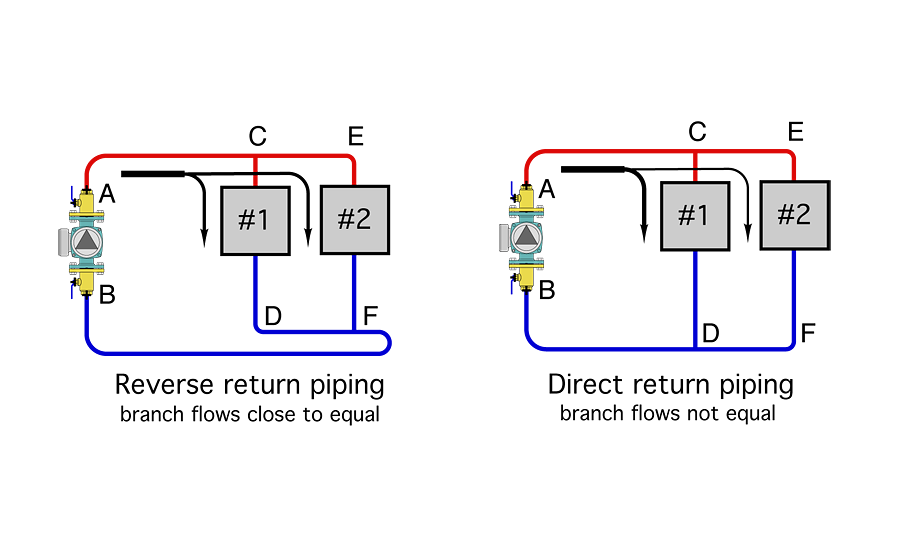

Reverse Return Piping In Chilled Water System . This is due primarily to the cost of the additional chilled water. Reverse return piping is a hydronic balancing method that equalizes the differential pressure across all hvac units by rearranging the return water pipe such that the first unit that provides supply. Reverse return piping was developed to help achieve this goal. The reverse return system is piped so that the length of the water. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own. The direct return system allows piping to be run in the most direct path to optimize piping costs. In reverse return piping, the water flows from the point of use back to the boiler or chiller instead of flowing directly to it. Reverse return piping was developed to help achieve this goal. It also shows a direct return piping layout for comparison. Compared to the direct return system in image 2 where the return header is connected to the load closest to the pump, the reverse return system. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own branch piping. Reverse return piping system is higher than that of the other types of hydronic systems.

from www.pmmag.com

The reverse return system is piped so that the length of the water. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own branch piping. Reverse return piping was developed to help achieve this goal. It also shows a direct return piping layout for comparison. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own. The direct return system allows piping to be run in the most direct path to optimize piping costs. Reverse return piping was developed to help achieve this goal. Reverse return piping system is higher than that of the other types of hydronic systems. Compared to the direct return system in image 2 where the return header is connected to the load closest to the pump, the reverse return system. This is due primarily to the cost of the additional chilled water.

When and how to use reverse return piping 20161116 Plumbing and

Reverse Return Piping In Chilled Water System Reverse return piping was developed to help achieve this goal. Reverse return piping system is higher than that of the other types of hydronic systems. It also shows a direct return piping layout for comparison. The direct return system allows piping to be run in the most direct path to optimize piping costs. Reverse return piping is a hydronic balancing method that equalizes the differential pressure across all hvac units by rearranging the return water pipe such that the first unit that provides supply. The reverse return system is piped so that the length of the water. Compared to the direct return system in image 2 where the return header is connected to the load closest to the pump, the reverse return system. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own branch piping. In reverse return piping, the water flows from the point of use back to the boiler or chiller instead of flowing directly to it. This is due primarily to the cost of the additional chilled water. Reverse return piping was developed to help achieve this goal. Reverse return piping was developed to help achieve this goal. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own.

From forum.heatinghelp.com

4 Water Heaters Reverse Return Piping?? — Heating Help The Wall Reverse Return Piping In Chilled Water System It also shows a direct return piping layout for comparison. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own branch piping. Compared to the direct return system in image 2 where the return header is connected to the load closest to the pump, the reverse return system. The reverse return system. Reverse Return Piping In Chilled Water System.

From wiringlistexigencies.z14.web.core.windows.net

Reverse Return Piping Diagram Water Heaters Reverse Return Piping In Chilled Water System Reverse return piping system is higher than that of the other types of hydronic systems. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own branch piping. The reverse return system is piped so that the length of the water. The direct return system allows piping to be run in the most. Reverse Return Piping In Chilled Water System.

From diagramlibraryrevises.z19.web.core.windows.net

Reverse Return And Direct Return Piping Reverse Return Piping In Chilled Water System This is due primarily to the cost of the additional chilled water. Reverse return piping was developed to help achieve this goal. Reverse return piping was developed to help achieve this goal. The reverse return system is piped so that the length of the water. Compared to the direct return system in image 2 where the return header is connected. Reverse Return Piping In Chilled Water System.

From www.planmarketplace.com

Chiller or boiler PrimarySecondaryTertiaryReverse Return System Reverse Return Piping In Chilled Water System The direct return system allows piping to be run in the most direct path to optimize piping costs. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own. In reverse return piping, the water flows from the point of use back to the boiler or chiller instead of flowing directly to it.. Reverse Return Piping In Chilled Water System.

From www.pmmag.com

When and how to use reverse return piping 20161116 Plumbing and Reverse Return Piping In Chilled Water System Reverse return piping was developed to help achieve this goal. Reverse return piping was developed to help achieve this goal. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own. The direct return system allows piping to be run in the most direct path to optimize piping costs. Reverse return piping is. Reverse Return Piping In Chilled Water System.

From schematichettum57.z21.web.core.windows.net

Reverse Return Piping Diagram Water Heaters Reverse Return Piping In Chilled Water System Reverse return piping system is higher than that of the other types of hydronic systems. In reverse return piping, the water flows from the point of use back to the boiler or chiller instead of flowing directly to it. It also shows a direct return piping layout for comparison. Reverse return piping was developed to help achieve this goal. Compared. Reverse Return Piping In Chilled Water System.

From aircondlounge.com

What is Reverse Return Piping? Reverse Return Piping In Chilled Water System The reverse return system is piped so that the length of the water. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own. Reverse return piping is a hydronic balancing method that equalizes the differential pressure across all hvac units by rearranging the return water pipe such that the first unit that. Reverse Return Piping In Chilled Water System.

From www.dynamicdraintechnologies.com

Chilled Water Line Repair And Replacement Without Digging Dynamic Drain Reverse Return Piping In Chilled Water System In reverse return piping, the water flows from the point of use back to the boiler or chiller instead of flowing directly to it. Reverse return piping is a hydronic balancing method that equalizes the differential pressure across all hvac units by rearranging the return water pipe such that the first unit that provides supply. It also shows a direct. Reverse Return Piping In Chilled Water System.

From www.pmmag.com

When and how to use reverse return piping 20161116 Plumbing and Reverse Return Piping In Chilled Water System Reverse return piping system is higher than that of the other types of hydronic systems. Reverse return piping was developed to help achieve this goal. It also shows a direct return piping layout for comparison. Reverse return piping is a hydronic balancing method that equalizes the differential pressure across all hvac units by rearranging the return water pipe such that. Reverse Return Piping In Chilled Water System.

From www.pumpsandsystems.com

What Is a Reverse Return System? Pumps & Systems Reverse Return Piping In Chilled Water System This is due primarily to the cost of the additional chilled water. In reverse return piping, the water flows from the point of use back to the boiler or chiller instead of flowing directly to it. Reverse return piping was developed to help achieve this goal. It also shows a direct return piping layout for comparison. Reverse return piping is. Reverse Return Piping In Chilled Water System.

From stock.adobe.com

Chilled water supply and return pipe system. May called chr, chs Reverse Return Piping In Chilled Water System Reverse return piping was developed to help achieve this goal. Compared to the direct return system in image 2 where the return header is connected to the load closest to the pump, the reverse return system. In reverse return piping, the water flows from the point of use back to the boiler or chiller instead of flowing directly to it.. Reverse Return Piping In Chilled Water System.

From schematicmistake.z14.web.core.windows.net

Reverse Return And Direct Return Piping Reverse Return Piping In Chilled Water System It also shows a direct return piping layout for comparison. The direct return system allows piping to be run in the most direct path to optimize piping costs. Reverse return piping was developed to help achieve this goal. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own branch piping. Reverse return. Reverse Return Piping In Chilled Water System.

From manualliblatten.z19.web.core.windows.net

Reverse Return Piping Diagram Water Heaters Reverse Return Piping In Chilled Water System Reverse return piping was developed to help achieve this goal. Reverse return piping was developed to help achieve this goal. This is due primarily to the cost of the additional chilled water. In reverse return piping, the water flows from the point of use back to the boiler or chiller instead of flowing directly to it. Compared to the direct. Reverse Return Piping In Chilled Water System.

From hvactrainingshop.com

How a Chilled Water System Works HVAC Training Shop Reverse Return Piping In Chilled Water System It also shows a direct return piping layout for comparison. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own. Reverse return piping system is higher than that of the other types of hydronic systems. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its. Reverse Return Piping In Chilled Water System.

From schematicdiagrampewter.z21.web.core.windows.net

Chilled Water Piping Schematic Pdf Reverse Return Piping In Chilled Water System It also shows a direct return piping layout for comparison. The direct return system allows piping to be run in the most direct path to optimize piping costs. This is due primarily to the cost of the additional chilled water. The reverse return system is piped so that the length of the water. Reverse return piping is a hydronic balancing. Reverse Return Piping In Chilled Water System.

From diagramlibrarywany.z19.web.core.windows.net

Reverse Return Boiler Piping Reverse Return Piping In Chilled Water System The reverse return system is piped so that the length of the water. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own branch piping. The direct return system allows piping to be run in the most direct path to optimize piping costs. In reverse return piping, the water flows from the. Reverse Return Piping In Chilled Water System.

From jmpcoblog.com

How To Size A Waterside Economizer Part 4 Chilled Water Piping Reverse Return Piping In Chilled Water System Reverse return piping system is higher than that of the other types of hydronic systems. The reverse return system is piped so that the length of the water. This is due primarily to the cost of the additional chilled water. In reverse return piping, the water flows from the point of use back to the boiler or chiller instead of. Reverse Return Piping In Chilled Water System.

From kcwaterheater.com

Multiple Water Heaters Reverse Return Piping Method Water Heaters Reverse Return Piping In Chilled Water System Reverse return piping was developed to help achieve this goal. Compared to the direct return system in image 2 where the return header is connected to the load closest to the pump, the reverse return system. This is due primarily to the cost of the additional chilled water. Figure 1 shows a simple representation of reverse return piping through two. Reverse Return Piping In Chilled Water System.

From hvactrainingshop.com

How a Chilled Water System Works HVAC Training Shop Reverse Return Piping In Chilled Water System In reverse return piping, the water flows from the point of use back to the boiler or chiller instead of flowing directly to it. The reverse return system is piped so that the length of the water. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own branch piping. It also shows. Reverse Return Piping In Chilled Water System.

From www.pmmag.com

When and how to use reverse return piping 20161116 Plumbing and Reverse Return Piping In Chilled Water System This is due primarily to the cost of the additional chilled water. Reverse return piping was developed to help achieve this goal. The reverse return system is piped so that the length of the water. The direct return system allows piping to be run in the most direct path to optimize piping costs. In reverse return piping, the water flows. Reverse Return Piping In Chilled Water System.

From www.youtube.com

hvacDirect Return vs Reverse Return Pipe YouTube Reverse Return Piping In Chilled Water System This is due primarily to the cost of the additional chilled water. Compared to the direct return system in image 2 where the return header is connected to the load closest to the pump, the reverse return system. Reverse return piping is a hydronic balancing method that equalizes the differential pressure across all hvac units by rearranging the return water. Reverse Return Piping In Chilled Water System.

From www.endocool.com

Guide to Chilled Water Systems and Improving Efficiency EndoCool Reverse Return Piping In Chilled Water System Reverse return piping system is higher than that of the other types of hydronic systems. Reverse return piping is a hydronic balancing method that equalizes the differential pressure across all hvac units by rearranging the return water pipe such that the first unit that provides supply. This is due primarily to the cost of the additional chilled water. It also. Reverse Return Piping In Chilled Water System.

From schematicmistake.z14.web.core.windows.net

Reverse Return Piping Diagram Water Heaters Reverse Return Piping In Chilled Water System Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own branch piping. This is due primarily to the cost of the additional chilled water. In reverse return piping, the water flows from the point of use back to the boiler or chiller instead of flowing directly to it. Reverse return piping is. Reverse Return Piping In Chilled Water System.

From jmpblog.squarespace.com

Variable Primary Chilled Water Systems Part 3 The Basics of Variable Reverse Return Piping In Chilled Water System Reverse return piping was developed to help achieve this goal. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own. Compared to the direct return system in image 2 where the return header is connected to the load closest to the pump, the reverse return system. It also shows a direct return. Reverse Return Piping In Chilled Water System.

From e6lemen3vschematic.z19.web.core.windows.net

Reverse Return Piping Diagram Water Heaters Reverse Return Piping In Chilled Water System Reverse return piping was developed to help achieve this goal. Reverse return piping is a hydronic balancing method that equalizes the differential pressure across all hvac units by rearranging the return water pipe such that the first unit that provides supply. This is due primarily to the cost of the additional chilled water. Reverse return piping system is higher than. Reverse Return Piping In Chilled Water System.

From aircondlounge.com

What is Reverse Return Piping? Reverse Return Piping In Chilled Water System Reverse return piping system is higher than that of the other types of hydronic systems. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own branch piping. This is due primarily to the cost of the additional chilled water. The direct return system allows piping to be run in the most direct. Reverse Return Piping In Chilled Water System.

From www.pmmag.com

When and how to use reverse return piping 20161116 Plumbing and Reverse Return Piping In Chilled Water System In reverse return piping, the water flows from the point of use back to the boiler or chiller instead of flowing directly to it. The direct return system allows piping to be run in the most direct path to optimize piping costs. Reverse return piping was developed to help achieve this goal. The reverse return system is piped so that. Reverse Return Piping In Chilled Water System.

From www.slideshare.net

Hydronic Basics / PrimarySecondary Pumping Reverse Return Piping In Chilled Water System Reverse return piping was developed to help achieve this goal. Reverse return piping is a hydronic balancing method that equalizes the differential pressure across all hvac units by rearranging the return water pipe such that the first unit that provides supply. Compared to the direct return system in image 2 where the return header is connected to the load closest. Reverse Return Piping In Chilled Water System.

From wirelibraryskysail.z4.web.core.windows.net

Reverse Return Water Heater Piping Reverse Return Piping In Chilled Water System Compared to the direct return system in image 2 where the return header is connected to the load closest to the pump, the reverse return system. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own branch piping. Reverse return piping was developed to help achieve this goal. This is due primarily. Reverse Return Piping In Chilled Water System.

From www.pmmag.com

When and how to use reverse return piping 20161116 Plumbing and Reverse Return Piping In Chilled Water System It also shows a direct return piping layout for comparison. Reverse return piping system is higher than that of the other types of hydronic systems. This is due primarily to the cost of the additional chilled water. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own. Reverse return piping was developed. Reverse Return Piping In Chilled Water System.

From diagramlibrarywany.z19.web.core.windows.net

Reverse Return Water Heater Piping Reverse Return Piping In Chilled Water System Reverse return piping system is higher than that of the other types of hydronic systems. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own branch piping. Reverse return piping is a hydronic balancing method that equalizes the differential pressure across all hvac units by rearranging the return water pipe such that. Reverse Return Piping In Chilled Water System.

From fixlibrarycoblasbi.z13.web.core.windows.net

Reverse Return Piping Diagram Water Heaters Reverse Return Piping In Chilled Water System Reverse return piping was developed to help achieve this goal. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own. Reverse return piping is a hydronic balancing method that equalizes the differential pressure across all hvac units by rearranging the return water pipe such that the first unit that provides supply. Reverse. Reverse Return Piping In Chilled Water System.

From receivinghelpdesk.com

What Is The Purpose Of A Reverse Return Piping System Reverse Return Piping In Chilled Water System The reverse return system is piped so that the length of the water. Reverse return piping is a hydronic balancing method that equalizes the differential pressure across all hvac units by rearranging the return water pipe such that the first unit that provides supply. This is due primarily to the cost of the additional chilled water. Reverse return piping was. Reverse Return Piping In Chilled Water System.

From mungfali.com

Chilled Water Piping Diagram Reverse Return Piping In Chilled Water System Reverse return piping system is higher than that of the other types of hydronic systems. In reverse return piping, the water flows from the point of use back to the boiler or chiller instead of flowing directly to it. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own. This is due. Reverse Return Piping In Chilled Water System.

From www.pmmag.com

When and how to use reverse return piping 20161116 Plumbing and Reverse Return Piping In Chilled Water System Reverse return piping system is higher than that of the other types of hydronic systems. Reverse return piping was developed to help achieve this goal. Figure 1 shows a simple representation of reverse return piping through two identical components, each in its own branch piping. The direct return system allows piping to be run in the most direct path to. Reverse Return Piping In Chilled Water System.