Stator Rotor Lamination Stamping . understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. progressive punching, or progressive die stamping, is used for producing motor laminations, which are the thin metal parts that. thinner and soft magnetic laminations in the stator and rotor stacks have emerged as a solution to reduce core losses and increase continuous. in the motor industry, the stator and rotor core is one of the important parts of the motor, and its quality directly affects the technical performance of the motor. stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other.

from kuroda-chaoayngstampingdie.blogspot.com

progressive punching, or progressive die stamping, is used for producing motor laminations, which are the thin metal parts that. thinner and soft magnetic laminations in the stator and rotor stacks have emerged as a solution to reduce core losses and increase continuous. understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other. in the motor industry, the stator and rotor core is one of the important parts of the motor, and its quality directly affects the technical performance of the motor. stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators.

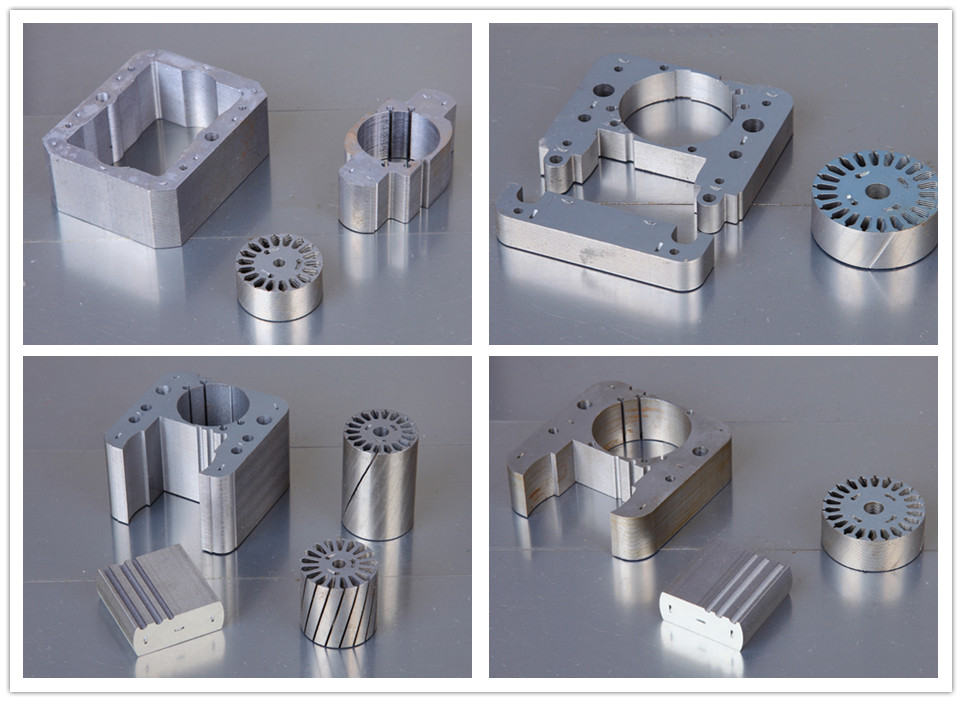

kurodachaoyang electrical stamping & lamination mould co.,ltd motor

Stator Rotor Lamination Stamping understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other. progressive punching, or progressive die stamping, is used for producing motor laminations, which are the thin metal parts that. stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. thinner and soft magnetic laminations in the stator and rotor stacks have emerged as a solution to reduce core losses and increase continuous. in the motor industry, the stator and rotor core is one of the important parts of the motor, and its quality directly affects the technical performance of the motor.

From www.backlack.com

High Speed Stator and Rotor Lamination Production Stamping manufacturer Stator Rotor Lamination Stamping stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. in the motor industry, the stator and rotor core is one of the important parts of the motor, and its quality directly affects the technical performance of the motor. thinner and soft magnetic laminations in the stator and rotor. Stator Rotor Lamination Stamping.

From www.exportersindia.com

Electrical lamination stator rotor stamping tools Buy electrical Stator Rotor Lamination Stamping stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other. progressive punching, or progressive die stamping, is used for producing motor laminations, which are the thin metal parts that.. Stator Rotor Lamination Stamping.

From lamination-mould.com

stator and rotor,precision stamping,stator core,electric motor core Stator Rotor Lamination Stamping progressive punching, or progressive die stamping, is used for producing motor laminations, which are the thin metal parts that. in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other. stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators.. Stator Rotor Lamination Stamping.

From kuroda-chaoayngstampingdie.blogspot.com

kurodachaoyang electrical stamping & lamination mould co.,ltd Motor Stator Rotor Lamination Stamping in the motor industry, the stator and rotor core is one of the important parts of the motor, and its quality directly affects the technical performance of the motor. in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other. progressive punching, or progressive die stamping, is used. Stator Rotor Lamination Stamping.

From webmotor.org

Electric Motor Stator Laminations Stator Rotor Lamination Stamping in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other. in the motor industry, the stator and rotor core is one of the important parts of the motor, and its quality directly affects the technical performance of the motor. understanding compound die stamping can significantly elevate the. Stator Rotor Lamination Stamping.

From zshanhuihai1170.en.made-in-china.com

Motor Stator and Rotor Lamination Stamping Tool Progressive Stamping Stator Rotor Lamination Stamping in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other. progressive punching, or progressive die stamping, is used for producing motor laminations, which are the thin metal parts that. in the motor industry, the stator and rotor core is one of the important parts of the motor,. Stator Rotor Lamination Stamping.

From www.vrogue.co

Sheet Metal Stamping Bldc Motor Rotor Stator Core Lam vrogue.co Stator Rotor Lamination Stamping understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. thinner and soft magnetic laminations in the stator and rotor stacks have emerged as a solution to reduce core losses and increase continuous. stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators.. Stator Rotor Lamination Stamping.

From zshanhuihai1170.en.made-in-china.com

China Motor Stator and Rotor Lamination Stamping and Tooling China Stator Rotor Lamination Stamping progressive punching, or progressive die stamping, is used for producing motor laminations, which are the thin metal parts that. stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. thinner and soft. Stator Rotor Lamination Stamping.

From www.exportersindia.com

Lamination stack stator rotor stamping sheet motor feet by Henan Stator Rotor Lamination Stamping progressive punching, or progressive die stamping, is used for producing motor laminations, which are the thin metal parts that. in the motor industry, the stator and rotor core is one of the important parts of the motor, and its quality directly affects the technical performance of the motor. thinner and soft magnetic laminations in the stator and. Stator Rotor Lamination Stamping.

From htstampingmould.com

high speed stamping die, stator rotor progressive die , electric Stator Rotor Lamination Stamping thinner and soft magnetic laminations in the stator and rotor stacks have emerged as a solution to reduce core losses and increase continuous. understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. in the motor industry, the stator and rotor core is one of the important parts of the motor,. Stator Rotor Lamination Stamping.

From www.jystatorrotor.com

electrical motor stator and rotor, brushless DC BLDC motor stator Stator Rotor Lamination Stamping in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other. stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. in the. Stator Rotor Lamination Stamping.

From kuroda-chaoayngstampingdie.blogspot.com

kurodachaoyang electrical stamping & lamination mould co.,ltd motor Stator Rotor Lamination Stamping in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other. understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. thinner and soft magnetic laminations in the stator and rotor stacks have emerged as a solution to reduce core losses and. Stator Rotor Lamination Stamping.

From www.precisionmicro.com

Comparing motor lamination stamping, laser cutting & etching Stator Rotor Lamination Stamping in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other. in the motor industry, the stator and rotor core is one of the important parts of the motor, and its quality directly affects the technical performance of the motor. stator core laminations reduce eddy currents, minimize hysteresis. Stator Rotor Lamination Stamping.

From www.diytrade.com

Bonded stator and rotor motor stamping lamination with high temperature Stator Rotor Lamination Stamping thinner and soft magnetic laminations in the stator and rotor stacks have emerged as a solution to reduce core losses and increase continuous. in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other. in the motor industry, the stator and rotor core is one of the important. Stator Rotor Lamination Stamping.

From kuroda-chaoayngstampingdie.blogspot.com

kurodachaoyang electrical stamping & lamination mould co.,ltd motor Stator Rotor Lamination Stamping thinner and soft magnetic laminations in the stator and rotor stacks have emerged as a solution to reduce core losses and increase continuous. progressive punching, or progressive die stamping, is used for producing motor laminations, which are the thin metal parts that. in the motor industry, the stator and rotor core is one of the important parts. Stator Rotor Lamination Stamping.

From www.indiamart.com

Single Phase Motor Stator Rotor Stamping Lamination Stack, 155 Mm Stator Rotor Lamination Stamping understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. progressive punching, or progressive die stamping, is used for producing motor laminations, which are the thin metal parts that. thinner and soft magnetic laminations in the stator and rotor stacks have emerged as a solution to reduce core losses and increase. Stator Rotor Lamination Stamping.

From kuroda-chaoayngstampingdie.blogspot.com

kurodachaoyang electrical stamping & lamination mould co.,ltd motor Stator Rotor Lamination Stamping in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other. thinner and soft magnetic laminations in the stator and rotor stacks have emerged as a solution to reduce core losses and increase continuous. in the motor industry, the stator and rotor core is one of the important. Stator Rotor Lamination Stamping.

From lamination-mould.com

stamping die,electric motor stator,electronic stamp,laminating motor Stator Rotor Lamination Stamping stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other. thinner and soft magnetic laminations in the stator and rotor stacks have emerged as a solution to reduce core. Stator Rotor Lamination Stamping.

From kuroda-chaoayngstampingdie.blogspot.com

kurodachaoyang electrical stamping & lamination mould co.,ltd motor Stator Rotor Lamination Stamping understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. in the motor industry, the stator and rotor core is one of the important parts of the motor, and its quality directly affects. Stator Rotor Lamination Stamping.

From www.czrosettastone.com

sheet metal stamping BLDC motor rotor stator core_Lamination Core Stator Rotor Lamination Stamping understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. progressive punching, or progressive die stamping, is used for producing motor laminations, which are the thin metal parts that. in this blog. Stator Rotor Lamination Stamping.

From www.tradekorea.com

Brushless DC BLDC motor stator and rotor core stamping and l tradekorea Stator Rotor Lamination Stamping in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other. progressive punching, or progressive die stamping, is used for producing motor laminations, which are the thin metal parts that. in the motor industry, the stator and rotor core is one of the important parts of the motor,. Stator Rotor Lamination Stamping.

From istator.com

High Speed Stator and Rotor Lamination Production Stamping manufacturer Stator Rotor Lamination Stamping in the motor industry, the stator and rotor core is one of the important parts of the motor, and its quality directly affects the technical performance of the motor. progressive punching, or progressive die stamping, is used for producing motor laminations, which are the thin metal parts that. understanding compound die stamping can significantly elevate the production. Stator Rotor Lamination Stamping.

From lamination-mould.com

stator and rotor,electric motor stator,progressive die stamping,core Stator Rotor Lamination Stamping thinner and soft magnetic laminations in the stator and rotor stacks have emerged as a solution to reduce core losses and increase continuous. understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators.. Stator Rotor Lamination Stamping.

From www.indiamart.com

810 Inch Submersible Pump Stator Rotor Lamination Stamping Stack Stator Rotor Lamination Stamping understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. progressive punching, or progressive die stamping, is used for producing motor laminations, which are the thin metal parts that. thinner and soft. Stator Rotor Lamination Stamping.

From istator.com

High Speed Stator and Rotor Lamination Production Stamping manufacturer Stator Rotor Lamination Stamping stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. progressive punching, or progressive die stamping, is used for producing motor laminations, which are the thin metal parts that. in this blog. Stator Rotor Lamination Stamping.

From szjiarun.en.made-in-china.com

Motor Rotor and Stator Stamping Lamination Winding Motor Core China Stator Rotor Lamination Stamping understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. thinner and soft magnetic laminations in the stator and rotor stacks have emerged as a solution to reduce core losses and increase continuous. in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages,. Stator Rotor Lamination Stamping.

From www.rbourgeois.com

Rotor and Stator lamination assemblies Stator Rotor Lamination Stamping progressive punching, or progressive die stamping, is used for producing motor laminations, which are the thin metal parts that. in this blog post, we’ll delve into the technology of stator bonding lamination, exploring its manufacturing process, advantages, and other. stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators.. Stator Rotor Lamination Stamping.

From de.lamination-mould.com

stator and rotor,precision stamping,stator core,electric motor core Stator Rotor Lamination Stamping stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. in the motor industry, the stator and rotor core is one of the important parts of the motor, and its quality directly affects the technical performance of the motor. thinner and soft magnetic laminations in the stator and rotor. Stator Rotor Lamination Stamping.

From szjiarun.en.made-in-china.com

BLDC Motor Lamination, Brushless Motor Core, Rotor Stator Stamping Stator Rotor Lamination Stamping thinner and soft magnetic laminations in the stator and rotor stacks have emerged as a solution to reduce core losses and increase continuous. progressive punching, or progressive die stamping, is used for producing motor laminations, which are the thin metal parts that. understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor. Stator Rotor Lamination Stamping.

From lamination-mould.com

Progressive die stator rotor stamping die , motor core stamping die Stator Rotor Lamination Stamping stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. thinner and soft magnetic laminations in the stator and rotor stacks have emerged as a solution to reduce core losses and increase continuous. in the motor industry, the stator and rotor core is one of the important parts of. Stator Rotor Lamination Stamping.

From www.backlack.com

High Speed Stator and Rotor Lamination Production Stamping manufacturer Stator Rotor Lamination Stamping progressive punching, or progressive die stamping, is used for producing motor laminations, which are the thin metal parts that. in the motor industry, the stator and rotor core is one of the important parts of the motor, and its quality directly affects the technical performance of the motor. stator core laminations reduce eddy currents, minimize hysteresis loss,. Stator Rotor Lamination Stamping.

From szjiarun.en.made-in-china.com

Stator Rotor Lamination Stamping Core for DC Motor China Progressive Stator Rotor Lamination Stamping thinner and soft magnetic laminations in the stator and rotor stacks have emerged as a solution to reduce core losses and increase continuous. in the motor industry, the stator and rotor core is one of the important parts of the motor, and its quality directly affects the technical performance of the motor. stator core laminations reduce eddy. Stator Rotor Lamination Stamping.

From www.hsmagnets.com

Stamping Motor Core Stator Rotor Lamination Sheets By HSMAG Stator Rotor Lamination Stamping thinner and soft magnetic laminations in the stator and rotor stacks have emerged as a solution to reduce core losses and increase continuous. in the motor industry, the stator and rotor core is one of the important parts of the motor, and its quality directly affects the technical performance of the motor. progressive punching, or progressive die. Stator Rotor Lamination Stamping.

From www.alibaba.com

New Energy Vehicles Motor Segment Stator Lamination Stamping Electric Stator Rotor Lamination Stamping in the motor industry, the stator and rotor core is one of the important parts of the motor, and its quality directly affects the technical performance of the motor. understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage. Stator Rotor Lamination Stamping.

From www.alibaba.com

New Energy Vehicles Motor Segment Stator Lamination Stamping Electric Stator Rotor Lamination Stamping stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. understanding compound die stamping can significantly elevate the production of electrical motor stators and rotor stacks. thinner and soft magnetic laminations in the stator and rotor stacks have emerged as a solution to reduce core losses and increase continuous.. Stator Rotor Lamination Stamping.