End Mill Depth Of Cut Chart . And axial depth of cut (adoc), the distance a tool engages a workpiece along its centerline, are the backbones of machining. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. Depths of cut (more than.5 x diameter) the lower range of surface speeds (sfm) should be used axial depth of cut:. The radial depth of cut (shown as a e,. Therefore, a typical graph for the cutting forces acting on a solid carbide endmill as a function of time (or rotation angle) is like shown here. 1) select your material in the iso colored chart with respect to material description. The axial depth of cut (shown as a p, below), is also known as “stepdown” or adoc. 2) start with a middle/average value for spindle speed, n. Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. In shoulder millin g there are two depths of cut: The tougher the material the shallower the cut. Every machining operation entails a radial and axial depth of cut strategy.

from hgt.en.taiwantrade.com

2) start with a middle/average value for spindle speed, n. Depths of cut (more than.5 x diameter) the lower range of surface speeds (sfm) should be used axial depth of cut:. Therefore, a typical graph for the cutting forces acting on a solid carbide endmill as a function of time (or rotation angle) is like shown here. Every machining operation entails a radial and axial depth of cut strategy. The radial depth of cut (shown as a e,. In shoulder millin g there are two depths of cut: Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. The axial depth of cut (shown as a p, below), is also known as “stepdown” or adoc. Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece;

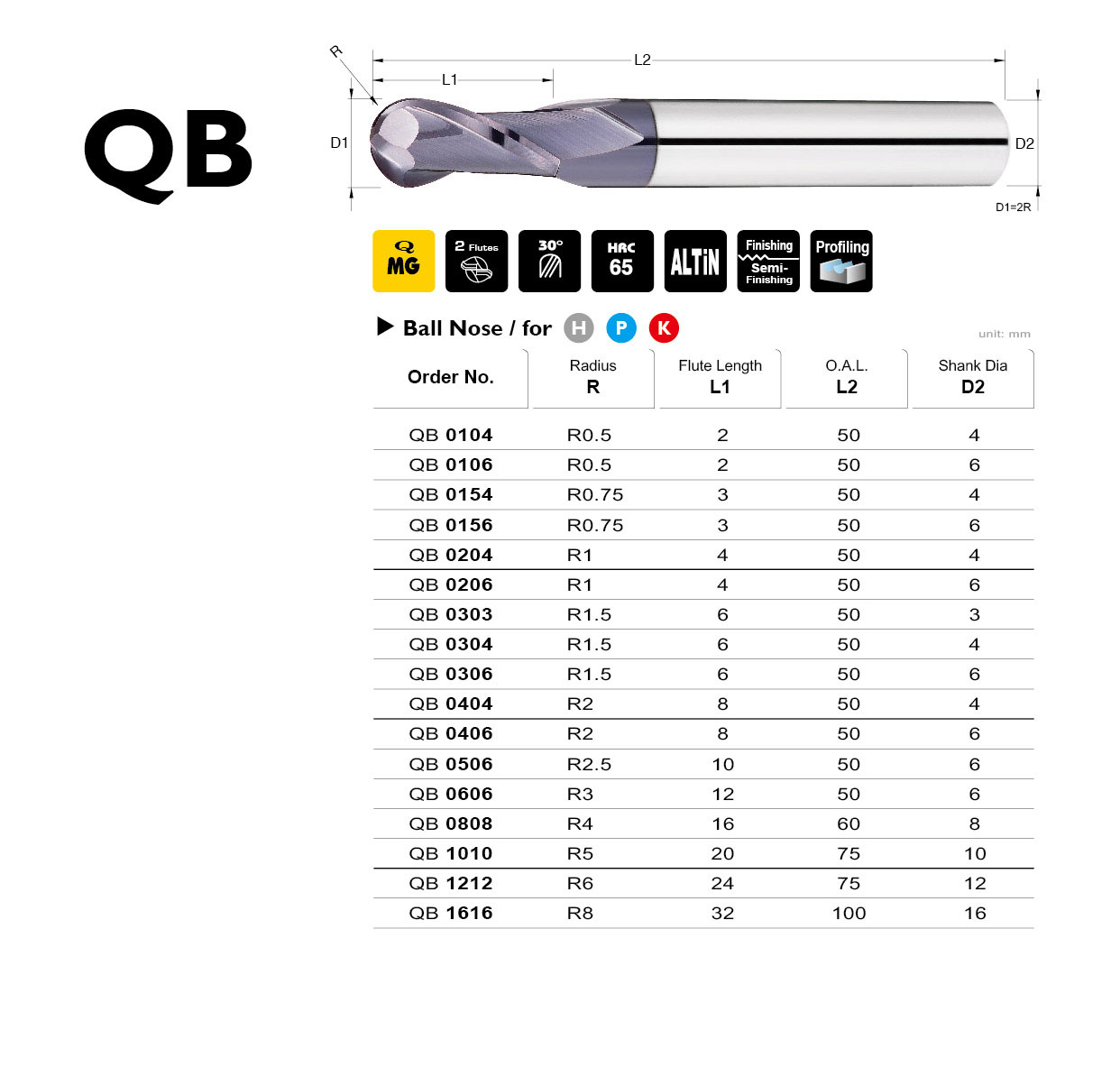

Ball Nose End Mills HG TECHNOLOGY CO., LTD.

End Mill Depth Of Cut Chart Every machining operation entails a radial and axial depth of cut strategy. Every machining operation entails a radial and axial depth of cut strategy. Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; The axial depth of cut (shown as a p, below), is also known as “stepdown” or adoc. In shoulder millin g there are two depths of cut: 1) select your material in the iso colored chart with respect to material description. Therefore, a typical graph for the cutting forces acting on a solid carbide endmill as a function of time (or rotation angle) is like shown here. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. The radial depth of cut (shown as a e,. 2) start with a middle/average value for spindle speed, n. And axial depth of cut (adoc), the distance a tool engages a workpiece along its centerline, are the backbones of machining. Depths of cut (more than.5 x diameter) the lower range of surface speeds (sfm) should be used axial depth of cut:. The tougher the material the shallower the cut. The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc.

From femjoy-virtuagirl-hd-25.blogspot.com

roughing end mill depth of cut Big History Blogger Photography End Mill Depth Of Cut Chart Depths of cut (more than.5 x diameter) the lower range of surface speeds (sfm) should be used axial depth of cut:. The radial depth of cut (shown as a e,. Every machining operation entails a radial and axial depth of cut strategy. And axial depth of cut (adoc), the distance a tool engages a workpiece along its centerline, are the. End Mill Depth Of Cut Chart.

From mellowpine.com

Speeds and Feeds Beginner Guide with Table MellowPine End Mill Depth Of Cut Chart 1) select your material in the iso colored chart with respect to material description. Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; The tougher the material the shallower the cut. Every machining operation entails a radial and axial depth of cut strategy. 2) start with a middle/average value for spindle speed, n. In. End Mill Depth Of Cut Chart.

From www.qualitytechtool.com

Premium Class End Mills Metric Quality Tech Tool End Mill Depth Of Cut Chart Therefore, a typical graph for the cutting forces acting on a solid carbide endmill as a function of time (or rotation angle) is like shown here. The radial depth of cut (shown as a e,. And axial depth of cut (adoc), the distance a tool engages a workpiece along its centerline, are the backbones of machining. Depths of cut (more. End Mill Depth Of Cut Chart.

From www.sainsmart.com

Genmitsu 2Flute Flat Nose Spiral End Mill, 1/8'' Shank, 0.8mm3.175mm End Mill Depth Of Cut Chart Depths of cut (more than.5 x diameter) the lower range of surface speeds (sfm) should be used axial depth of cut:. The axial depth of cut (shown as a p, below), is also known as “stepdown” or adoc. Therefore, a typical graph for the cutting forces acting on a solid carbide endmill as a function of time (or rotation angle). End Mill Depth Of Cut Chart.

From support.bantamtools.com

End Mill Identification Guide Bantam Tools End Mill Depth Of Cut Chart 1) select your material in the iso colored chart with respect to material description. Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; And axial depth of cut (adoc), the distance a tool engages a workpiece along its centerline, are the backbones of machining. Every machining operation entails a radial and axial depth of. End Mill Depth Of Cut Chart.

From mavink.com

Carbide End Mill Speed And Feed Chart End Mill Depth Of Cut Chart 1) select your material in the iso colored chart with respect to material description. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. Every machining operation entails a radial and axial depth of cut strategy. In shoulder millin g there are two depths of cut: The axial. End Mill Depth Of Cut Chart.

From www.alibaba.com

End Mill Cutter Sizes;2flute Flattened End Mills With Straight Shank End Mill Depth Of Cut Chart Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; In shoulder millin g there are two depths of cut: Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. The axial depth of cut (shown as a p, below), is also known. End Mill Depth Of Cut Chart.

From www.speedtigertools.com

End Mill Size Standards Chart & IntroductionSPEED TIGER End Mill Depth Of Cut Chart In shoulder millin g there are two depths of cut: The radial depth of cut (shown as a e,. And axial depth of cut (adoc), the distance a tool engages a workpiece along its centerline, are the backbones of machining. 1) select your material in the iso colored chart with respect to material description. Therefore, a typical graph for the. End Mill Depth Of Cut Chart.

From www.qualitytechtool.com

General Purpose End Mills Metric Quality Tech Tool End Mill Depth Of Cut Chart 1) select your material in the iso colored chart with respect to material description. And axial depth of cut (adoc), the distance a tool engages a workpiece along its centerline, are the backbones of machining. The axial depth of cut (shown as a p, below), is also known as “stepdown” or adoc. Generally, a shallow depth of cut is recommended. End Mill Depth Of Cut Chart.

From endmill.com.au

Choosing the right end mill for the job Adam's Bits End Mill Depth Of Cut Chart Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. The radial depth of cut (shown as a e,. And axial depth of cut (adoc), the distance a tool engages a workpiece along its centerline, are the backbones of machining. Every machining operation entails a radial and axial. End Mill Depth Of Cut Chart.

From us.misumi-ec.com

Milling Tips / Holders Ball End Mills Technical Information Tools End Mill Depth Of Cut Chart Depths of cut (more than.5 x diameter) the lower range of surface speeds (sfm) should be used axial depth of cut:. 1) select your material in the iso colored chart with respect to material description. 2) start with a middle/average value for spindle speed, n. The axial depth of cut (shown as a p, below), is also known as “stepdown”. End Mill Depth Of Cut Chart.

From toolnotes.com

End Mills ToolNotes End Mill Depth Of Cut Chart 2) start with a middle/average value for spindle speed, n. The radial depth of cut (shown as a e,. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. Every machining operation entails a radial and axial depth of cut strategy. Therefore, a typical graph for the cutting. End Mill Depth Of Cut Chart.

From mungfali.com

End Mill Cutting Chart End Mill Depth Of Cut Chart The axial depth of cut (shown as a p, below), is also known as “stepdown” or adoc. The radial depth of cut (shown as a e,. Every machining operation entails a radial and axial depth of cut strategy. Therefore, a typical graph for the cutting forces acting on a solid carbide endmill as a function of time (or rotation angle). End Mill Depth Of Cut Chart.

From www.cnccookbook.com

Ball Nose End Mill [Easy Guide to Ball Cutters] CNCCookbook Be A End Mill Depth Of Cut Chart The radial depth of cut (shown as a e,. 2) start with a middle/average value for spindle speed, n. The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. The tougher the material the shallower the cut. The axial depth of cut (shown as. End Mill Depth Of Cut Chart.

From darrylbjoneso.blob.core.windows.net

Metal Lathe Cutting Speed Chart Metric at darrylbjoneso blog End Mill Depth Of Cut Chart The radial depth of cut (shown as a e,. The axial depth of cut (shown as a p, below), is also known as “stepdown” or adoc. The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. Every machining operation entails a radial and axial. End Mill Depth Of Cut Chart.

From www.qualitytechtool.com

General Purpose End Mills Inch Quality Tech Tool End Mill Depth Of Cut Chart In shoulder millin g there are two depths of cut: The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. The axial. End Mill Depth Of Cut Chart.

From www.mscdirect.com

9 MustKnow Milling Types Better MRO End Mill Depth Of Cut Chart In shoulder millin g there are two depths of cut: Every machining operation entails a radial and axial depth of cut strategy. 1) select your material in the iso colored chart with respect to material description. The radial depth of cut (shown as a e,. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth. End Mill Depth Of Cut Chart.

From www.carbideanddiamondtooling.com

0.4 x 4 x 0.3(1.2) x 50 CBN Cubic Boron Nitride 2 Flute Ball Nose End End Mill Depth Of Cut Chart 2) start with a middle/average value for spindle speed, n. Every machining operation entails a radial and axial depth of cut strategy. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. The optimal depth of cut for a machining process depends upon various factors such as type. End Mill Depth Of Cut Chart.

From www.mmc-carbide.com

End Mill Terminology Technical Info / Cutting Formula MITSUBISHI End Mill Depth Of Cut Chart In shoulder millin g there are two depths of cut: Therefore, a typical graph for the cutting forces acting on a solid carbide endmill as a function of time (or rotation angle) is like shown here. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. Depths of. End Mill Depth Of Cut Chart.

From www.harveyperformance.com

The Anatomy of an End Mill In The Loupe Machinist Blog End Mill Depth Of Cut Chart And axial depth of cut (adoc), the distance a tool engages a workpiece along its centerline, are the backbones of machining. The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. 2) start with a middle/average value for spindle speed, n. The radial depth. End Mill Depth Of Cut Chart.

From www.researchgate.net

Discretization of the ballend mill cutting edge (a), scheme of cutting End Mill Depth Of Cut Chart The radial depth of cut (shown as a e,. The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. The tougher the material the shallower the cut. Therefore, a typical graph for the cutting forces acting on a solid carbide endmill as a function. End Mill Depth Of Cut Chart.

From www.peaktoolworks.com

Standard Length Endmills (Ball End) Peak Toolworks End Mill Depth Of Cut Chart The axial depth of cut (shown as a p, below), is also known as “stepdown” or adoc. And axial depth of cut (adoc), the distance a tool engages a workpiece along its centerline, are the backbones of machining. The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type. End Mill Depth Of Cut Chart.

From www.minaprem.com

What is Depth of Cut in Machining? Its Unit, Value, Effects and Selection End Mill Depth Of Cut Chart Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; The axial depth of cut (shown as a p, below), is also known as “stepdown” or adoc. And axial depth of cut (adoc), the distance a tool engages a workpiece along its centerline, are the backbones of machining. 1) select your material in the iso. End Mill Depth Of Cut Chart.

From mathscinotes.com

Circular Saw DepthOfCut Formula Math Encounters Blog End Mill Depth Of Cut Chart The tougher the material the shallower the cut. Depths of cut (more than.5 x diameter) the lower range of surface speeds (sfm) should be used axial depth of cut:. The radial depth of cut (shown as a e,. In shoulder millin g there are two depths of cut: The optimal depth of cut for a machining process depends upon various. End Mill Depth Of Cut Chart.

From enginemechanics.tpub.com

Figure 735.End mill terms. End Mill Depth Of Cut Chart 1) select your material in the iso colored chart with respect to material description. The radial depth of cut (shown as a e,. The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. Every machining operation entails a radial and axial depth of cut. End Mill Depth Of Cut Chart.

From hgt.en.taiwantrade.com

Ball Nose End Mills HG TECHNOLOGY CO., LTD. End Mill Depth Of Cut Chart Every machining operation entails a radial and axial depth of cut strategy. The radial depth of cut (shown as a e,. The axial depth of cut (shown as a p, below), is also known as “stepdown” or adoc. Therefore, a typical graph for the cutting forces acting on a solid carbide endmill as a function of time (or rotation angle). End Mill Depth Of Cut Chart.

From www.youtube.com

Speeds Feeds and Depth of Cut for Milling YouTube End Mill Depth Of Cut Chart In shoulder millin g there are two depths of cut: The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. Depths of cut (more than.5 x diameter) the lower range of surface speeds (sfm) should be used axial depth of cut:. Radial depth of. End Mill Depth Of Cut Chart.

From www.davehylands.com

Charts End Mill Depth Of Cut Chart The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. 1) select your material in the iso colored chart with respect to material description. Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; The axial depth of cut. End Mill Depth Of Cut Chart.

From nelsontheraingaid.blogspot.com

Difference Between Feed Rate and Depth of Cut Nelson Theraingaid End Mill Depth Of Cut Chart Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. The radial depth of cut (shown as a e,. 1) select your. End Mill Depth Of Cut Chart.

From www.qualitytechtool.com

General Purpose End Mills Inch Quality Tech Tool End Mill Depth Of Cut Chart The radial depth of cut (shown as a e,. Every machining operation entails a radial and axial depth of cut strategy. 2) start with a middle/average value for spindle speed, n. The tougher the material the shallower the cut. Therefore, a typical graph for the cutting forces acting on a solid carbide endmill as a function of time (or rotation. End Mill Depth Of Cut Chart.

From toolnotes.com

Cutting Parameters for Milling ToolNotes End Mill Depth Of Cut Chart The tougher the material the shallower the cut. 1) select your material in the iso colored chart with respect to material description. Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; In shoulder millin g there are two depths of cut: The axial depth of cut (shown as a p, below), is also known. End Mill Depth Of Cut Chart.

From mavink.com

Standard End Mill Sizes Chart End Mill Depth Of Cut Chart The tougher the material the shallower the cut. In shoulder millin g there are two depths of cut: And axial depth of cut (adoc), the distance a tool engages a workpiece along its centerline, are the backbones of machining. The axial depth of cut (shown as a p, below), is also known as “stepdown” or adoc. Therefore, a typical graph. End Mill Depth Of Cut Chart.

From www.redlinetools.com

Endmill Selection Guide RedLine Tools Redline Tools End Mill Depth Of Cut Chart The radial depth of cut (shown as a e,. Every machining operation entails a radial and axial depth of cut strategy. The tougher the material the shallower the cut. The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. The axial depth of cut. End Mill Depth Of Cut Chart.

From www.qualitytechtool.com

Premium Class End Mills Metric Quality Tech Tool End Mill Depth Of Cut Chart Radial depth of cut (rdoc), the distance a tool is stepping over into a workpiece; The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. Every machining operation entails a radial and axial depth of cut strategy. The tougher the material the shallower the. End Mill Depth Of Cut Chart.

From mungfali.com

End Mill Speed And Feed Chart End Mill Depth Of Cut Chart Every machining operation entails a radial and axial depth of cut strategy. The optimal depth of cut for a machining process depends upon various factors such as type of material, type of endmill, type of machining operation, etc. The tougher the material the shallower the cut. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater. End Mill Depth Of Cut Chart.