Bevel Gear Geometry . Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear— whether using face milling. For many decades, information on bevel, and especially hypoid, gear geometry has been developed and published by the gear machine manufacturers. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Bevel gear geometry page 2 of 4 tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. It is clear that the specific formulae. Many types of bevel and hypoid gears can be observed and manipulated with this model — without alteration of the notation.

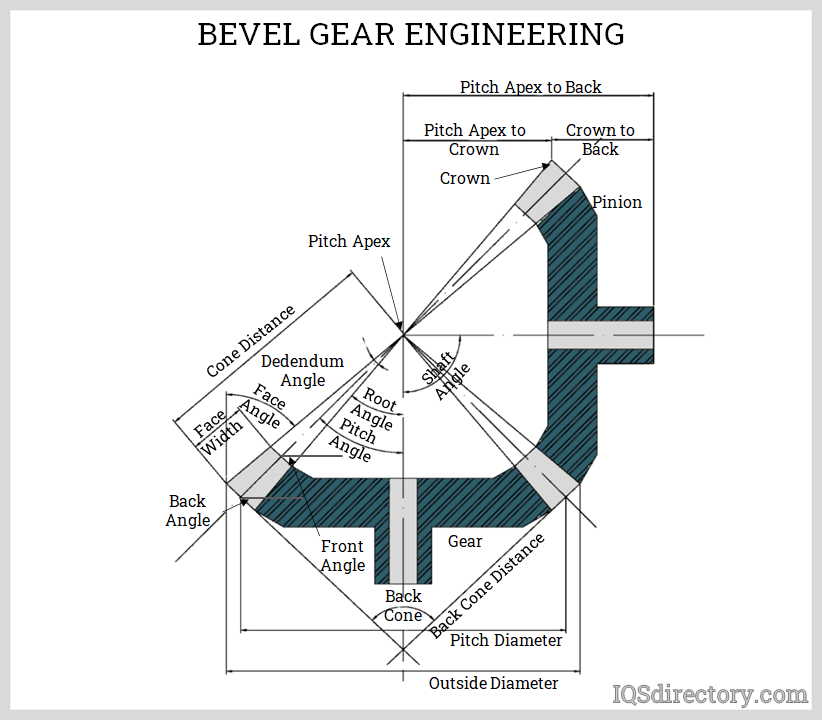

from www.iqsdirectory.com

Bevel gear geometry page 2 of 4 tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. Many types of bevel and hypoid gears can be observed and manipulated with this model — without alteration of the notation. Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear— whether using face milling. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. For many decades, information on bevel, and especially hypoid, gear geometry has been developed and published by the gear machine manufacturers. It is clear that the specific formulae.

Bevel Gear What Is It? How Does It Work? Types, Uses

Bevel Gear Geometry Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear— whether using face milling. Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear— whether using face milling. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Bevel gear geometry page 2 of 4 tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. It is clear that the specific formulae. For many decades, information on bevel, and especially hypoid, gear geometry has been developed and published by the gear machine manufacturers. Many types of bevel and hypoid gears can be observed and manipulated with this model — without alteration of the notation.

From grabcad.com

can create gear. help Straight Bevel Gear GrabCAD Questions Bevel Gear Geometry Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear— whether using face milling. For many decades, information on bevel, and especially hypoid, gear geometry has been developed and published by the gear machine manufacturers. Many types of bevel and hypoid gears can be observed and manipulated with this model —. Bevel Gear Geometry.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear Geometry Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. For many decades, information on bevel, and especially hypoid, gear geometry has been developed and published by the gear machine manufacturers. Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear—. Bevel Gear Geometry.

From present5.com

BEVEL GEARSBEVEL GEARSGEOMETRY OF BEVEL GEARSGEOMETRY OF BEVEL Bevel Gear Geometry For many decades, information on bevel, and especially hypoid, gear geometry has been developed and published by the gear machine manufacturers. It is clear that the specific formulae. Many types of bevel and hypoid gears can be observed and manipulated with this model — without alteration of the notation. Bevel gear geometry page 2 of 4 tooth shape for bevel. Bevel Gear Geometry.

From www.slideserve.com

PPT Chapter 15 Helical, Bevel, and Worm Gears PowerPoint Bevel Gear Geometry It is clear that the specific formulae. Many types of bevel and hypoid gears can be observed and manipulated with this model — without alteration of the notation. For many decades, information on bevel, and especially hypoid, gear geometry has been developed and published by the gear machine manufacturers. Bevel gear geometry page 2 of 4 tooth shape for bevel. Bevel Gear Geometry.

From www.zhygear.com

Cutting modeling of spiral bevel gear blank ZHY Gear Bevel Gear Geometry It is clear that the specific formulae. Many types of bevel and hypoid gears can be observed and manipulated with this model — without alteration of the notation. Bevel gear geometry page 2 of 4 tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. For many decades, information on bevel, and especially. Bevel Gear Geometry.

From www.zhygear.com

Tooth surface modeling of hypoid gear and spiral bevel gear ZHY Gear Bevel Gear Geometry For many decades, information on bevel, and especially hypoid, gear geometry has been developed and published by the gear machine manufacturers. It is clear that the specific formulae. Bevel gear geometry page 2 of 4 tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. Geometry of a spiral bevel gear is mathematically. Bevel Gear Geometry.

From pdfslide.net

(PDF) Bevel Gear Geometry dspace.mit.edu · Bevel Gear Geometry Page 2 Bevel Gear Geometry Bevel gear geometry page 2 of 4 tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. It is clear that the specific formulae. Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear— whether using face milling. Gear dimensions are determined in accordance. Bevel Gear Geometry.

From creativeidee.github.io

54 Nice Bevel gear design formula for Creative Ideas Sample Design Bevel Gear Geometry Bevel gear geometry page 2 of 4 tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a. Bevel Gear Geometry.

From www.tbksoft.com

TBK Spiral bevel gears Bevel Gear Geometry Many types of bevel and hypoid gears can be observed and manipulated with this model — without alteration of the notation. It is clear that the specific formulae. For many decades, information on bevel, and especially hypoid, gear geometry has been developed and published by the gear machine manufacturers. Gear dimensions are determined in accordance with their specifications, such as. Bevel Gear Geometry.

From www.dsoftcon.be

Bevel Gears Geometry Bevel Gear Geometry Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. For many decades, information on bevel, and especially hypoid, gear geometry has been developed and published by the gear machine manufacturers. It is clear that the specific formulae. Geometry of a spiral bevel gear is mathematically complicated, the machine settings. Bevel Gear Geometry.

From www.zhygear.com

Innovation on strength and timevarying meshing characteristics of Bevel Gear Geometry Many types of bevel and hypoid gears can be observed and manipulated with this model — without alteration of the notation. It is clear that the specific formulae. Bevel gear geometry page 2 of 4 tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. Geometry of a spiral bevel gear is mathematically. Bevel Gear Geometry.

From www.semanticscholar.org

Figure 7 from Design and Analysis of a Spiral Bevel Gear Semantic Scholar Bevel Gear Geometry Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. It is clear that the specific formulae. Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear— whether using face milling. For many decades, information on bevel, and especially hypoid, gear. Bevel Gear Geometry.

From www.zhygear.com

Rotary forming of straight bevel gear ZHY Gear Bevel Gear Geometry Bevel gear geometry page 2 of 4 tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. It is clear that the specific formulae. Many types of bevel and hypoid gears can be observed and manipulated with this model — without alteration of the notation. Gear dimensions are determined in accordance with their. Bevel Gear Geometry.

From skill-lync.com

Week 2 Bevel Gear Challenge SkillLync Bevel Gear Geometry Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. For many decades, information on bevel, and especially hypoid, gear geometry has been developed and published by the gear machine manufacturers. Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear—. Bevel Gear Geometry.

From present5.com

BEVEL GEARSBEVEL GEARSGEOMETRY OF BEVEL GEARSGEOMETRY OF BEVEL Bevel Gear Geometry Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear— whether using face milling. It is clear that the specific formulae. For many decades, information on bevel, and especially hypoid, gear geometry has been developed and published by the gear machine manufacturers. Many types of bevel and hypoid gears can be. Bevel Gear Geometry.

From www.mitcalc.com

MITcalc Bevel and hypoid gears according ISO 23509 Bevel Gear Geometry Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear— whether using face milling. It is clear that the specific formulae. Many types of bevel and hypoid gears can be observed and manipulated with this model — without alteration of the notation. For many decades, information on bevel, and especially hypoid,. Bevel Gear Geometry.

From en.wikipedia.org

Spiral bevel gear Wikipedia Bevel Gear Geometry It is clear that the specific formulae. Bevel gear geometry page 2 of 4 tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. For many decades, information on bevel, and especially hypoid, gear geometry has been developed and published by the gear machine manufacturers. Many types of bevel and hypoid gears can. Bevel Gear Geometry.

From selmec.org.uk

The Theory of Meccano Gears Part 3 — Bevel Gears — South East London Bevel Gear Geometry Many types of bevel and hypoid gears can be observed and manipulated with this model — without alteration of the notation. Bevel gear geometry page 2 of 4 tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. For many decades, information on bevel, and especially hypoid, gear geometry has been developed and. Bevel Gear Geometry.

From mavink.com

Bevel Gear Calculation Bevel Gear Geometry Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear— whether using face milling. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. For many decades, information on bevel, and especially hypoid, gear geometry has been developed and published by. Bevel Gear Geometry.

From www.scribd.com

Bevel Gear Geometry PDF Bevel Gear Geometry Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear— whether using face milling. Bevel gear geometry page 2 of 4 tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. Many types of bevel and hypoid gears can be observed and manipulated with. Bevel Gear Geometry.

From camnetics.com

Bevel Gears Bevel Gear Geometry Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear— whether using face milling. For many decades, information on bevel, and especially hypoid, gear geometry has been developed and published by. Bevel Gear Geometry.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear Geometry Many types of bevel and hypoid gears can be observed and manipulated with this model — without alteration of the notation. Bevel gear geometry page 2 of 4 tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. For many decades, information on bevel, and especially hypoid, gear geometry has been developed and. Bevel Gear Geometry.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear Geometry Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear— whether using face milling. It is clear that the specific formulae. Many types of bevel and hypoid gears can be observed and manipulated with this model — without alteration of the notation. For many decades, information on bevel, and especially hypoid,. Bevel Gear Geometry.

From khkgears.net

Basic Gear Terminology and Calculation KHK Gears Bevel Gear Geometry It is clear that the specific formulae. Many types of bevel and hypoid gears can be observed and manipulated with this model — without alteration of the notation. For many decades, information on bevel, and especially hypoid, gear geometry has been developed and published by the gear machine manufacturers. Bevel gear geometry page 2 of 4 tooth shape for bevel. Bevel Gear Geometry.

From www.slideserve.com

PPT Gears PowerPoint Presentation, free download ID6198008 Bevel Gear Geometry It is clear that the specific formulae. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. For many decades, information on bevel, and especially hypoid, gear geometry has been developed and published by the gear machine manufacturers. Many types of bevel and hypoid gears can be observed and manipulated. Bevel Gear Geometry.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear Geometry Bevel gear geometry page 2 of 4 tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear— whether using face milling. Many types of bevel and hypoid gears can be observed and manipulated with. Bevel Gear Geometry.

From www.slideserve.com

PPT Chapter 15 Helical, Bevel, and Worm Gears PowerPoint Bevel Gear Geometry Bevel gear geometry page 2 of 4 tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. Many types of bevel and hypoid gears can be observed and manipulated with this model — without alteration of the notation. It is clear that the specific formulae. Gear dimensions are determined in accordance with their. Bevel Gear Geometry.

From www.pinterest.es

Gear tooth geometry. Mechanical engineering, Wooden gears, Machine parts Bevel Gear Geometry Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. It is clear that the specific formulae. Many types of bevel and hypoid gears can be observed and manipulated with this model — without alteration of the notation. Geometry of a spiral bevel gear is mathematically complicated, the machine settings. Bevel Gear Geometry.

From link.springer.com

Fundamentals of Bevel Gears SpringerLink Bevel Gear Geometry It is clear that the specific formulae. For many decades, information on bevel, and especially hypoid, gear geometry has been developed and published by the gear machine manufacturers. Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear— whether using face milling. Many types of bevel and hypoid gears can be. Bevel Gear Geometry.

From www.zhygear.com

Classification of spiral bevel gears ZHY Gear Bevel Gear Geometry Many types of bevel and hypoid gears can be observed and manipulated with this model — without alteration of the notation. It is clear that the specific formulae. Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear— whether using face milling. For many decades, information on bevel, and especially hypoid,. Bevel Gear Geometry.

From www.mdpi.com

Metals Free FullText FiveAxis Milling of Large Spiral Bevel Gears Bevel Gear Geometry Bevel gear geometry page 2 of 4 tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. It is clear that the specific formulae. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Many types of bevel and hypoid gears can be. Bevel Gear Geometry.

From www.slideserve.com

PPT Bevel Gear Exercise PowerPoint Presentation, free download ID Bevel Gear Geometry Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear— whether using face milling. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. It is clear that the specific formulae. Many types of bevel and hypoid gears can be observed. Bevel Gear Geometry.

From present5.com

BEVEL GEARSBEVEL GEARSGEOMETRY OF BEVEL GEARSGEOMETRY OF BEVEL Bevel Gear Geometry It is clear that the specific formulae. Bevel gear geometry page 2 of 4 tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Geometry of a spiral bevel gear is mathematically complicated,. Bevel Gear Geometry.

From www.zhygear.com

Dynamic model of straight bevel gear ZHY Gear Bevel Gear Geometry Many types of bevel and hypoid gears can be observed and manipulated with this model — without alteration of the notation. It is clear that the specific formulae. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Bevel gear geometry page 2 of 4 tooth shape for bevel gears. Bevel Gear Geometry.

From www.researchgate.net

Concept of spiral bevel gear hobbing. Download Scientific Diagram Bevel Gear Geometry It is clear that the specific formulae. Geometry of a spiral bevel gear is mathematically complicated, the machine settings used to create a spiral bevel gear— whether using face milling. Bevel gear geometry page 2 of 4 tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. For many decades, information on bevel,. Bevel Gear Geometry.