Rebar Splicing Requirements . Type 1 mechanical splice shall develop in tension and compression as. The length of the lap varies depend on concrete strength, the rebar grade, size,. There are three primary methods for rebar splicing: Lap splices, welded splices, and mechanical splices. In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. Each method has its advantages and specific applications,. Properly designed splices of individual reinforcing bars are a key element in transmitting forces through the structure and creating a load path. 18, and in 20 to 40 ft lengths for. Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars) to create a continuous.

from www.aboutcivil.org

18, and in 20 to 40 ft lengths for. Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars) to create a continuous. Lap splices, welded splices, and mechanical splices. In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. Type 1 mechanical splice shall develop in tension and compression as. Properly designed splices of individual reinforcing bars are a key element in transmitting forces through the structure and creating a load path. The length of the lap varies depend on concrete strength, the rebar grade, size,. Each method has its advantages and specific applications,. A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. There are three primary methods for rebar splicing:

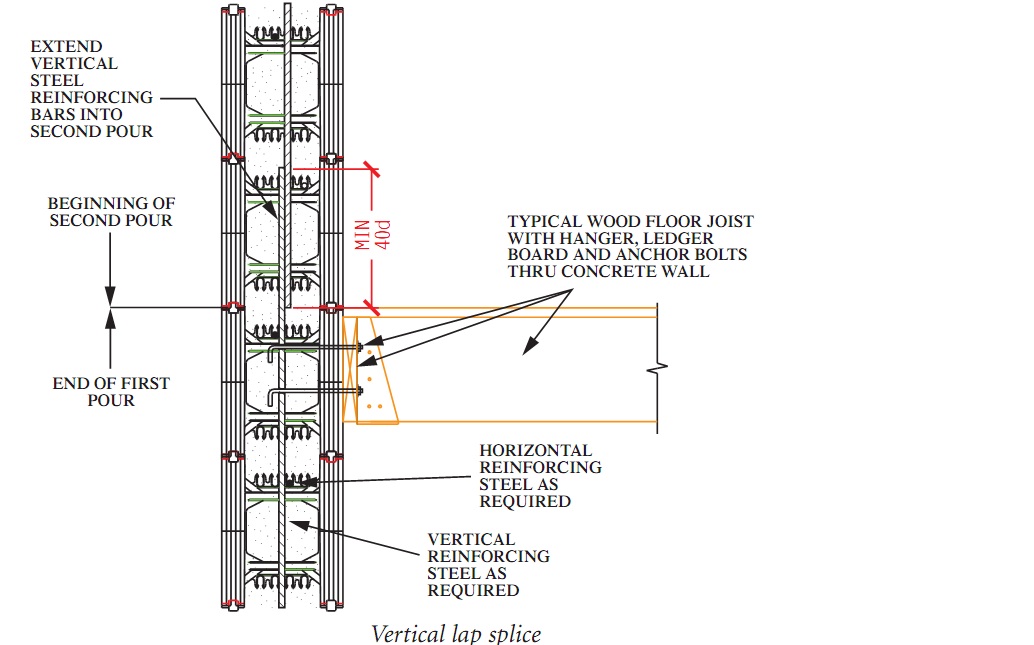

Steel Reinforcement for Walls Horizontal Rebars, Vertical and Splicing

Rebar Splicing Requirements Properly designed splices of individual reinforcing bars are a key element in transmitting forces through the structure and creating a load path. Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars) to create a continuous. 18, and in 20 to 40 ft lengths for. A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. Lap splices, welded splices, and mechanical splices. The length of the lap varies depend on concrete strength, the rebar grade, size,. Each method has its advantages and specific applications,. Type 1 mechanical splice shall develop in tension and compression as. In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. There are three primary methods for rebar splicing: Properly designed splices of individual reinforcing bars are a key element in transmitting forces through the structure and creating a load path.

From todayslopi.weebly.com

Rebar lap splice requirements todayslopi Rebar Splicing Requirements Type 1 mechanical splice shall develop in tension and compression as. The length of the lap varies depend on concrete strength, the rebar grade, size,. 18, and in 20 to 40 ft lengths for. Properly designed splices of individual reinforcing bars are a key element in transmitting forces through the structure and creating a load path. Lap splices, welded splices,. Rebar Splicing Requirements.

From constrofacilitator.com

Different methods for splicing reinforced bars Rebar Splicing Requirements Properly designed splices of individual reinforcing bars are a key element in transmitting forces through the structure and creating a load path. Each method has its advantages and specific applications,. Type 1 mechanical splice shall develop in tension and compression as. In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. Lap splices,. Rebar Splicing Requirements.

From mungfali.com

Rebar Splice Length Chart Rebar Splicing Requirements Type 1 mechanical splice shall develop in tension and compression as. Lap splices, welded splices, and mechanical splices. The length of the lap varies depend on concrete strength, the rebar grade, size,. Properly designed splices of individual reinforcing bars are a key element in transmitting forces through the structure and creating a load path. 18, and in 20 to 40. Rebar Splicing Requirements.

From classlisthertz.z21.web.core.windows.net

Aci Rebar Lap Splice Length Chart Rebar Splicing Requirements Type 1 mechanical splice shall develop in tension and compression as. There are three primary methods for rebar splicing: 18, and in 20 to 40 ft lengths for. A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. In general reinforcing bars are stocked by suppliers in lengths of 60 ft. Rebar Splicing Requirements.

From civilmint.com

What Is Splicing Of Reinforcement Bars? Rebar Splicing Requirements Type 1 mechanical splice shall develop in tension and compression as. There are three primary methods for rebar splicing: 18, and in 20 to 40 ft lengths for. A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. In general reinforcing bars are stocked by suppliers in lengths of 60 ft. Rebar Splicing Requirements.

From engineeringfeed.com

Arrangement of Rebars, Splicing points and splice length, development length, hooks requirement Rebar Splicing Requirements Properly designed splices of individual reinforcing bars are a key element in transmitting forces through the structure and creating a load path. The length of the lap varies depend on concrete strength, the rebar grade, size,. Each method has its advantages and specific applications,. Lap splices, welded splices, and mechanical splices. 18, and in 20 to 40 ft lengths for.. Rebar Splicing Requirements.

From www.pinterest.com

Mechanical splices are used to establish a mechanical connection between two pieces of Rebar Splicing Requirements The length of the lap varies depend on concrete strength, the rebar grade, size,. There are three primary methods for rebar splicing: Type 1 mechanical splice shall develop in tension and compression as. Each method has its advantages and specific applications,. 18, and in 20 to 40 ft lengths for. Lap splices, welded splices, and mechanical splices. Reinforcement splicing, also. Rebar Splicing Requirements.

From civilmint.com

What Is Splicing Of Reinforcement Bars? Rebar Splicing Requirements Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars) to create a continuous. Properly designed splices of individual reinforcing bars are a key element in transmitting forces through the structure and creating a load path. In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from. Rebar Splicing Requirements.

From ar.inspiredpencil.com

Aci Rebar Splice Length Rebar Splicing Requirements The length of the lap varies depend on concrete strength, the rebar grade, size,. Lap splices, welded splices, and mechanical splices. Properly designed splices of individual reinforcing bars are a key element in transmitting forces through the structure and creating a load path. There are three primary methods for rebar splicing: Reinforcement splicing, also known as rebar splicing, is the. Rebar Splicing Requirements.

From www.youtube.com

What is Overlap Length in Reinforcement Structure Member What is Splice length Overlapping Rebar Splicing Requirements Each method has its advantages and specific applications,. Type 1 mechanical splice shall develop in tension and compression as. In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. Properly designed splices of individual reinforcing bars are a key element in transmitting forces through the structure and creating a load path. Lap splices,. Rebar Splicing Requirements.

From dat.perueduca.edu.pe

Rebar Splice Length Chart Printable Templates Free Rebar Splicing Requirements Properly designed splices of individual reinforcing bars are a key element in transmitting forces through the structure and creating a load path. Lap splices, welded splices, and mechanical splices. The length of the lap varies depend on concrete strength, the rebar grade, size,. Each method has its advantages and specific applications,. Reinforcement splicing, also known as rebar splicing, is the. Rebar Splicing Requirements.

From www.monolithic.org

Rebar Splicing and Rebar Sizing Monolithic Dome Institute Rebar Splicing Requirements Properly designed splices of individual reinforcing bars are a key element in transmitting forces through the structure and creating a load path. In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. Type 1 mechanical splice shall develop in tension and compression as. Each method has its advantages and specific applications,. A lap. Rebar Splicing Requirements.

From www.aboutcivil.org

Steel Reinforcement for Walls Horizontal Rebars, Vertical and Splicing Rebar Splicing Requirements The length of the lap varies depend on concrete strength, the rebar grade, size,. Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars) to create a continuous. There are three primary methods for rebar splicing: Properly designed splices of individual reinforcing bars are a key element in transmitting forces through the. Rebar Splicing Requirements.

From www.scribd.com

Kelken US Metric Chart ASTM A615 Grade 60 Rebar Ultimate Tensile Strength Building Engineering Rebar Splicing Requirements Properly designed splices of individual reinforcing bars are a key element in transmitting forces through the structure and creating a load path. Type 1 mechanical splice shall develop in tension and compression as. 18, and in 20 to 40 ft lengths for. Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars). Rebar Splicing Requirements.

From www.vrogue.co

Understanding Lap Splices In Reinforcing Bars vrogue.co Rebar Splicing Requirements A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. Each method has its advantages and specific applications,. Type 1 mechanical splice shall develop in tension and compression as. In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. Properly designed splices of individual. Rebar Splicing Requirements.

From www.aleono.com

3 Methods of Rebar Splicing Aleono Blogs Rebar Splicing Requirements In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. Each method has its advantages and specific applications,. Type 1 mechanical splice shall develop in tension and compression as. There are three primary methods for rebar splicing: The length of the lap varies depend on concrete strength, the rebar grade, size,. Lap splices,. Rebar Splicing Requirements.

From ar.inspiredpencil.com

Aci Rebar Splice Length Rebar Splicing Requirements Type 1 mechanical splice shall develop in tension and compression as. Lap splices, welded splices, and mechanical splices. Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars) to create a continuous. Properly designed splices of individual reinforcing bars are a key element in transmitting forces through the structure and creating a. Rebar Splicing Requirements.

From structuralcalc.com

Rebar Development Length Calculator to ACI 318 (US) — Structural Calc Rebar Splicing Requirements In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. There are three primary methods for rebar splicing: Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars) to create a continuous. Type 1 mechanical splice shall develop in tension and compression as. Properly designed. Rebar Splicing Requirements.

From www.monolithic.org

Rebar Splicing and Rebar Sizing Rebar Splicing Requirements Lap splices, welded splices, and mechanical splices. A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. Each method has its advantages and specific applications,. Type 1 mechanical splice shall develop in tension and compression as. Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more. Rebar Splicing Requirements.

From labbyag.es

Rebar Splice Chart Labb by AG Rebar Splicing Requirements The length of the lap varies depend on concrete strength, the rebar grade, size,. Each method has its advantages and specific applications,. Lap splices, welded splices, and mechanical splices. A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. Reinforcement splicing, also known as rebar splicing, is the process of connecting. Rebar Splicing Requirements.

From www.excelcalcs.com

REINFORCING BAR DEVELOPMENT AND SPLICE LENGTHS ACI 31811 Rebar Splicing Requirements Type 1 mechanical splice shall develop in tension and compression as. There are three primary methods for rebar splicing: Each method has its advantages and specific applications,. Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars) to create a continuous. Lap splices, welded splices, and mechanical splices. A lap is when. Rebar Splicing Requirements.

From www.thebalance.com

Understanding Rebar Lap Splices Rebar Splicing Requirements Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars) to create a continuous. Type 1 mechanical splice shall develop in tension and compression as. There are three primary methods for rebar splicing: Lap splices, welded splices, and mechanical splices. 18, and in 20 to 40 ft lengths for. Each method has. Rebar Splicing Requirements.

From www.researchgate.net

(a) The cross section and reinforcement details of the lap splice beam;... Download Scientific Rebar Splicing Requirements Type 1 mechanical splice shall develop in tension and compression as. 18, and in 20 to 40 ft lengths for. Each method has its advantages and specific applications,. In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. Lap splices, welded splices, and mechanical splices. A lap is when two pieces of reinforcing. Rebar Splicing Requirements.

From homerepairgeek.com

Rebar Size Chart [With Explanations for Sizes, Types & Grades] Home Repair Geek Rebar Splicing Requirements A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars) to create a continuous. Type 1 mechanical splice shall develop in tension and compression as. Lap splices, welded splices, and mechanical splices. Properly. Rebar Splicing Requirements.

From learninglibschuhmancher.z13.web.core.windows.net

Aci Rebar Lap Splice Length Chart Rebar Splicing Requirements Lap splices, welded splices, and mechanical splices. Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars) to create a continuous. In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. Type 1 mechanical splice shall develop in tension and compression as. Properly designed splices. Rebar Splicing Requirements.

From www.youtube.com

E6 Beam Rebar Cutting List with Splicing (Lapping Length, Lapping Zone) YouTube Rebar Splicing Requirements Type 1 mechanical splice shall develop in tension and compression as. Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars) to create a continuous. The length of the lap varies depend on concrete strength, the rebar grade, size,. Lap splices, welded splices, and mechanical splices. 18, and in 20 to 40. Rebar Splicing Requirements.

From keski.condesan-ecoandes.org

rebar splice length chart Keski Rebar Splicing Requirements 18, and in 20 to 40 ft lengths for. Each method has its advantages and specific applications,. Properly designed splices of individual reinforcing bars are a key element in transmitting forces through the structure and creating a load path. The length of the lap varies depend on concrete strength, the rebar grade, size,. In general reinforcing bars are stocked by. Rebar Splicing Requirements.

From mavink.com

Crsi Rebar Lap Splice Chart Rebar Splicing Requirements Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars) to create a continuous. Each method has its advantages and specific applications,. In general reinforcing bars are stocked by suppliers in lengths of 60 ft for bars from no. There are three primary methods for rebar splicing: 18, and in 20 to. Rebar Splicing Requirements.

From www.engineeringclicks.com

A Guide to Rebar Sizes an overview of steel reinforcement bars EngineeringClicks Rebar Splicing Requirements There are three primary methods for rebar splicing: 18, and in 20 to 40 ft lengths for. A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. Each method has its advantages and specific applications,. Lap splices, welded splices, and mechanical splices. Reinforcement splicing, also known as rebar splicing, is the. Rebar Splicing Requirements.

From www.researchgate.net

Overlap in steel bar by splicing by wire Download Table Rebar Splicing Requirements Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars) to create a continuous. Lap splices, welded splices, and mechanical splices. The length of the lap varies depend on concrete strength, the rebar grade, size,. Properly designed splices of individual reinforcing bars are a key element in transmitting forces through the structure. Rebar Splicing Requirements.

From constrofacilitator.com

Different methods for splicing reinforced bars Rebar Splicing Requirements Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars) to create a continuous. 18, and in 20 to 40 ft lengths for. Lap splices, welded splices, and mechanical splices. There are three primary methods for rebar splicing: In general reinforcing bars are stocked by suppliers in lengths of 60 ft for. Rebar Splicing Requirements.

From ar.inspiredpencil.com

Lap Splice Reinforcement Rebar Splicing Requirements A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars) to create a continuous. The length of the lap varies depend on concrete strength, the rebar grade, size,. 18, and in 20 to. Rebar Splicing Requirements.

From www.aleono.com

3 Methods of Rebar Splicing Aleono Blogs Rebar Splicing Requirements 18, and in 20 to 40 ft lengths for. The length of the lap varies depend on concrete strength, the rebar grade, size,. Each method has its advantages and specific applications,. Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars) to create a continuous. Type 1 mechanical splice shall develop in. Rebar Splicing Requirements.

From kuudesign.com

28+ Aci Rebar Lap Splice Chart Design Gallery Rebar Splicing Requirements Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars) to create a continuous. Lap splices, welded splices, and mechanical splices. Each method has its advantages and specific applications,. Type 1 mechanical splice shall develop in tension and compression as. The length of the lap varies depend on concrete strength, the rebar. Rebar Splicing Requirements.

From www.structuremag.org

STRUCTURE magazine Details for Reinforced Concrete Construction Rebar Splicing Requirements Type 1 mechanical splice shall develop in tension and compression as. 18, and in 20 to 40 ft lengths for. Reinforcement splicing, also known as rebar splicing, is the process of connecting two or more reinforcing bars (rebars) to create a continuous. The length of the lap varies depend on concrete strength, the rebar grade, size,. Properly designed splices of. Rebar Splicing Requirements.