Pneumatic Actuator Troubleshooting . refer to the valve manufacturer's recommendations for specific requirements. When the valve has internal stops, the. ensure that the air supply is not restricted in any way. pneumatic control valves operate using compressed air to control the flow of liquids or gasses. Check for air leakage on supply lines to the actuator. The system leakage in front of the actuator is not allowing the minimum scfm (standard. preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical assembly, calibrating the positioner, repairing any leaks, bends or discoloration in the pneumatic tubing and replacement of worn components with properly sized parts. pneumatic rotary actuators.

from proper-cooking.info

Check for air leakage on supply lines to the actuator. The system leakage in front of the actuator is not allowing the minimum scfm (standard. pneumatic rotary actuators. When the valve has internal stops, the. refer to the valve manufacturer's recommendations for specific requirements. pneumatic control valves operate using compressed air to control the flow of liquids or gasses. ensure that the air supply is not restricted in any way. preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical assembly, calibrating the positioner, repairing any leaks, bends or discoloration in the pneumatic tubing and replacement of worn components with properly sized parts.

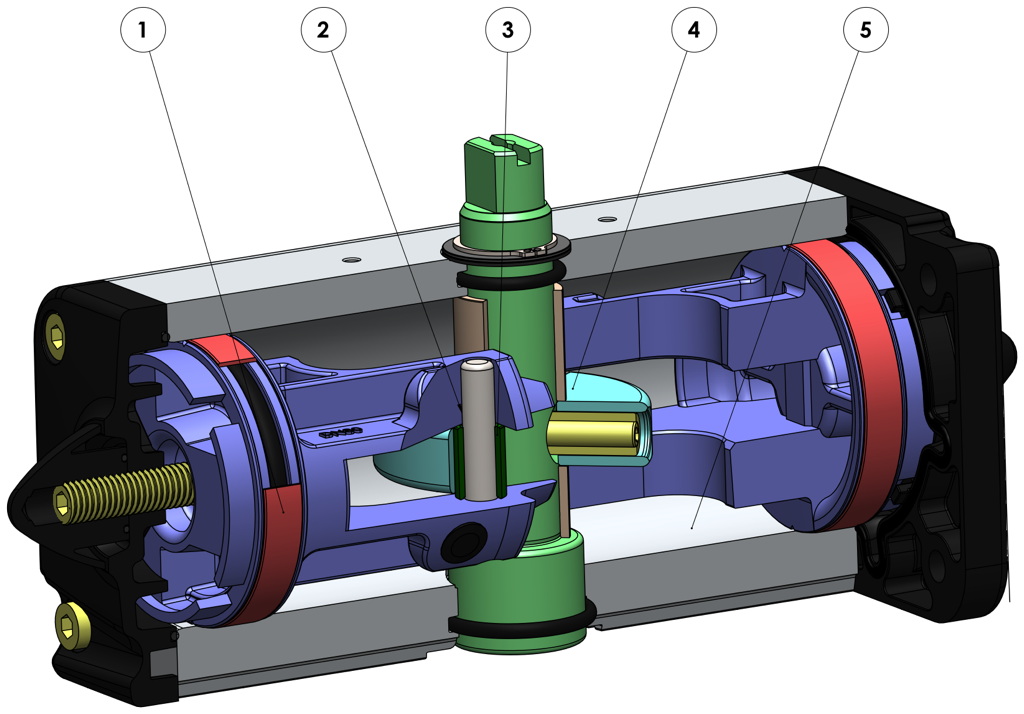

Pneumatic Actuator Diagram

Pneumatic Actuator Troubleshooting Check for air leakage on supply lines to the actuator. preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical assembly, calibrating the positioner, repairing any leaks, bends or discoloration in the pneumatic tubing and replacement of worn components with properly sized parts. pneumatic rotary actuators. Check for air leakage on supply lines to the actuator. refer to the valve manufacturer's recommendations for specific requirements. ensure that the air supply is not restricted in any way. When the valve has internal stops, the. pneumatic control valves operate using compressed air to control the flow of liquids or gasses. The system leakage in front of the actuator is not allowing the minimum scfm (standard.

From ar.inspiredpencil.com

Pneumatic Actuator Diagram Pneumatic Actuator Troubleshooting Check for air leakage on supply lines to the actuator. The system leakage in front of the actuator is not allowing the minimum scfm (standard. ensure that the air supply is not restricted in any way. pneumatic control valves operate using compressed air to control the flow of liquids or gasses. refer to the valve manufacturer's recommendations. Pneumatic Actuator Troubleshooting.

From valve-automatic.com

Troubleshooting Tips For Your Segmented Ball Valve System Pneumatic Actuator Troubleshooting pneumatic control valves operate using compressed air to control the flow of liquids or gasses. preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical assembly, calibrating the positioner, repairing any leaks, bends or discoloration in the pneumatic tubing and replacement of worn components with. Pneumatic Actuator Troubleshooting.

From www.hearkenflow.com

How to troubleshoot pneumatic actuators? HEARKEN Pneumatic Actuator Troubleshooting Check for air leakage on supply lines to the actuator. ensure that the air supply is not restricted in any way. refer to the valve manufacturer's recommendations for specific requirements. The system leakage in front of the actuator is not allowing the minimum scfm (standard. pneumatic control valves operate using compressed air to control the flow of. Pneumatic Actuator Troubleshooting.

From assuredautomation.com

Buy an F Series Actuator Repair Kit Pneumatic Actuator Troubleshooting preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical assembly, calibrating the positioner, repairing any leaks, bends or discoloration in the pneumatic tubing and replacement of worn components with properly sized parts. refer to the valve manufacturer's recommendations for specific requirements. pneumatic control. Pneumatic Actuator Troubleshooting.

From www.ebay.com

KITZ Pneumatic Actuator Repair Kit DA4 776004 / 72065W NEW eBay Pneumatic Actuator Troubleshooting refer to the valve manufacturer's recommendations for specific requirements. ensure that the air supply is not restricted in any way. Check for air leakage on supply lines to the actuator. pneumatic rotary actuators. pneumatic control valves operate using compressed air to control the flow of liquids or gasses. preventive maintenance for pneumatic control valves should. Pneumatic Actuator Troubleshooting.

From www.youtube.com

Design of Pneumatic Rotary Actuator Mechanism of Rotary Actuator Pneumatic Actuator Troubleshooting refer to the valve manufacturer's recommendations for specific requirements. The system leakage in front of the actuator is not allowing the minimum scfm (standard. pneumatic rotary actuators. When the valve has internal stops, the. ensure that the air supply is not restricted in any way. preventive maintenance for pneumatic control valves should include a visual inspection. Pneumatic Actuator Troubleshooting.

From proper-cooking.info

Pneumatic Actuator Diagram Pneumatic Actuator Troubleshooting preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical assembly, calibrating the positioner, repairing any leaks, bends or discoloration in the pneumatic tubing and replacement of worn components with properly sized parts. pneumatic control valves operate using compressed air to control the flow of. Pneumatic Actuator Troubleshooting.

From www.eaglesky1286.com

PneumaticActuatorDrawing1 Rotary Automatic Pneumatic Valve Pneumatic Actuator Troubleshooting refer to the valve manufacturer's recommendations for specific requirements. When the valve has internal stops, the. pneumatic rotary actuators. pneumatic control valves operate using compressed air to control the flow of liquids or gasses. ensure that the air supply is not restricted in any way. preventive maintenance for pneumatic control valves should include a visual. Pneumatic Actuator Troubleshooting.

From valveman.com

Pneumatic Automation Explained by the ValveMan Valve Store Pneumatic Actuator Troubleshooting pneumatic rotary actuators. ensure that the air supply is not restricted in any way. Check for air leakage on supply lines to the actuator. preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical assembly, calibrating the positioner, repairing any leaks, bends or discoloration. Pneumatic Actuator Troubleshooting.

From control.com

Valve Positioners Basic Principles of Control Valves and Actuators Pneumatic Actuator Troubleshooting When the valve has internal stops, the. pneumatic rotary actuators. preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical assembly, calibrating the positioner, repairing any leaks, bends or discoloration in the pneumatic tubing and replacement of worn components with properly sized parts. pneumatic. Pneumatic Actuator Troubleshooting.

From www.youtube.com

Pneumatic Actuator Working Principle of Pneumatic Actuator Actuator Pneumatic Actuator Troubleshooting ensure that the air supply is not restricted in any way. refer to the valve manufacturer's recommendations for specific requirements. Check for air leakage on supply lines to the actuator. pneumatic control valves operate using compressed air to control the flow of liquids or gasses. The system leakage in front of the actuator is not allowing the. Pneumatic Actuator Troubleshooting.

From ar.inspiredpencil.com

How Do Pneumatic Actuators Work Pneumatic Actuator Troubleshooting pneumatic rotary actuators. Check for air leakage on supply lines to the actuator. refer to the valve manufacturer's recommendations for specific requirements. preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical assembly, calibrating the positioner, repairing any leaks, bends or discoloration in the. Pneumatic Actuator Troubleshooting.

From www.vrogue.co

Pneumatic Actuators Troubleshooting Youtube vrogue.co Pneumatic Actuator Troubleshooting Check for air leakage on supply lines to the actuator. pneumatic rotary actuators. When the valve has internal stops, the. ensure that the air supply is not restricted in any way. pneumatic control valves operate using compressed air to control the flow of liquids or gasses. refer to the valve manufacturer's recommendations for specific requirements. The. Pneumatic Actuator Troubleshooting.

From ar.inspiredpencil.com

How Do Pneumatic Actuators Work Pneumatic Actuator Troubleshooting When the valve has internal stops, the. ensure that the air supply is not restricted in any way. Check for air leakage on supply lines to the actuator. pneumatic rotary actuators. pneumatic control valves operate using compressed air to control the flow of liquids or gasses. The system leakage in front of the actuator is not allowing. Pneumatic Actuator Troubleshooting.

From www.realpars.com

What is a Pneumatic Actuator? Types & Applications RealPars Pneumatic Actuator Troubleshooting pneumatic rotary actuators. preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical assembly, calibrating the positioner, repairing any leaks, bends or discoloration in the pneumatic tubing and replacement of worn components with properly sized parts. pneumatic control valves operate using compressed air to. Pneumatic Actuator Troubleshooting.

From assuredautomation.com

Buy P Series Pneumatic Valve Actuator Parts Pneumatic Actuator Troubleshooting preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical assembly, calibrating the positioner, repairing any leaks, bends or discoloration in the pneumatic tubing and replacement of worn components with properly sized parts. ensure that the air supply is not restricted in any way. When. Pneumatic Actuator Troubleshooting.

From mavink.com

Hydraulic Actuator Diagram Pneumatic Actuator Troubleshooting Check for air leakage on supply lines to the actuator. When the valve has internal stops, the. preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical assembly, calibrating the positioner, repairing any leaks, bends or discoloration in the pneumatic tubing and replacement of worn components. Pneumatic Actuator Troubleshooting.

From instrumentationtools.com

What is a Pneumatic Actuator ? Instrumentation Tools Pneumatic Actuator Troubleshooting When the valve has internal stops, the. pneumatic rotary actuators. ensure that the air supply is not restricted in any way. refer to the valve manufacturer's recommendations for specific requirements. Check for air leakage on supply lines to the actuator. pneumatic control valves operate using compressed air to control the flow of liquids or gasses. . Pneumatic Actuator Troubleshooting.

From www.delvalflow.com

Pneumatic Rack & Pinion Delval Flow Controls Pneumatic Actuator Troubleshooting pneumatic rotary actuators. When the valve has internal stops, the. ensure that the air supply is not restricted in any way. The system leakage in front of the actuator is not allowing the minimum scfm (standard. preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in. Pneumatic Actuator Troubleshooting.

From www.researchgate.net

Diagram of the pneumatic control and drive system of the launch tube Pneumatic Actuator Troubleshooting When the valve has internal stops, the. pneumatic rotary actuators. preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical assembly, calibrating the positioner, repairing any leaks, bends or discoloration in the pneumatic tubing and replacement of worn components with properly sized parts. ensure. Pneumatic Actuator Troubleshooting.

From www.e-pneumatic.com

How Pneumatic Cylinder Work? Described Instructions Pneumatic Blog Pneumatic Actuator Troubleshooting Check for air leakage on supply lines to the actuator. preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical assembly, calibrating the positioner, repairing any leaks, bends or discoloration in the pneumatic tubing and replacement of worn components with properly sized parts. pneumatic rotary. Pneumatic Actuator Troubleshooting.

From www.scribd.com

310Developing Pneumatic Troubleshooting Skills PDF Actuator Pump Pneumatic Actuator Troubleshooting preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical assembly, calibrating the positioner, repairing any leaks, bends or discoloration in the pneumatic tubing and replacement of worn components with properly sized parts. pneumatic rotary actuators. refer to the valve manufacturer's recommendations for specific. Pneumatic Actuator Troubleshooting.

From www.rowse.co.uk

11 Steps Troubleshooting Pneumatic Systems Rowse Pneumatic Actuator Troubleshooting refer to the valve manufacturer's recommendations for specific requirements. Check for air leakage on supply lines to the actuator. pneumatic control valves operate using compressed air to control the flow of liquids or gasses. preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical. Pneumatic Actuator Troubleshooting.

From www.dwyer-inst.com

Series ARK Pneumatic Actuator Repair Kit includes orings for end Pneumatic Actuator Troubleshooting pneumatic rotary actuators. The system leakage in front of the actuator is not allowing the minimum scfm (standard. When the valve has internal stops, the. ensure that the air supply is not restricted in any way. preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in. Pneumatic Actuator Troubleshooting.

From www.anythingflows.com

How Electric and Pneumatic Valve Actuators Operate Pneumatic Actuator Troubleshooting When the valve has internal stops, the. pneumatic rotary actuators. The system leakage in front of the actuator is not allowing the minimum scfm (standard. refer to the valve manufacturer's recommendations for specific requirements. preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical. Pneumatic Actuator Troubleshooting.

From www.circuitdiagram.co

Electro Pneumatic Schematic Diagram » Circuit Diagram Pneumatic Actuator Troubleshooting pneumatic control valves operate using compressed air to control the flow of liquids or gasses. When the valve has internal stops, the. ensure that the air supply is not restricted in any way. pneumatic rotary actuators. preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration. Pneumatic Actuator Troubleshooting.

From www.bonanza.com

New NOS Keystone Pneumatic Actuator Repair Kit 198935301790037 SKU Pneumatic Actuator Troubleshooting pneumatic control valves operate using compressed air to control the flow of liquids or gasses. Check for air leakage on supply lines to the actuator. pneumatic rotary actuators. refer to the valve manufacturer's recommendations for specific requirements. ensure that the air supply is not restricted in any way. The system leakage in front of the actuator. Pneumatic Actuator Troubleshooting.

From www.youtube.com

Troubleshooting of Solenoid Valve SOV Problem Find Out & Solved Pneumatic Actuator Troubleshooting preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical assembly, calibrating the positioner, repairing any leaks, bends or discoloration in the pneumatic tubing and replacement of worn components with properly sized parts. Check for air leakage on supply lines to the actuator. pneumatic control. Pneumatic Actuator Troubleshooting.

From www.youtube.com

Working Principle of Pneumatic Actuator How Pneumatic Actuators Work Pneumatic Actuator Troubleshooting pneumatic control valves operate using compressed air to control the flow of liquids or gasses. When the valve has internal stops, the. preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical assembly, calibrating the positioner, repairing any leaks, bends or discoloration in the pneumatic. Pneumatic Actuator Troubleshooting.

From reviewmotors.co

Pneumatic Actuator Spare Parts Reviewmotors.co Pneumatic Actuator Troubleshooting pneumatic rotary actuators. The system leakage in front of the actuator is not allowing the minimum scfm (standard. Check for air leakage on supply lines to the actuator. pneumatic control valves operate using compressed air to control the flow of liquids or gasses. preventive maintenance for pneumatic control valves should include a visual inspection for wear and. Pneumatic Actuator Troubleshooting.

From www.pinterest.co.kr

Bray Pneumatic Actuators Direct Acting and Spring Return Series 92/ Pneumatic Actuator Troubleshooting The system leakage in front of the actuator is not allowing the minimum scfm (standard. pneumatic control valves operate using compressed air to control the flow of liquids or gasses. Check for air leakage on supply lines to the actuator. pneumatic rotary actuators. ensure that the air supply is not restricted in any way. refer to. Pneumatic Actuator Troubleshooting.

From fluidpowerworld.tradepub.com

Pneumatic Actuators Free Guide Pneumatic Actuator Troubleshooting pneumatic rotary actuators. refer to the valve manufacturer's recommendations for specific requirements. Check for air leakage on supply lines to the actuator. The system leakage in front of the actuator is not allowing the minimum scfm (standard. preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration. Pneumatic Actuator Troubleshooting.

From www.youtube.com

What is a Pneumatic Actuator? Types & ApplicationsHow Pneumatic Pneumatic Actuator Troubleshooting Check for air leakage on supply lines to the actuator. preventive maintenance for pneumatic control valves should include a visual inspection for wear and corrosion, ensuring there is no vibration in the mechanical assembly, calibrating the positioner, repairing any leaks, bends or discoloration in the pneumatic tubing and replacement of worn components with properly sized parts. refer to. Pneumatic Actuator Troubleshooting.

From www.processindustryforum.com

What is a Pneumatic Actuator and how do they work? Pneumatic Actuator Troubleshooting pneumatic rotary actuators. Check for air leakage on supply lines to the actuator. When the valve has internal stops, the. pneumatic control valves operate using compressed air to control the flow of liquids or gasses. The system leakage in front of the actuator is not allowing the minimum scfm (standard. ensure that the air supply is not. Pneumatic Actuator Troubleshooting.

From library.automationdirect.com

Pneumatic Actuator (Air Cylinder) Basics Pneumatic Actuator Troubleshooting pneumatic control valves operate using compressed air to control the flow of liquids or gasses. When the valve has internal stops, the. refer to the valve manufacturer's recommendations for specific requirements. Check for air leakage on supply lines to the actuator. The system leakage in front of the actuator is not allowing the minimum scfm (standard. pneumatic. Pneumatic Actuator Troubleshooting.