If Solder Joint Leaks . Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. The electrical conductivity/connection and the strength and. with leaded solder, it should be on the shinier side or the solder will be too cold which will create a weak joint that can eventually break. We will discuss the causes of bad solder joints and. While shiny joints might be more visually appealing, other factors play a more significant role in determining their reliability: poor solder joints can result in faulty boards which then end up failing during test or worse, in the field. a bad solder joint on a copper pipe can cause leaks and damage. solder one joint, then move to a joint further away, then back to a joint near the first, etc. This should allow some of the heat to. If there is too much solder, a solder.

from www.ourpcb.com

The electrical conductivity/connection and the strength and. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. with leaded solder, it should be on the shinier side or the solder will be too cold which will create a weak joint that can eventually break. This should allow some of the heat to. If there is too much solder, a solder. solder one joint, then move to a joint further away, then back to a joint near the first, etc. While shiny joints might be more visually appealing, other factors play a more significant role in determining their reliability: poor solder joints can result in faulty boards which then end up failing during test or worse, in the field. a bad solder joint on a copper pipe can cause leaks and damage. We will discuss the causes of bad solder joints and.

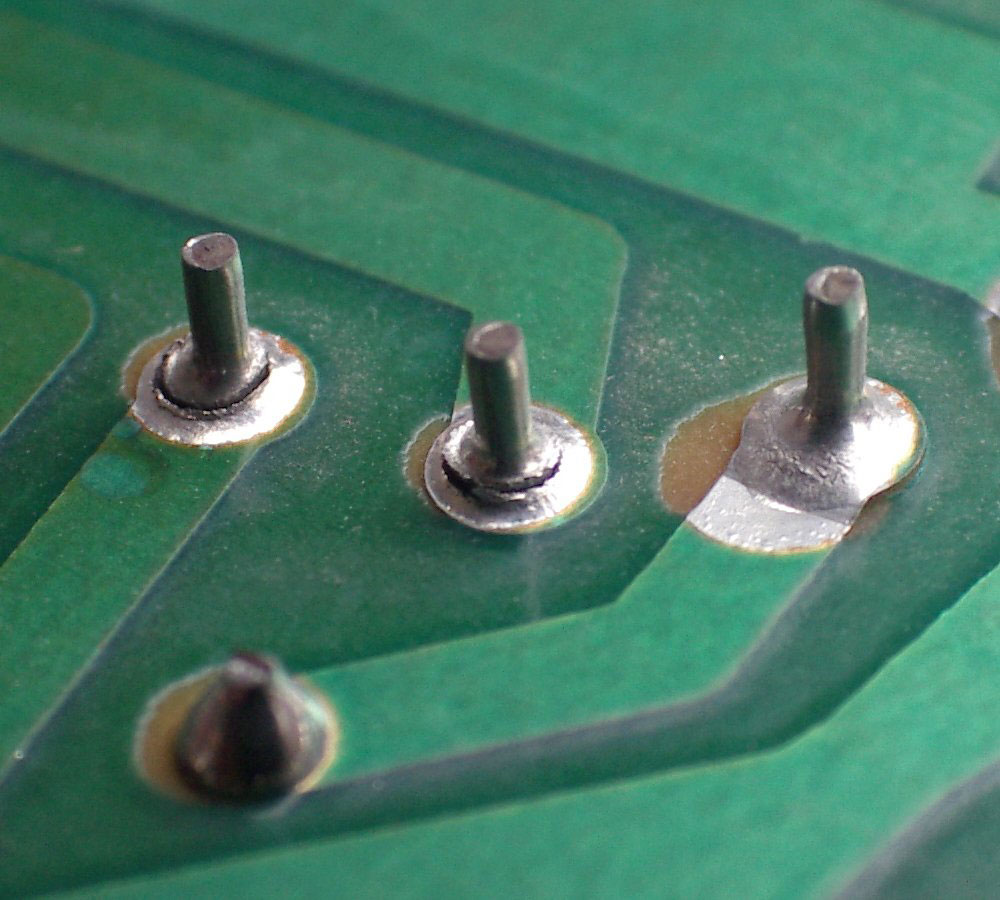

Cold Solder Joint A Dry or Cracked Solder Joint Caused by Improper

If Solder Joint Leaks with leaded solder, it should be on the shinier side or the solder will be too cold which will create a weak joint that can eventually break. If there is too much solder, a solder. While shiny joints might be more visually appealing, other factors play a more significant role in determining their reliability: solder one joint, then move to a joint further away, then back to a joint near the first, etc. This should allow some of the heat to. The electrical conductivity/connection and the strength and. a bad solder joint on a copper pipe can cause leaks and damage. We will discuss the causes of bad solder joints and. with leaded solder, it should be on the shinier side or the solder will be too cold which will create a weak joint that can eventually break. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. poor solder joints can result in faulty boards which then end up failing during test or worse, in the field.

From nerdytechy.com

What Is a Cold Solder Joint? NerdyTechy If Solder Joint Leaks poor solder joints can result in faulty boards which then end up failing during test or worse, in the field. a bad solder joint on a copper pipe can cause leaks and damage. While shiny joints might be more visually appealing, other factors play a more significant role in determining their reliability: solder one joint, then move. If Solder Joint Leaks.

From www.youtube.com

Helpful Steps to a LEAK FREE Solder Joint! YouTube If Solder Joint Leaks The electrical conductivity/connection and the strength and. solder one joint, then move to a joint further away, then back to a joint near the first, etc. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. a bad solder joint on a copper pipe can cause leaks. If Solder Joint Leaks.

From www.researchgate.net

Joint disturbed when soldering Download Scientific Diagram If Solder Joint Leaks If there is too much solder, a solder. The electrical conductivity/connection and the strength and. a bad solder joint on a copper pipe can cause leaks and damage. This should allow some of the heat to. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. with. If Solder Joint Leaks.

From www.youtube.com

How to repair cold solder joint YouTube If Solder Joint Leaks with leaded solder, it should be on the shinier side or the solder will be too cold which will create a weak joint that can eventually break. If there is too much solder, a solder. This should allow some of the heat to. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron. If Solder Joint Leaks.

From morepcb.com

How to Solder Wire on Circuit Board Mastering the Basics MorePCB If Solder Joint Leaks The electrical conductivity/connection and the strength and. This should allow some of the heat to. with leaded solder, it should be on the shinier side or the solder will be too cold which will create a weak joint that can eventually break. We will discuss the causes of bad solder joints and. Sometimes the excess solder can be drawn. If Solder Joint Leaks.

From rushpcb.com

What is a Solder Joint? RushPcb If Solder Joint Leaks solder one joint, then move to a joint further away, then back to a joint near the first, etc. a bad solder joint on a copper pipe can cause leaks and damage. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. with leaded solder, it. If Solder Joint Leaks.

From www.reddit.com

Learning to solder. Would you redo the bottom of this elbow? It’s If Solder Joint Leaks While shiny joints might be more visually appealing, other factors play a more significant role in determining their reliability: We will discuss the causes of bad solder joints and. a bad solder joint on a copper pipe can cause leaks and damage. with leaded solder, it should be on the shinier side or the solder will be too. If Solder Joint Leaks.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint If Solder Joint Leaks If there is too much solder, a solder. with leaded solder, it should be on the shinier side or the solder will be too cold which will create a weak joint that can eventually break. While shiny joints might be more visually appealing, other factors play a more significant role in determining their reliability: a bad solder joint. If Solder Joint Leaks.

From nerdytechy.com

What Is a Cold Solder Joint? NerdyTechy If Solder Joint Leaks If there is too much solder, a solder. We will discuss the causes of bad solder joints and. with leaded solder, it should be on the shinier side or the solder will be too cold which will create a weak joint that can eventually break. poor solder joints can result in faulty boards which then end up failing. If Solder Joint Leaks.

From www.reddit.com

Are these cracks in my solder joints? r/soldering If Solder Joint Leaks The electrical conductivity/connection and the strength and. a bad solder joint on a copper pipe can cause leaks and damage. solder one joint, then move to a joint further away, then back to a joint near the first, etc. This should allow some of the heat to. Sometimes the excess solder can be drawn off by dragging the. If Solder Joint Leaks.

From www.reddit.com

Are these cracks in my solder joints? r/soldering If Solder Joint Leaks If there is too much solder, a solder. solder one joint, then move to a joint further away, then back to a joint near the first, etc. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. While shiny joints might be more visually appealing, other factors play. If Solder Joint Leaks.

From www.semlab.com

Solder Joint Analysis SEM Lab Inc. If Solder Joint Leaks a bad solder joint on a copper pipe can cause leaks and damage. poor solder joints can result in faulty boards which then end up failing during test or worse, in the field. While shiny joints might be more visually appealing, other factors play a more significant role in determining their reliability: solder one joint, then move. If Solder Joint Leaks.

From dujcvjlueco.blob.core.windows.net

Best Way To Solder Copper Tube at Tristan Hoag blog If Solder Joint Leaks If there is too much solder, a solder. with leaded solder, it should be on the shinier side or the solder will be too cold which will create a weak joint that can eventually break. This should allow some of the heat to. poor solder joints can result in faulty boards which then end up failing during test. If Solder Joint Leaks.

From www.pcbaservices.com

What Is A Cold Solder Joint? Understanding The Basics If Solder Joint Leaks Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. The electrical conductivity/connection and the strength and. poor solder joints can result in faulty boards which then end up failing during test or worse, in the field. a bad solder joint on a copper pipe can cause. If Solder Joint Leaks.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint If Solder Joint Leaks We will discuss the causes of bad solder joints and. a bad solder joint on a copper pipe can cause leaks and damage. If there is too much solder, a solder. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. This should allow some of the heat. If Solder Joint Leaks.

From electronicshacks.com

Solder Not Sticking How to Fix That? ElectronicsHacks If Solder Joint Leaks We will discuss the causes of bad solder joints and. solder one joint, then move to a joint further away, then back to a joint near the first, etc. a bad solder joint on a copper pipe can cause leaks and damage. While shiny joints might be more visually appealing, other factors play a more significant role in. If Solder Joint Leaks.

From www.pcbaaa.com

Understanding solder joint basics and techniques IBE Electronics If Solder Joint Leaks While shiny joints might be more visually appealing, other factors play a more significant role in determining their reliability: If there is too much solder, a solder. poor solder joints can result in faulty boards which then end up failing during test or worse, in the field. with leaded solder, it should be on the shinier side or. If Solder Joint Leaks.

From www.ourpcb.com

Cold Solder Joint A Dry or Cracked Solder Joint Caused by Improper If Solder Joint Leaks The electrical conductivity/connection and the strength and. This should allow some of the heat to. While shiny joints might be more visually appealing, other factors play a more significant role in determining their reliability: Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. We will discuss the causes. If Solder Joint Leaks.

From www.anzer-usa.com

Q PCB Soldering Problems What Are They Anzer USA Blog If Solder Joint Leaks We will discuss the causes of bad solder joints and. While shiny joints might be more visually appealing, other factors play a more significant role in determining their reliability: The electrical conductivity/connection and the strength and. a bad solder joint on a copper pipe can cause leaks and damage. with leaded solder, it should be on the shinier. If Solder Joint Leaks.

From www.youtube.com

How to Spot a Bad Solder Joint YouTube If Solder Joint Leaks Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. We will discuss the causes of bad solder joints and. with leaded solder, it should be on the shinier side or the solder will be too cold which will create a weak joint that can eventually break. If. If Solder Joint Leaks.

From absolutepcbassembly.com

Cold Solder Joint Definitive Guide to Soldering Absolute If Solder Joint Leaks If there is too much solder, a solder. solder one joint, then move to a joint further away, then back to a joint near the first, etc. While shiny joints might be more visually appealing, other factors play a more significant role in determining their reliability: Sometimes the excess solder can be drawn off by dragging the tip of. If Solder Joint Leaks.

From www.dreamstime.com

Failed solder joint stock photo. Image of open, services 291588404 If Solder Joint Leaks If there is too much solder, a solder. a bad solder joint on a copper pipe can cause leaks and damage. While shiny joints might be more visually appealing, other factors play a more significant role in determining their reliability: poor solder joints can result in faulty boards which then end up failing during test or worse, in. If Solder Joint Leaks.

From www.researchgate.net

Common solder joint defects [23] Download Scientific Diagram If Solder Joint Leaks Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. If there is too much solder, a solder. poor solder joints can result in faulty boards which then end up failing during test or worse, in the field. a bad solder joint on a copper pipe can. If Solder Joint Leaks.

From electronicshacks.com

How to Solder Without a Soldering Iron? ElectronicsHacks If Solder Joint Leaks While shiny joints might be more visually appealing, other factors play a more significant role in determining their reliability: We will discuss the causes of bad solder joints and. solder one joint, then move to a joint further away, then back to a joint near the first, etc. This should allow some of the heat to. a bad. If Solder Joint Leaks.

From www.reddit.com

Holes are so close together the solder keeps connecting with the solder If Solder Joint Leaks The electrical conductivity/connection and the strength and. with leaded solder, it should be on the shinier side or the solder will be too cold which will create a weak joint that can eventually break. We will discuss the causes of bad solder joints and. While shiny joints might be more visually appealing, other factors play a more significant role. If Solder Joint Leaks.

From www.pcbaservices.com

What Is A Cold Solder Joint? Understanding The Basics If Solder Joint Leaks This should allow some of the heat to. with leaded solder, it should be on the shinier side or the solder will be too cold which will create a weak joint that can eventually break. a bad solder joint on a copper pipe can cause leaks and damage. Sometimes the excess solder can be drawn off by dragging. If Solder Joint Leaks.

From pcbassemblymanufacturing.com

Solder joint one basic lesson about PCB soldering If Solder Joint Leaks If there is too much solder, a solder. a bad solder joint on a copper pipe can cause leaks and damage. While shiny joints might be more visually appealing, other factors play a more significant role in determining their reliability: solder one joint, then move to a joint further away, then back to a joint near the first,. If Solder Joint Leaks.

From dokumen.tips

(PDF) Through Hole Solder Joint Evaluation If Solder Joint Leaks If there is too much solder, a solder. poor solder joints can result in faulty boards which then end up failing during test or worse, in the field. a bad solder joint on a copper pipe can cause leaks and damage. The electrical conductivity/connection and the strength and. This should allow some of the heat to. While shiny. If Solder Joint Leaks.

From nerdytechy.com

What Is a Cold Solder Joint? NerdyTechy If Solder Joint Leaks While shiny joints might be more visually appealing, other factors play a more significant role in determining their reliability: This should allow some of the heat to. If there is too much solder, a solder. The electrical conductivity/connection and the strength and. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the. If Solder Joint Leaks.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint If Solder Joint Leaks a bad solder joint on a copper pipe can cause leaks and damage. with leaded solder, it should be on the shinier side or the solder will be too cold which will create a weak joint that can eventually break. solder one joint, then move to a joint further away, then back to a joint near the. If Solder Joint Leaks.

From electronicshacks.com

What Is a Cold Solder Joint? ElectronicsHacks If Solder Joint Leaks Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. The electrical conductivity/connection and the strength and. poor solder joints can result in faulty boards which then end up failing during test or worse, in the field. We will discuss the causes of bad solder joints and. This. If Solder Joint Leaks.

From www.youtube.com

Repair a Repair "Dry solder", "Cold solder" or "Cracked Solder Joint If Solder Joint Leaks We will discuss the causes of bad solder joints and. with leaded solder, it should be on the shinier side or the solder will be too cold which will create a weak joint that can eventually break. solder one joint, then move to a joint further away, then back to a joint near the first, etc. The electrical. If Solder Joint Leaks.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint If Solder Joint Leaks This should allow some of the heat to. a bad solder joint on a copper pipe can cause leaks and damage. poor solder joints can result in faulty boards which then end up failing during test or worse, in the field. If there is too much solder, a solder. We will discuss the causes of bad solder joints. If Solder Joint Leaks.

From www.pcba-manufacturers.com

Understanding Cold Solder Joints Causes, Identification and Solutions If Solder Joint Leaks Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. a bad solder joint on a copper pipe can cause leaks and damage. solder one joint, then move to a joint further away, then back to a joint near the first, etc. The electrical conductivity/connection and the. If Solder Joint Leaks.

From nerdytechy.com

What Is a Cold Solder Joint? NerdyTechy If Solder Joint Leaks We will discuss the causes of bad solder joints and. poor solder joints can result in faulty boards which then end up failing during test or worse, in the field. with leaded solder, it should be on the shinier side or the solder will be too cold which will create a weak joint that can eventually break. The. If Solder Joint Leaks.