V Belt Vs Link Belt . Learn the definition, structure, performance, installation, cost, and environmental impact of cogged belts and v belts. That means you use it to replace old, worn belts in your drill press, table saw, sander. Compare the advantages and disadvantages of each type for different applications and choose the best option for your needs. They reduce the vibration issues of a thumping v. Link belts absorb vibration in a way standard belts cannot: Cogged belts work much better with small pulleys and are are less likely to take a set (a common cause of vibration with v belts but. The links move slightly within each other, dissipating the forces that create vibration. I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration of driven. Link belts are obviously very flexible and much less prone to taking a set, but they're less aerodynamic and make more wind noise.

from vbeltsdirect.com

Link belts absorb vibration in a way standard belts cannot: The links move slightly within each other, dissipating the forces that create vibration. I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration of driven. Learn the definition, structure, performance, installation, cost, and environmental impact of cogged belts and v belts. Cogged belts work much better with small pulleys and are are less likely to take a set (a common cause of vibration with v belts but. Compare the advantages and disadvantages of each type for different applications and choose the best option for your needs. That means you use it to replace old, worn belts in your drill press, table saw, sander. Link belts are obviously very flexible and much less prone to taking a set, but they're less aerodynamic and make more wind noise. They reduce the vibration issues of a thumping v.

What Is A VBelt And Why Use V Belts Direct

V Belt Vs Link Belt Cogged belts work much better with small pulleys and are are less likely to take a set (a common cause of vibration with v belts but. Learn the definition, structure, performance, installation, cost, and environmental impact of cogged belts and v belts. Compare the advantages and disadvantages of each type for different applications and choose the best option for your needs. The links move slightly within each other, dissipating the forces that create vibration. They reduce the vibration issues of a thumping v. Cogged belts work much better with small pulleys and are are less likely to take a set (a common cause of vibration with v belts but. Link belts absorb vibration in a way standard belts cannot: That means you use it to replace old, worn belts in your drill press, table saw, sander. I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration of driven. Link belts are obviously very flexible and much less prone to taking a set, but they're less aerodynamic and make more wind noise.

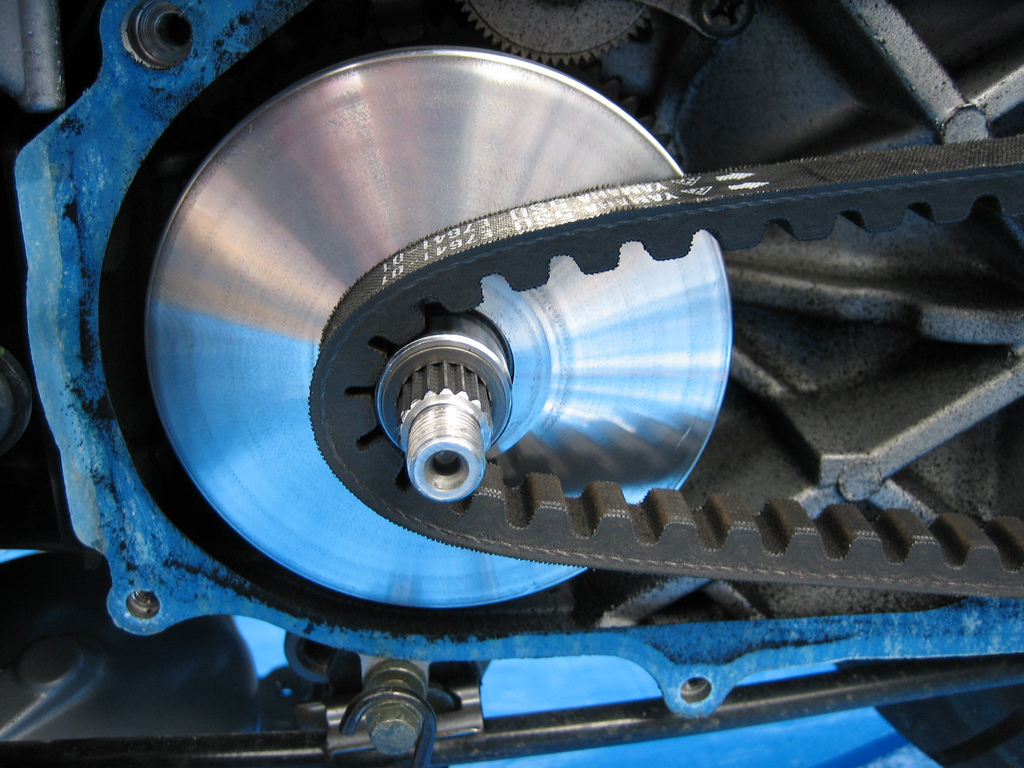

From www.cvfracing.com

Serpentine Belts vs. VBelts CVF Racing V Belt Vs Link Belt Cogged belts work much better with small pulleys and are are less likely to take a set (a common cause of vibration with v belts but. They reduce the vibration issues of a thumping v. Link belts absorb vibration in a way standard belts cannot: Link belts are obviously very flexible and much less prone to taking a set, but. V Belt Vs Link Belt.

From vbeltsdirect.com

What Is A VBelt And Why Use V Belts Direct V Belt Vs Link Belt I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration of driven. They reduce the vibration issues of a thumping v. That means you use it to replace old, worn belts in your drill press, table saw, sander. Cogged belts work much better with small pulleys and are are less likely to. V Belt Vs Link Belt.

From autoglobes.com

VBelt Vs Timing Belt Vs Flat Belt An Analogy AutoGlobes V Belt Vs Link Belt I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration of driven. The links move slightly within each other, dissipating the forces that create vibration. Learn the definition, structure, performance, installation, cost, and environmental impact of cogged belts and v belts. Link belts absorb vibration in a way standard belts cannot: Compare. V Belt Vs Link Belt.

From www.designworldonline.com

Synchronous belt and V belt How to pick between them? V Belt Vs Link Belt Link belts absorb vibration in a way standard belts cannot: I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration of driven. That means you use it to replace old, worn belts in your drill press, table saw, sander. Link belts are obviously very flexible and much less prone to taking a. V Belt Vs Link Belt.

From www.youtube.com

VBelt Code Guide Spec. Sense YouTube V Belt Vs Link Belt Cogged belts work much better with small pulleys and are are less likely to take a set (a common cause of vibration with v belts but. I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration of driven. Link belts absorb vibration in a way standard belts cannot: That means you use. V Belt Vs Link Belt.

From www.youtube.com

Replace V Belt With Link Belt YouTube V Belt Vs Link Belt I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration of driven. Link belts absorb vibration in a way standard belts cannot: Learn the definition, structure, performance, installation, cost, and environmental impact of cogged belts and v belts. Cogged belts work much better with small pulleys and are are less likely to. V Belt Vs Link Belt.

From www.wcducomb.com

W.C. Co., Inc. How to Identify a Vbelt V Belt Vs Link Belt Link belts absorb vibration in a way standard belts cannot: They reduce the vibration issues of a thumping v. That means you use it to replace old, worn belts in your drill press, table saw, sander. Compare the advantages and disadvantages of each type for different applications and choose the best option for your needs. I've seen link belt drive. V Belt Vs Link Belt.

From issuu.com

Different types of V Belts and Wedge Belts by bolton engineering V Belt Vs Link Belt Compare the advantages and disadvantages of each type for different applications and choose the best option for your needs. The links move slightly within each other, dissipating the forces that create vibration. I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration of driven. Learn the definition, structure, performance, installation, cost, and. V Belt Vs Link Belt.

From ricksfreeautorepairadvice.com

V Belt versus Serpentine Belt — Ricks Free Auto Repair Advice Ricks V Belt Vs Link Belt They reduce the vibration issues of a thumping v. The links move slightly within each other, dissipating the forces that create vibration. That means you use it to replace old, worn belts in your drill press, table saw, sander. Link belts are obviously very flexible and much less prone to taking a set, but they're less aerodynamic and make more. V Belt Vs Link Belt.

From www.lawnsite.com

Cogged vbelt vs standard vbelt (Conflicting Information) Lawn Care V Belt Vs Link Belt Link belts are obviously very flexible and much less prone to taking a set, but they're less aerodynamic and make more wind noise. Link belts absorb vibration in a way standard belts cannot: Compare the advantages and disadvantages of each type for different applications and choose the best option for your needs. The links move slightly within each other, dissipating. V Belt Vs Link Belt.

From thors.com

V belts, an overview V Belt Vs Link Belt I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration of driven. Cogged belts work much better with small pulleys and are are less likely to take a set (a common cause of vibration with v belts but. That means you use it to replace old, worn belts in your drill press,. V Belt Vs Link Belt.

From cargosu.com

Serpentine Belts VS. VBelts Which Ones Are Better? V Belt Vs Link Belt Link belts are obviously very flexible and much less prone to taking a set, but they're less aerodynamic and make more wind noise. Compare the advantages and disadvantages of each type for different applications and choose the best option for your needs. I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration. V Belt Vs Link Belt.

From ibtinc.com

VBelt vs Synchronous Belt ━ 5 Reasons To Upgrade Your Belt Drive V Belt Vs Link Belt Link belts are obviously very flexible and much less prone to taking a set, but they're less aerodynamic and make more wind noise. The links move slightly within each other, dissipating the forces that create vibration. Compare the advantages and disadvantages of each type for different applications and choose the best option for your needs. They reduce the vibration issues. V Belt Vs Link Belt.

From www.mitsuboshi.com

Narrow Vbelts / Narrow Cogged Vbelts V Belt Vs Link Belt Link belts absorb vibration in a way standard belts cannot: They reduce the vibration issues of a thumping v. I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration of driven. That means you use it to replace old, worn belts in your drill press, table saw, sander. Cogged belts work much. V Belt Vs Link Belt.

From www.indiamart.com

Fenner Drives Power Twist Link V Belt Adjustable Belts Locking Belts B V Belt Vs Link Belt I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration of driven. Cogged belts work much better with small pulleys and are are less likely to take a set (a common cause of vibration with v belts but. Link belts absorb vibration in a way standard belts cannot: Link belts are obviously. V Belt Vs Link Belt.

From baartgroup.com

RawEdge vs. Wrapped VBelts Baart Industrial Group V Belt Vs Link Belt Link belts absorb vibration in a way standard belts cannot: That means you use it to replace old, worn belts in your drill press, table saw, sander. Link belts are obviously very flexible and much less prone to taking a set, but they're less aerodynamic and make more wind noise. Compare the advantages and disadvantages of each type for different. V Belt Vs Link Belt.

From alhaqtraders.com

V Belt Types A, B, C, D, E types of Vee V Belts Providing Best V Belt Vs Link Belt Link belts are obviously very flexible and much less prone to taking a set, but they're less aerodynamic and make more wind noise. Link belts absorb vibration in a way standard belts cannot: Compare the advantages and disadvantages of each type for different applications and choose the best option for your needs. They reduce the vibration issues of a thumping. V Belt Vs Link Belt.

From www.iqsdirectory.com

VBelt What Is It? How Does It Work? Types Of, Uses V Belt Vs Link Belt Cogged belts work much better with small pulleys and are are less likely to take a set (a common cause of vibration with v belts but. I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration of driven. Learn the definition, structure, performance, installation, cost, and environmental impact of cogged belts and. V Belt Vs Link Belt.

From www.youtube.com

Vbelt vs Link belt YouTube V Belt Vs Link Belt The links move slightly within each other, dissipating the forces that create vibration. Link belts absorb vibration in a way standard belts cannot: They reduce the vibration issues of a thumping v. That means you use it to replace old, worn belts in your drill press, table saw, sander. Compare the advantages and disadvantages of each type for different applications. V Belt Vs Link Belt.

From ricksfreeautorepairadvice.com

V Belt versus Serpentine Belt — Ricks Free Auto Repair Advice Ricks V Belt Vs Link Belt They reduce the vibration issues of a thumping v. Compare the advantages and disadvantages of each type for different applications and choose the best option for your needs. Link belts are obviously very flexible and much less prone to taking a set, but they're less aerodynamic and make more wind noise. The links move slightly within each other, dissipating the. V Belt Vs Link Belt.

From 195.81.184.75

How to Identify a VBelt Megadyne Group V Belt Vs Link Belt Learn the definition, structure, performance, installation, cost, and environmental impact of cogged belts and v belts. They reduce the vibration issues of a thumping v. Link belts are obviously very flexible and much less prone to taking a set, but they're less aerodynamic and make more wind noise. The links move slightly within each other, dissipating the forces that create. V Belt Vs Link Belt.

From www.reddit.com

Vbelt vs Link Belt r/craftsman113 V Belt Vs Link Belt I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration of driven. They reduce the vibration issues of a thumping v. Compare the advantages and disadvantages of each type for different applications and choose the best option for your needs. That means you use it to replace old, worn belts in your. V Belt Vs Link Belt.

From www.desertcart.in

Buy V Belt Adjustable Link VBelt 5/8inches x 6feet B/5L Type B V Belt Vs Link Belt Learn the definition, structure, performance, installation, cost, and environmental impact of cogged belts and v belts. That means you use it to replace old, worn belts in your drill press, table saw, sander. Link belts are obviously very flexible and much less prone to taking a set, but they're less aerodynamic and make more wind noise. They reduce the vibration. V Belt Vs Link Belt.

From www.youtube.com

Link Belt vs V belt for shop tools YouTube V Belt Vs Link Belt Link belts absorb vibration in a way standard belts cannot: That means you use it to replace old, worn belts in your drill press, table saw, sander. Compare the advantages and disadvantages of each type for different applications and choose the best option for your needs. I've seen link belt drive belts advertised over the years with the claim that. V Belt Vs Link Belt.

From www.iqsdirectory.com

VBelt What Is It? How Does It Work? Types Of, Uses V Belt Vs Link Belt The links move slightly within each other, dissipating the forces that create vibration. Link belts are obviously very flexible and much less prone to taking a set, but they're less aerodynamic and make more wind noise. That means you use it to replace old, worn belts in your drill press, table saw, sander. Cogged belts work much better with small. V Belt Vs Link Belt.

From tameson.com

Vbelt Size Chart V Belt Vs Link Belt I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration of driven. Link belts absorb vibration in a way standard belts cannot: Learn the definition, structure, performance, installation, cost, and environmental impact of cogged belts and v belts. Cogged belts work much better with small pulleys and are are less likely to. V Belt Vs Link Belt.

From belthubs.com

VBelt Vs Serpentine Belt Belthubs V Belt Vs Link Belt I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration of driven. They reduce the vibration issues of a thumping v. That means you use it to replace old, worn belts in your drill press, table saw, sander. Link belts absorb vibration in a way standard belts cannot: Compare the advantages and. V Belt Vs Link Belt.

From www.vbeltguys.com

AX18 Cogged VBelt VBelt Guys V Belt Vs Link Belt The links move slightly within each other, dissipating the forces that create vibration. Link belts absorb vibration in a way standard belts cannot: That means you use it to replace old, worn belts in your drill press, table saw, sander. Cogged belts work much better with small pulleys and are are less likely to take a set (a common cause. V Belt Vs Link Belt.

From www.iqsdirectory.com

VBelt What Is It? How Does It Work? Types Of, Uses V Belt Vs Link Belt They reduce the vibration issues of a thumping v. That means you use it to replace old, worn belts in your drill press, table saw, sander. Compare the advantages and disadvantages of each type for different applications and choose the best option for your needs. Link belts are obviously very flexible and much less prone to taking a set, but. V Belt Vs Link Belt.

From www.tec-science.com

Types of belts for belt drives tecscience V Belt Vs Link Belt Link belts are obviously very flexible and much less prone to taking a set, but they're less aerodynamic and make more wind noise. Link belts absorb vibration in a way standard belts cannot: Learn the definition, structure, performance, installation, cost, and environmental impact of cogged belts and v belts. Cogged belts work much better with small pulleys and are are. V Belt Vs Link Belt.

From www.youtube.com

V & Wedge Belts YouTube V Belt Vs Link Belt Link belts are obviously very flexible and much less prone to taking a set, but they're less aerodynamic and make more wind noise. That means you use it to replace old, worn belts in your drill press, table saw, sander. I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration of driven.. V Belt Vs Link Belt.

From www.rubberbeltmanufacturer.com

Synchronous Belts vs VBelts Agricultural Belts Manufacturer V Belt Vs Link Belt Link belts absorb vibration in a way standard belts cannot: That means you use it to replace old, worn belts in your drill press, table saw, sander. Cogged belts work much better with small pulleys and are are less likely to take a set (a common cause of vibration with v belts but. I've seen link belt drive belts advertised. V Belt Vs Link Belt.

From belthubs.com

VBelt Vs Flat Belt Belthubs V Belt Vs Link Belt They reduce the vibration issues of a thumping v. Learn the definition, structure, performance, installation, cost, and environmental impact of cogged belts and v belts. That means you use it to replace old, worn belts in your drill press, table saw, sander. Link belts are obviously very flexible and much less prone to taking a set, but they're less aerodynamic. V Belt Vs Link Belt.

From www.powertransmission.com

Guide to VBelt Selection and Replacement Power Transmission V Belt Vs Link Belt I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration of driven. The links move slightly within each other, dissipating the forces that create vibration. They reduce the vibration issues of a thumping v. Cogged belts work much better with small pulleys and are are less likely to take a set (a. V Belt Vs Link Belt.

From www.iqsdirectory.com

VBelt What Is It? How Does It Work? Types Of, Uses V Belt Vs Link Belt I've seen link belt drive belts advertised over the years with the claim that they significantly reduce vibration of driven. That means you use it to replace old, worn belts in your drill press, table saw, sander. They reduce the vibration issues of a thumping v. Compare the advantages and disadvantages of each type for different applications and choose the. V Belt Vs Link Belt.