Blind Hole Edm . blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. This paper presents a new approach for effective self. in micro edm, the electrode size is too small for internal flushing. The main difficulty found was the evacuation of the. the aim of this study is to use us vibration in order to enhance the performance of the edm process during the machining of. the presented case study is a horizontal blind hole with an external diameter of 1 mm and an aspect ratio of 14. During the electrical discharge machining (edm) process, the tool electrode wear is inevitable, which affects. electrical discharge drilling of blind holes has been a challenging task due to the inherent difficulties in removing debris.

from www.youtube.com

electrical discharge drilling of blind holes has been a challenging task due to the inherent difficulties in removing debris. blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. During the electrical discharge machining (edm) process, the tool electrode wear is inevitable, which affects. the aim of this study is to use us vibration in order to enhance the performance of the edm process during the machining of. The main difficulty found was the evacuation of the. This paper presents a new approach for effective self. in micro edm, the electrode size is too small for internal flushing. the presented case study is a horizontal blind hole with an external diameter of 1 mm and an aspect ratio of 14.

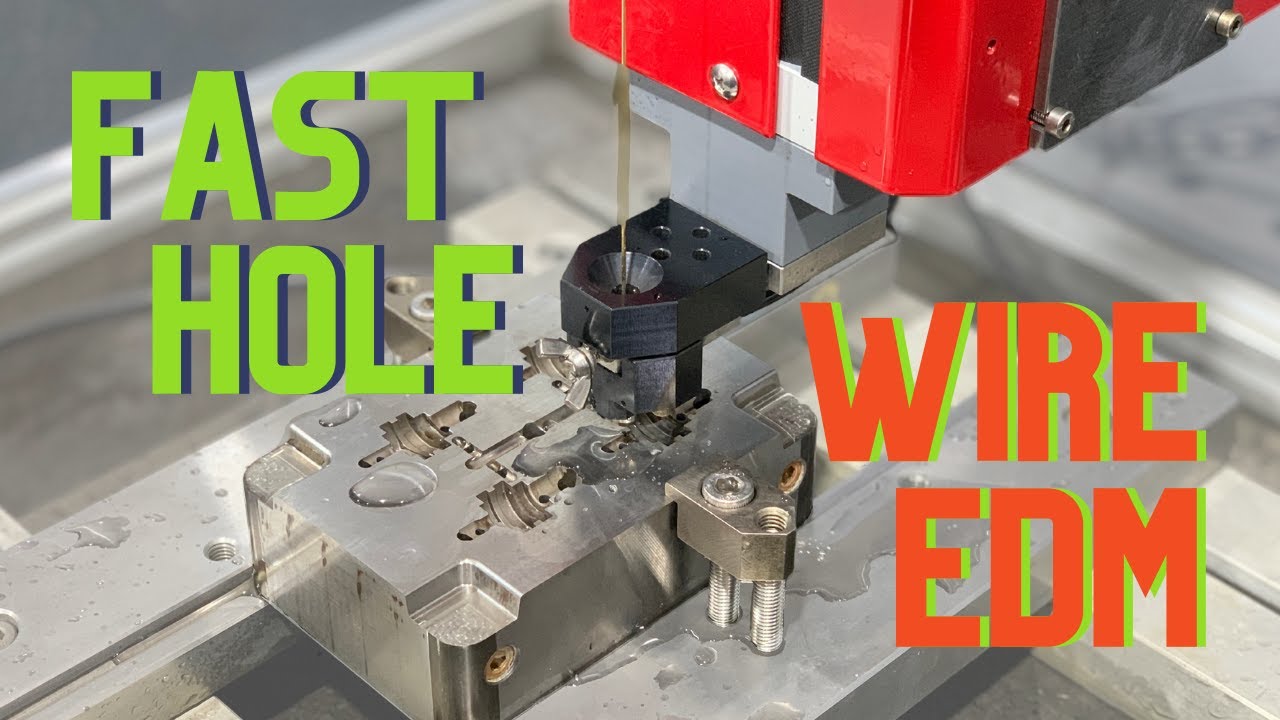

Fast Hole and Wire EDM Learn to Burn YouTube

Blind Hole Edm the presented case study is a horizontal blind hole with an external diameter of 1 mm and an aspect ratio of 14. the aim of this study is to use us vibration in order to enhance the performance of the edm process during the machining of. The main difficulty found was the evacuation of the. the presented case study is a horizontal blind hole with an external diameter of 1 mm and an aspect ratio of 14. electrical discharge drilling of blind holes has been a challenging task due to the inherent difficulties in removing debris. in micro edm, the electrode size is too small for internal flushing. blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. This paper presents a new approach for effective self. During the electrical discharge machining (edm) process, the tool electrode wear is inevitable, which affects.

From www.milcowireedm.com

MILCO Wire EDM Small Hole EDM Small Hole Drilling EDM Hole Burning Blind Hole Edm in micro edm, the electrode size is too small for internal flushing. During the electrical discharge machining (edm) process, the tool electrode wear is inevitable, which affects. blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. This paper presents a new approach for effective self. the aim of. Blind Hole Edm.

From www.xometry.com

All About Hole Drill EDM Machining Definition and Applications Xometry Blind Hole Edm blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. the aim of this study is to use us vibration in order to enhance the performance of the edm process during the machining of. During the electrical discharge machining (edm) process, the tool electrode wear is inevitable, which affects. This. Blind Hole Edm.

From www.youtube.com

Fast Hole and Wire EDM Learn to Burn YouTube Blind Hole Edm During the electrical discharge machining (edm) process, the tool electrode wear is inevitable, which affects. blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. the presented case study is a horizontal blind hole with an external diameter of 1 mm and an aspect ratio of 14. electrical discharge. Blind Hole Edm.

From www.edmdept.com

Precision Hole Drilling EDM Hole Drilling EDMIS Blind Hole Edm blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. During the electrical discharge machining (edm) process, the tool electrode wear is inevitable, which affects. electrical discharge drilling of blind holes has been a challenging task due to the inherent difficulties in removing debris. in micro edm, the electrode. Blind Hole Edm.

From www.researchgate.net

SEM image of a sectioned EDM hole, showing a typical microEDM surface Blind Hole Edm The main difficulty found was the evacuation of the. During the electrical discharge machining (edm) process, the tool electrode wear is inevitable, which affects. in micro edm, the electrode size is too small for internal flushing. electrical discharge drilling of blind holes has been a challenging task due to the inherent difficulties in removing debris. blind hole. Blind Hole Edm.

From www.degruyter.com

Improving the precision of microEDM for blind holes in titanium alloy Blind Hole Edm During the electrical discharge machining (edm) process, the tool electrode wear is inevitable, which affects. blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. in micro edm, the electrode size is too small for internal flushing. the aim of this study is to use us vibration in order. Blind Hole Edm.

From www.degruyter.com

Improving the precision of microEDM for blind holes in titanium alloy Blind Hole Edm the aim of this study is to use us vibration in order to enhance the performance of the edm process during the machining of. This paper presents a new approach for effective self. The main difficulty found was the evacuation of the. electrical discharge drilling of blind holes has been a challenging task due to the inherent difficulties. Blind Hole Edm.

From www.edmdept.com

Precision Hole Drilling EDM Hole Drilling EDMIS Blind Hole Edm This paper presents a new approach for effective self. the aim of this study is to use us vibration in order to enhance the performance of the edm process during the machining of. blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. in micro edm, the electrode size. Blind Hole Edm.

From edmtechman.com

Poco EDM Technical Manual Blind Hole Edm The main difficulty found was the evacuation of the. This paper presents a new approach for effective self. electrical discharge drilling of blind holes has been a challenging task due to the inherent difficulties in removing debris. the presented case study is a horizontal blind hole with an external diameter of 1 mm and an aspect ratio of. Blind Hole Edm.

From www.youtube.com

4 tips for perfect blind hole threads! YouTube Blind Hole Edm The main difficulty found was the evacuation of the. This paper presents a new approach for effective self. the aim of this study is to use us vibration in order to enhance the performance of the edm process during the machining of. in micro edm, the electrode size is too small for internal flushing. the presented case. Blind Hole Edm.

From www.researchgate.net

Drilling process (a) blind holes (b) through holes [10]. Download Blind Hole Edm the presented case study is a horizontal blind hole with an external diameter of 1 mm and an aspect ratio of 14. electrical discharge drilling of blind holes has been a challenging task due to the inherent difficulties in removing debris. This paper presents a new approach for effective self. During the electrical discharge machining (edm) process, the. Blind Hole Edm.

From www.degruyter.com

Improving the precision of microEDM for blind holes in titanium alloy Blind Hole Edm in micro edm, the electrode size is too small for internal flushing. This paper presents a new approach for effective self. blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. the aim of this study is to use us vibration in order to enhance the performance of the. Blind Hole Edm.

From www-degruyter-com.ezproxy.library.qmul.ac.uk

Improving the precision of microEDM for blind holes in titanium alloy Blind Hole Edm electrical discharge drilling of blind holes has been a challenging task due to the inherent difficulties in removing debris. the aim of this study is to use us vibration in order to enhance the performance of the edm process during the machining of. The main difficulty found was the evacuation of the. the presented case study is. Blind Hole Edm.

From www.iqsdirectory.com

Sinker EDM Components, Types, Applications, and Advantages Blind Hole Edm During the electrical discharge machining (edm) process, the tool electrode wear is inevitable, which affects. The main difficulty found was the evacuation of the. blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. This paper presents a new approach for effective self. the aim of this study is to. Blind Hole Edm.

From www.youtube.com

EDM Precision Technologies Fast Hole Drilling YouTube Blind Hole Edm the aim of this study is to use us vibration in order to enhance the performance of the edm process during the machining of. blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. The main difficulty found was the evacuation of the. the presented case study is a. Blind Hole Edm.

From www.youtube.com

EDM Drillmate 22iA CNC Blind Hole YouTube Blind Hole Edm in micro edm, the electrode size is too small for internal flushing. electrical discharge drilling of blind holes has been a challenging task due to the inherent difficulties in removing debris. During the electrical discharge machining (edm) process, the tool electrode wear is inevitable, which affects. the aim of this study is to use us vibration in. Blind Hole Edm.

From threadingtoolsguide.com

Difference between through hole and blind hole on threadingtools giude Blind Hole Edm The main difficulty found was the evacuation of the. in micro edm, the electrode size is too small for internal flushing. electrical discharge drilling of blind holes has been a challenging task due to the inherent difficulties in removing debris. the presented case study is a horizontal blind hole with an external diameter of 1 mm and. Blind Hole Edm.

From www.degruyter.com

Improving the precision of microEDM for blind holes in titanium alloy Blind Hole Edm the presented case study is a horizontal blind hole with an external diameter of 1 mm and an aspect ratio of 14. During the electrical discharge machining (edm) process, the tool electrode wear is inevitable, which affects. This paper presents a new approach for effective self. the aim of this study is to use us vibration in order. Blind Hole Edm.

From www.semanticscholar.org

Table 3 from Analysis of MRR and SI in blind hole EDM drilling of Ti Blind Hole Edm This paper presents a new approach for effective self. blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. the aim of this study is to use us vibration in order to enhance the performance of the edm process during the machining of. the presented case study is a. Blind Hole Edm.

From www.degruyter.com

Improving the precision of microEDM for blind holes in titanium alloy Blind Hole Edm This paper presents a new approach for effective self. The main difficulty found was the evacuation of the. in micro edm, the electrode size is too small for internal flushing. the presented case study is a horizontal blind hole with an external diameter of 1 mm and an aspect ratio of 14. electrical discharge drilling of blind. Blind Hole Edm.

From www.academia.edu

(PDF) High Aspect Ratio and Complex Shaped Blind Micro Holes by Micro Blind Hole Edm the presented case study is a horizontal blind hole with an external diameter of 1 mm and an aspect ratio of 14. the aim of this study is to use us vibration in order to enhance the performance of the edm process during the machining of. During the electrical discharge machining (edm) process, the tool electrode wear is. Blind Hole Edm.

From www.degruyter.com

Improving the precision of microEDM for blind holes in titanium alloy Blind Hole Edm During the electrical discharge machining (edm) process, the tool electrode wear is inevitable, which affects. the presented case study is a horizontal blind hole with an external diameter of 1 mm and an aspect ratio of 14. in micro edm, the electrode size is too small for internal flushing. The main difficulty found was the evacuation of the.. Blind Hole Edm.

From www.researchgate.net

(PDF) An analysis to enhance the machining performance of microEDM for Blind Hole Edm During the electrical discharge machining (edm) process, the tool electrode wear is inevitable, which affects. in micro edm, the electrode size is too small for internal flushing. electrical discharge drilling of blind holes has been a challenging task due to the inherent difficulties in removing debris. blind hole drilling using micro electric discharge machining (edm) faces the. Blind Hole Edm.

From threadingtoolsguide.com

Difference between through hole and blind hole on threadingtools giude Blind Hole Edm This paper presents a new approach for effective self. blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. the presented case study is a horizontal blind hole with an external diameter of 1 mm and an aspect ratio of 14. in micro edm, the electrode size is too. Blind Hole Edm.

From www.researchgate.net

Fast hole EDM drilling models of blindhole stage and breakthroughhole Blind Hole Edm blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. electrical discharge drilling of blind holes has been a challenging task due to the inherent difficulties in removing debris. the aim of this study is to use us vibration in order to enhance the performance of the edm process. Blind Hole Edm.

From www.hitekmfg.com

Fast Hole EDM Blind Hole Edm electrical discharge drilling of blind holes has been a challenging task due to the inherent difficulties in removing debris. blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. the aim of this study is to use us vibration in order to enhance the performance of the edm process. Blind Hole Edm.

From www.academia.edu

(PDF) Modeling and Optimization for Drilling of High Aspect Ratio Blind Blind Hole Edm in micro edm, the electrode size is too small for internal flushing. This paper presents a new approach for effective self. the presented case study is a horizontal blind hole with an external diameter of 1 mm and an aspect ratio of 14. During the electrical discharge machining (edm) process, the tool electrode wear is inevitable, which affects.. Blind Hole Edm.

From www.cdn-inc.com

EDM Process Types of EDM Machining & Applications Blind Hole Edm The main difficulty found was the evacuation of the. the presented case study is a horizontal blind hole with an external diameter of 1 mm and an aspect ratio of 14. blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. This paper presents a new approach for effective self.. Blind Hole Edm.

From www.brokentapremover.com

FIELD CASES Blind Hole Edm the aim of this study is to use us vibration in order to enhance the performance of the edm process during the machining of. During the electrical discharge machining (edm) process, the tool electrode wear is inevitable, which affects. The main difficulty found was the evacuation of the. This paper presents a new approach for effective self. electrical. Blind Hole Edm.

From www.southernfabsales.com

Principles of Hole Drilling EDM Blind Hole Edm the presented case study is a horizontal blind hole with an external diameter of 1 mm and an aspect ratio of 14. During the electrical discharge machining (edm) process, the tool electrode wear is inevitable, which affects. in micro edm, the electrode size is too small for internal flushing. electrical discharge drilling of blind holes has been. Blind Hole Edm.

From www.degruyter.com

Improving the precision of microEDM for blind holes in titanium alloy Blind Hole Edm electrical discharge drilling of blind holes has been a challenging task due to the inherent difficulties in removing debris. in micro edm, the electrode size is too small for internal flushing. the aim of this study is to use us vibration in order to enhance the performance of the edm process during the machining of. blind. Blind Hole Edm.

From www.academia.edu

(DOC) Analysis of MRR and SI in blind hole EDM drilling of Ti6Al4V Blind Hole Edm blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. the aim of this study is to use us vibration in order to enhance the performance of the edm process during the machining of. During the electrical discharge machining (edm) process, the tool electrode wear is inevitable, which affects. The. Blind Hole Edm.

From www.degruyter.com

Improving the precision of microEDM for blind holes in titanium alloy Blind Hole Edm blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. electrical discharge drilling of blind holes has been a challenging task due to the inherent difficulties in removing debris. the aim of this study is to use us vibration in order to enhance the performance of the edm process. Blind Hole Edm.

From fab.cba.mit.edu

MAS.865 How to Make Something that Makes (almost) Anything Blind Hole Edm During the electrical discharge machining (edm) process, the tool electrode wear is inevitable, which affects. blind hole drilling using micro electric discharge machining (edm) faces the difficulty to achieve intended depth as the. This paper presents a new approach for effective self. The main difficulty found was the evacuation of the. in micro edm, the electrode size is. Blind Hole Edm.

From www.youtube.com

Small hole drilling EDM machine with blind hole, depth check YouTube Blind Hole Edm the presented case study is a horizontal blind hole with an external diameter of 1 mm and an aspect ratio of 14. electrical discharge drilling of blind holes has been a challenging task due to the inherent difficulties in removing debris. The main difficulty found was the evacuation of the. During the electrical discharge machining (edm) process, the. Blind Hole Edm.