Piston In Shock . The piston face can further control the dampening rate by using a. Digressive and linear pistons in shock absorbers. Piston & shock designs for digressive, linear and progressive damping performance: As the shock compresses and extends, this piston moves up and down inside hydraulic. A piston is attached to the shock rod. Find out when to use. There are two traditional piston designs:. The pistons are called the working piston and the dividing or floating piston. The vast majority of aftermarket dampers use either a digressive (bilstein) or linear rate (kw) pistons. They are completely separate from the shock's fluid and gas components. Nitrogen in reservoir keeps pressure on the shock oil in the main body. Nitrogen pressure helps with tuning, forcing oil through the main. Learn about different types of shock valving curves and how they affect your suspension performance. It also does not have a compression valve, because the role has been taken up by the dividing piston. The standard, and most common piston used will provide a.

from www.ohlinscommunity.com

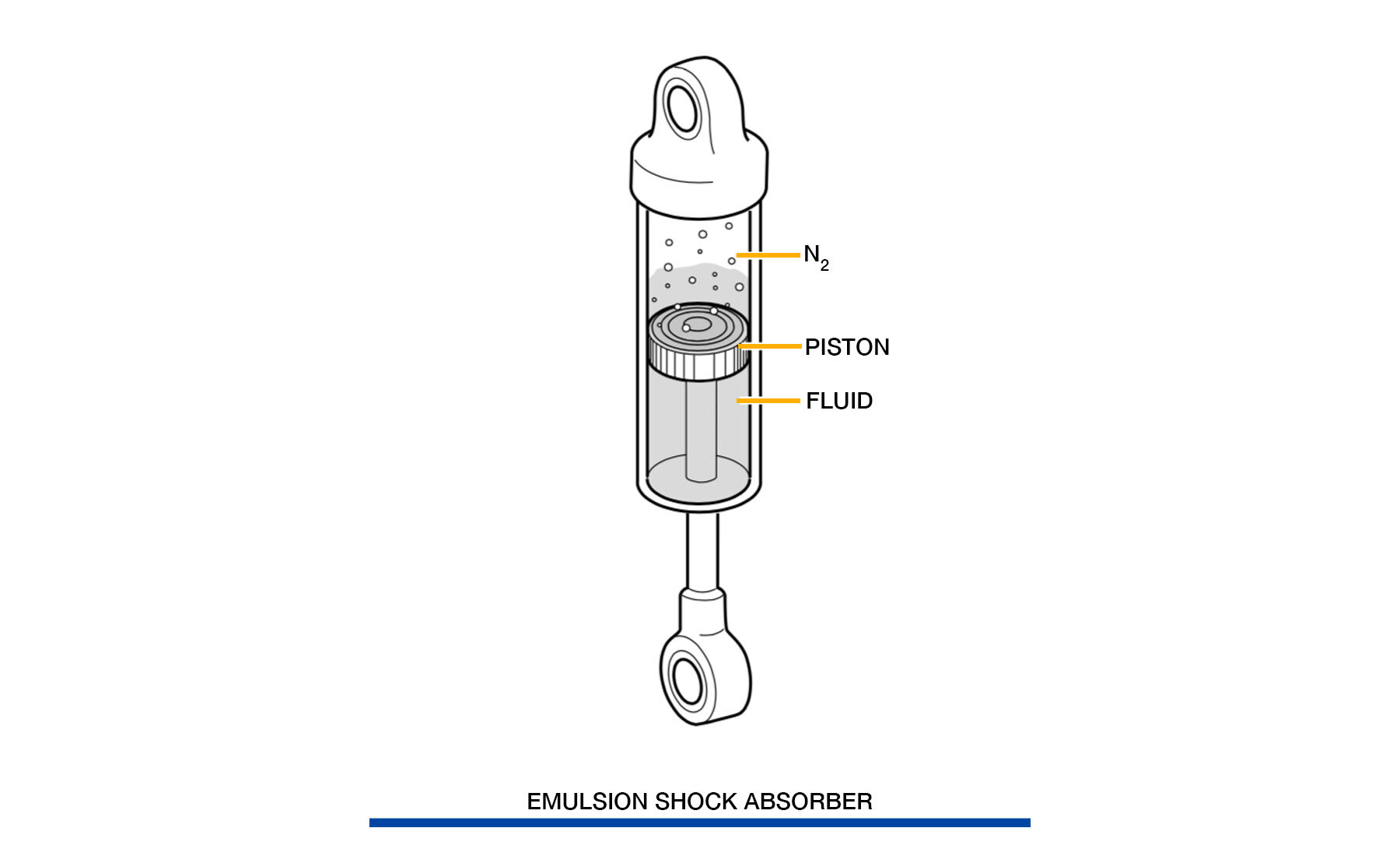

Nitrogen in reservoir keeps pressure on the shock oil in the main body. The pistons are called the working piston and the dividing or floating piston. The vast majority of aftermarket dampers use either a digressive (bilstein) or linear rate (kw) pistons. Nitrogen pressure helps with tuning, forcing oil through the main. Shocks are essentially hydraulic pumps. Find out when to use. They are completely separate from the shock's fluid and gas components. The piston face can further control the dampening rate by using a. Learn about different types of shock valving curves and how they affect your suspension performance. A piston is attached to the shock rod.

Öhlins Knowledge Centre Rear Suspension

Piston In Shock It also does not have a compression valve, because the role has been taken up by the dividing piston. A piston is attached to the shock rod. It also does not have a compression valve, because the role has been taken up by the dividing piston. Nitrogen in reservoir keeps pressure on the shock oil in the main body. The vast majority of aftermarket dampers use either a digressive (bilstein) or linear rate (kw) pistons. Shocks are essentially hydraulic pumps. There are two traditional piston designs:. They are completely separate from the shock's fluid and gas components. Learn about different types of shock valving curves and how they affect your suspension performance. Find out when to use. As the shock compresses and extends, this piston moves up and down inside hydraulic. The standard, and most common piston used will provide a. Nitrogen pressure helps with tuning, forcing oil through the main. The piston face can further control the dampening rate by using a. Piston & shock designs for digressive, linear and progressive damping performance: Digressive and linear pistons in shock absorbers.

From rsrc.biz

Quick tutorial 6 complete shock pistons guide for RC cars Piston In Shock Piston & shock designs for digressive, linear and progressive damping performance: Find out when to use. Nitrogen in reservoir keeps pressure on the shock oil in the main body. The piston face can further control the dampening rate by using a. There are two traditional piston designs:. The standard, and most common piston used will provide a. The pistons are. Piston In Shock.

From www.turnology.com

Inside The Racing Shock Absorber With Koni Piston In Shock The vast majority of aftermarket dampers use either a digressive (bilstein) or linear rate (kw) pistons. Learn about different types of shock valving curves and how they affect your suspension performance. As the shock compresses and extends, this piston moves up and down inside hydraulic. A piston is attached to the shock rod. They are completely separate from the shock's. Piston In Shock.

From www.aircraftsystemstech.com

Aircraft Landing Gear System Shock Strut Piston In Shock Find out when to use. It also does not have a compression valve, because the role has been taken up by the dividing piston. The pistons are called the working piston and the dividing or floating piston. Digressive and linear pistons in shock absorbers. They are completely separate from the shock's fluid and gas components. The standard, and most common. Piston In Shock.

From www.procircuit.com

Works Shock Piston 50mm 12 ID MD Port Piston In Shock Find out when to use. It also does not have a compression valve, because the role has been taken up by the dividing piston. The vast majority of aftermarket dampers use either a digressive (bilstein) or linear rate (kw) pistons. Learn about different types of shock valving curves and how they affect your suspension performance. The standard, and most common. Piston In Shock.

From www.amainhobbies.com

Fioroni T.A.P. 8x1.3mm 4Balls Shock Pistons (2) (KYO/AE/XRAY/MBX7R) [FIOOTUR1040] AMain Hobbies Piston In Shock They are completely separate from the shock's fluid and gas components. As the shock compresses and extends, this piston moves up and down inside hydraulic. A piston is attached to the shock rod. Digressive and linear pistons in shock absorbers. Nitrogen pressure helps with tuning, forcing oil through the main. It also does not have a compression valve, because the. Piston In Shock.

From www.aircraftsystemstech.com

Aircraft Landing Gear System Shock Strut Piston In Shock Find out when to use. Nitrogen in reservoir keeps pressure on the shock oil in the main body. Piston & shock designs for digressive, linear and progressive damping performance: As the shock compresses and extends, this piston moves up and down inside hydraulic. Nitrogen pressure helps with tuning, forcing oil through the main. Digressive and linear pistons in shock absorbers.. Piston In Shock.

From www.ohlinscommunity.com

Öhlins Knowledge Centre Rear Suspension Piston In Shock Digressive and linear pistons in shock absorbers. There are two traditional piston designs:. The standard, and most common piston used will provide a. They are completely separate from the shock's fluid and gas components. Learn about different types of shock valving curves and how they affect your suspension performance. Nitrogen pressure helps with tuning, forcing oil through the main. The. Piston In Shock.

From www.youtube.com

SKF Floating Piston WP Shock YouTube Piston In Shock There are two traditional piston designs:. A piston is attached to the shock rod. Digressive and linear pistons in shock absorbers. Nitrogen pressure helps with tuning, forcing oil through the main. The pistons are called the working piston and the dividing or floating piston. Learn about different types of shock valving curves and how they affect your suspension performance. The. Piston In Shock.

From www.carsports.com

RC Car Shock Pistons Setup Guides Piston In Shock It also does not have a compression valve, because the role has been taken up by the dividing piston. As the shock compresses and extends, this piston moves up and down inside hydraulic. Piston & shock designs for digressive, linear and progressive damping performance: Learn about different types of shock valving curves and how they affect your suspension performance. There. Piston In Shock.

From www.researchgate.net

Shock absorber parts and piston produced by P/M method Download Scientific Diagram Piston In Shock Shocks are essentially hydraulic pumps. A piston is attached to the shock rod. Learn about different types of shock valving curves and how they affect your suspension performance. It also does not have a compression valve, because the role has been taken up by the dividing piston. The standard, and most common piston used will provide a. As the shock. Piston In Shock.

From accutuneoffroad.com

Digressive vs Linear vs Progressive Pistons & Shock Valving AccuTune OffRoad Piston In Shock Learn about different types of shock valving curves and how they affect your suspension performance. Digressive and linear pistons in shock absorbers. Nitrogen in reservoir keeps pressure on the shock oil in the main body. They are completely separate from the shock's fluid and gas components. The vast majority of aftermarket dampers use either a digressive (bilstein) or linear rate. Piston In Shock.

From www.drivingline.com

Suspension Theory With King Shocks DrivingLine Piston In Shock Find out when to use. The standard, and most common piston used will provide a. It also does not have a compression valve, because the role has been taken up by the dividing piston. The vast majority of aftermarket dampers use either a digressive (bilstein) or linear rate (kw) pistons. A piston is attached to the shock rod. There are. Piston In Shock.

From www.sodialed.com

shock springs definition RC Car Glossary Piston In Shock Learn about different types of shock valving curves and how they affect your suspension performance. The vast majority of aftermarket dampers use either a digressive (bilstein) or linear rate (kw) pistons. Find out when to use. The piston face can further control the dampening rate by using a. Piston & shock designs for digressive, linear and progressive damping performance: Nitrogen. Piston In Shock.

From aftermarket.zf.com

tip Installing Shock Absorbers SACHS Piston In Shock The piston face can further control the dampening rate by using a. Shocks are essentially hydraulic pumps. The standard, and most common piston used will provide a. Nitrogen pressure helps with tuning, forcing oil through the main. The vast majority of aftermarket dampers use either a digressive (bilstein) or linear rate (kw) pistons. The pistons are called the working piston. Piston In Shock.

From themotorhood.com

Shock Absorbers — what you need to know — The Motorhood Piston In Shock They are completely separate from the shock's fluid and gas components. The vast majority of aftermarket dampers use either a digressive (bilstein) or linear rate (kw) pistons. The piston face can further control the dampening rate by using a. There are two traditional piston designs:. Nitrogen pressure helps with tuning, forcing oil through the main. The standard, and most common. Piston In Shock.

From howcarpartswork.blogspot.com

How Car Parts Work Shock Absorber Piston In Shock The pistons are called the working piston and the dividing or floating piston. As the shock compresses and extends, this piston moves up and down inside hydraulic. Shocks are essentially hydraulic pumps. The vast majority of aftermarket dampers use either a digressive (bilstein) or linear rate (kw) pistons. They are completely separate from the shock's fluid and gas components. A. Piston In Shock.

From www.bikeconnection.net

RockShox RockShox Rear Shock Damper Piston/Shaft Assembly (Inlcudes Piston Assembly) Deluxe Piston In Shock Find out when to use. The pistons are called the working piston and the dividing or floating piston. The piston face can further control the dampening rate by using a. It also does not have a compression valve, because the role has been taken up by the dividing piston. They are completely separate from the shock's fluid and gas components.. Piston In Shock.

From us.bicknellracingproducts.com

DIGRESSIVE SHOCK PISTON Piston In Shock Digressive and linear pistons in shock absorbers. Find out when to use. A piston is attached to the shock rod. There are two traditional piston designs:. The piston face can further control the dampening rate by using a. As the shock compresses and extends, this piston moves up and down inside hydraulic. The vast majority of aftermarket dampers use either. Piston In Shock.

From inchbyinch.de

INCH Technical English pictorial shock absorber Piston In Shock The standard, and most common piston used will provide a. Nitrogen in reservoir keeps pressure on the shock oil in the main body. The vast majority of aftermarket dampers use either a digressive (bilstein) or linear rate (kw) pistons. The piston face can further control the dampening rate by using a. It also does not have a compression valve, because. Piston In Shock.

From www.dreamstime.com

Piston and Shock Absorber on a Green Stock Vector Illustration of abstract, motor 114456372 Piston In Shock The piston face can further control the dampening rate by using a. The standard, and most common piston used will provide a. There are two traditional piston designs:. They are completely separate from the shock's fluid and gas components. Nitrogen in reservoir keeps pressure on the shock oil in the main body. A piston is attached to the shock rod.. Piston In Shock.

From www.europages.co.uk

Industrial Shock Absorbers, SC4525EUM5 Piston tube design for maximum energy absorption, ACE Piston In Shock The vast majority of aftermarket dampers use either a digressive (bilstein) or linear rate (kw) pistons. Nitrogen pressure helps with tuning, forcing oil through the main. It also does not have a compression valve, because the role has been taken up by the dividing piston. The standard, and most common piston used will provide a. Nitrogen in reservoir keeps pressure. Piston In Shock.

From www.yourmechanic.com

How to Buy Sport Shocks YourMechanic Advice Piston In Shock The pistons are called the working piston and the dividing or floating piston. It also does not have a compression valve, because the role has been taken up by the dividing piston. A piston is attached to the shock rod. Learn about different types of shock valving curves and how they affect your suspension performance. The vast majority of aftermarket. Piston In Shock.

From rsrc.biz

Quick tutorial 6 complete shock pistons guide for RC cars Piston In Shock Find out when to use. The piston face can further control the dampening rate by using a. Digressive and linear pistons in shock absorbers. They are completely separate from the shock's fluid and gas components. Learn about different types of shock valving curves and how they affect your suspension performance. The standard, and most common piston used will provide a.. Piston In Shock.

From www.drivingline.com

Suspension Theory With King Shocks DrivingLine Piston In Shock The pistons are called the working piston and the dividing or floating piston. As the shock compresses and extends, this piston moves up and down inside hydraulic. Nitrogen in reservoir keeps pressure on the shock oil in the main body. Digressive and linear pistons in shock absorbers. Shocks are essentially hydraulic pumps. The piston face can further control the dampening. Piston In Shock.

From adventuretaco.com

Rebuilding/Revalving Smooth Body Shocks (King version) AdventureTaco Piston In Shock The vast majority of aftermarket dampers use either a digressive (bilstein) or linear rate (kw) pistons. A piston is attached to the shock rod. Shocks are essentially hydraulic pumps. There are two traditional piston designs:. Piston & shock designs for digressive, linear and progressive damping performance: It also does not have a compression valve, because the role has been taken. Piston In Shock.

From blog.beforward.jp

The role of SHOCK ABSORBERS Piston In Shock Find out when to use. Learn about different types of shock valving curves and how they affect your suspension performance. The standard, and most common piston used will provide a. The pistons are called the working piston and the dividing or floating piston. Nitrogen in reservoir keeps pressure on the shock oil in the main body. Shocks are essentially hydraulic. Piston In Shock.

From www.shockabsorberparts.com

F50 U3 66 Customized Car Shock Absorber Piston With Flared Design Density 6.5 G / Cm3 Piston In Shock The vast majority of aftermarket dampers use either a digressive (bilstein) or linear rate (kw) pistons. A piston is attached to the shock rod. Digressive and linear pistons in shock absorbers. The piston face can further control the dampening rate by using a. Find out when to use. Nitrogen pressure helps with tuning, forcing oil through the main. Nitrogen in. Piston In Shock.

From www.shockabsorberparts.com

Filled PTFE Banded Low Friction Shock Absorber Piston Applied In Cars Piston In Shock The pistons are called the working piston and the dividing or floating piston. Digressive and linear pistons in shock absorbers. Learn about different types of shock valving curves and how they affect your suspension performance. The vast majority of aftermarket dampers use either a digressive (bilstein) or linear rate (kw) pistons. Nitrogen in reservoir keeps pressure on the shock oil. Piston In Shock.

From www.speedwaymotors.com

AFCO Shock Piston Upgrade Kit, Main Piston, Standard Base Valve Piston In Shock Nitrogen in reservoir keeps pressure on the shock oil in the main body. The standard, and most common piston used will provide a. It also does not have a compression valve, because the role has been taken up by the dividing piston. Piston & shock designs for digressive, linear and progressive damping performance: The pistons are called the working piston. Piston In Shock.

From www.kyb.com.au

Incorrect Installation Piston rod damage KYB Shock Absorbers KYB Shock Absorbers Piston In Shock The standard, and most common piston used will provide a. Nitrogen in reservoir keeps pressure on the shock oil in the main body. It also does not have a compression valve, because the role has been taken up by the dividing piston. Shocks are essentially hydraulic pumps. Learn about different types of shock valving curves and how they affect your. Piston In Shock.

From www.speedwaymotors.com

Bilstein 7 Inch SNS2 Series IMCA Shock, Linear Piston Piston In Shock Shocks are essentially hydraulic pumps. The vast majority of aftermarket dampers use either a digressive (bilstein) or linear rate (kw) pistons. The pistons are called the working piston and the dividing or floating piston. Find out when to use. Nitrogen pressure helps with tuning, forcing oil through the main. The piston face can further control the dampening rate by using. Piston In Shock.

From fixwiringhospital.z21.web.core.windows.net

Parts Of A Piston Labeled Piston In Shock Nitrogen pressure helps with tuning, forcing oil through the main. Digressive and linear pistons in shock absorbers. The pistons are called the working piston and the dividing or floating piston. The piston face can further control the dampening rate by using a. There are two traditional piston designs:. A piston is attached to the shock rod. Shocks are essentially hydraulic. Piston In Shock.

From accutuneoffroad.com

Byass Shocks Part 1 AccuTune OffRoad Piston In Shock As the shock compresses and extends, this piston moves up and down inside hydraulic. The standard, and most common piston used will provide a. Find out when to use. Nitrogen pressure helps with tuning, forcing oil through the main. There are two traditional piston designs:. Nitrogen in reservoir keeps pressure on the shock oil in the main body. The piston. Piston In Shock.

From www.carid.com

How Do Shock Absorbers Work? Piston In Shock The pistons are called the working piston and the dividing or floating piston. A piston is attached to the shock rod. The standard, and most common piston used will provide a. Piston & shock designs for digressive, linear and progressive damping performance: Digressive and linear pistons in shock absorbers. Nitrogen in reservoir keeps pressure on the shock oil in the. Piston In Shock.

From www.alibaba.com

Dependable Performance Ptfe Banded Shock Absorber Piston Buy Shock Absorber Piston,Ptfe Shock Piston In Shock They are completely separate from the shock's fluid and gas components. Digressive and linear pistons in shock absorbers. It also does not have a compression valve, because the role has been taken up by the dividing piston. Piston & shock designs for digressive, linear and progressive damping performance: Find out when to use. Nitrogen pressure helps with tuning, forcing oil. Piston In Shock.