Types Of Welding Tig . Tig welding and mig welding (gas metal arc welding or gmaw) are two popular arc welding processes, each with its own advantages and disadvantages. Learn about the different types of welding in our comprehensive guide covering mig, tig, fcaw, and saw welding to get efficient and effective results. Lift arc lift arc requires touching the workpiece and lifting the torch to initiate the weld cycle. Tig (tungsten inert gas) welding is a common method used in manufacturing to join pieces of metal together. Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze and even gold. It’s a form of gtaw (gas tungsten arc welding) and is used for many. Scratch start scratch start is the most basic form of tig welding and requires dragging the electrode across the surface of a workpiece to initiate the weld cycle. The tig process can be used to weld. In this video, i go ov. All of the different welding processes and acronyms can be really confusing.

from www.open.edu

The tig process can be used to weld. Tig (tungsten inert gas) welding is a common method used in manufacturing to join pieces of metal together. All of the different welding processes and acronyms can be really confusing. In this video, i go ov. Lift arc lift arc requires touching the workpiece and lifting the torch to initiate the weld cycle. Scratch start scratch start is the most basic form of tig welding and requires dragging the electrode across the surface of a workpiece to initiate the weld cycle. Tig welding and mig welding (gas metal arc welding or gmaw) are two popular arc welding processes, each with its own advantages and disadvantages. It’s a form of gtaw (gas tungsten arc welding) and is used for many. Learn about the different types of welding in our comprehensive guide covering mig, tig, fcaw, and saw welding to get efficient and effective results. Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze and even gold.

Gas shielded arc welding processes (TIG/MIG/MAG) OpenLearn Open

Types Of Welding Tig Tig (tungsten inert gas) welding is a common method used in manufacturing to join pieces of metal together. All of the different welding processes and acronyms can be really confusing. Scratch start scratch start is the most basic form of tig welding and requires dragging the electrode across the surface of a workpiece to initiate the weld cycle. The tig process can be used to weld. Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze and even gold. Lift arc lift arc requires touching the workpiece and lifting the torch to initiate the weld cycle. Learn about the different types of welding in our comprehensive guide covering mig, tig, fcaw, and saw welding to get efficient and effective results. In this video, i go ov. Tig welding and mig welding (gas metal arc welding or gmaw) are two popular arc welding processes, each with its own advantages and disadvantages. It’s a form of gtaw (gas tungsten arc welding) and is used for many. Tig (tungsten inert gas) welding is a common method used in manufacturing to join pieces of metal together.

From www.indianacontractmfg.com

TIG Welding Indiana Contract Manufacturing Professionals Types Of Welding Tig Scratch start scratch start is the most basic form of tig welding and requires dragging the electrode across the surface of a workpiece to initiate the weld cycle. The tig process can be used to weld. It’s a form of gtaw (gas tungsten arc welding) and is used for many. In this video, i go ov. Tig (tungsten inert gas). Types Of Welding Tig.

From www.open.edu

Gas shielded arc welding processes (TIG/MIG/MAG) OpenLearn Open Types Of Welding Tig Scratch start scratch start is the most basic form of tig welding and requires dragging the electrode across the surface of a workpiece to initiate the weld cycle. It’s a form of gtaw (gas tungsten arc welding) and is used for many. Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze. Types Of Welding Tig.

From info.naimormetalfabrication.com

What Is Welding, What Are Common Types, and How Does Welding Work? Types Of Welding Tig Tig (tungsten inert gas) welding is a common method used in manufacturing to join pieces of metal together. Scratch start scratch start is the most basic form of tig welding and requires dragging the electrode across the surface of a workpiece to initiate the weld cycle. The tig process can be used to weld. All of the different welding processes. Types Of Welding Tig.

From mechanicalinventions.blogspot.com

TIG Welding Basics Mechanical Engineering Types Of Welding Tig In this video, i go ov. It’s a form of gtaw (gas tungsten arc welding) and is used for many. Tig welding and mig welding (gas metal arc welding or gmaw) are two popular arc welding processes, each with its own advantages and disadvantages. Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper,. Types Of Welding Tig.

From weldingpros.net

Different Types of Welding Processes From TIG To Laser 2023 Types Of Welding Tig Tig (tungsten inert gas) welding is a common method used in manufacturing to join pieces of metal together. The tig process can be used to weld. Lift arc lift arc requires touching the workpiece and lifting the torch to initiate the weld cycle. Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass,. Types Of Welding Tig.

From weldguru.com

What is TIG Welding (GTAW) & How it Works Weld Guru Types Of Welding Tig Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze and even gold. Tig welding and mig welding (gas metal arc welding or gmaw) are two popular arc welding processes, each with its own advantages and disadvantages. Scratch start scratch start is the most basic form of tig welding and requires dragging. Types Of Welding Tig.

From www.muggyweld.com

3 Common Types of Welding Processes TIG, MIG, and Stick Types Of Welding Tig Lift arc lift arc requires touching the workpiece and lifting the torch to initiate the weld cycle. It’s a form of gtaw (gas tungsten arc welding) and is used for many. Tig (tungsten inert gas) welding is a common method used in manufacturing to join pieces of metal together. All of the different welding processes and acronyms can be really. Types Of Welding Tig.

From alroys.com

What is TIG welding and how does it work? Alroys Types Of Welding Tig Scratch start scratch start is the most basic form of tig welding and requires dragging the electrode across the surface of a workpiece to initiate the weld cycle. Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze and even gold. Lift arc lift arc requires touching the workpiece and lifting the. Types Of Welding Tig.

From www.technoxmachine.com

MIG vs TIG Welding Types, Materials, and Applications A Guide Types Of Welding Tig The tig process can be used to weld. In this video, i go ov. Scratch start scratch start is the most basic form of tig welding and requires dragging the electrode across the surface of a workpiece to initiate the weld cycle. Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze. Types Of Welding Tig.

From bearinforest.com

Three Types Of Welding; MIG, TIG and Flux Cored Arc Welding Bearinforest Types Of Welding Tig Learn about the different types of welding in our comprehensive guide covering mig, tig, fcaw, and saw welding to get efficient and effective results. The tig process can be used to weld. Tig (tungsten inert gas) welding is a common method used in manufacturing to join pieces of metal together. Lift arc lift arc requires touching the workpiece and lifting. Types Of Welding Tig.

From sensibledigs.com

How To TIG Weld (StepbyStep Process) Sensible Digs Types Of Welding Tig The tig process can be used to weld. Tig (tungsten inert gas) welding is a common method used in manufacturing to join pieces of metal together. All of the different welding processes and acronyms can be really confusing. In this video, i go ov. Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper,. Types Of Welding Tig.

From tigbrush.com

Various Types of Welding Joints and Their Uses TIG Brush Types Of Welding Tig In this video, i go ov. It’s a form of gtaw (gas tungsten arc welding) and is used for many. Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze and even gold. Tig (tungsten inert gas) welding is a common method used in manufacturing to join pieces of metal together. Learn. Types Of Welding Tig.

From www.technoxmachine.com

MIG vs TIG Welding Types, Materials, and Applications A Guide Types Of Welding Tig The tig process can be used to weld. It’s a form of gtaw (gas tungsten arc welding) and is used for many. Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze and even gold. Tig welding and mig welding (gas metal arc welding or gmaw) are two popular arc welding processes,. Types Of Welding Tig.

From www.millerwelds.com

How a TIG Welder Works and When to TIG Weld MillerWelds Types Of Welding Tig Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze and even gold. Lift arc lift arc requires touching the workpiece and lifting the torch to initiate the weld cycle. In this video, i go ov. Tig (tungsten inert gas) welding is a common method used in manufacturing to join pieces of. Types Of Welding Tig.

From www.theengineerspost.com

Tig and Mig Welding The Real Differences Explained [PDF] Types Of Welding Tig The tig process can be used to weld. Scratch start scratch start is the most basic form of tig welding and requires dragging the electrode across the surface of a workpiece to initiate the weld cycle. Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze and even gold. All of the. Types Of Welding Tig.

From www.weldingtypes.net

Tig Welding Welding Types Types Of Welding Tig Tig welding and mig welding (gas metal arc welding or gmaw) are two popular arc welding processes, each with its own advantages and disadvantages. Tig (tungsten inert gas) welding is a common method used in manufacturing to join pieces of metal together. Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze. Types Of Welding Tig.

From weldingpros.net

How to TIG Weld Steel and Aluminum Basics, Setup and Tips Types Of Welding Tig It’s a form of gtaw (gas tungsten arc welding) and is used for many. All of the different welding processes and acronyms can be really confusing. Tig (tungsten inert gas) welding is a common method used in manufacturing to join pieces of metal together. Lift arc lift arc requires touching the workpiece and lifting the torch to initiate the weld. Types Of Welding Tig.

From fractory.com

TIG Welding Explained Fractory Types Of Welding Tig Scratch start scratch start is the most basic form of tig welding and requires dragging the electrode across the surface of a workpiece to initiate the weld cycle. Tig (tungsten inert gas) welding is a common method used in manufacturing to join pieces of metal together. All of the different welding processes and acronyms can be really confusing. Learn about. Types Of Welding Tig.

From waterwelders.com

What is TIG Welding Used for? (& How to Know When to Use It) WaterWelders Types Of Welding Tig Lift arc lift arc requires touching the workpiece and lifting the torch to initiate the weld cycle. All of the different welding processes and acronyms can be really confusing. Tig welding and mig welding (gas metal arc welding or gmaw) are two popular arc welding processes, each with its own advantages and disadvantages. Tig welders can be used to weld. Types Of Welding Tig.

From www.theengineerspost.com

12 Types of Welding Processes & Their Uses [Full Guide] PDF Types Of Welding Tig All of the different welding processes and acronyms can be really confusing. Tig (tungsten inert gas) welding is a common method used in manufacturing to join pieces of metal together. Learn about the different types of welding in our comprehensive guide covering mig, tig, fcaw, and saw welding to get efficient and effective results. It’s a form of gtaw (gas. Types Of Welding Tig.

From weldersalliancenewshub.com

4 Types of Welding Explained MIG vs TIG vs Stick vs Flux Core Types Of Welding Tig Tig welding and mig welding (gas metal arc welding or gmaw) are two popular arc welding processes, each with its own advantages and disadvantages. The tig process can be used to weld. In this video, i go ov. Lift arc lift arc requires touching the workpiece and lifting the torch to initiate the weld cycle. Tig welders can be used. Types Of Welding Tig.

From www.ns-newelding.com

TIG welding everything you need to know Types Of Welding Tig Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze and even gold. The tig process can be used to weld. Tig (tungsten inert gas) welding is a common method used in manufacturing to join pieces of metal together. Scratch start scratch start is the most basic form of tig welding and. Types Of Welding Tig.

From www.researchgate.net

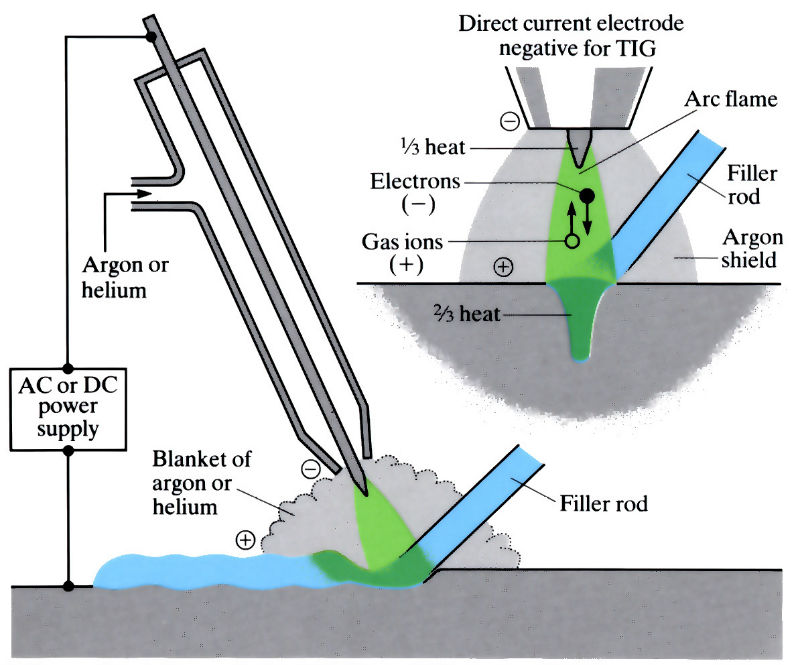

Schematic Diagram of TIG welding process Download Scientific Diagram Types Of Welding Tig It’s a form of gtaw (gas tungsten arc welding) and is used for many. Tig (tungsten inert gas) welding is a common method used in manufacturing to join pieces of metal together. All of the different welding processes and acronyms can be really confusing. In this video, i go ov. Scratch start scratch start is the most basic form of. Types Of Welding Tig.

From www.youtube.com

TIG Welding Tips and Techniques YouTube Types Of Welding Tig The tig process can be used to weld. Learn about the different types of welding in our comprehensive guide covering mig, tig, fcaw, and saw welding to get efficient and effective results. Scratch start scratch start is the most basic form of tig welding and requires dragging the electrode across the surface of a workpiece to initiate the weld cycle.. Types Of Welding Tig.

From www.hollyfab.com

Common Welding Methods Types Of Welding Tig Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze and even gold. Learn about the different types of welding in our comprehensive guide covering mig, tig, fcaw, and saw welding to get efficient and effective results. Tig welding and mig welding (gas metal arc welding or gmaw) are two popular arc. Types Of Welding Tig.

From weld.blog

Exploring Different Types of Welding MIG, TIG, Arc, and more Weld Blog Types Of Welding Tig It’s a form of gtaw (gas tungsten arc welding) and is used for many. Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze and even gold. Scratch start scratch start is the most basic form of tig welding and requires dragging the electrode across the surface of a workpiece to initiate. Types Of Welding Tig.

From www.metalwerksinc.com

TIG, MIG & Spot Welding Seattle, WA Metal Werks Types Of Welding Tig Lift arc lift arc requires touching the workpiece and lifting the torch to initiate the weld cycle. Learn about the different types of welding in our comprehensive guide covering mig, tig, fcaw, and saw welding to get efficient and effective results. It’s a form of gtaw (gas tungsten arc welding) and is used for many. Tig welders can be used. Types Of Welding Tig.

From engineerfix.com

A Complete Guide To Welding What It Is, Types, Types Of Joints, And Types Of Welding Tig All of the different welding processes and acronyms can be really confusing. Lift arc lift arc requires touching the workpiece and lifting the torch to initiate the weld cycle. Tig welding and mig welding (gas metal arc welding or gmaw) are two popular arc welding processes, each with its own advantages and disadvantages. It’s a form of gtaw (gas tungsten. Types Of Welding Tig.

From weldguru.com

4 Main Types of Welding Processes (with diagrams) Types Of Welding Tig In this video, i go ov. Lift arc lift arc requires touching the workpiece and lifting the torch to initiate the weld cycle. Learn about the different types of welding in our comprehensive guide covering mig, tig, fcaw, and saw welding to get efficient and effective results. Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel. Types Of Welding Tig.

From www.cromweld.com

Comparing Welding Types TIG vs. MIG vs. Stick vs. Arc Types Of Welding Tig In this video, i go ov. Lift arc lift arc requires touching the workpiece and lifting the torch to initiate the weld cycle. Tig welding and mig welding (gas metal arc welding or gmaw) are two popular arc welding processes, each with its own advantages and disadvantages. All of the different welding processes and acronyms can be really confusing. The. Types Of Welding Tig.

From engineeringlearn.com

Types of Welding MIG Welding, TIG Welding, Stick Welding & Flux Cored Types Of Welding Tig The tig process can be used to weld. Lift arc lift arc requires touching the workpiece and lifting the torch to initiate the weld cycle. It’s a form of gtaw (gas tungsten arc welding) and is used for many. Tig welding and mig welding (gas metal arc welding or gmaw) are two popular arc welding processes, each with its own. Types Of Welding Tig.

From www.rapiddirect.com

MIG VS TIG Welding A Guide to Choosing the Right Process RapidDirect Types Of Welding Tig Lift arc lift arc requires touching the workpiece and lifting the torch to initiate the weld cycle. It’s a form of gtaw (gas tungsten arc welding) and is used for many. The tig process can be used to weld. Tig welding and mig welding (gas metal arc welding or gmaw) are two popular arc welding processes, each with its own. Types Of Welding Tig.

From blog.hirebotics.com

15 Types of Welding Processes with Their Advantages and Limitations Types Of Welding Tig All of the different welding processes and acronyms can be really confusing. The tig process can be used to weld. In this video, i go ov. Tig welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze and even gold. Scratch start scratch start is the most basic form of tig welding and. Types Of Welding Tig.

From www.artofit.org

Types of welding welding process Artofit Types Of Welding Tig Tig welding and mig welding (gas metal arc welding or gmaw) are two popular arc welding processes, each with its own advantages and disadvantages. Lift arc lift arc requires touching the workpiece and lifting the torch to initiate the weld cycle. Tig (tungsten inert gas) welding is a common method used in manufacturing to join pieces of metal together. It’s. Types Of Welding Tig.

From www.youtube.com

Differences between MIG Welding and TIG Welding. YouTube Types Of Welding Tig All of the different welding processes and acronyms can be really confusing. Tig welding and mig welding (gas metal arc welding or gmaw) are two popular arc welding processes, each with its own advantages and disadvantages. Lift arc lift arc requires touching the workpiece and lifting the torch to initiate the weld cycle. Scratch start scratch start is the most. Types Of Welding Tig.