Molding Brass . Once molten brass cools, it. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Brass casting is a process of making brass products from molten brass. Brass casting is an intricate process that involves melting brass alloy, pouring it into a mold, and creating the desired shape. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Look for mold frames online or from specialty metal supply stores. It entails having the mold in the shape of the product you want to make. At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a.

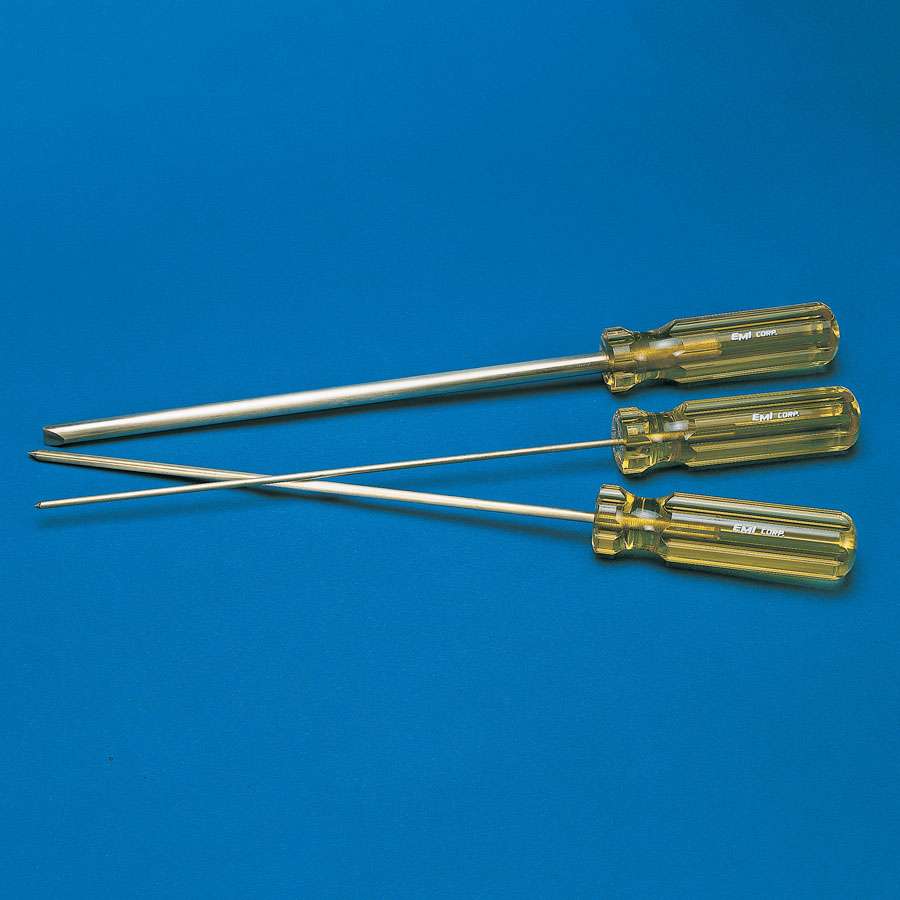

from www.emicorp.com

It entails having the mold in the shape of the product you want to make. Once molten brass cools, it. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Brass casting is a process of making brass products from molten brass. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a. Brass casting is an intricate process that involves melting brass alloy, pouring it into a mold, and creating the desired shape. Look for mold frames online or from specialty metal supply stores.

Brass Rods used in Injection Molding EMI Corp

Molding Brass To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Look for mold frames online or from specialty metal supply stores. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Brass casting is an intricate process that involves melting brass alloy, pouring it into a mold, and creating the desired shape. It entails having the mold in the shape of the product you want to make. Brass casting is a process of making brass products from molten brass. At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a. Once molten brass cools, it. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material.

From www.youtube.com

Open sand mold brass casting & steel mold copper coins Casting Copper & Brass YouTube Molding Brass To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. It entails having the mold in the shape of the product you want to make. Look for mold frames online or from specialty metal supply stores. Once molten brass cools, it. Brass casting. Molding Brass.

From www.tradeindia.com

Brass Molding Inserts at Best Price in Jamnagar, Gujarat Shree Bhagyalaxmi Industries Molding Brass At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a. Once molten brass cools, it. Brass casting is a process of making brass products from molten brass. Look for mold frames online or from specialty metal supply stores. To successfully cast metal, you’ll first need to acquire. Molding Brass.

From www.indiamart.com

M8 Brass Molding Insert, For Hardware Fitting at Rs 1.32/piece in Jamnagar ID 25944335873 Molding Brass To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Once molten brass cools, it. It entails having the mold in the shape of the product you want to make. Make sure the frame comes in 2 parts and is large enough to. Molding Brass.

From www.indiamart.com

Brass Molding Turned Components at best price in Jamnagar by Beejay Products ID 20117329797 Molding Brass It entails having the mold in the shape of the product you want to make. Once molten brass cools, it. Look for mold frames online or from specialty metal supply stores. At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a. Make sure the frame comes in. Molding Brass.

From www.emicorp.com

Brass Rods used in Injection Molding EMI Corp Molding Brass To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Look for mold frames online or from specialty metal supply stores. At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for. Molding Brass.

From www.indiamart.com

Prime Brass Molding Inserts, For Plastic Moulding at Rs 1.5/piece in Jamnagar Molding Brass Brass casting is an intricate process that involves melting brass alloy, pouring it into a mold, and creating the desired shape. Brass casting is a process of making brass products from molten brass. Look for mold frames online or from specialty metal supply stores. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a. Molding Brass.

From www.humboldtmfg.com

Brass Conical Mold for use with H3085 Vicat Apparatus Molding Brass At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a. It entails having the mold in the shape of the product you want to make. Brass casting is a process of making brass products from molten brass. Make sure the frame comes in 2 parts and is. Molding Brass.

From www.exportersindia.com

Polished Brass Molding Insert, for Fittings, Grade GB, JIS at Best Price in Jamnagar Molding Brass Once molten brass cools, it. At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Look for mold frames online or from specialty metal supply stores. Brass. Molding Brass.

From www.indiamart.com

Brass Molding Insert, For Electric And Hardware Fitting, Size 2.5x4inch at Rs 1/piece in Jamnagar Molding Brass Once molten brass cools, it. Brass casting is an intricate process that involves melting brass alloy, pouring it into a mold, and creating the desired shape. It entails having the mold in the shape of the product you want to make. At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can. Molding Brass.

From www.bedbathandbeyond.com

M3 x 7mm 5.3mm OD Brass Injection Molding Insert Knurled Thumb Nut 100PCS Brass Tone Bed Molding Brass Brass casting is an intricate process that involves melting brass alloy, pouring it into a mold, and creating the desired shape. It entails having the mold in the shape of the product you want to make. Look for mold frames online or from specialty metal supply stores. Brass casting is a process of making brass products from molten brass. Once. Molding Brass.

From www.tradeindia.com

Brass Molding Inserts at Best Price in Jamnagar, Gujarat Shree Laxmi Brass Industries Molding Brass Look for mold frames online or from specialty metal supply stores. Once molten brass cools, it. At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a. Brass casting is a process of making brass products from molten brass. Brass casting is an intricate process that involves melting. Molding Brass.

From www.robertsdesigns.com.au

LShape Trim Brass Roberts Designs Molding Brass Once molten brass cools, it. Brass casting is a process of making brass products from molten brass. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. It entails having the mold in the shape of the product you want to make. Look for mold frames online or from specialty. Molding Brass.

From www.aliexpress.com

Injection Molding Brass Knurled Thread Inserts Nut M2 M2.5 M3 M4 M5m6 Brass Aliexpress Molding Brass Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Look for mold frames online or from specialty metal supply stores. At deeco. Molding Brass.

From aksharbrass.tradeindia.com

Brass Molding Inserts Brass Molding Inserts Exporter, Manufacturer & Supplier, Jamnagar, India Molding Brass Brass casting is an intricate process that involves melting brass alloy, pouring it into a mold, and creating the desired shape. At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a. Look for mold frames online or from specialty metal supply stores. Brass casting is a process. Molding Brass.

From www.indiamart.com

Brass Molding Inserts, Packaging Type Packet at Rs 25/piece in Jamnagar ID 2570839091 Molding Brass To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. It entails having the mold in the shape of the product you want to make. Once molten brass cools, it. Make sure the frame comes in 2 parts and is large enough to. Molding Brass.

From www.honoble-precision.com

Injection molding Brass Stainless Steel 303 316 Carbon Steel Molded Insert nut for plastic Molding Brass To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Once molten brass cools, it. At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a. Look for mold frames online. Molding Brass.

From ever-hardware.com

Brass Molding Insert m4 m5 m6 m8 Brass Injection Molding Fittings Molding Brass Once molten brass cools, it. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a. Make sure the frame comes. Molding Brass.

From www.indiamart.com

Brass Molding Insert, For Electric And Hardware Fitting, Size 2.5x4inch at Rs 1/piece in Jamnagar Molding Brass It entails having the mold in the shape of the product you want to make. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Brass casting is an intricate process that involves melting brass alloy, pouring it into a mold, and creating the desired shape. Look for mold frames. Molding Brass.

From www.parts-cnc.com

Injection Molding Brass Cnc Machining Parts High Precision Molding Brass Once molten brass cools, it. Brass casting is an intricate process that involves melting brass alloy, pouring it into a mold, and creating the desired shape. Brass casting is a process of making brass products from molten brass. Look for mold frames online or from specialty metal supply stores. Make sure the frame comes in 2 parts and is large. Molding Brass.

From www.parts-cnc.com

Injection Molding Brass Cnc Machining Parts High Precision Molding Brass Brass casting is a process of making brass products from molten brass. Brass casting is an intricate process that involves melting brass alloy, pouring it into a mold, and creating the desired shape. Once molten brass cools, it. Look for mold frames online or from specialty metal supply stores. It entails having the mold in the shape of the product. Molding Brass.

From www.indiamart.com

Brass Molding Inserts at Rs 450/kilogram Brass Molding Insert in Jamnagar ID 4627307073 Molding Brass Brass casting is a process of making brass products from molten brass. It entails having the mold in the shape of the product you want to make. Look for mold frames online or from specialty metal supply stores. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron,. Molding Brass.

From www.pmseurope.com

Brass Scrapers and Mould Tools Plastic Moulding Supplies Limited Molding Brass Brass casting is a process of making brass products from molten brass. Brass casting is an intricate process that involves melting brass alloy, pouring it into a mold, and creating the desired shape. At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a. Once molten brass cools,. Molding Brass.

From www.indiamart.com

Brass Molding Insert at best price in Rajkot by Jay Ambe Enter. Ind ID 6429124912 Molding Brass To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Once molten brass cools, it. Brass casting is an intricate process that involves. Molding Brass.

From www.indiamart.com

Brass Rubber Molding at best price in Thane by Bhavna Rubber Industries ID 8597403991 Molding Brass Look for mold frames online or from specialty metal supply stores. Brass casting is a process of making brass products from molten brass. At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a. Once molten brass cools, it. It entails having the mold in the shape of. Molding Brass.

From www.youtube.com

HOW TO CAST MOLTEN BRASS IN SAND MOLDS SCRAP METAL CASTING YouTube Molding Brass It entails having the mold in the shape of the product you want to make. At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Once molten. Molding Brass.

From www.parts-cnc.com

Injection Molding Brass Cnc Machining Parts High Precision Molding Brass Look for mold frames online or from specialty metal supply stores. At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid. Molding Brass.

From www.indiamart.com

Injection Molding Brass Knurled Threaded Insert Nut at Rs 5/piece Brass Knurling Insert ID Molding Brass Look for mold frames online or from specialty metal supply stores. Brass casting is an intricate process that involves melting brass alloy, pouring it into a mold, and creating the desired shape. Once molten brass cools, it. At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a.. Molding Brass.

From www.modeltford.com

Brass floorboard molding for Model T Speedster body, NO.822 Molding Brass At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a. It entails having the mold in the shape of the product you want to make. To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron,. Molding Brass.

From www.indiamart.com

Brass Molding Insert, For Electric And Hardware Fitting, Size 2.5x4inch at Rs 1/piece in Jamnagar Molding Brass To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Brass casting is a process of making brass products from molten brass. It entails having the mold in the shape of the product you want to make. Make sure the frame comes in. Molding Brass.

From www.indiamart.com

Brass Custom Molding Insert, For Plastic Moulding at Rs 2.50/piece in Jamnagar Molding Brass Once molten brass cools, it. Brass casting is a process of making brass products from molten brass. Look for mold frames online or from specialty metal supply stores. It entails having the mold in the shape of the product you want to make. Make sure the frame comes in 2 parts and is large enough to hold the object you. Molding Brass.

From www.tradeindia.com

Round Hex Molding Brass Inserts Nut at Best Price in Jamnagar Shree Laxmi Brass Industries Molding Brass At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a. Brass casting is a process of making brass products from molten brass. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. Once molten brass cools, it.. Molding Brass.

From www.shivrajbrass.com

How to Install Brass Threaded Inserts for Plastic Injection Molding? Stepbystep Guide Brass Molding Brass To successfully cast metal, you’ll first need to acquire a mold frame (also known as a mold flask) made of wood, iron, or a similarly solid material. Once molten brass cools, it. Look for mold frames online or from specialty metal supply stores. Brass casting is a process of making brass products from molten brass. Make sure the frame comes. Molding Brass.

From wanjun.my

M6 Brass Threaded Inserts for Plastic Injection Molding WANJUN Molding Brass Brass casting is an intricate process that involves melting brass alloy, pouring it into a mold, and creating the desired shape. Once molten brass cools, it. At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a. It entails having the mold in the shape of the product. Molding Brass.

From www.plantautomation-technology.com

Brass Molding Inserts Screw Machine Products Meera Brass Products Plant Automation Technology Molding Brass Look for mold frames online or from specialty metal supply stores. Make sure the frame comes in 2 parts and is large enough to hold the object you want to cast. At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a. Once molten brass cools, it. Brass. Molding Brass.

From www.indiamart.com

Brass Molding Insert, For Electric And Hardware Fitting, Size 1.5x3inch at Rs 1/piece in Jamnagar Molding Brass Brass casting is an intricate process that involves melting brass alloy, pouring it into a mold, and creating the desired shape. At deeco metals we can provide brass and bronze architectural extrusions that provide aesthetically pleasing décor options, which can be used for a. Look for mold frames online or from specialty metal supply stores. It entails having the mold. Molding Brass.