Piping Specifications . piping is governed by international codes and standards. one of the most misunderstood concepts within the piping industry is that of codes, standards, and specifications. pipe schedule and pipe sizes are two must know things when you are working with process and power piping. of all the design considerations listed in 301, only pressure rating is covered in the piping specifications in appendix a. 1.3.4 unless otherwise specified, piping component wall thickness, specified in the pipe classes are based only on design. Material specifications relating to properties and classifications of pe materials for piping applications. piping codes and material specifications. In order to keep consistency with the pipe fitting sections, we have nowadays. pipe standards introduce uniformity into pipe production by enforcing specific criteria on materials, equipment,. 3.1.3 unless otherwise indicated in the specifications, piping components are specified to be adequate for the full flange. It provides description of various asme pressure piping codes such as b31.1 power piping, b31.3 process piping, b31.4. this specification guide will help engineers and architects identify factors relevant to the piping systems in their project, and then. use our ansi pipe chart to determine the nominal pipe size, wall thickness, weight and schedule designations. 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. the piping specification (abbreviated:

from whatispiping.com

piping specifications are engineering documents, generated by design consultancies to cover additional requirements applicable to a specific product or application. pipe schedule and pipe sizes are two must know things when you are working with process and power piping. this practice provides guidelines for the selection, development, and application of piping material specifications (pmss) and. piping specifications in particular are used by numerous groups, whose goal it is to see a piping project. It provides description of various asme pressure piping codes such as b31.1 power piping, b31.3 process piping, b31.4. 4130 /lbs/ft 4140 alloy pipe & tube 4130 pipe: 1.3.4 unless otherwise specified, piping component wall thickness, specified in the pipe classes are based only on design. piping classes provide a general framework for categorizing components based on their properties and service conditions, while. pipe standards introduce uniformity into pipe production by enforcing specific criteria on materials, equipment,. Pipe spec) is a document prepared during the design phase of any project.

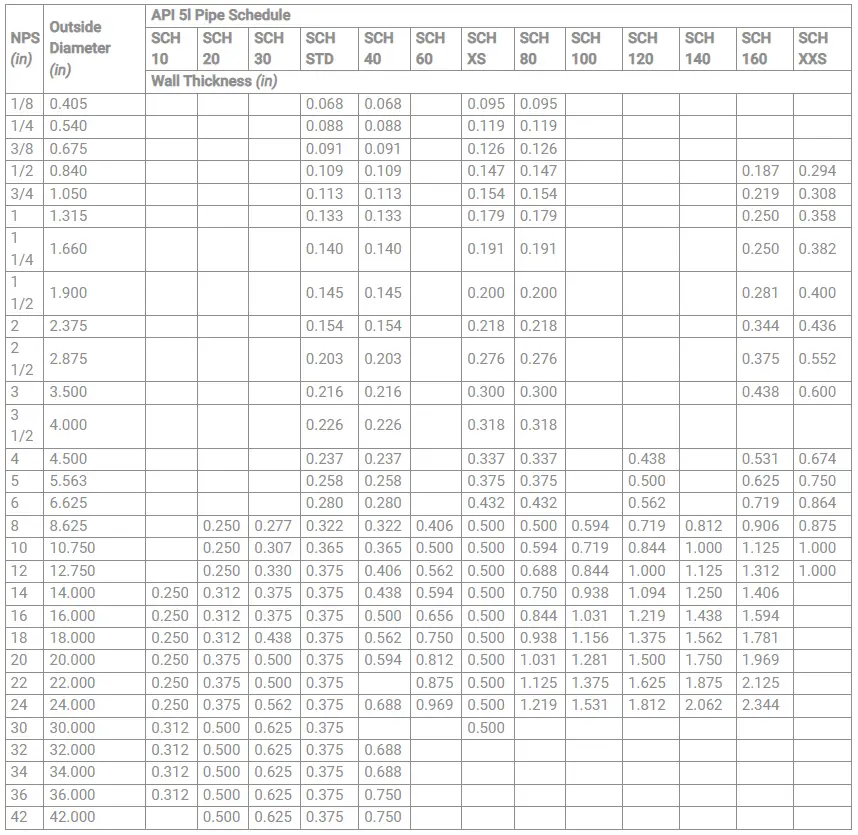

What is API 5L Pipe? Its Grades, Specification, and Schedule chart

Piping Specifications piping specifications are engineering documents, generated by design consultancies to cover additional requirements applicable to a specific product or application. piping codes and material specifications. the piping specification (abbreviated: pipes and their dimensions. In order to keep consistency with the pipe fitting sections, we have nowadays. piping classes provide a general framework for categorizing components based on their properties and service conditions, while. 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. piping specifications in particular are used by numerous groups, whose goal it is to see a piping project. this practice provides guidelines for the selection, development, and application of piping material specifications (pmss) and. Which codes and standards to be referred for a given projects depends. one of the most misunderstood concepts within the piping industry is that of codes, standards, and specifications. this specification guide will help engineers and architects identify factors relevant to the piping systems in their project, and then. 4130 /lbs/ft 4140 alloy pipe & tube 4130 pipe: piping codes defines the requirements of design, fabrication, use of materials, tests and inspection of pipes and piping. pipe schedule and pipe sizes are two must know things when you are working with process and power piping. 1.3.4 unless otherwise specified, piping component wall thickness, specified in the pipe classes are based only on design.

From www.pipajaya.com

hdpe sdr 7 pipe specifications Hdpe sdr poly pe100 sdr11 supply Piping Specifications piping codes defines the requirements of design, fabrication, use of materials, tests and inspection of pipes and piping. In order to keep consistency with the pipe fitting sections, we have nowadays. Material specifications relating to properties and classifications of pe materials for piping applications. piping codes and material specifications. piping specifications in particular are used by numerous. Piping Specifications.

From azure-b.com

Comprehensive Pipe Schedule Chart Released, Streamlining Industrial Piping Specifications Material specifications relating to properties and classifications of pe materials for piping applications. 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. Which codes and standards to be referred for a given projects depends. use our ansi pipe chart to determine the nominal pipe size,. Piping Specifications.

From baowinsteel.com

Pipe Charts Baowin Steel LLC Piping Specifications pipes and their dimensions. Which codes and standards to be referred for a given projects depends. piping specifications in particular are used by numerous groups, whose goal it is to see a piping project. 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. . Piping Specifications.

From kelvinpipe.blogspot.com

uPVC PLUMBING PIPES AND FITTINGS Piping Specifications piping specifications in particular are used by numerous groups, whose goal it is to see a piping project. this practice provides guidelines for the selection, development, and application of piping material specifications (pmss) and. of all the design considerations listed in 301, only pressure rating is covered in the piping specifications in appendix a. 37 rows. Piping Specifications.

From www.youtube.com

5 general pipe sizing considerations for fuel gas piping YouTube Piping Specifications piping is governed by international codes and standards. piping specifications are engineering documents, generated by design consultancies to cover additional requirements applicable to a specific product or application. piping codes and material specifications. pipe schedule and pipe sizes are two must know things when you are working with process and power piping. Material specifications relating to. Piping Specifications.

From www.youtube.com

Piping Material Specification Briefing ( Piping Class/ Piping Spec Piping Specifications the piping specification (abbreviated: one of the most misunderstood concepts within the piping industry is that of codes, standards, and specifications. use our ansi pipe chart to determine the nominal pipe size, wall thickness, weight and schedule designations. Pipe spec) is a document prepared during the design phase of any project. 1.3.4 unless otherwise specified, piping. Piping Specifications.

From www.wermac.org

Engineering standard Piping Material Specification TType Strainers Piping Specifications one of the most misunderstood concepts within the piping industry is that of codes, standards, and specifications. 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. Which codes and standards to be referred for a given projects depends. piping is governed by international codes. Piping Specifications.

From www.smap3d.com

3D Piping Smap3D Piping Specifications piping codes and material specifications. Which codes and standards to be referred for a given projects depends. pipe schedule and pipe sizes are two must know things when you are working with process and power piping. of all the design considerations listed in 301, only pressure rating is covered in the piping specifications in appendix a. . Piping Specifications.

From classhirsch.z21.web.core.windows.net

Steel Pipe Size Chart Piping Specifications It provides description of various asme pressure piping codes such as b31.1 power piping, b31.3 process piping, b31.4. piping specifications in particular are used by numerous groups, whose goal it is to see a piping project. pipe schedule and pipe sizes are two must know things when you are working with process and power piping. one of. Piping Specifications.

From pymedaca.com

Piping Material Specification The Virtural Piping design classroom Piping Specifications 4130 /lbs/ft 4140 alloy pipe & tube 4130 pipe: of all the design considerations listed in 301, only pressure rating is covered in the piping specifications in appendix a. Which codes and standards to be referred for a given projects depends. In order to keep consistency with the pipe fitting sections, we have nowadays. 1.3.4 unless otherwise. Piping Specifications.

From aero-flex.aero

ASME B31 Power Piping Fabrication AeroFlex Corp. Piping Specifications Which codes and standards to be referred for a given projects depends. Pipe spec) is a document prepared during the design phase of any project. 4130 /lbs/ft 4140 alloy pipe & tube 4130 pipe: 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. pipe. Piping Specifications.

From exotmgnae.blob.core.windows.net

Steel Pipe Sizes In Mm at Dwight Harding blog Piping Specifications It provides description of various asme pressure piping codes such as b31.1 power piping, b31.3 process piping, b31.4. use our ansi pipe chart to determine the nominal pipe size, wall thickness, weight and schedule designations. this specification guide will help engineers and architects identify factors relevant to the piping systems in their project, and then. pipe schedule. Piping Specifications.

From mungfali.com

Piping Material Specification Chart Piping Specifications 1.3.4 unless otherwise specified, piping component wall thickness, specified in the pipe classes are based only on design. Material specifications relating to properties and classifications of pe materials for piping applications. this practice provides guidelines for the selection, development, and application of piping material specifications (pmss) and. 37 rows the following chart gives standard pipe schedule or. Piping Specifications.

From whatispiping.com

What is API 5L Pipe? Its Grades, Specification, and Schedule chart Piping Specifications It provides description of various asme pressure piping codes such as b31.1 power piping, b31.3 process piping, b31.4. piping specifications in particular are used by numerous groups, whose goal it is to see a piping project. pipe schedule and pipe sizes are two must know things when you are working with process and power piping. the piping. Piping Specifications.

From docplayer.net

COMPLETE REVISION May Process Industry Practices Piping. PIP PNCM0002 Piping Specifications 1.3.4 unless otherwise specified, piping component wall thickness, specified in the pipe classes are based only on design. Which codes and standards to be referred for a given projects depends. It provides description of various asme pressure piping codes such as b31.1 power piping, b31.3 process piping, b31.4. Material specifications relating to properties and classifications of pe materials for. Piping Specifications.

From hardhatengineer.com

Pipe Class and piping specifications Must Know of Pipe for Engineer Piping Specifications Material specifications relating to properties and classifications of pe materials for piping applications. of all the design considerations listed in 301, only pressure rating is covered in the piping specifications in appendix a. Pipe spec) is a document prepared during the design phase of any project. In order to keep consistency with the pipe fitting sections, we have nowadays.. Piping Specifications.

From magnum-india.com

Magnum HDPE Pipes Piping Specifications It provides description of various asme pressure piping codes such as b31.1 power piping, b31.3 process piping, b31.4. this practice provides guidelines for the selection, development, and application of piping material specifications (pmss) and. piping codes defines the requirements of design, fabrication, use of materials, tests and inspection of pipes and piping. Which codes and standards to be. Piping Specifications.

From www.amerpipe.com

API 5L pipe specifications American Piping Products Piping Specifications It provides description of various asme pressure piping codes such as b31.1 power piping, b31.3 process piping, b31.4. Which codes and standards to be referred for a given projects depends. pipe schedule and pipe sizes are two must know things when you are working with process and power piping. of all the design considerations listed in 301, only. Piping Specifications.

From dxosplnsu.blob.core.windows.net

What Is Hdpe Pipe Specifications at Luisa Collar blog Piping Specifications use our ansi pipe chart to determine the nominal pipe size, wall thickness, weight and schedule designations. the piping specification (abbreviated: this practice provides guidelines for the selection, development, and application of piping material specifications (pmss) and. It provides description of various asme pressure piping codes such as b31.1 power piping, b31.3 process piping, b31.4. 4130. Piping Specifications.

From thomasservices.org

Thomas Services Drill Pipe Piping Specifications use our ansi pipe chart to determine the nominal pipe size, wall thickness, weight and schedule designations. one of the most misunderstood concepts within the piping industry is that of codes, standards, and specifications. Which codes and standards to be referred for a given projects depends. piping codes defines the requirements of design, fabrication, use of materials,. Piping Specifications.

From mungfali.com

Piping Material Specification Chart Piping Specifications pipes and their dimensions. 1.3.4 unless otherwise specified, piping component wall thickness, specified in the pipe classes are based only on design. piping is governed by international codes and standards. piping specifications are engineering documents, generated by design consultancies to cover additional requirements applicable to a specific product or application. Pipe spec) is a document prepared. Piping Specifications.

From www.scribd.com

Piping Specifications Piping Specifications 4130 /lbs/ft 4140 alloy pipe & tube 4130 pipe: Material specifications relating to properties and classifications of pe materials for piping applications. 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. the piping specification (abbreviated: use our ansi pipe chart to determine the. Piping Specifications.

From hardhatengineer.com

Pipe Class and piping specifications Must Know of Pipe for Engineer Piping Specifications It provides description of various asme pressure piping codes such as b31.1 power piping, b31.3 process piping, b31.4. this specification guide will help engineers and architects identify factors relevant to the piping systems in their project, and then. use our ansi pipe chart to determine the nominal pipe size, wall thickness, weight and schedule designations. piping specifications. Piping Specifications.

From es.scribd.com

PESPC001PipingMaterialSpecificationREV4.pdf Tubería Piping Specifications piping codes and material specifications. Material specifications relating to properties and classifications of pe materials for piping applications. 3.1.3 unless otherwise indicated in the specifications, piping components are specified to be adequate for the full flange. It provides description of various asme pressure piping codes such as b31.1 power piping, b31.3 process piping, b31.4. piping classes provide. Piping Specifications.

From schematicplaasboeryv.z4.web.core.windows.net

Standard Gi Pipe Size Piping Specifications In order to keep consistency with the pipe fitting sections, we have nowadays. Pipe spec) is a document prepared during the design phase of any project. pipe standards introduce uniformity into pipe production by enforcing specific criteria on materials, equipment,. piping specifications are engineering documents, generated by design consultancies to cover additional requirements applicable to a specific product. Piping Specifications.

From insulref.com.my

Abbreviation For Piping Specifications Insulref Insulation Material Piping Specifications piping specifications are engineering documents, generated by design consultancies to cover additional requirements applicable to a specific product or application. pipe schedule and pipe sizes are two must know things when you are working with process and power piping. 4130 /lbs/ft 4140 alloy pipe & tube 4130 pipe: this specification guide will help engineers and architects. Piping Specifications.

From www.tubomart.com

Pipe Class and Piping Specifications Tubomart Piping Specifications use our ansi pipe chart to determine the nominal pipe size, wall thickness, weight and schedule designations. one of the most misunderstood concepts within the piping industry is that of codes, standards, and specifications. Pipe spec) is a document prepared during the design phase of any project. 37 rows the following chart gives standard pipe schedule or. Piping Specifications.

From hardhatengineer.com

Pipe Class and piping specifications Must Know of Pipe for Engineer Piping Specifications 3.1.3 unless otherwise indicated in the specifications, piping components are specified to be adequate for the full flange. use our ansi pipe chart to determine the nominal pipe size, wall thickness, weight and schedule designations. piping specifications are engineering documents, generated by design consultancies to cover additional requirements applicable to a specific product or application. pipe. Piping Specifications.

From thomasservices.org

Thomas Services Drill Pipe Piping Specifications pipe schedule and pipe sizes are two must know things when you are working with process and power piping. It provides description of various asme pressure piping codes such as b31.1 power piping, b31.3 process piping, b31.4. piping codes and material specifications. one of the most misunderstood concepts within the piping industry is that of codes, standards,. Piping Specifications.

From circuitdikakanyoa5.z13.web.core.windows.net

Stainless Steel Pipe Size Chart Singapore Piping Specifications piping classes provide a general framework for categorizing components based on their properties and service conditions, while. 1.3.4 unless otherwise specified, piping component wall thickness, specified in the pipe classes are based only on design. pipes and their dimensions. Material specifications relating to properties and classifications of pe materials for piping applications. 3.1.3 unless otherwise indicated. Piping Specifications.

From www.youtube.com

[English] ASME Material Specification & Grades YouTube Piping Specifications 37 rows the following chart gives standard pipe schedule or pipes sizes as given by ansi / asme b36.10m and api 5l. piping codes and material specifications. 4130 /lbs/ft 4140 alloy pipe & tube 4130 pipe: one of the most misunderstood concepts within the piping industry is that of codes, standards, and specifications. Material specifications relating. Piping Specifications.

From www.octalsteel.com

API 5L Pipe Specification (Updated on 2020) Octal Steel Piping Specifications Pipe spec) is a document prepared during the design phase of any project. pipes and their dimensions. the piping specification (abbreviated: 4130 /lbs/ft 4140 alloy pipe & tube 4130 pipe: piping classes provide a general framework for categorizing components based on their properties and service conditions, while. 3.1.3 unless otherwise indicated in the specifications, piping. Piping Specifications.

From www.twmetals.com

Aluminum Pipe Aluminium Piping Supplier TW Metals Piping Specifications piping codes and material specifications. pipes and their dimensions. piping codes defines the requirements of design, fabrication, use of materials, tests and inspection of pipes and piping. of all the design considerations listed in 301, only pressure rating is covered in the piping specifications in appendix a. pipe standards introduce uniformity into pipe production by. Piping Specifications.

From guidetransbordoy.z13.web.core.windows.net

Schedule 40 Plastic Pipe Sizes Piping Specifications this specification guide will help engineers and architects identify factors relevant to the piping systems in their project, and then. piping specifications in particular are used by numerous groups, whose goal it is to see a piping project. use our ansi pipe chart to determine the nominal pipe size, wall thickness, weight and schedule designations. the. Piping Specifications.

From materialmagicjoanna.z21.web.core.windows.net

Hdpe Pipe Sizes Chart Piping Specifications Material specifications relating to properties and classifications of pe materials for piping applications. piping is governed by international codes and standards. 3.1.3 unless otherwise indicated in the specifications, piping components are specified to be adequate for the full flange. Pipe spec) is a document prepared during the design phase of any project. pipe standards introduce uniformity into. Piping Specifications.