Copper Electroplating Current . The concept of copper electroplating is straightforward: Electroplating of copper is one of the most commonly used plating processes for both functional and decorative applications 1, 2. This is done by dipping two terminals called electrodes into the electrolyte. In most production processes, electroplating (ecp) is the primary method of copper metallization. Electroplating involves passing an electric current through a solution called an electrolyte. Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. Submerge the wafer to be plated into an electrolyte bath,.

from www.comsol.com

Submerge the wafer to be plated into an electrolyte bath,. In most production processes, electroplating (ecp) is the primary method of copper metallization. This is done by dipping two terminals called electrodes into the electrolyte. Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. Electroplating involves passing an electric current through a solution called an electrolyte. The concept of copper electroplating is straightforward: Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. Electroplating of copper is one of the most commonly used plating processes for both functional and decorative applications 1, 2.

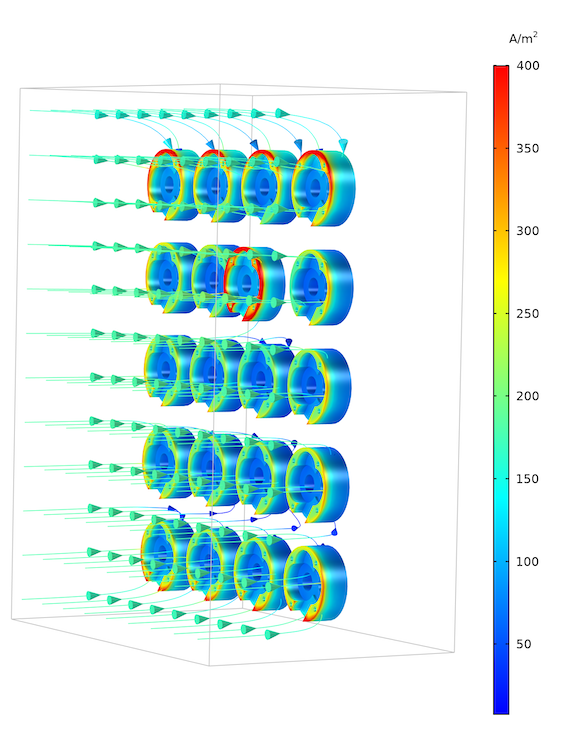

Optimizing the Electroplating Process for Multiple Components COMSOL Blog

Copper Electroplating Current Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. This is done by dipping two terminals called electrodes into the electrolyte. The concept of copper electroplating is straightforward: In most production processes, electroplating (ecp) is the primary method of copper metallization. Submerge the wafer to be plated into an electrolyte bath,. Electroplating involves passing an electric current through a solution called an electrolyte. Electroplating of copper is one of the most commonly used plating processes for both functional and decorative applications 1, 2. Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the.

From www.indiamart.com

Copper Electroplating Service, Copper Electroplating Krishna Metal Copper Electroplating Current Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. Submerge the wafer to be plated into an electrolyte bath,. This is done by dipping two terminals called electrodes into the electrolyte. Electroplating of copper is one of the most commonly used plating processes for both functional and decorative applications 1,. Copper Electroplating Current.

From ar.inspiredpencil.com

Electroplating Copper Copper Electroplating Current Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. In most production processes, electroplating (ecp) is the primary method of copper metallization. The concept of copper electroplating is straightforward: Electroplating of copper is one. Copper Electroplating Current.

From okdor.com

What is copper electroplating? okdor Copper Electroplating Current This is done by dipping two terminals called electrodes into the electrolyte. Electroplating of copper is one of the most commonly used plating processes for both functional and decorative applications 1, 2. Electroplating involves passing an electric current through a solution called an electrolyte. Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric. Copper Electroplating Current.

From www.researchgate.net

Schematic representation of copper electroplating setup. Download Copper Electroplating Current The concept of copper electroplating is straightforward: Electroplating involves passing an electric current through a solution called an electrolyte. Electroplating of copper is one of the most commonly used plating processes for both functional and decorative applications 1, 2. Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. Submerge the. Copper Electroplating Current.

From favpng.com

Electroplating Copper Plating Metal, PNG, 550x700px, Electroplating Copper Electroplating Current Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. This is done by dipping two terminals called electrodes into the electrolyte. The concept of copper electroplating is straightforward: Electroplating involves passing an electric current. Copper Electroplating Current.

From www.chemistrylearner.com

Electroplating Definition, Process, Example, and Equation Copper Electroplating Current The concept of copper electroplating is straightforward: In most production processes, electroplating (ecp) is the primary method of copper metallization. Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. This is done by dipping two terminals called electrodes into the electrolyte. Electroplating involves passing an electric current through a solution called an electrolyte.. Copper Electroplating Current.

From www.teamrapidtooling.com

How Copper Electroplating Works And Applications Copper Electroplating Current The concept of copper electroplating is straightforward: Submerge the wafer to be plated into an electrolyte bath,. Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. Electroplating involves passing an electric current through a solution called an electrolyte. This is done by dipping two terminals called electrodes into the electrolyte.. Copper Electroplating Current.

From hxefjxbtg.blob.core.windows.net

Copper Electroplating Current Density at Scott Hager blog Copper Electroplating Current Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. In most production processes, electroplating (ecp) is the primary method of copper metallization. Electroplating involves passing an electric current through a solution called an electrolyte. Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties.. Copper Electroplating Current.

From www.indiamart.com

Copper Electroplating Filter at Rs 26000 Vasai ID 22459340930 Copper Electroplating Current Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. In most production processes, electroplating (ecp) is the primary method of copper metallization. Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. This is done by dipping two terminals called electrodes into the electrolyte.. Copper Electroplating Current.

From studylib.net

11 Electroplating.doc Copper Electroplating Current Electroplating of copper is one of the most commonly used plating processes for both functional and decorative applications 1, 2. This is done by dipping two terminals called electrodes into the electrolyte. The concept of copper electroplating is straightforward: Submerge the wafer to be plated into an electrolyte bath,. Once prepared, copper is deposited onto the zinc through a standard. Copper Electroplating Current.

From www.curriculumvisions.com

What is electroplating? Electroplating is the coating of metal applied Copper Electroplating Current Electroplating of copper is one of the most commonly used plating processes for both functional and decorative applications 1, 2. Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. In most production processes, electroplating (ecp) is the primary method of copper metallization. Once prepared, copper is deposited onto the zinc through a standard. Copper Electroplating Current.

From www.youtube.com

Electroplating & The Purification Of Copper (GCSE Chemistry) YouTube Copper Electroplating Current In most production processes, electroplating (ecp) is the primary method of copper metallization. Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. This is done by dipping two terminals called electrodes into the electrolyte.. Copper Electroplating Current.

From www.chemedx.org

Electroplating Copper Chemical Education Xchange Copper Electroplating Current Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. Electroplating involves passing an electric current through a solution called an electrolyte. Electroplating of copper is one of the most commonly used plating processes for both functional and decorative applications 1, 2. The concept of copper electroplating is straightforward: Once prepared, copper is deposited. Copper Electroplating Current.

From mantavya.com

What Is Electroplating & How does it work 2021 Guide Mantavya Copper Electroplating Current Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. This is done by dipping two terminals called electrodes into the electrolyte. In most production processes, electroplating (ecp) is the primary method of copper metallization.. Copper Electroplating Current.

From www.indiamart.com

Copper Electroplating Service, Copper Electroplating Akshar Proses Copper Electroplating Current Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. This is done by dipping two terminals called electrodes into the electrolyte. Submerge the wafer to be plated into an electrolyte bath,. Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. The concept of. Copper Electroplating Current.

From chemresearchco.com

What Is Copper Electroplating? Copper Electroplating Current The concept of copper electroplating is straightforward: Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. Electroplating of copper is one of the most commonly used plating processes for both functional and decorative applications 1, 2. Copper is an outstanding replacement for aluminium in numerous electronic applications due to its. Copper Electroplating Current.

From www.researchgate.net

Simulations of galvanostatic copper electrodeposition in throughhole Copper Electroplating Current Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. Submerge the wafer to be plated into an electrolyte bath,. Electroplating of copper is one of the most commonly used plating processes for both functional. Copper Electroplating Current.

From www.comsol.com

Optimizing the Electroplating Process for Multiple Components COMSOL Blog Copper Electroplating Current Electroplating involves passing an electric current through a solution called an electrolyte. This is done by dipping two terminals called electrodes into the electrolyte. Electroplating of copper is one of the most commonly used plating processes for both functional and decorative applications 1, 2. Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric. Copper Electroplating Current.

From www.thoughtco.com

What Is Electroplating and How Does It Work? Copper Electroplating Current The concept of copper electroplating is straightforward: Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. This is done by dipping two terminals called electrodes into the electrolyte. Electroplating involves passing an electric current through a solution called an electrolyte. In most production processes, electroplating (ecp) is the primary method. Copper Electroplating Current.

From www.researchgate.net

The effect of current density on the cathodic current efficiency (CCE Copper Electroplating Current Electroplating of copper is one of the most commonly used plating processes for both functional and decorative applications 1, 2. Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. Submerge the wafer to be plated into an electrolyte bath,. Electroplating involves passing an electric current through a solution called an electrolyte. In most. Copper Electroplating Current.

From www.chegg.com

Solved Electroplating In this experiment, you will conduct, Copper Electroplating Current The concept of copper electroplating is straightforward: This is done by dipping two terminals called electrodes into the electrolyte. Electroplating involves passing an electric current through a solution called an electrolyte. Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. Electroplating of copper is one of the most commonly used. Copper Electroplating Current.

From www.indiamart.com

Copper Electroplating Services, Rs 70/kg Triplex Electro Chem ID Copper Electroplating Current Electroplating of copper is one of the most commonly used plating processes for both functional and decorative applications 1, 2. Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. In most production processes, electroplating (ecp) is the primary method of copper metallization. Electroplating involves passing an electric current through a solution called an. Copper Electroplating Current.

From www.flickr.com

Copper Dendrites This dendritic structure of pure copper w… Flickr Copper Electroplating Current In most production processes, electroplating (ecp) is the primary method of copper metallization. Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. This is done by dipping two terminals called electrodes into the electrolyte. The concept of copper electroplating is straightforward: Electroplating of copper is one of the most commonly. Copper Electroplating Current.

From www.youtube.com

Electroplating CopperPlate a Key YouTube Copper Electroplating Current The concept of copper electroplating is straightforward: In most production processes, electroplating (ecp) is the primary method of copper metallization. Electroplating of copper is one of the most commonly used plating processes for both functional and decorative applications 1, 2. Electroplating involves passing an electric current through a solution called an electrolyte. Once prepared, copper is deposited onto the zinc. Copper Electroplating Current.

From www.ourpcb.com

PCB Edge Plating Metalizing Circuit Board Edges via Electroless Copper Copper Electroplating Current This is done by dipping two terminals called electrodes into the electrolyte. Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. In most production processes, electroplating (ecp) is the primary method of copper metallization. Electroplating involves passing an electric current through a solution called an electrolyte. Submerge the wafer to. Copper Electroplating Current.

From www.pinterest.com

Electroplating of Copper Demonstration Setup Ap Chemistry Exam Copper Electroplating Current Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. This is done by dipping two terminals called electrodes into the electrolyte. Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. The concept of copper electroplating is straightforward: Submerge the wafer to be plated. Copper Electroplating Current.

From dir.indiamart.com

Copper Electroplating in India Copper Electroplating Current Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. In most production processes, electroplating (ecp) is the primary method of copper metallization. This is done by dipping two terminals called electrodes into the electrolyte. Submerge the wafer to be plated into an electrolyte bath,. Electroplating of copper is one of the most commonly. Copper Electroplating Current.

From www.mdpi.com

Coatings Free FullText Controlled Electroplating of Noble Metals Copper Electroplating Current Submerge the wafer to be plated into an electrolyte bath,. Electroplating of copper is one of the most commonly used plating processes for both functional and decorative applications 1, 2. The concept of copper electroplating is straightforward: Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. This is done by dipping two terminals. Copper Electroplating Current.

From chemresearchco.com

Advantages of the Copper Electroplating Process Copper Electroplating Current Electroplating involves passing an electric current through a solution called an electrolyte. The concept of copper electroplating is straightforward: This is done by dipping two terminals called electrodes into the electrolyte. Submerge the wafer to be plated into an electrolyte bath,. Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. In most production. Copper Electroplating Current.

From www.youtube.com

Copper Electroplating On Another Level Paint Metals With Copper Electroplating Current This is done by dipping two terminals called electrodes into the electrolyte. Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. Electroplating of copper is one of the most commonly used plating processes for both functional and decorative applications 1, 2. Submerge the wafer to be plated into an electrolyte bath,. Once prepared,. Copper Electroplating Current.

From metalcoating.ae

Copper Electro Plating Copper Electroplating Current Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. This is done by dipping two terminals called electrodes into the electrolyte. Electroplating involves passing an electric current through a solution called an electrolyte. Electroplating of copper is one of the most commonly used plating processes for both functional and decorative applications 1, 2.. Copper Electroplating Current.

From www.youtube.com

Electroplating a key with copper The Real Chemist YouTube Copper Electroplating Current Once prepared, copper is deposited onto the zinc through a standard electroplating method, where an electric current drives the. Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. Electroplating involves passing an electric current through a solution called an electrolyte. Electroplating of copper is one of the most commonly used plating processes for. Copper Electroplating Current.

From www.pinterest.es

Copper Electroforming What You Need To Get Started Copper Copper Electroplating Current Electroplating involves passing an electric current through a solution called an electrolyte. Submerge the wafer to be plated into an electrolyte bath,. In most production processes, electroplating (ecp) is the primary method of copper metallization. Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. This is done by dipping two terminals called electrodes. Copper Electroplating Current.

From www.slideserve.com

PPT Electroplating PowerPoint Presentation, free download ID3733316 Copper Electroplating Current This is done by dipping two terminals called electrodes into the electrolyte. Copper is an outstanding replacement for aluminium in numerous electronic applications due to its exceptional properties. Electroplating involves passing an electric current through a solution called an electrolyte. In most production processes, electroplating (ecp) is the primary method of copper metallization. Once prepared, copper is deposited onto the. Copper Electroplating Current.

From www.researchgate.net

SEM images of samples after copper electroplating in solution 03_0.40 Copper Electroplating Current The concept of copper electroplating is straightforward: Submerge the wafer to be plated into an electrolyte bath,. Electroplating of copper is one of the most commonly used plating processes for both functional and decorative applications 1, 2. In most production processes, electroplating (ecp) is the primary method of copper metallization. Electroplating involves passing an electric current through a solution called. Copper Electroplating Current.