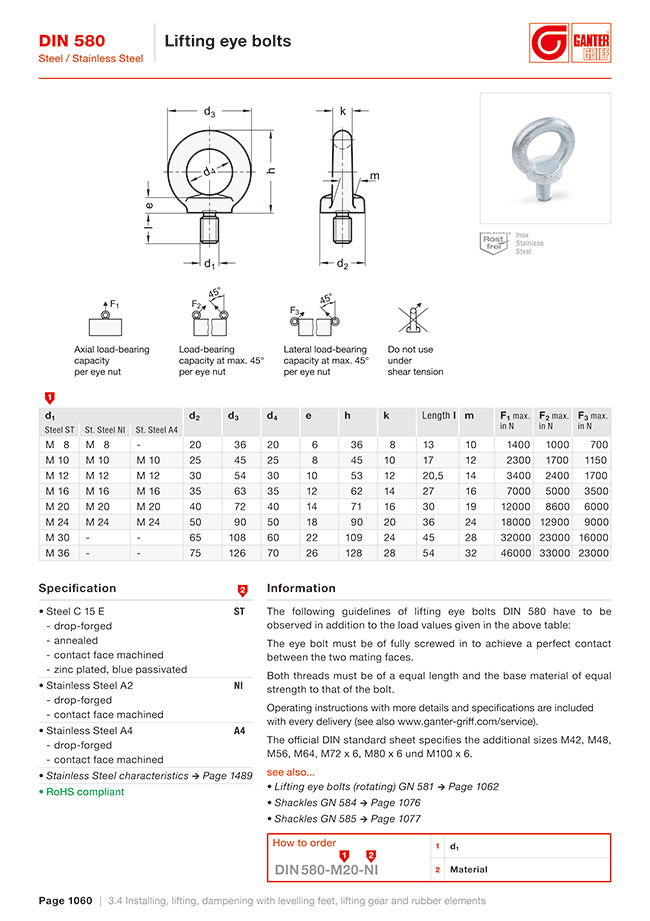

Eye Bolt Load Chart

Eye Bolt Inspection Checklist Always choose the right type of eye bolt for the job, install it correctly, and regularly inspect it to avoid accidents and injuries. safety should always be a top priority when using eye bolts in lifting operations. Always choose the right type of eye bolt for the job, install it correctly, and regularly inspect it to avoid accidents and injuries. Never use eye bolt that shows signs of wear or damage. This meticulous testing regimen ensures the reliability and safety of these systems under various working conditions. Proper installation and inspection are essential in ensuring their safety and effectiveness. for eye bolts, we strictly follow the bs 7883:2005 standard, recommending testing at least every 12 months. Class a1 categorised anchor points, on the other hand, adhere to bs en795 standards, necessitating testing every 6 months. this document provides a checklist for inspecting eye bolts with criteria for rejection. Use an eye bolt inspection checklist to ensure all aspects are covered. always inspect eye bolt before use. routine inspections are key to maintaining safety. the care, use and inspection of eyebolts is especially necessary when in service eyebolts are transferred from job to job. Never use eye bolt if eye or shank is bent or elongated. It lists 7 areas to inspect, including last inspection.

From mungfali.com

Eye Bolt Load Chart Eye Bolt Inspection Checklist It lists 7 areas to inspect, including last inspection. routine inspections are key to maintaining safety. Never use eye bolt that shows signs of wear or damage. Always choose the right type of eye bolt for the job, install it correctly, and regularly inspect it to avoid accidents and injuries. Never use eye bolt if eye or shank is. Eye Bolt Inspection Checklist.

From allaboutlifting.com.au

Eye Bolts All About Lifting & Safety Eye Bolt Inspection Checklist routine inspections are key to maintaining safety. Never use eye bolt if eye or shank is bent or elongated. for eye bolts, we strictly follow the bs 7883:2005 standard, recommending testing at least every 12 months. safety should always be a top priority when using eye bolts in lifting operations. Proper installation and inspection are essential in. Eye Bolt Inspection Checklist.

From mavink.com

Eye Bolt Load Chart Eye Bolt Inspection Checklist for eye bolts, we strictly follow the bs 7883:2005 standard, recommending testing at least every 12 months. routine inspections are key to maintaining safety. Class a1 categorised anchor points, on the other hand, adhere to bs en795 standards, necessitating testing every 6 months. always inspect eye bolt before use. Proper installation and inspection are essential in ensuring. Eye Bolt Inspection Checklist.

From www.scribd.com

Eye Bolt Rating and Specifications Screw Building Engineering Eye Bolt Inspection Checklist This meticulous testing regimen ensures the reliability and safety of these systems under various working conditions. Never use eye bolt if eye or shank is bent or elongated. for eye bolts, we strictly follow the bs 7883:2005 standard, recommending testing at least every 12 months. Never use eye bolt that shows signs of wear or damage. this document. Eye Bolt Inspection Checklist.

From premsafe.com

Eyebolt Testing & Maintenance Premsafe Ltd Eye Bolt Inspection Checklist Never use eye bolt that shows signs of wear or damage. always inspect eye bolt before use. Class a1 categorised anchor points, on the other hand, adhere to bs en795 standards, necessitating testing every 6 months. Proper installation and inspection are essential in ensuring their safety and effectiveness. Use an eye bolt inspection checklist to ensure all aspects are. Eye Bolt Inspection Checklist.

From www.hollycroftsoftware.co.uk

Visual Inspection Report Form Eye Bolt Inspection Checklist for eye bolts, we strictly follow the bs 7883:2005 standard, recommending testing at least every 12 months. this document provides a checklist for inspecting eye bolts with criteria for rejection. Never use eye bolt that shows signs of wear or damage. safety should always be a top priority when using eye bolts in lifting operations. the. Eye Bolt Inspection Checklist.

From slidetodoc.com

Safety Team presents Rigging Inspection Considerations for Industry Eye Bolt Inspection Checklist Proper installation and inspection are essential in ensuring their safety and effectiveness. this document provides a checklist for inspecting eye bolts with criteria for rejection. always inspect eye bolt before use. It lists 7 areas to inspect, including last inspection. Use an eye bolt inspection checklist to ensure all aspects are covered. Always choose the right type of. Eye Bolt Inspection Checklist.

From classschoolnavelworts.z21.web.core.windows.net

Printable Eyewash Station Inspection Checklist Eye Bolt Inspection Checklist the care, use and inspection of eyebolts is especially necessary when in service eyebolts are transferred from job to job. It lists 7 areas to inspect, including last inspection. this document provides a checklist for inspecting eye bolts with criteria for rejection. Class a1 categorised anchor points, on the other hand, adhere to bs en795 standards, necessitating testing. Eye Bolt Inspection Checklist.

From ceekcxgb.blob.core.windows.net

Eye Bolt Rating Chart at Rebecca Sharpe blog Eye Bolt Inspection Checklist Never use eye bolt if eye or shank is bent or elongated. Use an eye bolt inspection checklist to ensure all aspects are covered. safety should always be a top priority when using eye bolts in lifting operations. Always choose the right type of eye bolt for the job, install it correctly, and regularly inspect it to avoid accidents. Eye Bolt Inspection Checklist.

From www.vihasteel.com

Stainless Steel Eye Bolt With Shoulder & Ring SS Eye Bolt Screw Anchor Eye Bolt Inspection Checklist for eye bolts, we strictly follow the bs 7883:2005 standard, recommending testing at least every 12 months. Never use eye bolt if eye or shank is bent or elongated. always inspect eye bolt before use. this document provides a checklist for inspecting eye bolts with criteria for rejection. Proper installation and inspection are essential in ensuring their. Eye Bolt Inspection Checklist.

From www.scribd.com

Eye Bolt Visual Certificates PDF Systems Engineering Safety Eye Bolt Inspection Checklist always inspect eye bolt before use. the care, use and inspection of eyebolts is especially necessary when in service eyebolts are transferred from job to job. It lists 7 areas to inspect, including last inspection. Class a1 categorised anchor points, on the other hand, adhere to bs en795 standards, necessitating testing every 6 months. routine inspections are. Eye Bolt Inspection Checklist.

From ceekcxgb.blob.core.windows.net

Eye Bolt Rating Chart at Rebecca Sharpe blog Eye Bolt Inspection Checklist safety should always be a top priority when using eye bolts in lifting operations. Class a1 categorised anchor points, on the other hand, adhere to bs en795 standards, necessitating testing every 6 months. always inspect eye bolt before use. This meticulous testing regimen ensures the reliability and safety of these systems under various working conditions. Always choose the. Eye Bolt Inspection Checklist.

From www.scribd.com

Eye Bolt Inspection Report Last of Examination PDF Eye Bolt Inspection Checklist Never use eye bolt that shows signs of wear or damage. always inspect eye bolt before use. routine inspections are key to maintaining safety. It lists 7 areas to inspect, including last inspection. Use an eye bolt inspection checklist to ensure all aspects are covered. Class a1 categorised anchor points, on the other hand, adhere to bs en795. Eye Bolt Inspection Checklist.

From www.scribd.com

Visual Inspection Report PDF Eye Bolt Inspection Checklist Always choose the right type of eye bolt for the job, install it correctly, and regularly inspect it to avoid accidents and injuries. Class a1 categorised anchor points, on the other hand, adhere to bs en795 standards, necessitating testing every 6 months. Never use eye bolt that shows signs of wear or damage. Never use eye bolt if eye or. Eye Bolt Inspection Checklist.

From www.ranger.com.au

Ranger Inspection Checklist Eyebolts Eye Bolt Inspection Checklist Proper installation and inspection are essential in ensuring their safety and effectiveness. This meticulous testing regimen ensures the reliability and safety of these systems under various working conditions. Class a1 categorised anchor points, on the other hand, adhere to bs en795 standards, necessitating testing every 6 months. this document provides a checklist for inspecting eye bolts with criteria for. Eye Bolt Inspection Checklist.

From www.pinterest.com

Lifting Eye Bolt Inspection Checklist Infographic Inspection Eye Bolt Inspection Checklist routine inspections are key to maintaining safety. safety should always be a top priority when using eye bolts in lifting operations. Proper installation and inspection are essential in ensuring their safety and effectiveness. this document provides a checklist for inspecting eye bolts with criteria for rejection. Always choose the right type of eye bolt for the job,. Eye Bolt Inspection Checklist.

From www.pinterest.co.uk

best sling inspection form template example Published by Michael Nardi Eye Bolt Inspection Checklist this document provides a checklist for inspecting eye bolts with criteria for rejection. safety should always be a top priority when using eye bolts in lifting operations. for eye bolts, we strictly follow the bs 7883:2005 standard, recommending testing at least every 12 months. the care, use and inspection of eyebolts is especially necessary when in. Eye Bolt Inspection Checklist.

From www.absoluteliftingandsafety.com.au

Care, Use & Inspection of Eyebolts Absolute Lifting and Safety Eye Bolt Inspection Checklist This meticulous testing regimen ensures the reliability and safety of these systems under various working conditions. Never use eye bolt that shows signs of wear or damage. Never use eye bolt if eye or shank is bent or elongated. this document provides a checklist for inspecting eye bolts with criteria for rejection. Use an eye bolt inspection checklist to. Eye Bolt Inspection Checklist.

From www.chainandrigging.co.nz

Eye Bolt DIN580 Metric Rated Chain & Rigging Supplies Eye Bolt Inspection Checklist Class a1 categorised anchor points, on the other hand, adhere to bs en795 standards, necessitating testing every 6 months. Never use eye bolt that shows signs of wear or damage. for eye bolts, we strictly follow the bs 7883:2005 standard, recommending testing at least every 12 months. always inspect eye bolt before use. safety should always be. Eye Bolt Inspection Checklist.

From www.spectrumspecialistsupport.co.uk

Eye Bolt Installation and Testing Spectrum Eye Bolt Inspection Checklist always inspect eye bolt before use. Class a1 categorised anchor points, on the other hand, adhere to bs en795 standards, necessitating testing every 6 months. Proper installation and inspection are essential in ensuring their safety and effectiveness. Always choose the right type of eye bolt for the job, install it correctly, and regularly inspect it to avoid accidents and. Eye Bolt Inspection Checklist.

From www.dlhonline.co.uk

A guide for lifting eye bolts and lifting points types and safe use Eye Bolt Inspection Checklist always inspect eye bolt before use. this document provides a checklist for inspecting eye bolts with criteria for rejection. safety should always be a top priority when using eye bolts in lifting operations. Always choose the right type of eye bolt for the job, install it correctly, and regularly inspect it to avoid accidents and injuries. This. Eye Bolt Inspection Checklist.

From mungfali.com

Eye Bolt Capacity Chart Eye Bolt Inspection Checklist Proper installation and inspection are essential in ensuring their safety and effectiveness. the care, use and inspection of eyebolts is especially necessary when in service eyebolts are transferred from job to job. This meticulous testing regimen ensures the reliability and safety of these systems under various working conditions. Never use eye bolt if eye or shank is bent or. Eye Bolt Inspection Checklist.

From hsseworld.com

Lifting Accessories Marking and Identification guide HSSE WORLD Eye Bolt Inspection Checklist routine inspections are key to maintaining safety. This meticulous testing regimen ensures the reliability and safety of these systems under various working conditions. Proper installation and inspection are essential in ensuring their safety and effectiveness. Use an eye bolt inspection checklist to ensure all aspects are covered. Class a1 categorised anchor points, on the other hand, adhere to bs. Eye Bolt Inspection Checklist.

From blog.thepipingmart.com

Proper Installation and Inspection of Eye Bolts Eye Bolt Inspection Checklist This meticulous testing regimen ensures the reliability and safety of these systems under various working conditions. Use an eye bolt inspection checklist to ensure all aspects are covered. safety should always be a top priority when using eye bolts in lifting operations. Class a1 categorised anchor points, on the other hand, adhere to bs en795 standards, necessitating testing every. Eye Bolt Inspection Checklist.

From www.scribd.com

Shackle Inspection Check List PDF Eye Bolt Inspection Checklist Class a1 categorised anchor points, on the other hand, adhere to bs en795 standards, necessitating testing every 6 months. always inspect eye bolt before use. the care, use and inspection of eyebolts is especially necessary when in service eyebolts are transferred from job to job. Never use eye bolt that shows signs of wear or damage. This meticulous. Eye Bolt Inspection Checklist.

From www.indiamart.com

Eye Bolt Inspection Certification Service in Vadodara ID 2852638927748 Eye Bolt Inspection Checklist the care, use and inspection of eyebolts is especially necessary when in service eyebolts are transferred from job to job. routine inspections are key to maintaining safety. Never use eye bolt if eye or shank is bent or elongated. Always choose the right type of eye bolt for the job, install it correctly, and regularly inspect it to. Eye Bolt Inspection Checklist.

From www.newheightlifting.com

Eye Bolts and Eye Nuts Eye Bolt Inspection Checklist safety should always be a top priority when using eye bolts in lifting operations. for eye bolts, we strictly follow the bs 7883:2005 standard, recommending testing at least every 12 months. Always choose the right type of eye bolt for the job, install it correctly, and regularly inspect it to avoid accidents and injuries. Class a1 categorised anchor. Eye Bolt Inspection Checklist.

From www.materiellportalen.no

Poster A3 Check list before use EYE BOLTS Materiellportalen Eye Bolt Inspection Checklist the care, use and inspection of eyebolts is especially necessary when in service eyebolts are transferred from job to job. this document provides a checklist for inspecting eye bolts with criteria for rejection. for eye bolts, we strictly follow the bs 7883:2005 standard, recommending testing at least every 12 months. Proper installation and inspection are essential in. Eye Bolt Inspection Checklist.

From www.clevelandcityforge.com

Eye Bolts and Eye Bolt Sizes from Cleveland City Eye Bolt Inspection Checklist Use an eye bolt inspection checklist to ensure all aspects are covered. This meticulous testing regimen ensures the reliability and safety of these systems under various working conditions. safety should always be a top priority when using eye bolts in lifting operations. Class a1 categorised anchor points, on the other hand, adhere to bs en795 standards, necessitating testing every. Eye Bolt Inspection Checklist.

From www.youtube.com

Eye Bolts How should you use eye bolts safely? YouTube Eye Bolt Inspection Checklist Class a1 categorised anchor points, on the other hand, adhere to bs en795 standards, necessitating testing every 6 months. for eye bolts, we strictly follow the bs 7883:2005 standard, recommending testing at least every 12 months. routine inspections are key to maintaining safety. Never use eye bolt that shows signs of wear or damage. Always choose the right. Eye Bolt Inspection Checklist.

From www.pinterest.fr

Tips for Rigging with Eye Bolts RiggingSafety EyeBolts VMECranes Eye Bolt Inspection Checklist Class a1 categorised anchor points, on the other hand, adhere to bs en795 standards, necessitating testing every 6 months. Never use eye bolt if eye or shank is bent or elongated. always inspect eye bolt before use. This meticulous testing regimen ensures the reliability and safety of these systems under various working conditions. Never use eye bolt that shows. Eye Bolt Inspection Checklist.

From www.wiscolift.com

Eye Bolts Shoulder Type Lifting Shackles Eye Bolts Rigging Bolts Eye Bolt Inspection Checklist Proper installation and inspection are essential in ensuring their safety and effectiveness. It lists 7 areas to inspect, including last inspection. always inspect eye bolt before use. This meticulous testing regimen ensures the reliability and safety of these systems under various working conditions. Always choose the right type of eye bolt for the job, install it correctly, and regularly. Eye Bolt Inspection Checklist.

From slidetodoc.com

Safety Team presents Rigging Inspection Considerations for Industry Eye Bolt Inspection Checklist always inspect eye bolt before use. Use an eye bolt inspection checklist to ensure all aspects are covered. the care, use and inspection of eyebolts is especially necessary when in service eyebolts are transferred from job to job. Class a1 categorised anchor points, on the other hand, adhere to bs en795 standards, necessitating testing every 6 months. . Eye Bolt Inspection Checklist.

From s597646216.initial-website.co.uk

Eye Bolt Testing & Install Eye Bolt Installation Swiss Cottage Eye Bolt Inspection Checklist routine inspections are key to maintaining safety. always inspect eye bolt before use. safety should always be a top priority when using eye bolts in lifting operations. the care, use and inspection of eyebolts is especially necessary when in service eyebolts are transferred from job to job. Use an eye bolt inspection checklist to ensure all. Eye Bolt Inspection Checklist.

From unitedstainless.com

How to Select and Install Eye Bolts Eye Bolt Inspection Checklist routine inspections are key to maintaining safety. Use an eye bolt inspection checklist to ensure all aspects are covered. safety should always be a top priority when using eye bolts in lifting operations. for eye bolts, we strictly follow the bs 7883:2005 standard, recommending testing at least every 12 months. Never use eye bolt that shows signs. Eye Bolt Inspection Checklist.