How Does A Cold Milling Machine Work . Operators are under pressure to get the best performance out of their cold mills in terms of consistency of milling pattern, correct grade and slope, cleanliness of cut,. Asphalt milling, also called cold milling or cold planing, is the process of removing a part of the existing pavement surface to help restore it to a uniform texture to use or repave. Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. The rows of metal cutting teeth mounted diagonally on a large rotating. Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient thickness to. The range of applications extends from the. In doing so, they create a level foundation with the.

from www.cncmasters.com

Operators are under pressure to get the best performance out of their cold mills in terms of consistency of milling pattern, correct grade and slope, cleanliness of cut,. In doing so, they create a level foundation with the. The rows of metal cutting teeth mounted diagonally on a large rotating. The range of applications extends from the. Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient thickness to. Asphalt milling, also called cold milling or cold planing, is the process of removing a part of the existing pavement surface to help restore it to a uniform texture to use or repave.

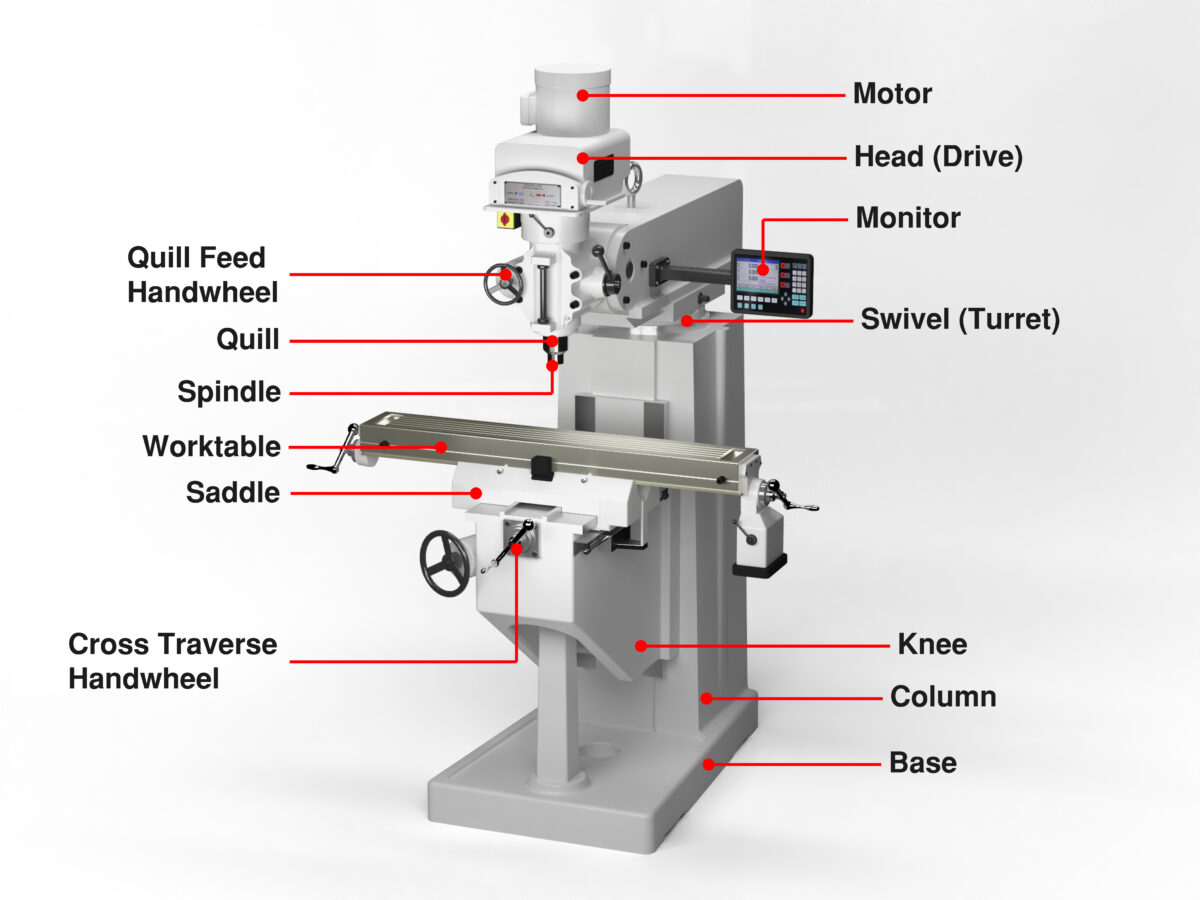

The 8 Most Important Parts of a Milling Machine CNC Masters

How Does A Cold Milling Machine Work Operators are under pressure to get the best performance out of their cold mills in terms of consistency of milling pattern, correct grade and slope, cleanliness of cut,. Asphalt milling, also called cold milling or cold planing, is the process of removing a part of the existing pavement surface to help restore it to a uniform texture to use or repave. The range of applications extends from the. Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. In doing so, they create a level foundation with the. Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient thickness to. The rows of metal cutting teeth mounted diagonally on a large rotating. Operators are under pressure to get the best performance out of their cold mills in terms of consistency of milling pattern, correct grade and slope, cleanliness of cut,.

From www.cncmasters.com

The 8 Most Important Parts of a Milling Machine CNC Masters How Does A Cold Milling Machine Work Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. The range of applications extends from the. Operators are under pressure to get the best performance out of their cold mills in terms of consistency of milling pattern, correct grade and slope, cleanliness of cut,. In doing so, they create a level foundation with the. Asphalt. How Does A Cold Milling Machine Work.

From www.doggettequipment.com

Cold milling machines Doggett How Does A Cold Milling Machine Work Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient thickness to. Operators are under pressure to get the best performance out of their cold mills in terms of consistency of milling pattern, correct grade and slope, cleanliness of cut,. Asphalt milling, also called cold milling or cold planing, is. How Does A Cold Milling Machine Work.

From www.vecteezy.com

Vector illustration color children construction cold milling machine How Does A Cold Milling Machine Work Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. The rows of metal cutting teeth mounted diagonally on a large rotating. Asphalt milling, also called cold milling or cold planing, is the process of removing a part of the existing pavement surface to help restore it to a uniform texture to use or repave. Operators. How Does A Cold Milling Machine Work.

From www.glomacht.com

what are the different types of milling machines? GLOMACHT BV Used How Does A Cold Milling Machine Work Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient thickness to. Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. The range of applications extends from the. Asphalt milling, also called cold milling or cold planing, is the process of removing a part of. How Does A Cold Milling Machine Work.

From www.algonquincollege.com

metal machining industry. Worker operating cnc milling machine School How Does A Cold Milling Machine Work Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. Asphalt milling, also called cold milling or cold planing, is the process of removing a part of the existing pavement surface to help restore it to a uniform texture to use or repave. Also called cold planning or asphalt milling and profiling, involves removing part of. How Does A Cold Milling Machine Work.

From www.fotma.com

XM35200E Cold Milling Machine FOTMA Machinery How Does A Cold Milling Machine Work The rows of metal cutting teeth mounted diagonally on a large rotating. In doing so, they create a level foundation with the. The range of applications extends from the. Asphalt milling, also called cold milling or cold planing, is the process of removing a part of the existing pavement surface to help restore it to a uniform texture to use. How Does A Cold Milling Machine Work.

From www.youtube.com

Milling machine , Road construction working . Wirtgen W100H milling How Does A Cold Milling Machine Work The range of applications extends from the. Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. Operators are under pressure to get the best performance out of their cold mills in terms of consistency of milling pattern, correct grade and slope, cleanliness of cut,. The rows of metal cutting teeth mounted diagonally on a large. How Does A Cold Milling Machine Work.

From www.alamy.com

Cold milling machine in use Stock Photo Alamy How Does A Cold Milling Machine Work The rows of metal cutting teeth mounted diagonally on a large rotating. The range of applications extends from the. In doing so, they create a level foundation with the. Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt. How Does A Cold Milling Machine Work.

From inchbyinch.de

INCH Technical English pictorial cold milling machine/road planer How Does A Cold Milling Machine Work The rows of metal cutting teeth mounted diagonally on a large rotating. Operators are under pressure to get the best performance out of their cold mills in terms of consistency of milling pattern, correct grade and slope, cleanliness of cut,. The range of applications extends from the. Cold milling machines are used to remove asphalt and concrete surfaces quickly and. How Does A Cold Milling Machine Work.

From www.youtube.com

HOW? Groundnut Oil is made? Cold Pressed Oil Factory Explorer YouTube How Does A Cold Milling Machine Work Asphalt milling, also called cold milling or cold planing, is the process of removing a part of the existing pavement surface to help restore it to a uniform texture to use or repave. The rows of metal cutting teeth mounted diagonally on a large rotating. Also called cold planning or asphalt milling and profiling, involves removing part of the existing. How Does A Cold Milling Machine Work.

From www.youtube.com

कोल्ड प्रेस तेल मशीन,तेल पेरने की मशीन,Cold Press Oil Machine,Oil Mill How Does A Cold Milling Machine Work The range of applications extends from the. The rows of metal cutting teeth mounted diagonally on a large rotating. Asphalt milling, also called cold milling or cold planing, is the process of removing a part of the existing pavement surface to help restore it to a uniform texture to use or repave. In doing so, they create a level foundation. How Does A Cold Milling Machine Work.

From 3axis-group.com

How does a horizontal milling machine work? • 3axis Group How Does A Cold Milling Machine Work The range of applications extends from the. Asphalt milling, also called cold milling or cold planing, is the process of removing a part of the existing pavement surface to help restore it to a uniform texture to use or repave. In doing so, they create a level foundation with the. Also called cold planning or asphalt milling and profiling, involves. How Does A Cold Milling Machine Work.

From www.youtube.com

Wirtgen W 50 DC Cold Milling Machine working YouTube How Does A Cold Milling Machine Work Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. Asphalt milling, also called cold milling or cold planing, is the process of removing a part of the existing pavement surface to help restore it to a uniform texture to use or repave. The range of applications extends from the. The rows of metal cutting teeth. How Does A Cold Milling Machine Work.

From www.storyblocks.com

Work Milling Machine Slow Motion Sparks From Stock Footage SBV How Does A Cold Milling Machine Work Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. The range of applications extends from the. The rows of metal cutting teeth mounted diagonally on a large rotating. Asphalt milling, also called cold milling or cold planing, is the process of removing a part of the existing pavement surface to help restore it to a. How Does A Cold Milling Machine Work.

From mungfali.com

Wirtgen Cold Milling Machine How Does A Cold Milling Machine Work Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. The rows of metal cutting teeth mounted diagonally on a large rotating. Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient thickness to. Asphalt milling, also called cold milling or cold planing, is the process. How Does A Cold Milling Machine Work.

From www.alibaba.com

Road Construction Machinery 1000mm Cold Milling Machine Xm1005h With How Does A Cold Milling Machine Work The rows of metal cutting teeth mounted diagonally on a large rotating. In doing so, they create a level foundation with the. The range of applications extends from the. Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient thickness to. Operators are under pressure to get the best performance. How Does A Cold Milling Machine Work.

From www.alamy.com

Road cold milling machine removes the old asphalt. Repaving the road How Does A Cold Milling Machine Work The rows of metal cutting teeth mounted diagonally on a large rotating. In doing so, they create a level foundation with the. Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient thickness to. Operators are under pressure to get the best performance out of their cold mills in terms. How Does A Cold Milling Machine Work.

From www.lathemastery.com

How Does a Milling Machine Work? Lathe Mastery How Does A Cold Milling Machine Work The rows of metal cutting teeth mounted diagonally on a large rotating. In doing so, they create a level foundation with the. Operators are under pressure to get the best performance out of their cold mills in terms of consistency of milling pattern, correct grade and slope, cleanliness of cut,. Asphalt milling, also called cold milling or cold planing, is. How Does A Cold Milling Machine Work.

From mavink.com

Parts Of A Horizontal Milling Machine How Does A Cold Milling Machine Work In doing so, they create a level foundation with the. The rows of metal cutting teeth mounted diagonally on a large rotating. Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. The range of applications extends from the. Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt. How Does A Cold Milling Machine Work.

From www.tradeindia.com

Cold Press Oil Mill Machine at 180000.00 INR in Coimbatore Sri How Does A Cold Milling Machine Work Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. The rows of metal cutting teeth mounted diagonally on a large rotating. The range of applications extends from the. In doing so, they create a level foundation with the. Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt. How Does A Cold Milling Machine Work.

From www.mechanicalbooster.com

What is Milling Machine Operation, Parts and Types. Mechanical Booster How Does A Cold Milling Machine Work Asphalt milling, also called cold milling or cold planing, is the process of removing a part of the existing pavement surface to help restore it to a uniform texture to use or repave. Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient thickness to. In doing so, they create. How Does A Cold Milling Machine Work.

From www.verifiedmarketresearch.com

Cold Milling Machine Market Size, Share, Scope & Forecast How Does A Cold Milling Machine Work The rows of metal cutting teeth mounted diagonally on a large rotating. Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient thickness to. The range of applications extends from the. Asphalt milling, also called cold milling or cold planing, is the process of removing a part of the existing. How Does A Cold Milling Machine Work.

From www.alamy.com

view of a Wirtgen W 2100 Cold Milling Machine at work, removing the How Does A Cold Milling Machine Work In doing so, they create a level foundation with the. Operators are under pressure to get the best performance out of their cold mills in terms of consistency of milling pattern, correct grade and slope, cleanliness of cut,. The range of applications extends from the. Also called cold planning or asphalt milling and profiling, involves removing part of the existing. How Does A Cold Milling Machine Work.

From www.youtube.com

4HI Cold Rolling Mill with AGC YouTube How Does A Cold Milling Machine Work Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. The range of applications extends from the. Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient thickness to. The rows of metal cutting teeth mounted diagonally on a large rotating. In doing so, they create. How Does A Cold Milling Machine Work.

From mungfali.com

Wirtgen Cold Milling Machine How Does A Cold Milling Machine Work Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient thickness to. Operators are under pressure to get the best performance out of their cold mills in terms of consistency of milling pattern, correct grade and. How Does A Cold Milling Machine Work.

From www.primetals.com

Aluminum Cold Rolling Mills by Primetals Technologies How Does A Cold Milling Machine Work Asphalt milling, also called cold milling or cold planing, is the process of removing a part of the existing pavement surface to help restore it to a uniform texture to use or repave. The range of applications extends from the. Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient. How Does A Cold Milling Machine Work.

From www.dreamstime.com

Asphalt Cold Milling Machine on the Street during Municipality How Does A Cold Milling Machine Work Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient thickness to. The rows of metal cutting teeth mounted diagonally on a large rotating. Operators are under pressure to get the best performance out of their cold mills in terms of consistency of milling pattern, correct grade and slope, cleanliness. How Does A Cold Milling Machine Work.

From www.stabroeknews.com

Works Ministry acquires Cold Milling Machine for road repairs How Does A Cold Milling Machine Work The rows of metal cutting teeth mounted diagonally on a large rotating. Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. The range of applications extends from the. Operators are under pressure to get the best performance out of their cold mills in terms of consistency of milling pattern, correct grade and slope, cleanliness of. How Does A Cold Milling Machine Work.

From www.storyblocks.com

Working Process Of Milling Drilling Machine Stock Footage SBV313089864 How Does A Cold Milling Machine Work Asphalt milling, also called cold milling or cold planing, is the process of removing a part of the existing pavement surface to help restore it to a uniform texture to use or repave. In doing so, they create a level foundation with the. Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt. How Does A Cold Milling Machine Work.

From mungfali.com

Wirtgen Cold Milling Machine How Does A Cold Milling Machine Work The rows of metal cutting teeth mounted diagonally on a large rotating. Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient thickness to. Operators are under pressure to get the best performance out of their cold mills in terms of consistency of milling pattern, correct grade and slope, cleanliness. How Does A Cold Milling Machine Work.

From www.nxcnc.com

difference between horizontal and vertical milling mach... How Does A Cold Milling Machine Work Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient thickness to. Asphalt milling, also called cold milling or cold planing, is the process of removing a part of the existing pavement surface to help restore it to a uniform texture to use or repave. Cold milling machines are used. How Does A Cold Milling Machine Work.

From www.dreamstime.com

CNC Milling Machine Work. Coolant and Lubrication in Metalwork Industry How Does A Cold Milling Machine Work In doing so, they create a level foundation with the. Operators are under pressure to get the best performance out of their cold mills in terms of consistency of milling pattern, correct grade and slope, cleanliness of cut,. Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. The range of applications extends from the. Also. How Does A Cold Milling Machine Work.

From www.newstrail.com

Cold Milling Machine Market Paving the Way for Efficient Road How Does A Cold Milling Machine Work Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient thickness to. The range of applications extends from the. The rows of metal cutting teeth mounted diagonally on a large rotating. In doing so, they create a level foundation with the. Asphalt milling, also called cold milling or cold planing,. How Does A Cold Milling Machine Work.

From exozssvju.blob.core.windows.net

How To Get Cnc Machine Work at Ellen Stephens blog How Does A Cold Milling Machine Work Operators are under pressure to get the best performance out of their cold mills in terms of consistency of milling pattern, correct grade and slope, cleanliness of cut,. Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient thickness to. Cold milling machines are used to remove asphalt and concrete. How Does A Cold Milling Machine Work.

From www.mdpi.com

Applied Sciences Free FullText Practical Control of a Cold Milling How Does A Cold Milling Machine Work The rows of metal cutting teeth mounted diagonally on a large rotating. In doing so, they create a level foundation with the. Also called cold planning or asphalt milling and profiling, involves removing part of the existing paved asphalt surface with sufficient thickness to. Cold milling machines are used to remove asphalt and concrete surfaces quickly and efficiently. Operators are. How Does A Cold Milling Machine Work.