What Are Silicon Oxide Grinding Wheels Used For . Silicon carbide harder than standard aluminium oxide with a very sharp abrasive grain. Silicon carbide wheels are harder and more brittle than aluminum oxide wheels. Grinding wheels are available in various abrasive materials, including aluminum oxide, silicon carbide, and diamond. A wheel made from a blend of silicon carbide and aluminum oxide provides ideal grinding for. Based on the abrasive material, there are four types of grinding wheels: Aluminium oxide is the most commonly used abrasive on. Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast. There are two principal types of silicon carbide wheels: The four primary types of grains used on abrasive wheels for metal include aluminum oxide, zirconia alumina, silicon carbide, and ceramic alumina: It is a versatile material, recommended for grinding relatively soft metals such as.

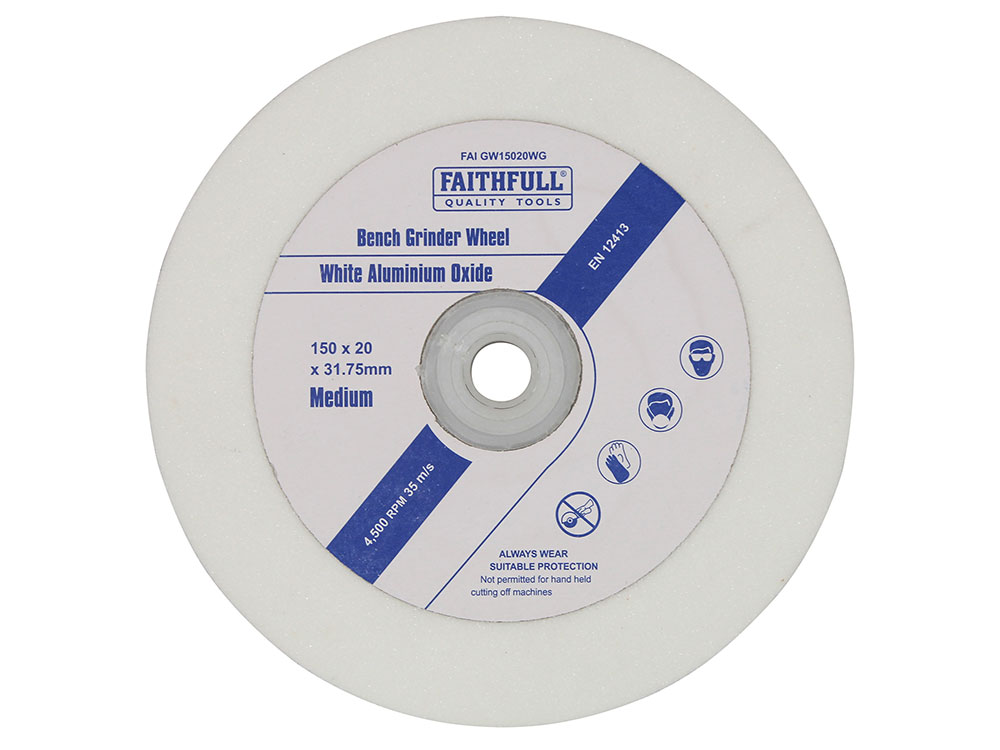

from www.faithfulltools.com

Silicon carbide harder than standard aluminium oxide with a very sharp abrasive grain. Grinding wheels are available in various abrasive materials, including aluminum oxide, silicon carbide, and diamond. There are two principal types of silicon carbide wheels: A wheel made from a blend of silicon carbide and aluminum oxide provides ideal grinding for. Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast. Aluminium oxide is the most commonly used abrasive on. The four primary types of grains used on abrasive wheels for metal include aluminum oxide, zirconia alumina, silicon carbide, and ceramic alumina: Silicon carbide wheels are harder and more brittle than aluminum oxide wheels. Based on the abrasive material, there are four types of grinding wheels: It is a versatile material, recommended for grinding relatively soft metals such as.

Grinding Wheels White Aluminium Oxide

What Are Silicon Oxide Grinding Wheels Used For There are two principal types of silicon carbide wheels: It is a versatile material, recommended for grinding relatively soft metals such as. Silicon carbide wheels are harder and more brittle than aluminum oxide wheels. The four primary types of grains used on abrasive wheels for metal include aluminum oxide, zirconia alumina, silicon carbide, and ceramic alumina: Grinding wheels are available in various abrasive materials, including aluminum oxide, silicon carbide, and diamond. Aluminium oxide is the most commonly used abrasive on. A wheel made from a blend of silicon carbide and aluminum oxide provides ideal grinding for. There are two principal types of silicon carbide wheels: Silicon carbide harder than standard aluminium oxide with a very sharp abrasive grain. Based on the abrasive material, there are four types of grinding wheels: Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast.

From www.forturetools.com

Aluminum oxide surface grinding wheels Forture Tools What Are Silicon Oxide Grinding Wheels Used For It is a versatile material, recommended for grinding relatively soft metals such as. Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast. Aluminium oxide is the most commonly used abrasive on. Silicon carbide wheels are harder and more brittle than aluminum oxide wheels. Silicon carbide harder than standard aluminium oxide. What Are Silicon Oxide Grinding Wheels Used For.

From www.indiamart.com

8mm Aluminium Oxide Grinding Wheels, For Heavy Duty Work, Rs 38 /piece What Are Silicon Oxide Grinding Wheels Used For Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast. Silicon carbide wheels are harder and more brittle than aluminum oxide wheels. Based on the abrasive material, there are four types of grinding wheels: It is a versatile material, recommended for grinding relatively soft metals such as. A wheel made from. What Are Silicon Oxide Grinding Wheels Used For.

From www.tooled-up.com

Faithfull Aluminium Oxide Grinding Wheel Grinding Wheels What Are Silicon Oxide Grinding Wheels Used For Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast. Silicon carbide harder than standard aluminium oxide with a very sharp abrasive grain. Silicon carbide wheels are harder and more brittle than aluminum oxide wheels. It is a versatile material, recommended for grinding relatively soft metals such as. There are two. What Are Silicon Oxide Grinding Wheels Used For.

From www.forturetools.com

Plain shape Green silicon carbide grinding wheels Forture Tools What Are Silicon Oxide Grinding Wheels Used For Grinding wheels are available in various abrasive materials, including aluminum oxide, silicon carbide, and diamond. Silicon carbide wheels are harder and more brittle than aluminum oxide wheels. Aluminium oxide is the most commonly used abrasive on. Silicon carbide harder than standard aluminium oxide with a very sharp abrasive grain. A wheel made from a blend of silicon carbide and aluminum. What Are Silicon Oxide Grinding Wheels Used For.

From www.pinterest.com

Resin aluminum oxide Barrel grinding wheels for knife grinding What Are Silicon Oxide Grinding Wheels Used For Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast. The four primary types of grains used on abrasive wheels for metal include aluminum oxide, zirconia alumina, silicon carbide, and ceramic alumina: Grinding wheels are available in various abrasive materials, including aluminum oxide, silicon carbide, and diamond. Silicon carbide harder than. What Are Silicon Oxide Grinding Wheels Used For.

From www.forturetools.com

Plain shape Green silicon carbide grinding wheels Forture Tools What Are Silicon Oxide Grinding Wheels Used For It is a versatile material, recommended for grinding relatively soft metals such as. Based on the abrasive material, there are four types of grinding wheels: Silicon carbide harder than standard aluminium oxide with a very sharp abrasive grain. Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast. Silicon carbide wheels. What Are Silicon Oxide Grinding Wheels Used For.

From www.indiamart.com

Aluminium Oxide Precision Grinding Wheels, For Heavy Duty Work at Rs 80 What Are Silicon Oxide Grinding Wheels Used For A wheel made from a blend of silicon carbide and aluminum oxide provides ideal grinding for. Based on the abrasive material, there are four types of grinding wheels: Silicon carbide wheels are harder and more brittle than aluminum oxide wheels. Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast. There. What Are Silicon Oxide Grinding Wheels Used For.

From www.indiamart.com

Aluminium Oxide Bench Grinding Wheel, Abrasive Grade Silicon Carbide What Are Silicon Oxide Grinding Wheels Used For Grinding wheels are available in various abrasive materials, including aluminum oxide, silicon carbide, and diamond. There are two principal types of silicon carbide wheels: A wheel made from a blend of silicon carbide and aluminum oxide provides ideal grinding for. Silicon carbide harder than standard aluminium oxide with a very sharp abrasive grain. Aluminium oxide is the most commonly used. What Are Silicon Oxide Grinding Wheels Used For.

From grindingwheels-china.blogspot.com

Silicon Carbide Grinding Wheels For Stone Fabrication What Are Silicon Oxide Grinding Wheels Used For Silicon carbide wheels are harder and more brittle than aluminum oxide wheels. It is a versatile material, recommended for grinding relatively soft metals such as. Grinding wheels are available in various abrasive materials, including aluminum oxide, silicon carbide, and diamond. Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast. The. What Are Silicon Oxide Grinding Wheels Used For.

From www.centrictool.com

Aluminum Oxide and Ceramic Grinding Wheels What Are Silicon Oxide Grinding Wheels Used For Silicon carbide wheels are harder and more brittle than aluminum oxide wheels. It is a versatile material, recommended for grinding relatively soft metals such as. Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast. Grinding wheels are available in various abrasive materials, including aluminum oxide, silicon carbide, and diamond. There. What Are Silicon Oxide Grinding Wheels Used For.

From www.grainger.com

NORTON Type 1 Aluminum Oxide Straight Grinding Wheel, 10 in, 1 1/4 in What Are Silicon Oxide Grinding Wheels Used For Silicon carbide wheels are harder and more brittle than aluminum oxide wheels. Aluminium oxide is the most commonly used abrasive on. Based on the abrasive material, there are four types of grinding wheels: Silicon carbide harder than standard aluminium oxide with a very sharp abrasive grain. Grinding wheels are available in various abrasive materials, including aluminum oxide, silicon carbide, and. What Are Silicon Oxide Grinding Wheels Used For.

From www.alibaba.com

200x25x31.75 Silicon Carbide Grinding Wheel Buy Green Silicon Carbide What Are Silicon Oxide Grinding Wheels Used For Based on the abrasive material, there are four types of grinding wheels: The four primary types of grains used on abrasive wheels for metal include aluminum oxide, zirconia alumina, silicon carbide, and ceramic alumina: Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast. A wheel made from a blend of. What Are Silicon Oxide Grinding Wheels Used For.

From www.faithfulltools.com

Grinding Wheels White Aluminium Oxide What Are Silicon Oxide Grinding Wheels Used For Aluminium oxide is the most commonly used abrasive on. Based on the abrasive material, there are four types of grinding wheels: A wheel made from a blend of silicon carbide and aluminum oxide provides ideal grinding for. The four primary types of grains used on abrasive wheels for metal include aluminum oxide, zirconia alumina, silicon carbide, and ceramic alumina: Silicon. What Are Silicon Oxide Grinding Wheels Used For.

From www.walmart.com

6Inch Bench Grinding Wheel Aluminum Oxide A 60 Grit for Surface What Are Silicon Oxide Grinding Wheels Used For Aluminium oxide is the most commonly used abrasive on. Grinding wheels are available in various abrasive materials, including aluminum oxide, silicon carbide, and diamond. A wheel made from a blend of silicon carbide and aluminum oxide provides ideal grinding for. Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast. It. What Are Silicon Oxide Grinding Wheels Used For.

From www.youtube.com

Pink aluminum oxide grinding wheels forturetools bonded abrasives YouTube What Are Silicon Oxide Grinding Wheels Used For The four primary types of grains used on abrasive wheels for metal include aluminum oxide, zirconia alumina, silicon carbide, and ceramic alumina: Based on the abrasive material, there are four types of grinding wheels: Silicon carbide harder than standard aluminium oxide with a very sharp abrasive grain. Aluminium oxide is the most commonly used abrasive on. Grinding wheels are available. What Are Silicon Oxide Grinding Wheels Used For.

From www.preciseceramic.com

CB4040 Silicon Carbide Bench Grinding Wheel What Are Silicon Oxide Grinding Wheels Used For Silicon carbide harder than standard aluminium oxide with a very sharp abrasive grain. The four primary types of grains used on abrasive wheels for metal include aluminum oxide, zirconia alumina, silicon carbide, and ceramic alumina: Based on the abrasive material, there are four types of grinding wheels: A wheel made from a blend of silicon carbide and aluminum oxide provides. What Are Silicon Oxide Grinding Wheels Used For.

From www.knuth.com

Siliconcarbide grinding wheels, 6.89 x 0.787 x 1.26" Grinding Wheels What Are Silicon Oxide Grinding Wheels Used For Silicon carbide wheels are harder and more brittle than aluminum oxide wheels. It is a versatile material, recommended for grinding relatively soft metals such as. There are two principal types of silicon carbide wheels: Silicon carbide harder than standard aluminium oxide with a very sharp abrasive grain. Grinding wheels are available in various abrasive materials, including aluminum oxide, silicon carbide,. What Are Silicon Oxide Grinding Wheels Used For.

From tooltec.co.uk

Grinding Wheels Diamond Borazon Alloy Oxide Tooltec What Are Silicon Oxide Grinding Wheels Used For Silicon carbide harder than standard aluminium oxide with a very sharp abrasive grain. Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast. The four primary types of grains used on abrasive wheels for metal include aluminum oxide, zirconia alumina, silicon carbide, and ceramic alumina: It is a versatile material, recommended. What Are Silicon Oxide Grinding Wheels Used For.

From hindustanabrasives.com

White Aluminum Oxide Grinding Wheel Manufacturer Hindustan Abrasives What Are Silicon Oxide Grinding Wheels Used For Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast. Silicon carbide wheels are harder and more brittle than aluminum oxide wheels. Aluminium oxide is the most commonly used abrasive on. The four primary types of grains used on abrasive wheels for metal include aluminum oxide, zirconia alumina, silicon carbide, and. What Are Silicon Oxide Grinding Wheels Used For.

From www.penntoolco.com

Radiac 7" Diameter White Aluminum Oxide Surface Grinding Wheels Penn What Are Silicon Oxide Grinding Wheels Used For It is a versatile material, recommended for grinding relatively soft metals such as. Aluminium oxide is the most commonly used abrasive on. The four primary types of grains used on abrasive wheels for metal include aluminum oxide, zirconia alumina, silicon carbide, and ceramic alumina: Silicon carbide harder than standard aluminium oxide with a very sharp abrasive grain. Based on the. What Are Silicon Oxide Grinding Wheels Used For.

From www.faithfulltools.com

Grinding Wheels Aluminium Oxide What Are Silicon Oxide Grinding Wheels Used For It is a versatile material, recommended for grinding relatively soft metals such as. A wheel made from a blend of silicon carbide and aluminum oxide provides ideal grinding for. Aluminium oxide is the most commonly used abrasive on. Silicon carbide harder than standard aluminium oxide with a very sharp abrasive grain. Silicon carbide wheels are harder and more brittle than. What Are Silicon Oxide Grinding Wheels Used For.

From www.stonecontact.com

Aluminium Oxide Grinding Wheels for Steel from China What Are Silicon Oxide Grinding Wheels Used For Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast. The four primary types of grains used on abrasive wheels for metal include aluminum oxide, zirconia alumina, silicon carbide, and ceramic alumina: Silicon carbide harder than standard aluminium oxide with a very sharp abrasive grain. Silicon carbide wheels are harder and. What Are Silicon Oxide Grinding Wheels Used For.

From chris-marine.com

Grinding Wheels CBN for each type of metal alloy ChrisMarine What Are Silicon Oxide Grinding Wheels Used For The four primary types of grains used on abrasive wheels for metal include aluminum oxide, zirconia alumina, silicon carbide, and ceramic alumina: A wheel made from a blend of silicon carbide and aluminum oxide provides ideal grinding for. Silicon carbide wheels are harder and more brittle than aluminum oxide wheels. Silicon carbide the brittleness of silicon carbide molecules makes it. What Are Silicon Oxide Grinding Wheels Used For.

From bigamart.com

Draper 99568 Silicon Carbide Bench Grinding Wheel 120G (150mm x 20mm What Are Silicon Oxide Grinding Wheels Used For There are two principal types of silicon carbide wheels: Grinding wheels are available in various abrasive materials, including aluminum oxide, silicon carbide, and diamond. A wheel made from a blend of silicon carbide and aluminum oxide provides ideal grinding for. Silicon carbide wheels are harder and more brittle than aluminum oxide wheels. The four primary types of grains used on. What Are Silicon Oxide Grinding Wheels Used For.

From www.johnsonbrotherslapidary.com

Grinding Wheels Silicon Carbide 6 x 1 220 Grit 1 pc. What Are Silicon Oxide Grinding Wheels Used For Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast. There are two principal types of silicon carbide wheels: Silicon carbide harder than standard aluminium oxide with a very sharp abrasive grain. Aluminium oxide is the most commonly used abrasive on. Based on the abrasive material, there are four types of. What Are Silicon Oxide Grinding Wheels Used For.

From www.pinterest.com

6 inch grinding wheel aluminum oxide and silicon carbide abrasive wheel What Are Silicon Oxide Grinding Wheels Used For Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast. There are two principal types of silicon carbide wheels: Based on the abrasive material, there are four types of grinding wheels: Aluminium oxide is the most commonly used abrasive on. A wheel made from a blend of silicon carbide and aluminum. What Are Silicon Oxide Grinding Wheels Used For.

From www.alibaba.com

Bench Grinding Wheels For Silicon Carbide Gc Wheels Buy Pedestal What Are Silicon Oxide Grinding Wheels Used For A wheel made from a blend of silicon carbide and aluminum oxide provides ideal grinding for. There are two principal types of silicon carbide wheels: Silicon carbide harder than standard aluminium oxide with a very sharp abrasive grain. Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast. Silicon carbide wheels. What Are Silicon Oxide Grinding Wheels Used For.

From www.aliexpress.com

5 inch Straight cup grinding wheel of ceramic aluminum oxide and What Are Silicon Oxide Grinding Wheels Used For The four primary types of grains used on abrasive wheels for metal include aluminum oxide, zirconia alumina, silicon carbide, and ceramic alumina: Silicon carbide harder than standard aluminium oxide with a very sharp abrasive grain. Based on the abrasive material, there are four types of grinding wheels: A wheel made from a blend of silicon carbide and aluminum oxide provides. What Are Silicon Oxide Grinding Wheels Used For.

From www.indiamart.com

Aluminium Oxide Grinding Wheels at Rs 100/piece Grinder Wheel in What Are Silicon Oxide Grinding Wheels Used For Aluminium oxide is the most commonly used abrasive on. There are two principal types of silicon carbide wheels: Silicon carbide wheels are harder and more brittle than aluminum oxide wheels. Based on the abrasive material, there are four types of grinding wheels: Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like. What Are Silicon Oxide Grinding Wheels Used For.

From www.farmacologiaactual.com

Order online NEW GENERAL INDUSTRIAL DIAMOND GRINDING WHEEL 180 GRIT 1/8 What Are Silicon Oxide Grinding Wheels Used For It is a versatile material, recommended for grinding relatively soft metals such as. A wheel made from a blend of silicon carbide and aluminum oxide provides ideal grinding for. Aluminium oxide is the most commonly used abrasive on. The four primary types of grains used on abrasive wheels for metal include aluminum oxide, zirconia alumina, silicon carbide, and ceramic alumina:. What Are Silicon Oxide Grinding Wheels Used For.

From www.aliexpress.com

1 piece grinding wheel of Black and white aluminum oxide and Green What Are Silicon Oxide Grinding Wheels Used For It is a versatile material, recommended for grinding relatively soft metals such as. Silicon carbide harder than standard aluminium oxide with a very sharp abrasive grain. There are two principal types of silicon carbide wheels: The four primary types of grains used on abrasive wheels for metal include aluminum oxide, zirconia alumina, silicon carbide, and ceramic alumina: Aluminium oxide is. What Are Silicon Oxide Grinding Wheels Used For.

From grindingwheelschina.en.made-in-china.com

Abrasive Vitrified Ceramic Stone Aluminum Oxide Corundum Green Silicon What Are Silicon Oxide Grinding Wheels Used For Grinding wheels are available in various abrasive materials, including aluminum oxide, silicon carbide, and diamond. Based on the abrasive material, there are four types of grinding wheels: The four primary types of grains used on abrasive wheels for metal include aluminum oxide, zirconia alumina, silicon carbide, and ceramic alumina: Silicon carbide harder than standard aluminium oxide with a very sharp. What Are Silicon Oxide Grinding Wheels Used For.

From www.forturetools.com

Aluminum oxide surface grinding wheels Forture Tools What Are Silicon Oxide Grinding Wheels Used For Aluminium oxide is the most commonly used abrasive on. Silicon carbide the brittleness of silicon carbide molecules makes it suitable for grinding low tensile strength metals like cast. A wheel made from a blend of silicon carbide and aluminum oxide provides ideal grinding for. Grinding wheels are available in various abrasive materials, including aluminum oxide, silicon carbide, and diamond. It. What Are Silicon Oxide Grinding Wheels Used For.

From www.pinterest.com

Bonded Abrasives, Aluminum oxide and silicon carbide grinding stones What Are Silicon Oxide Grinding Wheels Used For There are two principal types of silicon carbide wheels: It is a versatile material, recommended for grinding relatively soft metals such as. Silicon carbide wheels are harder and more brittle than aluminum oxide wheels. Based on the abrasive material, there are four types of grinding wheels: A wheel made from a blend of silicon carbide and aluminum oxide provides ideal. What Are Silicon Oxide Grinding Wheels Used For.

From forturetools.com

Aluminum oxide cup grinding wheels Forture Tools What Are Silicon Oxide Grinding Wheels Used For Silicon carbide wheels are harder and more brittle than aluminum oxide wheels. Based on the abrasive material, there are four types of grinding wheels: A wheel made from a blend of silicon carbide and aluminum oxide provides ideal grinding for. Aluminium oxide is the most commonly used abrasive on. The four primary types of grains used on abrasive wheels for. What Are Silicon Oxide Grinding Wheels Used For.