Steel Casting Mold Material . These materials can be broadly categorized into cold work. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Die casting is a permanent mould metal casting method in which liquid metal is poured into the “dies” at pressures ranging from 0.7 to 700 mpa, where it solidifies as a. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. Make sure the frame comes in. In mold making or mold casting, materials are meticulously chosen based on their specific service conditions. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting.

from sites.google.com

These materials can be broadly categorized into cold work. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. In mold making or mold casting, materials are meticulously chosen based on their specific service conditions. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. Make sure the frame comes in. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. Die casting is a permanent mould metal casting method in which liquid metal is poured into the “dies” at pressures ranging from 0.7 to 700 mpa, where it solidifies as a.

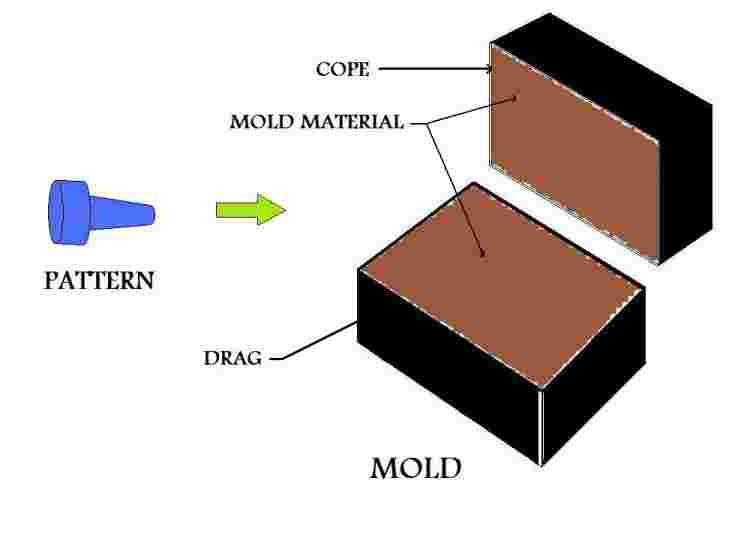

Metal Casting Process eer

Steel Casting Mold Material To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. In mold making or mold casting, materials are meticulously chosen based on their specific service conditions. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. These materials can be broadly categorized into cold work. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. Make sure the frame comes in. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Die casting is a permanent mould metal casting method in which liquid metal is poured into the “dies” at pressures ranging from 0.7 to 700 mpa, where it solidifies as a. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting.

From blog.eaglegroupmanufacturers.com

Getting Started with Permanent Mold Casting Steel Casting Mold Material Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. Die casting is a permanent mould metal casting method in which liquid metal is poured into the “dies” at pressures ranging from 0.7 to 700 mpa, where it solidifies as a. Make sure the frame comes in. Find out the materials and. Steel Casting Mold Material.

From www.nomuraplating.com

Product example of Continuous casting mold Largesize Machining Steel Casting Mold Material Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. In mold making or mold casting, materials are meticulously chosen based on their specific service conditions. These materials can be broadly categorized into cold work. Die casting is a permanent mould metal casting method in which liquid metal is poured into the. Steel Casting Mold Material.

From www.indiamart.com

Mild Steel Gravity Die Casting mould, Packaging Type Box, Rs 100000 Steel Casting Mold Material Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. Make sure the frame comes in. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. To successfully cast metal, you’ll first need to acquire a mold frame (also known. Steel Casting Mold Material.

From www.sunrise-metal.com

Die Casting Mold Expert Sunrise Metal Your Reliable Partner Steel Casting Mold Material To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. Make sure the frame comes in. These materials can be broadly categorized. Steel Casting Mold Material.

From www.3erp.com

Everything you need to know about metal casting Steel Casting Mold Material Make sure the frame comes in. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. Learn the six steps involved in creating custom. Steel Casting Mold Material.

From www.leclairemfg.com

Ultimate Guide to the Permanent Mold Casting Process Steel Casting Mold Material In mold making or mold casting, materials are meticulously chosen based on their specific service conditions. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. Die casting is a permanent mould metal casting method in which liquid metal is poured into the “dies” at pressures ranging from 0.7 to 700. Steel Casting Mold Material.

From brandfuge.com

From Sand to Solid Exploring the Art of Shell Moulding Castings BrandFuge Steel Casting Mold Material In mold making or mold casting, materials are meticulously chosen based on their specific service conditions. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. Permanent mold casting is. Steel Casting Mold Material.

From artnsyn.com

How slip casting and plaster molds work artnsyn Steel Casting Mold Material Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. Die casting is a permanent mould metal casting method in which liquid metal is poured into the “dies” at pressures ranging. Steel Casting Mold Material.

From www.reliance-foundry.com

Shakeout, Cleaning, and Machining Metal Casting Blog Steel Casting Mold Material Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Make sure the frame comes in. Die casting is a permanent mould. Steel Casting Mold Material.

From veenaengicast.com

Metal Casting Guide for Beginners Veena Enterprise Steel Casting Mold Material Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. Die casting is a permanent mould metal casting method in which liquid metal is poured into the “dies” at pressures ranging from 0.7 to 700 mpa, where it solidifies as a. In mold making or mold casting, materials are meticulously chosen based. Steel Casting Mold Material.

From centurymfg.com

metal casting mold Century Manufacturing Steel Casting Mold Material In mold making or mold casting, materials are meticulously chosen based on their specific service conditions. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. Make sure the frame comes in. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. Die. Steel Casting Mold Material.

From ppcpinc.com

Pennsylvania Precision Cast Parts Investment Casting Process Steel Casting Mold Material Make sure the frame comes in. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Permanent mold casting is a metal casting process. Steel Casting Mold Material.

From www.omicroncasting.com

5 Different Methods Used in Casting Steel Casting Mold Material Make sure the frame comes in. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Learn the six steps involved in creating custom. Steel Casting Mold Material.

From sites.google.com

Metal Casting Process eer Steel Casting Mold Material These materials can be broadly categorized into cold work. Die casting is a permanent mould metal casting method in which liquid metal is poured into the “dies” at pressures ranging from 0.7 to 700 mpa, where it solidifies as a. Make sure the frame comes in. Find out the materials and methods for different casting methods, such as sand casting,. Steel Casting Mold Material.

From www.thelibraryofmanufacturing.com

Metal Casting Process Steel Casting Mold Material Die casting is a permanent mould metal casting method in which liquid metal is poured into the “dies” at pressures ranging from 0.7 to 700 mpa, where it solidifies as a. These materials can be broadly categorized into cold work. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. Find out. Steel Casting Mold Material.

From www.dreamstime.com

Casting is a Manufacturing Process in a Liquid Material is Usually Steel Casting Mold Material To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. In mold making or mold casting, materials are meticulously chosen based on their specific. Steel Casting Mold Material.

From stainlesssteelcasting.net

Stainless Steel Casting in China Stainless Steel Casting Steel Casting Mold Material Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. In mold making or mold casting, materials are meticulously chosen based on their specific service conditions. Die casting is a permanent mould metal casting method in which liquid metal is poured into the “dies” at pressures ranging from 0.7. Steel Casting Mold Material.

From www.iqsdirectory.com

Iron Castings Types, Applications, Process, and Benefits Steel Casting Mold Material Make sure the frame comes in. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. Die casting is a permanent mould metal casting method in which liquid metal is poured into the “dies” at pressures ranging from 0.7 to 700 mpa, where it solidifies as a. Learn the six steps involved. Steel Casting Mold Material.

From punchlistzero.com

Metal Casting Process, Techniques and Applications Steel Casting Mold Material Make sure the frame comes in. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. In mold making or mold casting, materials are meticulously. Steel Casting Mold Material.

From www.indiamart.com

Stainless Steel Die Casting Mould, For Industrial at Rs 500000 in Vasai Steel Casting Mold Material These materials can be broadly categorized into cold work. Make sure the frame comes in. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. To successfully cast metal, you’ll. Steel Casting Mold Material.

From www.thecrucible.org

Metal Casting 101 Learn To Cast Metal [Types & Processes] Steel Casting Mold Material Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. Die casting is a permanent mould metal casting method in which liquid metal is poured into the “dies” at pressures ranging from 0.7 to 700 mpa, where it solidifies as a. These materials can be broadly categorized into cold work. Learn. Steel Casting Mold Material.

From theeventchronicle.com

Metal And Steel Casting Tips & Tricks for Beginners in 2024 The Event Steel Casting Mold Material Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. These materials can be broadly categorized into cold work. In mold making or mold casting, materials are meticulously chosen based on their specific service conditions. Find out the materials and methods for different casting methods, such as sand casting,. Steel Casting Mold Material.

From www.blasting-medias.com

P40 Steel Casting Mold Base Standard ASTM S136 Hot Steel Casting Mold Material To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Die casting is a permanent mould metal casting method in which liquid metal is poured into the “dies” at pressures ranging from 0.7 to 700 mpa, where it solidifies as a. In mold. Steel Casting Mold Material.

From www.alamy.com

Metal casting process in foundry, liquid metal pouring from container Steel Casting Mold Material In mold making or mold casting, materials are meticulously chosen based on their specific service conditions. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. Die casting is a permanent mould metal casting method in which liquid metal is poured into the “dies” at pressures ranging from 0.7. Steel Casting Mold Material.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz Steel Casting Mold Material Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. These materials can be broadly categorized into cold work. In mold making or mold casting, materials are meticulously chosen based on their specific service conditions. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a. Steel Casting Mold Material.

From engineeringlearn.com

16 Types of Moulding [Explained with Complete Details] Engineering Learn Steel Casting Mold Material Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Make sure the frame comes in. Find out the materials and methods for different casting. Steel Casting Mold Material.

From www.ace-mold.com

Die Casting Mould Material for Industrial Applications Steel Casting Mold Material Make sure the frame comes in. These materials can be broadly categorized into cold work. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. In mold making or mold casting, materials are meticulously chosen based on their specific service conditions. Permanent mold. Steel Casting Mold Material.

From www.dreamstime.com

A mold for steel casting stock photo. Image of process 118205038 Steel Casting Mold Material Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood,. Steel Casting Mold Material.

From www.sunrise-metal.com

Die Cast Aluminum Mold Sunrise Metal Aluminium Die Casting Expert Steel Casting Mold Material Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. These materials. Steel Casting Mold Material.

From www.dreamstime.com

Casting in a Mold for the Production of Metal, Automatice Line Hot Steel Casting Mold Material Make sure the frame comes in. Die casting is a permanent mould metal casting method in which liquid metal is poured into the “dies” at pressures ranging from 0.7 to 700 mpa, where it solidifies as a. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. Permanent mold casting is. Steel Casting Mold Material.

From www.youtube.com

The Basic Permanent Mold Casting Process YouTube Steel Casting Mold Material In mold making or mold casting, materials are meticulously chosen based on their specific service conditions. Make sure the frame comes in. Die casting is a permanent mould metal casting method in which liquid metal is poured into the “dies” at pressures ranging from 0.7 to 700 mpa, where it solidifies as a. Find out the materials and methods for. Steel Casting Mold Material.

From www.reliance-foundry.com

Cast Steel Production Metal Casting Blog Steel Casting Mold Material Make sure the frame comes in. Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. In mold making or mold casting, materials are meticulously chosen based on their specific service conditions. To. Steel Casting Mold Material.

From buntyllc.com

Custom Metal Casting Molds Bunty LLC Steel Casting Mold Material Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. These materials can be broadly categorized into cold work. In mold making or mold casting, materials are meticulously chosen based on their specific service conditions. Learn the six steps involved in creating custom molds for metal casting, from designing the pattern. Steel Casting Mold Material.

From www.glasshousestore.com

6″ Square Casting Stainless Steel Mold Glass House Store Steel Casting Mold Material Permanent mold casting is a metal casting process that employs reusable molds (permanent molds), usually made from metal. Die casting is a permanent mould metal casting method in which liquid metal is poured into the “dies” at pressures ranging from 0.7 to 700 mpa, where it solidifies as a. To successfully cast metal, you’ll first need to acquire a mold. Steel Casting Mold Material.

From aminds.com

3 POPULAR TYPES OF METAL CASTING AM Industries Vietnam Steel Casting Mold Material Learn the six steps involved in creating custom molds for metal casting, from designing the pattern to applying the refractory coating. Find out the materials and methods for different casting methods, such as sand casting, investment casting, and die casting. Die casting is a permanent mould metal casting method in which liquid metal is poured into the “dies” at pressures. Steel Casting Mold Material.