When To Reorder Inventory . A reorder point (rop) indicates when it’s time to reorder inventory so you can restock before you sell out completely. The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent. In simpler words, it's the exact inventory. Calculating inventory reorder points helps with the reduction in inventory cost, reduces stockouts, and improves forecasting. It’s calculated using average daily usage, lead time, and safety. A reorder point is crucial for effective inventory management. Reorder point is the inventory level at which a company should place a new order to avoid stockouts. It saves holding costs and prevents stockouts, overstocking,. The reorder point is important because it helps businesses in. The reorder point is the point at which a business needs to reorder inventory to keep up with customer demand.

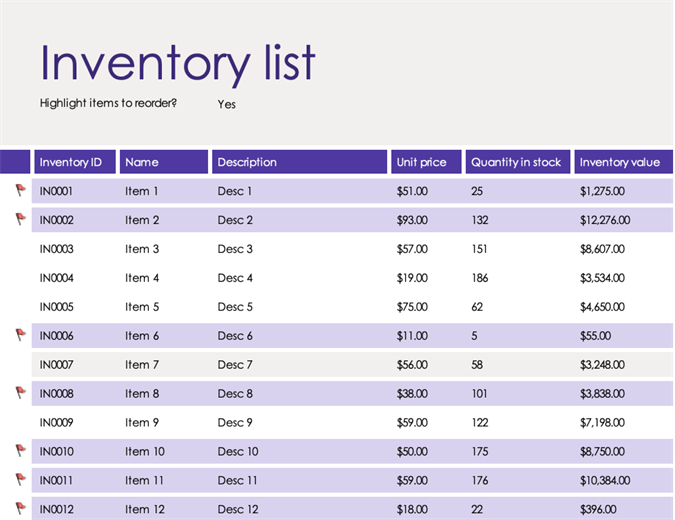

from www.excelstemplates.com

In simpler words, it's the exact inventory. The reorder point is the point at which a business needs to reorder inventory to keep up with customer demand. The reorder point is important because it helps businesses in. The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent. A reorder point (rop) indicates when it’s time to reorder inventory so you can restock before you sell out completely. Calculating inventory reorder points helps with the reduction in inventory cost, reduces stockouts, and improves forecasting. A reorder point is crucial for effective inventory management. Reorder point is the inventory level at which a company should place a new order to avoid stockouts. It saves holding costs and prevents stockouts, overstocking,. It’s calculated using average daily usage, lead time, and safety.

Inventory Order Templates 10+ Free MS Docs, Xlsx & PDF Formats

When To Reorder Inventory A reorder point is crucial for effective inventory management. It’s calculated using average daily usage, lead time, and safety. A reorder point (rop) indicates when it’s time to reorder inventory so you can restock before you sell out completely. In simpler words, it's the exact inventory. The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent. The reorder point is important because it helps businesses in. It saves holding costs and prevents stockouts, overstocking,. The reorder point is the point at which a business needs to reorder inventory to keep up with customer demand. Calculating inventory reorder points helps with the reduction in inventory cost, reduces stockouts, and improves forecasting. A reorder point is crucial for effective inventory management. Reorder point is the inventory level at which a company should place a new order to avoid stockouts.

From www.ecommercefulfilment.com

How to calculate reorder level a stepbystep guide J&J USA When To Reorder Inventory Reorder point is the inventory level at which a company should place a new order to avoid stockouts. Calculating inventory reorder points helps with the reduction in inventory cost, reduces stockouts, and improves forecasting. It’s calculated using average daily usage, lead time, and safety. A reorder point (rop) indicates when it’s time to reorder inventory so you can restock before. When To Reorder Inventory.

From www.vrogue.co

Formula To Calculate Inventory Reorder Points And Saf vrogue.co When To Reorder Inventory A reorder point is crucial for effective inventory management. In simpler words, it's the exact inventory. It’s calculated using average daily usage, lead time, and safety. The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent. A reorder point (rop) indicates when it’s time to reorder inventory so. When To Reorder Inventory.

From www.deskera.com

What is Inventory Reorder Point in Inventory Management? When To Reorder Inventory A reorder point is crucial for effective inventory management. The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent. The reorder point is important because it helps businesses in. Calculating inventory reorder points helps with the reduction in inventory cost, reduces stockouts, and improves forecasting. In simpler words,. When To Reorder Inventory.

From www.youtube.com

Re Order Level (ROL) Calculation in Inventory Management in Excel YouTube When To Reorder Inventory The reorder point is the point at which a business needs to reorder inventory to keep up with customer demand. Reorder point is the inventory level at which a company should place a new order to avoid stockouts. The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent.. When To Reorder Inventory.

From www.slideteam.net

Reorder Point Method For Determining Inventory Order Retail Inventory When To Reorder Inventory A reorder point is crucial for effective inventory management. The reorder point is important because it helps businesses in. The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent. In simpler words, it's the exact inventory. Calculating inventory reorder points helps with the reduction in inventory cost, reduces. When To Reorder Inventory.

From kb.srimax.com

Stock Reorder Report Stock Reorder Level Obo Inventory Tracking When To Reorder Inventory A reorder point (rop) indicates when it’s time to reorder inventory so you can restock before you sell out completely. The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent. It’s calculated using average daily usage, lead time, and safety. In simpler words, it's the exact inventory. Calculating. When To Reorder Inventory.

From www.deskera.com

What is Inventory Reorder Point in Inventory Management? When To Reorder Inventory It’s calculated using average daily usage, lead time, and safety. It saves holding costs and prevents stockouts, overstocking,. Calculating inventory reorder points helps with the reduction in inventory cost, reduces stockouts, and improves forecasting. The reorder point is the point at which a business needs to reorder inventory to keep up with customer demand. The reorder point is important because. When To Reorder Inventory.

From docs.oracle.com

NetSuite Applications Suite Advanced Inventory Management FAQ When To Reorder Inventory It saves holding costs and prevents stockouts, overstocking,. The reorder point is the point at which a business needs to reorder inventory to keep up with customer demand. A reorder point (rop) indicates when it’s time to reorder inventory so you can restock before you sell out completely. It’s calculated using average daily usage, lead time, and safety. A reorder. When To Reorder Inventory.

From www.excelstemplates.com

Inventory Order Templates 10+ Free MS Docs, Xlsx & PDF Formats When To Reorder Inventory Reorder point is the inventory level at which a company should place a new order to avoid stockouts. The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent. A reorder point (rop) indicates when it’s time to reorder inventory so you can restock before you sell out completely.. When To Reorder Inventory.

From www.accoxi.com

Inventory Reorder Point Accoxi When To Reorder Inventory It saves holding costs and prevents stockouts, overstocking,. The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent. A reorder point is crucial for effective inventory management. The reorder point is important because it helps businesses in. It’s calculated using average daily usage, lead time, and safety. The. When To Reorder Inventory.

From www.slideteam.net

Reorder Point Inventory Management Ppt Powerpoint Presentation Template When To Reorder Inventory The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent. It saves holding costs and prevents stockouts, overstocking,. A reorder point is crucial for effective inventory management. Reorder point is the inventory level at which a company should place a new order to avoid stockouts. The reorder point. When To Reorder Inventory.

From erpnext.com

Inventory management 101 All you need to know from techniques to reporting When To Reorder Inventory The reorder point is important because it helps businesses in. Reorder point is the inventory level at which a company should place a new order to avoid stockouts. It saves holding costs and prevents stockouts, overstocking,. A reorder point (rop) indicates when it’s time to reorder inventory so you can restock before you sell out completely. The reorder level, or. When To Reorder Inventory.

From www.executivpro.com

Inventory to reorder Golden Inventory management System When To Reorder Inventory The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent. Reorder point is the inventory level at which a company should place a new order to avoid stockouts. In simpler words, it's the exact inventory. It’s calculated using average daily usage, lead time, and safety. Calculating inventory reorder. When To Reorder Inventory.

From www.deskera.com

What is Inventory Reorder Point in Inventory Management? When To Reorder Inventory A reorder point is crucial for effective inventory management. The reorder point is important because it helps businesses in. Calculating inventory reorder points helps with the reduction in inventory cost, reduces stockouts, and improves forecasting. It’s calculated using average daily usage, lead time, and safety. It saves holding costs and prevents stockouts, overstocking,. The reorder point is the point at. When To Reorder Inventory.

From forceintellect.com

Reorder Point Optimize Inventory with Reorder Point When To Reorder Inventory The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent. It saves holding costs and prevents stockouts, overstocking,. Calculating inventory reorder points helps with the reduction in inventory cost, reduces stockouts, and improves forecasting. Reorder point is the inventory level at which a company should place a new. When To Reorder Inventory.

From www.eloquens.com

Inventory Valuation, Reorder and Price Trend Template Eloquens When To Reorder Inventory It’s calculated using average daily usage, lead time, and safety. The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent. The reorder point is the point at which a business needs to reorder inventory to keep up with customer demand. Calculating inventory reorder points helps with the reduction. When To Reorder Inventory.

From www.numericalinsights.com

How to Calculate Inventory Reorder Points and Safety Stock Values When To Reorder Inventory The reorder point is important because it helps businesses in. The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent. Calculating inventory reorder points helps with the reduction in inventory cost, reduces stockouts, and improves forecasting. In simpler words, it's the exact inventory. A reorder point (rop) indicates. When To Reorder Inventory.

From www.tranquilbs.com

What is Inventory Reorder Point? Importance of ROP When To Reorder Inventory A reorder point (rop) indicates when it’s time to reorder inventory so you can restock before you sell out completely. Calculating inventory reorder points helps with the reduction in inventory cost, reduces stockouts, and improves forecasting. In simpler words, it's the exact inventory. The reorder point is the point at which a business needs to reorder inventory to keep up. When To Reorder Inventory.

From www.inflowinventory.com

Reorder Point Formula and Safety Stock A Complete Guide When To Reorder Inventory It’s calculated using average daily usage, lead time, and safety. The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent. It saves holding costs and prevents stockouts, overstocking,. Reorder point is the inventory level at which a company should place a new order to avoid stockouts. A reorder. When To Reorder Inventory.

From www.numericalinsights.com

How to Calculate Inventory Reorder Points and Safety Stock Values When To Reorder Inventory A reorder point (rop) indicates when it’s time to reorder inventory so you can restock before you sell out completely. In simpler words, it's the exact inventory. The reorder point is the point at which a business needs to reorder inventory to keep up with customer demand. It saves holding costs and prevents stockouts, overstocking,. The reorder point is important. When To Reorder Inventory.

From www.youtube.com

sale Purchase reorder level formula excel YouTube When To Reorder Inventory Reorder point is the inventory level at which a company should place a new order to avoid stockouts. It saves holding costs and prevents stockouts, overstocking,. Calculating inventory reorder points helps with the reduction in inventory cost, reduces stockouts, and improves forecasting. The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order. When To Reorder Inventory.

From 101businessinsights.com

Inventory Excel List With Reorder Business Insights Group AG When To Reorder Inventory The reorder point is important because it helps businesses in. In simpler words, it's the exact inventory. It’s calculated using average daily usage, lead time, and safety. The reorder point is the point at which a business needs to reorder inventory to keep up with customer demand. The reorder level, or reorder point, is a vital threshold in inventory management. When To Reorder Inventory.

From www.eloquens.com

Inventory List with Reorder Level Eloquens When To Reorder Inventory A reorder point (rop) indicates when it’s time to reorder inventory so you can restock before you sell out completely. The reorder point is the point at which a business needs to reorder inventory to keep up with customer demand. Calculating inventory reorder points helps with the reduction in inventory cost, reduces stockouts, and improves forecasting. It saves holding costs. When To Reorder Inventory.

From www.pinterest.ca

Know When to Reorder Inventory for Stock!Reorder Point Shipping Lead When To Reorder Inventory A reorder point (rop) indicates when it’s time to reorder inventory so you can restock before you sell out completely. In simpler words, it's the exact inventory. It saves holding costs and prevents stockouts, overstocking,. It’s calculated using average daily usage, lead time, and safety. The reorder point is important because it helps businesses in. The reorder level, or reorder. When To Reorder Inventory.

From eswap.global

Reorder Point vs Safety Stock in Inventory Management When To Reorder Inventory In simpler words, it's the exact inventory. Calculating inventory reorder points helps with the reduction in inventory cost, reduces stockouts, and improves forecasting. It’s calculated using average daily usage, lead time, and safety. It saves holding costs and prevents stockouts, overstocking,. A reorder point (rop) indicates when it’s time to reorder inventory so you can restock before you sell out. When To Reorder Inventory.

From vetlogic.co

Using Reorder Tags for Your Inventory When To Reorder Inventory A reorder point is crucial for effective inventory management. The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent. Calculating inventory reorder points helps with the reduction in inventory cost, reduces stockouts, and improves forecasting. Reorder point is the inventory level at which a company should place a. When To Reorder Inventory.

From accountinguide.com

Inventory Control Level Definition Example Accountinguide When To Reorder Inventory It’s calculated using average daily usage, lead time, and safety. Calculating inventory reorder points helps with the reduction in inventory cost, reduces stockouts, and improves forecasting. It saves holding costs and prevents stockouts, overstocking,. The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent. A reorder point is. When To Reorder Inventory.

From exponea.com

How to Solve the Reorder Point Formula Inventory Management Strategy When To Reorder Inventory The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent. Calculating inventory reorder points helps with the reduction in inventory cost, reduces stockouts, and improves forecasting. Reorder point is the inventory level at which a company should place a new order to avoid stockouts. A reorder point (rop). When To Reorder Inventory.

From pubhtml5.com

Importance of Reorder Point in Inventory Management Tranquil Business When To Reorder Inventory Reorder point is the inventory level at which a company should place a new order to avoid stockouts. The reorder point is important because it helps businesses in. A reorder point (rop) indicates when it’s time to reorder inventory so you can restock before you sell out completely. It saves holding costs and prevents stockouts, overstocking,. Calculating inventory reorder points. When To Reorder Inventory.

From lesboucans.com

Inventory Reorder Template For Your Needs When To Reorder Inventory The reorder point is the point at which a business needs to reorder inventory to keep up with customer demand. It’s calculated using average daily usage, lead time, and safety. The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent. The reorder point is important because it helps. When To Reorder Inventory.

From goworkhorse.com

Order Management Order & Inventory Management Workhorse Home When To Reorder Inventory Reorder point is the inventory level at which a company should place a new order to avoid stockouts. A reorder point (rop) indicates when it’s time to reorder inventory so you can restock before you sell out completely. The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to prevent.. When To Reorder Inventory.

From blog.tatanexarc.com

Reorder quantity formula and calculating reorder levels When To Reorder Inventory A reorder point (rop) indicates when it’s time to reorder inventory so you can restock before you sell out completely. In simpler words, it's the exact inventory. It saves holding costs and prevents stockouts, overstocking,. Reorder point is the inventory level at which a company should place a new order to avoid stockouts. The reorder point is important because it. When To Reorder Inventory.

From mungfali.com

Physical Inventory Process Flow Chart When To Reorder Inventory Reorder point is the inventory level at which a company should place a new order to avoid stockouts. The reorder point is important because it helps businesses in. A reorder point (rop) indicates when it’s time to reorder inventory so you can restock before you sell out completely. The reorder point is the point at which a business needs to. When To Reorder Inventory.

From www.numericalinsights.com

How to Calculate Inventory Reorder Points and Safety Stock Values When To Reorder Inventory A reorder point (rop) indicates when it’s time to reorder inventory so you can restock before you sell out completely. It’s calculated using average daily usage, lead time, and safety. Calculating inventory reorder points helps with the reduction in inventory cost, reduces stockouts, and improves forecasting. Reorder point is the inventory level at which a company should place a new. When To Reorder Inventory.

From www.mecalux.com

Reorder point formula how does it affect your warehouse? When To Reorder Inventory The reorder point is the point at which a business needs to reorder inventory to keep up with customer demand. A reorder point is crucial for effective inventory management. The reorder point is important because it helps businesses in. The reorder level, or reorder point, is a vital threshold in inventory management that indicates when to order new stock to. When To Reorder Inventory.