Wire Rope Sling Capacity Calculation Formula . First, divide the total load to. d/d ratio is the ratio of the diameter around which the sling is bent divided by the body diameter of the sling (figure 4). This ratio has an effect on the rated capacity. how much the lifting capacity is affected can be calculated by dividing the diameter of the bend where the rope contacts the load. proceed as follows to calculate this load—and determine the rated capacity required of the sling, or slings, needed for a lift: the rated capacity is based both on sling fabrication components (minimum breaking force of rope used, splicing efciency, number. this comprehensive guide equips you with the knowledge needed to calculate the safe working load of wire rope slings. Click the “calculate” button, and the calculator will determine the safe working load (swl) for your wire rope. the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope used.

from pms-ind.com

First, divide the total load to. This ratio has an effect on the rated capacity. proceed as follows to calculate this load—and determine the rated capacity required of the sling, or slings, needed for a lift: Click the “calculate” button, and the calculator will determine the safe working load (swl) for your wire rope. the rated capacity is based both on sling fabrication components (minimum breaking force of rope used, splicing efciency, number. this comprehensive guide equips you with the knowledge needed to calculate the safe working load of wire rope slings. the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope used. how much the lifting capacity is affected can be calculated by dividing the diameter of the bend where the rope contacts the load. d/d ratio is the ratio of the diameter around which the sling is bent divided by the body diameter of the sling (figure 4).

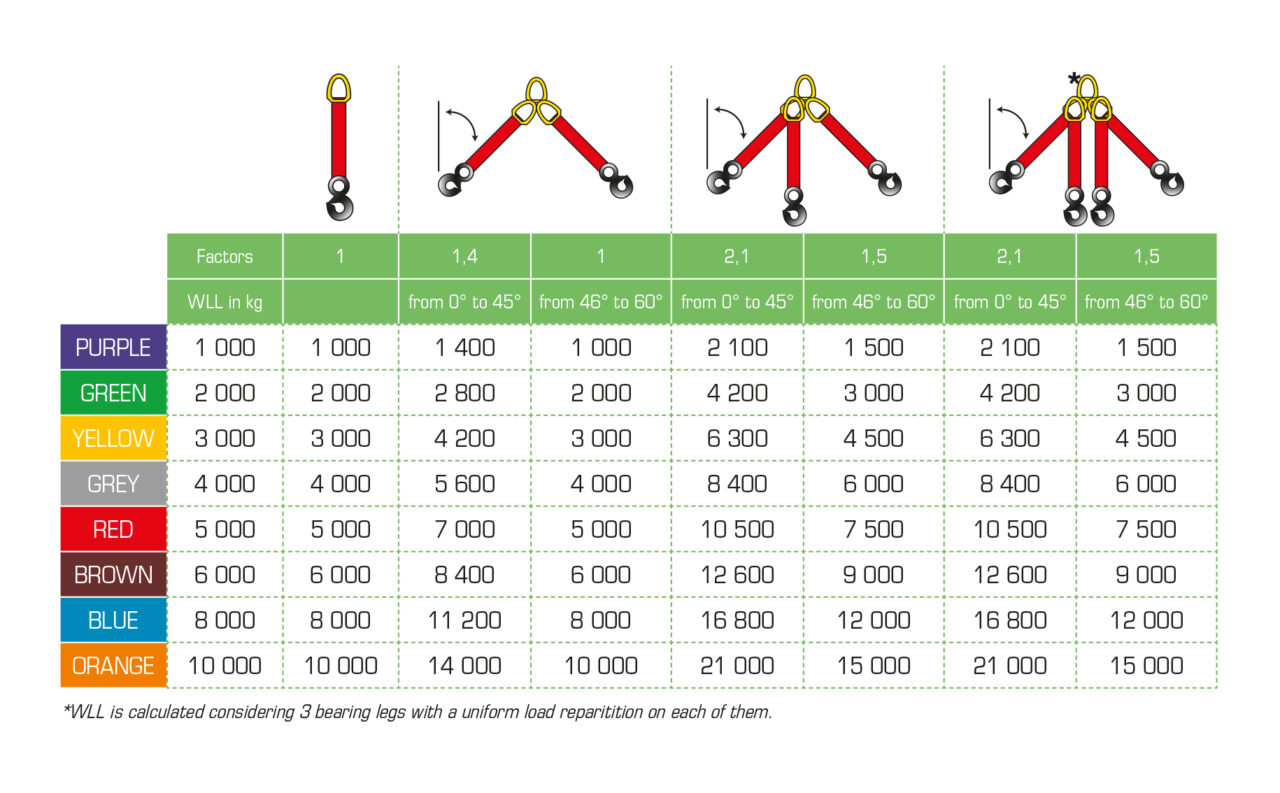

Load configuration chart for textile slings

Wire Rope Sling Capacity Calculation Formula First, divide the total load to. proceed as follows to calculate this load—and determine the rated capacity required of the sling, or slings, needed for a lift: how much the lifting capacity is affected can be calculated by dividing the diameter of the bend where the rope contacts the load. this comprehensive guide equips you with the knowledge needed to calculate the safe working load of wire rope slings. First, divide the total load to. This ratio has an effect on the rated capacity. the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope used. d/d ratio is the ratio of the diameter around which the sling is bent divided by the body diameter of the sling (figure 4). the rated capacity is based both on sling fabrication components (minimum breaking force of rope used, splicing efciency, number. Click the “calculate” button, and the calculator will determine the safe working load (swl) for your wire rope.

From www.mazzellacompanies.com

Mazzella 7Part™ Wire Rope Slings and Sling Assemblies Wire Rope Sling Capacity Calculation Formula this comprehensive guide equips you with the knowledge needed to calculate the safe working load of wire rope slings. d/d ratio is the ratio of the diameter around which the sling is bent divided by the body diameter of the sling (figure 4). the rated capacity is based both on sling fabrication components (minimum breaking force of. Wire Rope Sling Capacity Calculation Formula.

From www.youtube.com

Calculation of safe working load of wire Rope sling YouTube Wire Rope Sling Capacity Calculation Formula the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope used. proceed as follows to calculate this load—and determine the rated capacity required of the sling, or slings, needed for a lift: This ratio has an effect on the rated capacity. how much the lifting capacity is. Wire Rope Sling Capacity Calculation Formula.

From www.hsestudyguide.com

How to Calculate SWL of Wire Rope Sling HSE STUDY GUIDE Wire Rope Sling Capacity Calculation Formula This ratio has an effect on the rated capacity. d/d ratio is the ratio of the diameter around which the sling is bent divided by the body diameter of the sling (figure 4). First, divide the total load to. the rated capacity is based both on sling fabrication components (minimum breaking force of rope used, splicing efciency, number.. Wire Rope Sling Capacity Calculation Formula.

From design.udlvirtual.edu.pe

Wire Rope Sling Capacity Formula Design Talk Wire Rope Sling Capacity Calculation Formula the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope used. Click the “calculate” button, and the calculator will determine the safe working load (swl) for your wire rope. This ratio has an effect on the rated capacity. proceed as follows to calculate this load—and determine the rated. Wire Rope Sling Capacity Calculation Formula.

From www.ehsdb.com

Sling Wire rope sling Wire Rope Sling Capacity Calculation Formula this comprehensive guide equips you with the knowledge needed to calculate the safe working load of wire rope slings. proceed as follows to calculate this load—and determine the rated capacity required of the sling, or slings, needed for a lift: the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of. Wire Rope Sling Capacity Calculation Formula.

From shaws.co.nz

Resources Technical Guides Wire Rope Lifting Sling Guide Wire Rope Sling Capacity Calculation Formula the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope used. First, divide the total load to. how much the lifting capacity is affected can be calculated by dividing the diameter of the bend where the rope contacts the load. proceed as follows to calculate this load—and. Wire Rope Sling Capacity Calculation Formula.

From theriggersloft.com.au

Resources/Downloads The Riggers Loft Wire Rope Sling Capacity Calculation Formula d/d ratio is the ratio of the diameter around which the sling is bent divided by the body diameter of the sling (figure 4). the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope used. the rated capacity is based both on sling fabrication components (minimum breaking. Wire Rope Sling Capacity Calculation Formula.

From rentlgh.com

What is the D/d ratio? Explained LGH Wire Rope Sling Capacity Calculation Formula This ratio has an effect on the rated capacity. the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope used. d/d ratio is the ratio of the diameter around which the sling is bent divided by the body diameter of the sling (figure 4). the rated capacity. Wire Rope Sling Capacity Calculation Formula.

From www.youtube.com

How To Calculate SWL of Wire Rope Sling Wire Rope Sling Capacity Wire Rope Sling Capacity Calculation Formula Click the “calculate” button, and the calculator will determine the safe working load (swl) for your wire rope. First, divide the total load to. this comprehensive guide equips you with the knowledge needed to calculate the safe working load of wire rope slings. d/d ratio is the ratio of the diameter around which the sling is bent divided. Wire Rope Sling Capacity Calculation Formula.

From mungfali.com

Wire Rope Sling Capacity Chart Wire Rope Sling Capacity Calculation Formula Click the “calculate” button, and the calculator will determine the safe working load (swl) for your wire rope. This ratio has an effect on the rated capacity. the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope used. d/d ratio is the ratio of the diameter around which. Wire Rope Sling Capacity Calculation Formula.

From rentlgh.com

Effect of Angles on Sling Capacities LGH Rigging Safety Wire Rope Sling Capacity Calculation Formula First, divide the total load to. the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope used. This ratio has an effect on the rated capacity. the rated capacity is based both on sling fabrication components (minimum breaking force of rope used, splicing efciency, number. how much. Wire Rope Sling Capacity Calculation Formula.

From www.youtube.com

Wire Rope Sling Calculation Wire Rope Sling Load Capacity How To Wire Rope Sling Capacity Calculation Formula Click the “calculate” button, and the calculator will determine the safe working load (swl) for your wire rope. d/d ratio is the ratio of the diameter around which the sling is bent divided by the body diameter of the sling (figure 4). this comprehensive guide equips you with the knowledge needed to calculate the safe working load of. Wire Rope Sling Capacity Calculation Formula.

From www.youtube.com

How To Calculate SWL of Wire Rope Sling Wire Rope Sling Capacity (mm Wire Rope Sling Capacity Calculation Formula this comprehensive guide equips you with the knowledge needed to calculate the safe working load of wire rope slings. the rated capacity is based both on sling fabrication components (minimum breaking force of rope used, splicing efciency, number. proceed as follows to calculate this load—and determine the rated capacity required of the sling, or slings, needed for. Wire Rope Sling Capacity Calculation Formula.

From www.ehsdb.com

Sling Wire rope sling Wire Rope Sling Capacity Calculation Formula this comprehensive guide equips you with the knowledge needed to calculate the safe working load of wire rope slings. the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope used. First, divide the total load to. This ratio has an effect on the rated capacity. Click the “calculate”. Wire Rope Sling Capacity Calculation Formula.

From mungfali.com

Wire Rope Sling Capacity Chart Wire Rope Sling Capacity Calculation Formula the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope used. This ratio has an effect on the rated capacity. how much the lifting capacity is affected can be calculated by dividing the diameter of the bend where the rope contacts the load. Click the “calculate” button, and. Wire Rope Sling Capacity Calculation Formula.

From www.youtube.com

Wire Rope Sling Explained with SWL Loading capacity formula Wirerope Wire Rope Sling Capacity Calculation Formula First, divide the total load to. the rated capacity is based both on sling fabrication components (minimum breaking force of rope used, splicing efciency, number. how much the lifting capacity is affected can be calculated by dividing the diameter of the bend where the rope contacts the load. Click the “calculate” button, and the calculator will determine the. Wire Rope Sling Capacity Calculation Formula.

From bceweb.org

Wire Rope Sling Chart A Visual Reference of Charts Chart Master Wire Rope Sling Capacity Calculation Formula proceed as follows to calculate this load—and determine the rated capacity required of the sling, or slings, needed for a lift: First, divide the total load to. Click the “calculate” button, and the calculator will determine the safe working load (swl) for your wire rope. how much the lifting capacity is affected can be calculated by dividing the. Wire Rope Sling Capacity Calculation Formula.

From www.ehsdb.com

Sling Wire rope sling Wire Rope Sling Capacity Calculation Formula the rated capacity is based both on sling fabrication components (minimum breaking force of rope used, splicing efciency, number. how much the lifting capacity is affected can be calculated by dividing the diameter of the bend where the rope contacts the load. This ratio has an effect on the rated capacity. First, divide the total load to. . Wire Rope Sling Capacity Calculation Formula.

From www.facebook.com

HSE Integro Slings Load Calculation Textile Slings... Wire Rope Sling Capacity Calculation Formula the rated capacity is based both on sling fabrication components (minimum breaking force of rope used, splicing efciency, number. this comprehensive guide equips you with the knowledge needed to calculate the safe working load of wire rope slings. First, divide the total load to. This ratio has an effect on the rated capacity. the rated capacity of. Wire Rope Sling Capacity Calculation Formula.

From www.scribd.com

Understanding Wire Rope Slings An InDepth Guide to Nominal Strength Wire Rope Sling Capacity Calculation Formula how much the lifting capacity is affected can be calculated by dividing the diameter of the bend where the rope contacts the load. the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope used. Click the “calculate” button, and the calculator will determine the safe working load (swl). Wire Rope Sling Capacity Calculation Formula.

From www.engineeringtoolbox.com

Wire Rope Slings Wire Rope Sling Capacity Calculation Formula this comprehensive guide equips you with the knowledge needed to calculate the safe working load of wire rope slings. the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope used. the rated capacity is based both on sling fabrication components (minimum breaking force of rope used, splicing. Wire Rope Sling Capacity Calculation Formula.

From www.youtube.com

Wire rope sling load capacity calculation YouTube Wire Rope Sling Capacity Calculation Formula this comprehensive guide equips you with the knowledge needed to calculate the safe working load of wire rope slings. d/d ratio is the ratio of the diameter around which the sling is bent divided by the body diameter of the sling (figure 4). how much the lifting capacity is affected can be calculated by dividing the diameter. Wire Rope Sling Capacity Calculation Formula.

From pms-ind.com

Load configuration chart for textile slings Wire Rope Sling Capacity Calculation Formula the rated capacity is based both on sling fabrication components (minimum breaking force of rope used, splicing efciency, number. the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope used. d/d ratio is the ratio of the diameter around which the sling is bent divided by the. Wire Rope Sling Capacity Calculation Formula.

From www.engineeringtoolbox.com

Wire Rope Slings Wire Rope Sling Capacity Calculation Formula how much the lifting capacity is affected can be calculated by dividing the diameter of the bend where the rope contacts the load. First, divide the total load to. This ratio has an effect on the rated capacity. d/d ratio is the ratio of the diameter around which the sling is bent divided by the body diameter of. Wire Rope Sling Capacity Calculation Formula.

From twaylifting.com

Tway 1/2" Eye & Eye Wire Rope Sling Wire Rope Sling Capacity Calculation Formula d/d ratio is the ratio of the diameter around which the sling is bent divided by the body diameter of the sling (figure 4). First, divide the total load to. proceed as follows to calculate this load—and determine the rated capacity required of the sling, or slings, needed for a lift: this comprehensive guide equips you with. Wire Rope Sling Capacity Calculation Formula.

From gabrielbruce.z19.web.core.windows.net

Wire Rope Sling Capacity Chart Wire Rope Sling Capacity Calculation Formula how much the lifting capacity is affected can be calculated by dividing the diameter of the bend where the rope contacts the load. proceed as follows to calculate this load—and determine the rated capacity required of the sling, or slings, needed for a lift: First, divide the total load to. This ratio has an effect on the rated. Wire Rope Sling Capacity Calculation Formula.

From www.scribd.com

wireropeslingcapacitychart.pdf Wire Rope Sling Capacity Calculation Formula the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope used. proceed as follows to calculate this load—and determine the rated capacity required of the sling, or slings, needed for a lift: the rated capacity is based both on sling fabrication components (minimum breaking force of rope. Wire Rope Sling Capacity Calculation Formula.

From www.youtube.com

How to calculate sling capacity or tension during lifting of material Wire Rope Sling Capacity Calculation Formula Click the “calculate” button, and the calculator will determine the safe working load (swl) for your wire rope. d/d ratio is the ratio of the diameter around which the sling is bent divided by the body diameter of the sling (figure 4). the rated capacity is based both on sling fabrication components (minimum breaking force of rope used,. Wire Rope Sling Capacity Calculation Formula.

From allrigging.com

Wire Rope Sling Capacities All Rigging Co. Rigging Equipment Wire Rope Sling Capacity Calculation Formula this comprehensive guide equips you with the knowledge needed to calculate the safe working load of wire rope slings. First, divide the total load to. This ratio has an effect on the rated capacity. proceed as follows to calculate this load—and determine the rated capacity required of the sling, or slings, needed for a lift: the rated. Wire Rope Sling Capacity Calculation Formula.

From cepfadjb.blob.core.windows.net

Steel Wire Rope Sling Lifting Capacity Calculation at Faith Wilson blog Wire Rope Sling Capacity Calculation Formula First, divide the total load to. how much the lifting capacity is affected can be calculated by dividing the diameter of the bend where the rope contacts the load. proceed as follows to calculate this load—and determine the rated capacity required of the sling, or slings, needed for a lift: this comprehensive guide equips you with the. Wire Rope Sling Capacity Calculation Formula.

From www.teci.it

TECI WIRE ROPE SLINGS Wire Rope Sling Capacity Calculation Formula proceed as follows to calculate this load—and determine the rated capacity required of the sling, or slings, needed for a lift: the rated capacity is based both on sling fabrication components (minimum breaking force of rope used, splicing efciency, number. First, divide the total load to. This ratio has an effect on the rated capacity. this comprehensive. Wire Rope Sling Capacity Calculation Formula.

From cepfadjb.blob.core.windows.net

Steel Wire Rope Sling Lifting Capacity Calculation at Faith Wilson blog Wire Rope Sling Capacity Calculation Formula how much the lifting capacity is affected can be calculated by dividing the diameter of the bend where the rope contacts the load. Click the “calculate” button, and the calculator will determine the safe working load (swl) for your wire rope. This ratio has an effect on the rated capacity. proceed as follows to calculate this load—and determine. Wire Rope Sling Capacity Calculation Formula.

From www.scribd.com

WireRopeSlingCapacityCharts.pdf Rope Wire Wire Rope Sling Capacity Calculation Formula proceed as follows to calculate this load—and determine the rated capacity required of the sling, or slings, needed for a lift: this comprehensive guide equips you with the knowledge needed to calculate the safe working load of wire rope slings. d/d ratio is the ratio of the diameter around which the sling is bent divided by the. Wire Rope Sling Capacity Calculation Formula.

From dxohitwhn.blob.core.windows.net

Lifting Wire Rope Calculation at Federico blog Wire Rope Sling Capacity Calculation Formula Click the “calculate” button, and the calculator will determine the safe working load (swl) for your wire rope. proceed as follows to calculate this load—and determine the rated capacity required of the sling, or slings, needed for a lift: This ratio has an effect on the rated capacity. this comprehensive guide equips you with the knowledge needed to. Wire Rope Sling Capacity Calculation Formula.

From allrigging.com

Wire Rope Sling Capacities All Rigging Co. Rigging Equipment Wire Rope Sling Capacity Calculation Formula Click the “calculate” button, and the calculator will determine the safe working load (swl) for your wire rope. First, divide the total load to. proceed as follows to calculate this load—and determine the rated capacity required of the sling, or slings, needed for a lift: this comprehensive guide equips you with the knowledge needed to calculate the safe. Wire Rope Sling Capacity Calculation Formula.