Flaw Detection Translation . ultrasonic flaw detection uses these ultrasonic sound waves to detect flaws inside a solid metal or concrete object without causing any damage to its original structure. ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can. In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border frequencies up to 50 mhz are transmitted through materials. ultrasonic inspection can be used to detect surface flaws such as cracks and internal flaws such as voids or inclusions of. google's service, offered free of charge, instantly translates words, phrases, and web pages between english and over 100 other. since the 1940s, the laws of physics that govern the propagation of high frequency sound waves through solid materials have.

from www.permanentsteel.com

google's service, offered free of charge, instantly translates words, phrases, and web pages between english and over 100 other. In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border frequencies up to 50 mhz are transmitted through materials. ultrasonic inspection can be used to detect surface flaws such as cracks and internal flaws such as voids or inclusions of. ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can. ultrasonic flaw detection uses these ultrasonic sound waves to detect flaws inside a solid metal or concrete object without causing any damage to its original structure. since the 1940s, the laws of physics that govern the propagation of high frequency sound waves through solid materials have.

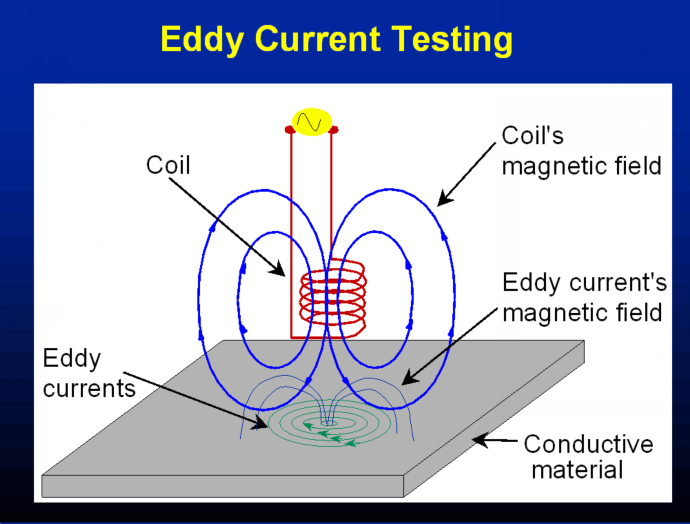

Seamless Tube Eddy Current Flaw Detection

Flaw Detection Translation ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can. google's service, offered free of charge, instantly translates words, phrases, and web pages between english and over 100 other. since the 1940s, the laws of physics that govern the propagation of high frequency sound waves through solid materials have. ultrasonic flaw detection uses these ultrasonic sound waves to detect flaws inside a solid metal or concrete object without causing any damage to its original structure. In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border frequencies up to 50 mhz are transmitted through materials. ultrasonic inspection can be used to detect surface flaws such as cracks and internal flaws such as voids or inclusions of. ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can.

From www.semanticscholar.org

Figure 1 from Nonparametric flaw detection in large grained materials Flaw Detection Translation ultrasonic inspection can be used to detect surface flaws such as cracks and internal flaws such as voids or inclusions of. In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border frequencies up to 50 mhz are transmitted through materials. since the 1940s, the laws of physics that govern the. Flaw Detection Translation.

From www.semanticscholar.org

Figure 4 from The feature extraction and analysis of flaw detection and Flaw Detection Translation ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can. since the 1940s, the laws of physics that govern the propagation of high frequency sound waves through solid materials have. In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border. Flaw Detection Translation.

From www.environmentalengineering.org.uk

Third Generation Advanced Phased Array Flaw Detector Flaw Detection Translation ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can. ultrasonic inspection can be used to detect surface flaws such as cracks and internal flaws such as voids or inclusions of. google's service, offered free of charge, instantly translates words, phrases, and web pages between english and. Flaw Detection Translation.

From www.scribd.com

Principles and Techniques of Advanced Ultrasonic Flaw Detection Using Flaw Detection Translation since the 1940s, the laws of physics that govern the propagation of high frequency sound waves through solid materials have. In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border frequencies up to 50 mhz are transmitted through materials. ultrasonic flaw detection is a powerful ndt technology and a well. Flaw Detection Translation.

From www.findlight.net

Flaw Detection in Laser Powder Bed Fusion Flaw Detection Translation ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can. google's service, offered free of charge, instantly translates words, phrases, and web pages between english and over 100 other. In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border frequencies. Flaw Detection Translation.

From modsonic.com

Ultrasonic Flaw Detection A Complete Guide Flaw Detection Translation google's service, offered free of charge, instantly translates words, phrases, and web pages between english and over 100 other. In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border frequencies up to 50 mhz are transmitted through materials. ultrasonic inspection can be used to detect surface flaws such as cracks. Flaw Detection Translation.

From www.semanticscholar.org

Figure 2 from Surface Flaw Detection with Resonance Flaw Detection Translation In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border frequencies up to 50 mhz are transmitted through materials. ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can. ultrasonic inspection can be used to detect surface flaws such as. Flaw Detection Translation.

From www.semanticscholar.org

Figure 1 from Rail Flaw Detection Using Image Processing Concepts A Flaw Detection Translation ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can. since the 1940s, the laws of physics that govern the propagation of high frequency sound waves through solid materials have. google's service, offered free of charge, instantly translates words, phrases, and web pages between english and over. Flaw Detection Translation.

From www.shimadzu.com

SHIMADZU CORPORATION Detecting Flaws within Objects Quickly and Flaw Detection Translation since the 1940s, the laws of physics that govern the propagation of high frequency sound waves through solid materials have. ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can. ultrasonic inspection can be used to detect surface flaws such as cracks and internal flaws such as. Flaw Detection Translation.

From eureka.patsnap.com

Ultrasound flaw detector, ultrasound flaw detection method, and program Flaw Detection Translation ultrasonic inspection can be used to detect surface flaws such as cracks and internal flaws such as voids or inclusions of. ultrasonic flaw detection uses these ultrasonic sound waves to detect flaws inside a solid metal or concrete object without causing any damage to its original structure. In most conventional ut applications, ultrasonic pulses with center frequencies ranging. Flaw Detection Translation.

From www.findlight.net

Flaw Detection in Laser Powder Bed Fusion Flaw Detection Translation since the 1940s, the laws of physics that govern the propagation of high frequency sound waves through solid materials have. google's service, offered free of charge, instantly translates words, phrases, and web pages between english and over 100 other. ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however. Flaw Detection Translation.

From eureka.patsnap.com

A water immersion ultrasonic flaw detection method for defects in Flaw Detection Translation since the 1940s, the laws of physics that govern the propagation of high frequency sound waves through solid materials have. ultrasonic inspection can be used to detect surface flaws such as cracks and internal flaws such as voids or inclusions of. ultrasonic flaw detection uses these ultrasonic sound waves to detect flaws inside a solid metal or. Flaw Detection Translation.

From www.researchgate.net

(PDF) Investigations on a pulsed eddy current system for flaw detection Flaw Detection Translation In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border frequencies up to 50 mhz are transmitted through materials. ultrasonic flaw detection uses these ultrasonic sound waves to detect flaws inside a solid metal or concrete object without causing any damage to its original structure. ultrasonic inspection can be used. Flaw Detection Translation.

From www.electronicdesign.com

A DigitizerBased Ultrasonic FlawDetection System Electronic Design Flaw Detection Translation ultrasonic inspection can be used to detect surface flaws such as cracks and internal flaws such as voids or inclusions of. google's service, offered free of charge, instantly translates words, phrases, and web pages between english and over 100 other. In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border. Flaw Detection Translation.

From www.permanentsteel.com

Seamless Tube Eddy Current Flaw Detection Flaw Detection Translation ultrasonic inspection can be used to detect surface flaws such as cracks and internal flaws such as voids or inclusions of. In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border frequencies up to 50 mhz are transmitted through materials. ultrasonic flaw detection is a powerful ndt technology and a. Flaw Detection Translation.

From www.mdpi.com

Sensors Free FullText The Improvement of Flaw Detection by the Flaw Detection Translation since the 1940s, the laws of physics that govern the propagation of high frequency sound waves through solid materials have. In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border frequencies up to 50 mhz are transmitted through materials. google's service, offered free of charge, instantly translates words, phrases, and. Flaw Detection Translation.

From www.olympus-ims.com

Alain Le Duff Guillaume PainchaudApril Phase Coherence Imaging for Flaw Detection Translation ultrasonic flaw detection uses these ultrasonic sound waves to detect flaws inside a solid metal or concrete object without causing any damage to its original structure. google's service, offered free of charge, instantly translates words, phrases, and web pages between english and over 100 other. ultrasonic flaw detection is a powerful ndt technology and a well established. Flaw Detection Translation.

From www.wabteccorp.com

FLEX Ultrasonic Rail Flaw Detection System Wabtec Corporation Flaw Detection Translation google's service, offered free of charge, instantly translates words, phrases, and web pages between english and over 100 other. ultrasonic flaw detection uses these ultrasonic sound waves to detect flaws inside a solid metal or concrete object without causing any damage to its original structure. ultrasonic flaw detection is a powerful ndt technology and a well established. Flaw Detection Translation.

From www.researchgate.net

Principle of the flaw detection method. Download Scientific Diagram Flaw Detection Translation In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border frequencies up to 50 mhz are transmitted through materials. ultrasonic inspection can be used to detect surface flaws such as cracks and internal flaws such as voids or inclusions of. ultrasonic flaw detection uses these ultrasonic sound waves to detect. Flaw Detection Translation.

From www.zetec.com

Metallurgical Flaw Detection Zetec Flaw Detection Translation ultrasonic flaw detection uses these ultrasonic sound waves to detect flaws inside a solid metal or concrete object without causing any damage to its original structure. In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border frequencies up to 50 mhz are transmitted through materials. ultrasonic flaw detection is a. Flaw Detection Translation.

From www.mdpi.com

Sensors Free FullText The Improvement of Flaw Detection by the Flaw Detection Translation google's service, offered free of charge, instantly translates words, phrases, and web pages between english and over 100 other. In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border frequencies up to 50 mhz are transmitted through materials. ultrasonic flaw detection is a powerful ndt technology and a well established. Flaw Detection Translation.

From modsonic.com

Operating Principle of Ultrasonic Flaw Detector How They Work? Flaw Detection Translation google's service, offered free of charge, instantly translates words, phrases, and web pages between english and over 100 other. ultrasonic flaw detection uses these ultrasonic sound waves to detect flaws inside a solid metal or concrete object without causing any damage to its original structure. since the 1940s, the laws of physics that govern the propagation of. Flaw Detection Translation.

From www.semanticscholar.org

Figure 1 from Application of Ultrasonic Flaw Detection Technology in Flaw Detection Translation google's service, offered free of charge, instantly translates words, phrases, and web pages between english and over 100 other. ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can. ultrasonic inspection can be used to detect surface flaws such as cracks and internal flaws such as voids. Flaw Detection Translation.

From www.researchgate.net

illustrates the principle of ultrasonic flaw detection. Download Flaw Detection Translation ultrasonic flaw detection uses these ultrasonic sound waves to detect flaws inside a solid metal or concrete object without causing any damage to its original structure. In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border frequencies up to 50 mhz are transmitted through materials. ultrasonic inspection can be used. Flaw Detection Translation.

From www.youtube.com

Profile Vu FlawSense true 360 degree surface flaw detection with 3D Flaw Detection Translation In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border frequencies up to 50 mhz are transmitted through materials. ultrasonic flaw detection uses these ultrasonic sound waves to detect flaws inside a solid metal or concrete object without causing any damage to its original structure. ultrasonic inspection can be used. Flaw Detection Translation.

From www.researchgate.net

Curves of Flaw Detectability Depending on the Flaw Diameter. Download Flaw Detection Translation google's service, offered free of charge, instantly translates words, phrases, and web pages between english and over 100 other. since the 1940s, the laws of physics that govern the propagation of high frequency sound waves through solid materials have. ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however. Flaw Detection Translation.

From www.findlight.net

Flaw Detection in Laser Powder Bed Fusion Flaw Detection Translation ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can. ultrasonic flaw detection uses these ultrasonic sound waves to detect flaws inside a solid metal or concrete object without causing any damage to its original structure. ultrasonic inspection can be used to detect surface flaws such as. Flaw Detection Translation.

From eureka.patsnap.com

Operating vehiclebased rail nucleus flaw detection system and method Flaw Detection Translation ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can. google's service, offered free of charge, instantly translates words, phrases, and web pages between english and over 100 other. In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border frequencies. Flaw Detection Translation.

From www.qualitymag.com

Flaw Detection Tutorial Quantifying and Qualifying Flaws 20151105 Flaw Detection Translation ultrasonic flaw detection uses these ultrasonic sound waves to detect flaws inside a solid metal or concrete object without causing any damage to its original structure. ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can. google's service, offered free of charge, instantly translates words, phrases, and. Flaw Detection Translation.

From www.researchgate.net

Diagram of flaw detection of parts of the hole type ω the scattering Flaw Detection Translation since the 1940s, the laws of physics that govern the propagation of high frequency sound waves through solid materials have. ultrasonic flaw detection uses these ultrasonic sound waves to detect flaws inside a solid metal or concrete object without causing any damage to its original structure. In most conventional ut applications, ultrasonic pulses with center frequencies ranging from. Flaw Detection Translation.

From ultrainstrument.com

Principle and Characteristics of Ultrasonic Flaw Detection Flaw Detection Translation ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can. since the 1940s, the laws of physics that govern the propagation of high frequency sound waves through solid materials have. ultrasonic inspection can be used to detect surface flaws such as cracks and internal flaws such as. Flaw Detection Translation.

From www.researchgate.net

Flawdetection system on a pipeline of 1020 mm diameter Download Flaw Detection Translation ultrasonic flaw detection uses these ultrasonic sound waves to detect flaws inside a solid metal or concrete object without causing any damage to its original structure. ultrasonic inspection can be used to detect surface flaws such as cracks and internal flaws such as voids or inclusions of. In most conventional ut applications, ultrasonic pulses with center frequencies ranging. Flaw Detection Translation.

From www.gloryrail.com

Physical Examination of RailsRail Flaw Detection Steel Rail Specialist Flaw Detection Translation In most conventional ut applications, ultrasonic pulses with center frequencies ranging from 0.1 to 15 mhz and border frequencies up to 50 mhz are transmitted through materials. google's service, offered free of charge, instantly translates words, phrases, and web pages between english and over 100 other. since the 1940s, the laws of physics that govern the propagation of. Flaw Detection Translation.

From studylib.net

UT Flaw Detection Tutorial 202108 Flaw Detection Translation ultrasonic flaw detection is a powerful ndt technology and a well established test method in many industries, however it can. ultrasonic inspection can be used to detect surface flaws such as cracks and internal flaws such as voids or inclusions of. google's service, offered free of charge, instantly translates words, phrases, and web pages between english and. Flaw Detection Translation.

From www.mdpi.com

Processes Free FullText Rail Flux Leakage Detection and Flaw Detection Translation google's service, offered free of charge, instantly translates words, phrases, and web pages between english and over 100 other. ultrasonic flaw detection uses these ultrasonic sound waves to detect flaws inside a solid metal or concrete object without causing any damage to its original structure. since the 1940s, the laws of physics that govern the propagation of. Flaw Detection Translation.