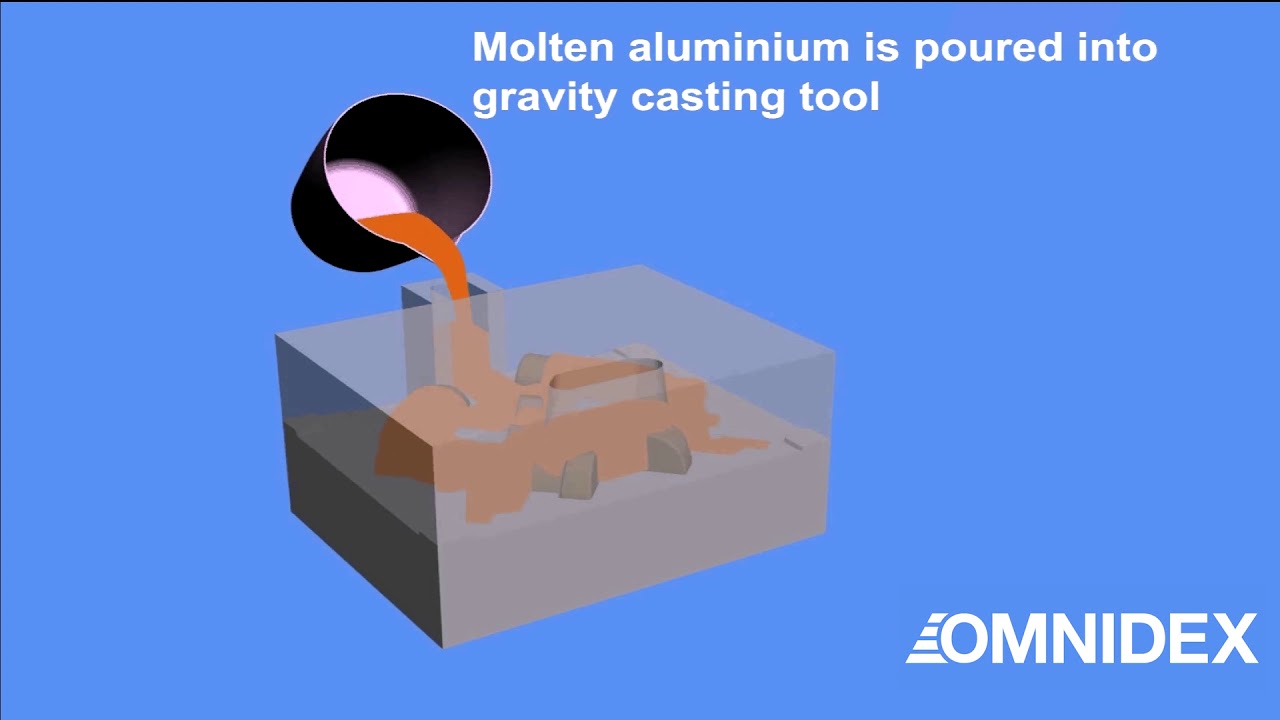

Gravity Mold Casting . Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject the molten metal into the mould. The casting method relies on gravity to fill a mold with molten metal. Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity mold. The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die.

from www.youtube.com

The casting method relies on gravity to fill a mold with molten metal. Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject the molten metal into the mould. The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity mold.

Permanent gravity mold YouTube

Gravity Mold Casting The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity mold. Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The casting method relies on gravity to fill a mold with molten metal. Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject the molten metal into the mould. The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity mold. The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die.

From www.engineeringclicks.com

Die Casting design guide, materials, advantages and disadvantages Gravity Mold Casting The casting method relies on gravity to fill a mold with molten metal. The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The gravity die casting technique involves. Gravity Mold Casting.

From diecastingmfg.net

Die Casting vs Sand Casting A Comparative Analysis Gravity Mold Casting Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject the molten metal into the mould. The casting method relies on gravity to fill a mold with molten metal. Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The. Gravity Mold Casting.

From www.bcplimited.co.uk

Gravity Die Castings High Integrity Die Castings Gravity Mold Casting The casting method relies on gravity to fill a mold with molten metal. The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity mold. Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject the molten metal into the. Gravity Mold Casting.

From www.researchgate.net

(a) Schematic diagram for gravity diecasting using a permanent mold Gravity Mold Casting The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity mold. The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject. Gravity Mold Casting.

From superband188.en.made-in-china.com

Gravity Motor Wheel Mold Low Pressure Casting Dies Manufacturing Gravity Mold Casting The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity mold. The casting method relies on gravity to fill a mold with molten metal. Gravity die casting uses. Gravity Mold Casting.

From www.indiamart.com

Gravity Permanent Mold Casting at best price in Greater Noida by Rajshi Gravity Mold Casting Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity mold. Gravity die casting uses gravity to fill the mould, while pressure die. Gravity Mold Casting.

From news.ewmfg.com

Gravity Casting and 101 Gravity Mold Casting The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject the molten metal into the mould. The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal. Gravity Mold Casting.

From www.btscl.com

Gravity casting what is it and how to know if it is right for you? Gravity Mold Casting The casting method relies on gravity to fill a mold with molten metal. Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. The gravity die casting technique involves. Gravity Mold Casting.

From betadiecasting.com

Used Stahl Permanent Mold Gravity Casting Machine For Sale Gravity Mold Casting Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal. Gravity Mold Casting.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz Gravity Mold Casting The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. The casting method relies on gravity to fill a mold with molten metal. Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. Gravity die casting uses gravity to. Gravity Mold Casting.

From www.indiamart.com

Aluminium Gravity Casting Die at Rs 50000/piece Gravity Casting Dies Gravity Mold Casting Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity mold. Gravity die casting uses gravity to fill the mould, while pressure die. Gravity Mold Casting.

From omnidexcastings.com

1 Quality Permanent Mold Gravity Casting solutions Omnidex Gravity Mold Casting The casting method relies on gravity to fill a mold with molten metal. Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject the molten metal into the mould. Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The. Gravity Mold Casting.

From 2021.help.altair.com

Gravity Process Gravity Mold Casting The casting method relies on gravity to fill a mold with molten metal. The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity mold. Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject the molten metal into the. Gravity Mold Casting.

From betadiecasting.com

AllCast Gravity Casting Machine For Sale Beta Die Casting Gravity Mold Casting Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The casting method relies on gravity to fill a mold with molten metal. Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject the molten metal into the mould. The. Gravity Mold Casting.

From www.indiamart.com

Gravity Die Casting Mould, Die Casting Mold Edgecon Technologies Gravity Mold Casting The casting method relies on gravity to fill a mold with molten metal. The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject the molten metal into the mould. The gravity die casting technique involves. Gravity Mold Casting.

From www.youtube.com

Permanent Mold Casting, Gravity Casting,Permanent mold aluminum casting Gravity Mold Casting Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject the molten metal into the mould. The casting method relies on gravity to fill a mold with molten metal. The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity. Gravity Mold Casting.

From omnidexmining.com

Permanent Mould Gravity Casting Omnidex Mining site Gravity Mold Casting Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject the molten metal into the mould. Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The mould cavity fills with no force other than gravity, filling can be controlled. Gravity Mold Casting.

From elite-tec.en.made-in-china.com

Die Cast Mold Gravity Die Casting Mold Aluminium Mould Die Casting Mold Gravity Mold Casting The casting method relies on gravity to fill a mold with molten metal. The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity mold. The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. Gravity die casting is. Gravity Mold Casting.

From www.newayprecision.com

Die Casting and Gravity Casting Understanding the Major Differences Gravity Mold Casting The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. The casting method relies on gravity to fill a mold with molten metal. The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity mold. Gravity die casting is. Gravity Mold Casting.

From betadiecasting.com

Used Stahl Permanent Mold Gravity Die Casting Machine For Sale Gravity Mold Casting The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity mold. Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The casting method relies on gravity to fill a mold with molten. Gravity Mold Casting.

From www.youtube.com

Permanent gravity mold YouTube Gravity Mold Casting Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject the molten metal into the mould. The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. The casting method relies on gravity to fill a mold with molten metal. The gravity die casting technique involves. Gravity Mold Casting.

From www.indiamart.com

Aluminium Gravity Die Casting at Rs 10000/piece Permanent Mold Gravity Mold Casting Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The casting method relies on gravity to fill a mold with molten metal. The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity. Gravity Mold Casting.

From www.iqsdirectory.com

Permanent Mold Castings What Is It? How Does It Work? Advantages Gravity Mold Casting Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject the molten metal into the mould. The casting method relies on gravity to fill a mold with molten metal. Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The. Gravity Mold Casting.

From e-batterystore.com

Gravity Casting Mechanical Grid Mould SLAB Gravity Mold Casting The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity mold. Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject. Gravity Mold Casting.

From www.weld2cast.com

Gravity Die Casting Weld2Cast Gravity Mold Casting The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject the molten metal into the mould. The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal. Gravity Mold Casting.

From www.indiamart.com

Steel Gravity Permanent Mold Casting, Range 0.05 20 Kg, ID Gravity Mold Casting The casting method relies on gravity to fill a mold with molten metal. The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. Gravity die casting uses gravity to. Gravity Mold Casting.

From thors.com

Gravity Die Casting Basics Course Gravity Mold Casting Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject the molten metal into the mould. The mould cavity fills with no force other than gravity, filling can be controlled. Gravity Mold Casting.

From www.molddiecast.com

New Energy Aluminum Alloy Die Casting A356 Gravity Mold Casting Gravity Mold Casting The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity mold. The casting method relies on gravity to fill a mold with molten metal. The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. Gravity die casting is. Gravity Mold Casting.

From www.indiamart.com

Mild Steel Gravity Die Casting mould, Packaging Type Box, Rs 100000 Gravity Mold Casting Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject the molten metal into the mould. The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity mold. Gravity die casting is a permanent mould casting process, where the molten. Gravity Mold Casting.

From www.langjuemould.com

China Gravity Casting Mold Manufacturers, Suppliers, Factory Good Gravity Mold Casting The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity mold. The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. Gravity die casting is a permanent mould casting process, where the molten metal is poured from a. Gravity Mold Casting.

From www.topgrid.co

Gravity Die Casting Definition, Gravity Die Casting Process Gravity Mold Casting The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. The gravity die casting technique involves making both simple and highly complex metal components by simply pouring molten metal into a reusable, steel cavity mold. Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject. Gravity Mold Casting.

From www.apexesmachinery.com

Gravity Casting Foundry Steel Mold Casting Gravity Mold Casting The casting method relies on gravity to fill a mold with molten metal. The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. Gravity die casting uses gravity to. Gravity Mold Casting.

From www.semanticscholar.org

Figure 1.2 from COST EFFECTIVE PRODUCTION OF A PERMANENT MOLD GRAVITY Gravity Mold Casting The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The casting method relies on gravity to fill a mold with molten metal. The gravity die casting technique involves. Gravity Mold Casting.

From omnidexmining.com

Permanent Mould Gravity Casting Omnidex Mining site Gravity Mold Casting The casting method relies on gravity to fill a mold with molten metal. Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject the molten metal into the mould. The mould cavity fills with no force other than gravity, filling can be controlled by tilting the die. Gravity die casting is a permanent. Gravity Mold Casting.

From rdcastings.co.uk

Gravity Die Casting Aluminium & Zinc Castings RD Castings Gravity Mold Casting The casting method relies on gravity to fill a mold with molten metal. Gravity die casting uses gravity to fill the mould, while pressure die casting employs pressure to inject the molten metal into the mould. Gravity die casting is a permanent mould casting process, where the molten metal is poured from a vessel or ladle into the mould. The. Gravity Mold Casting.